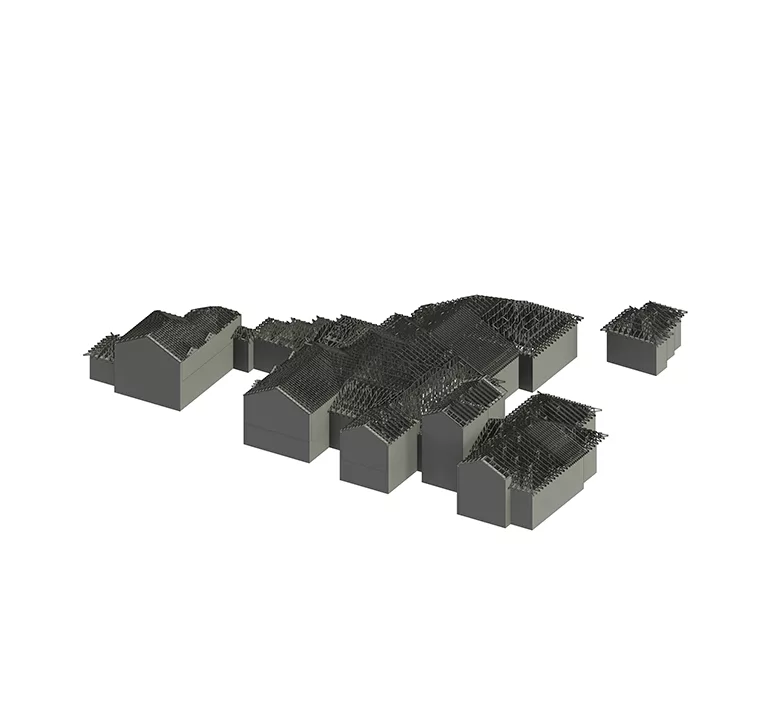

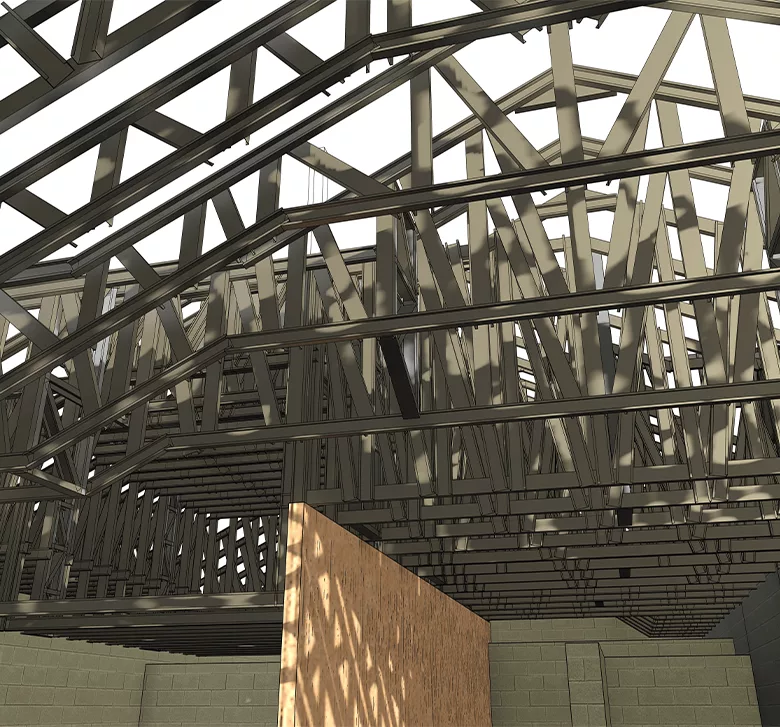

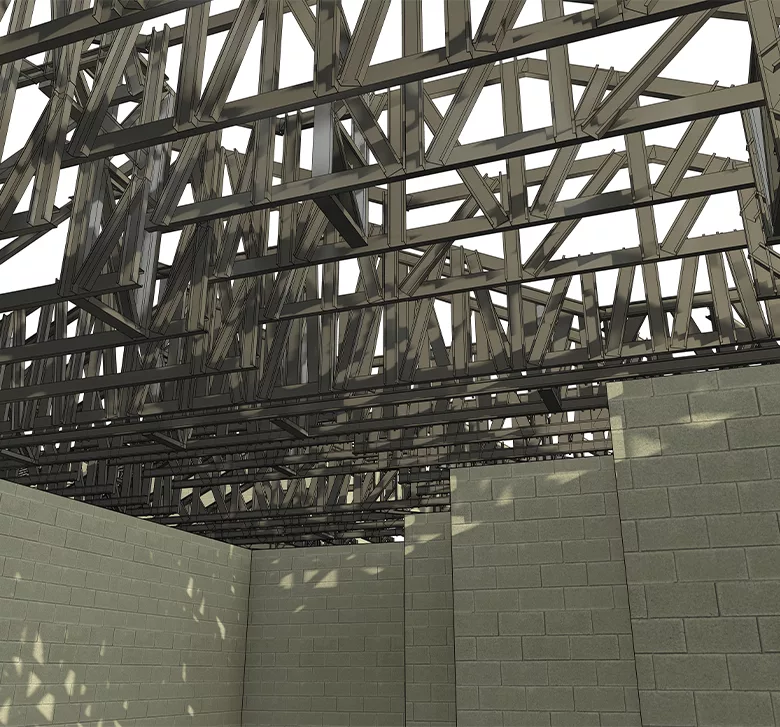

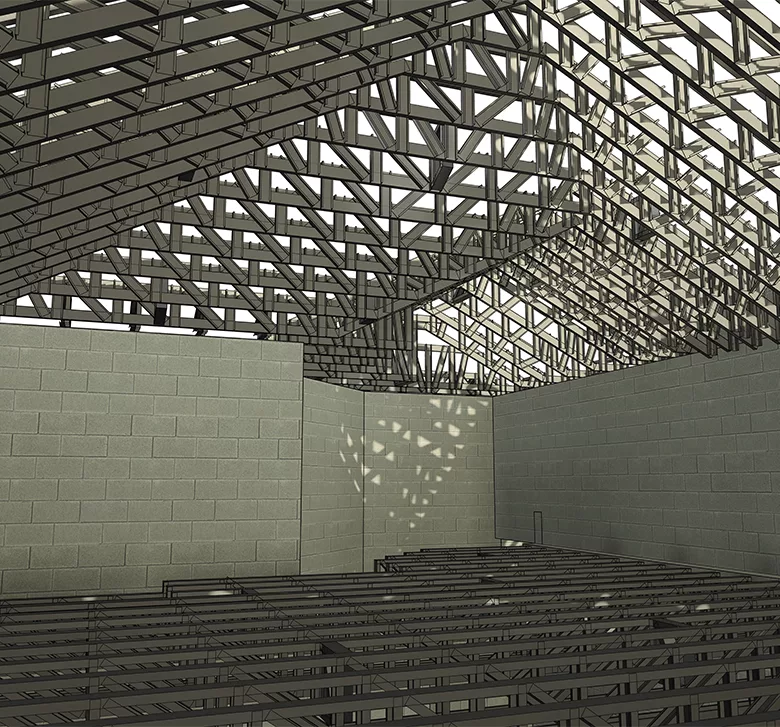

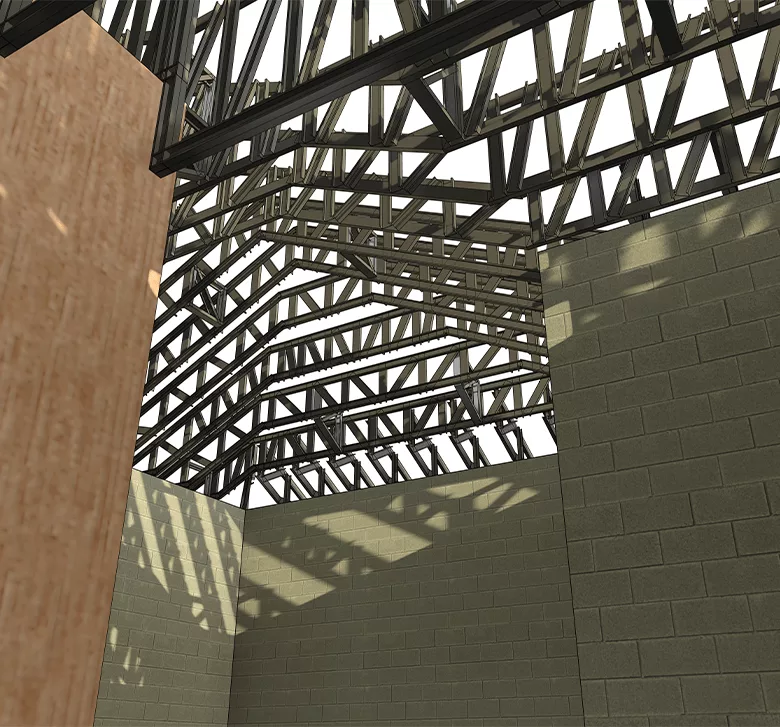

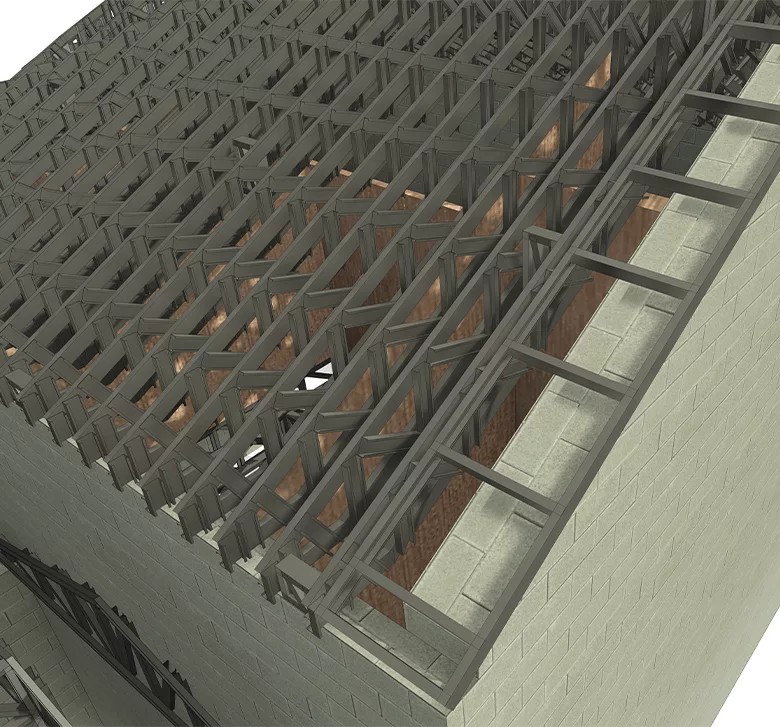

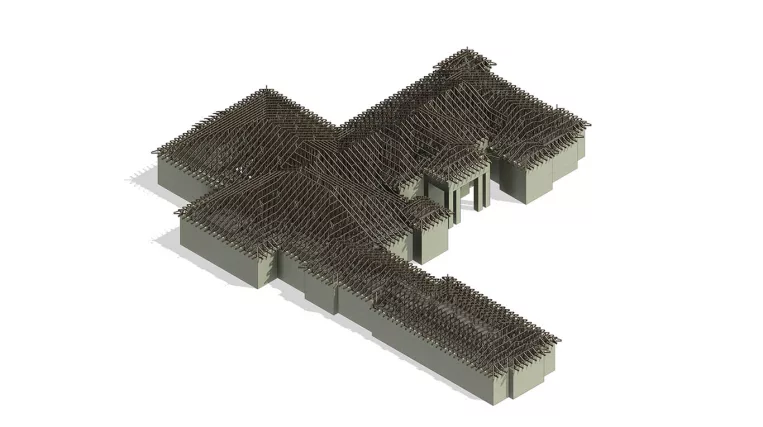

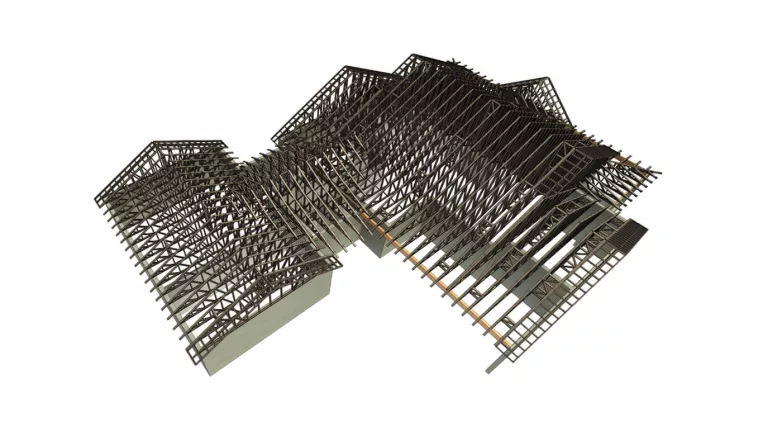

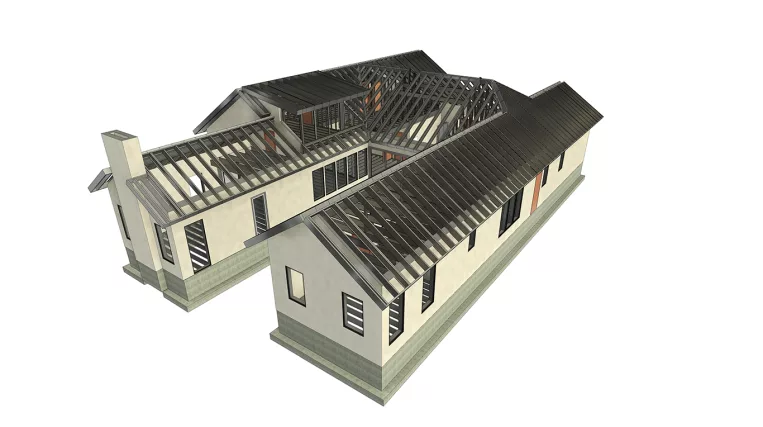

In this project, the ORIGIN team was committed to designing the LGS roof framing for a residential building.

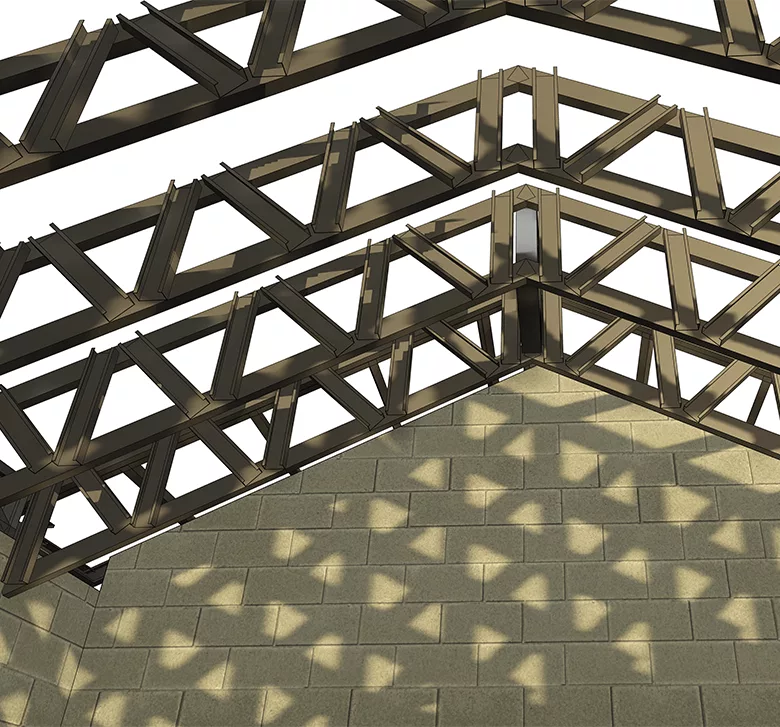

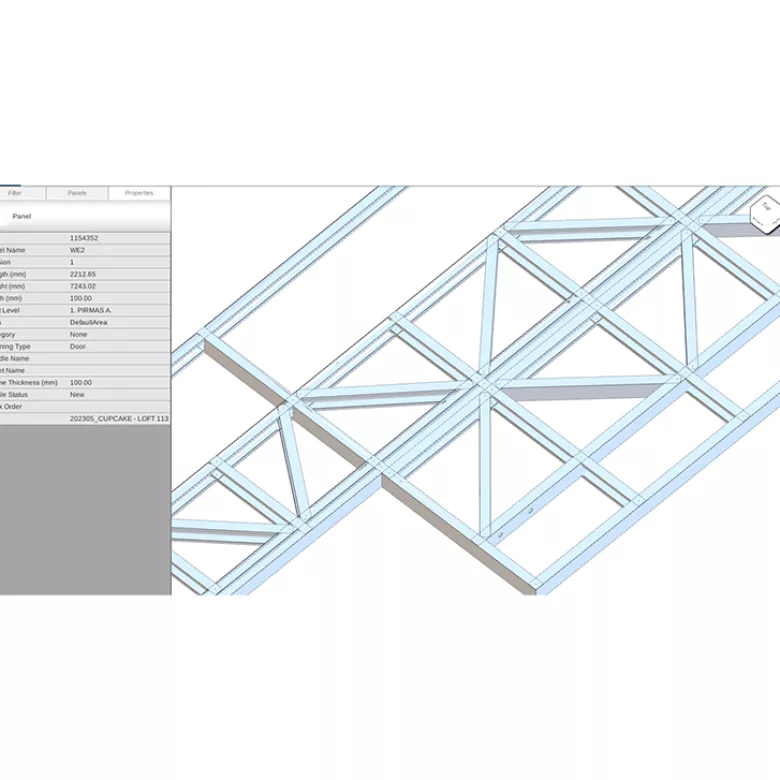

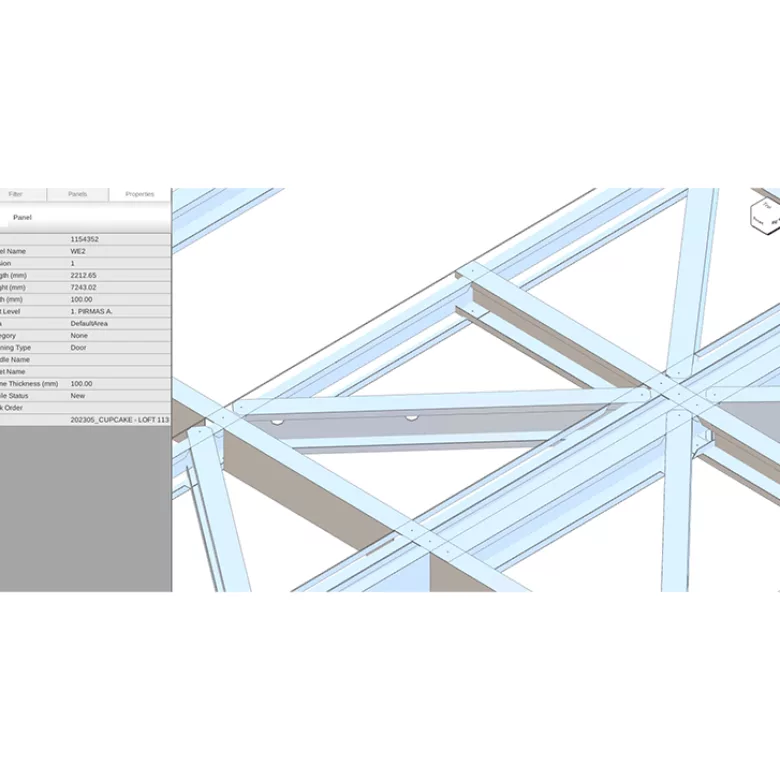

One of the most crucial requirements was to ensure compatibility of the truss design with the FRAMECAD rollformer system.

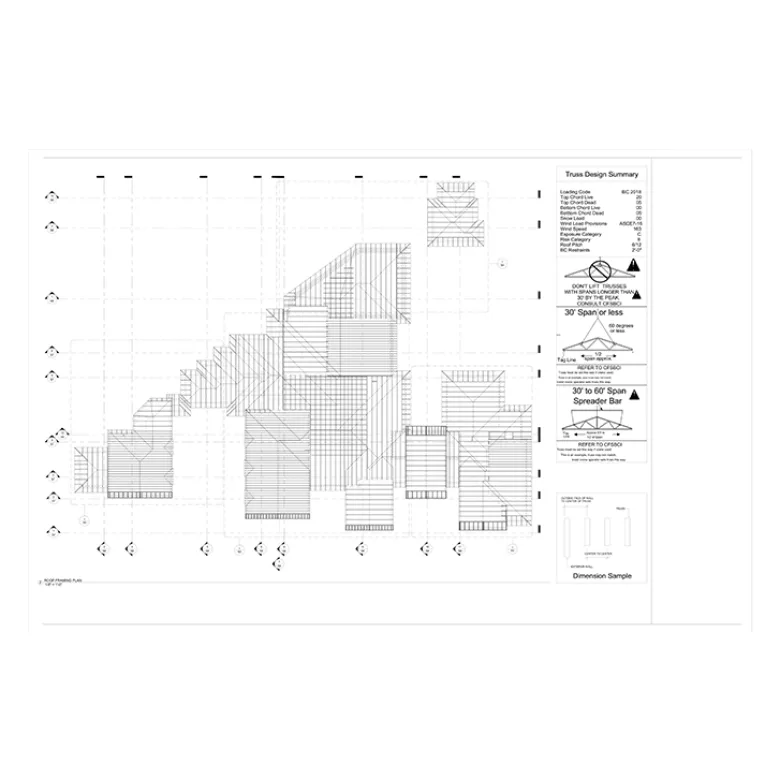

Input: Structural drawing set.

Project Deliverables:

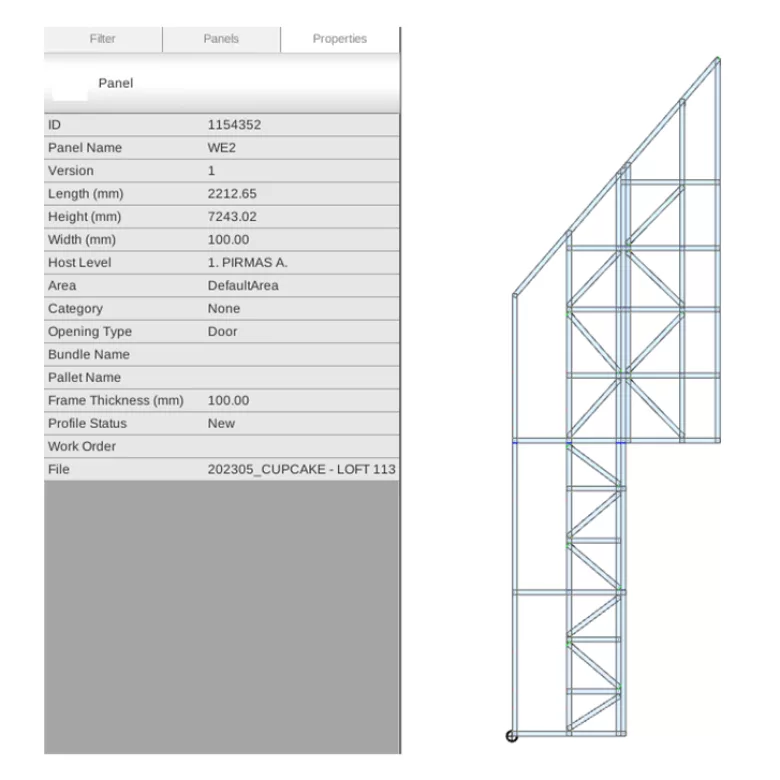

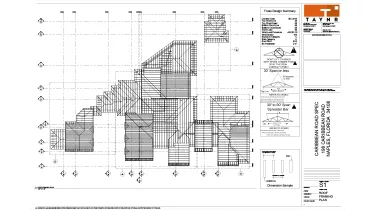

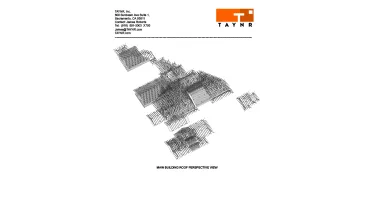

- Roof trusses layout;

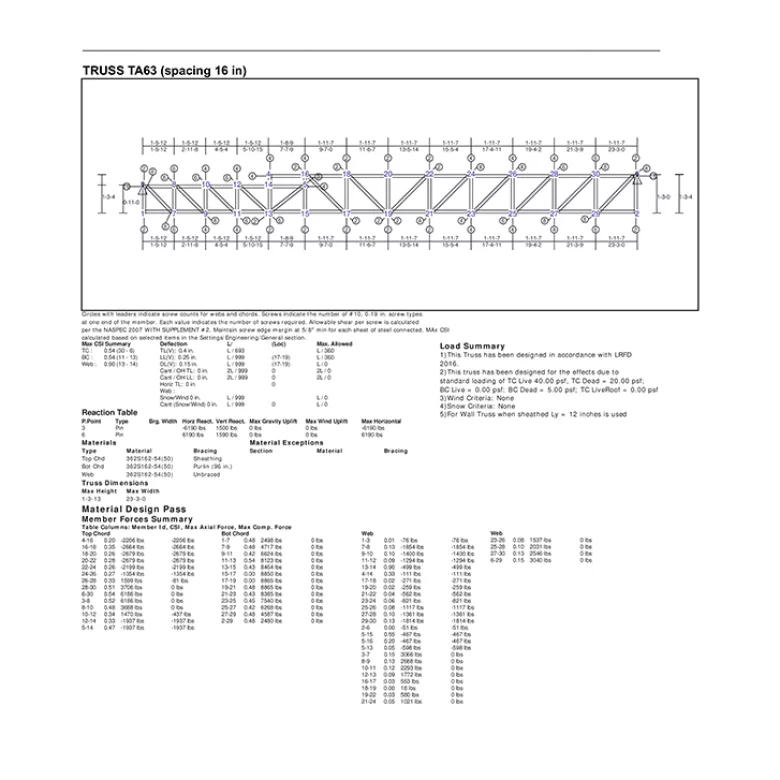

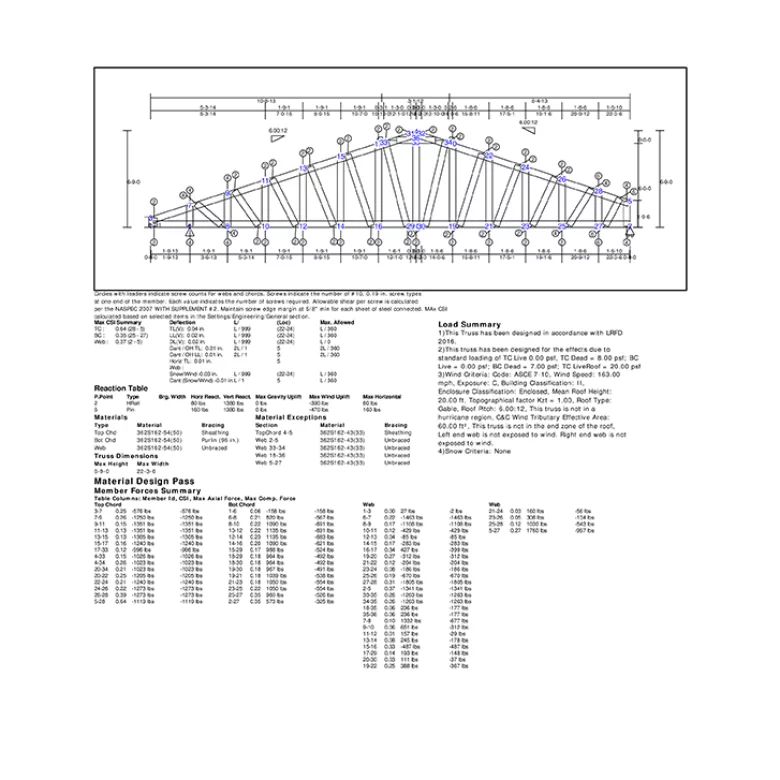

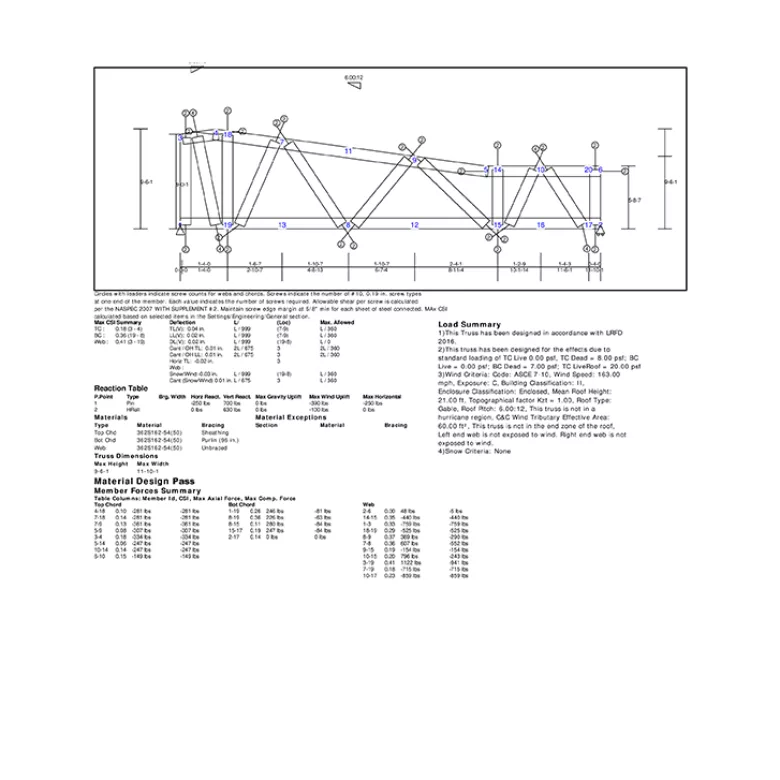

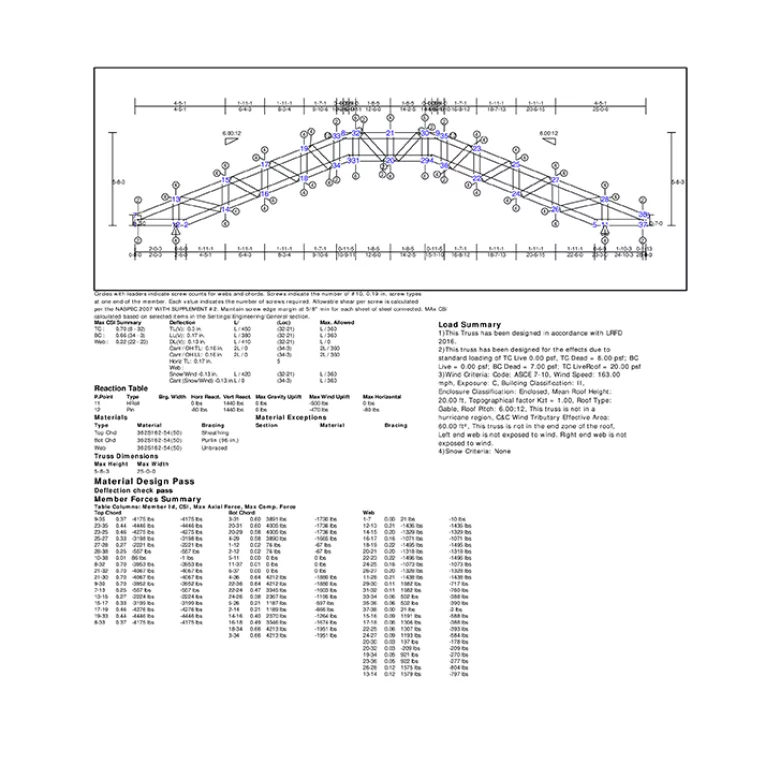

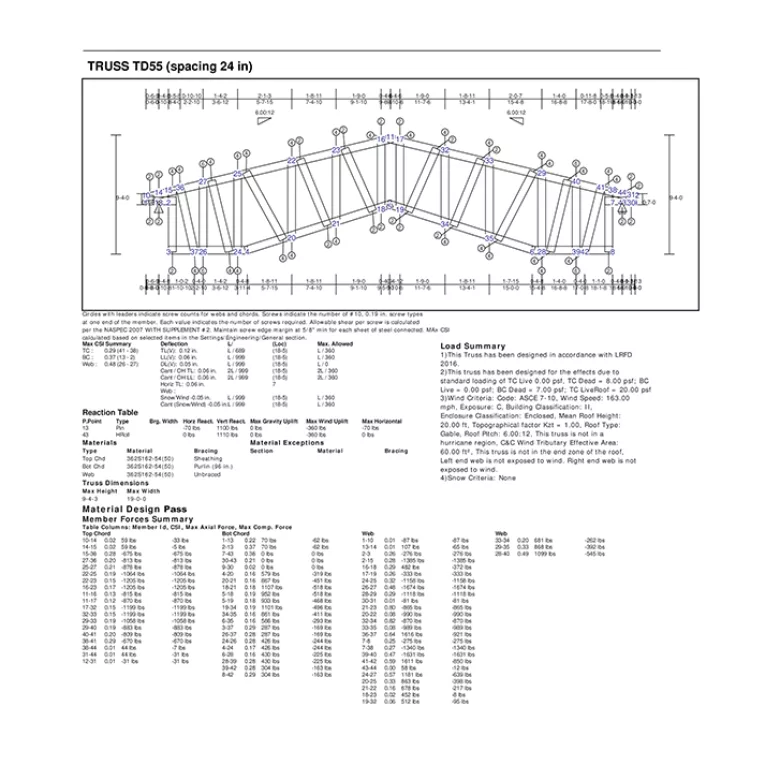

- Truss reports;

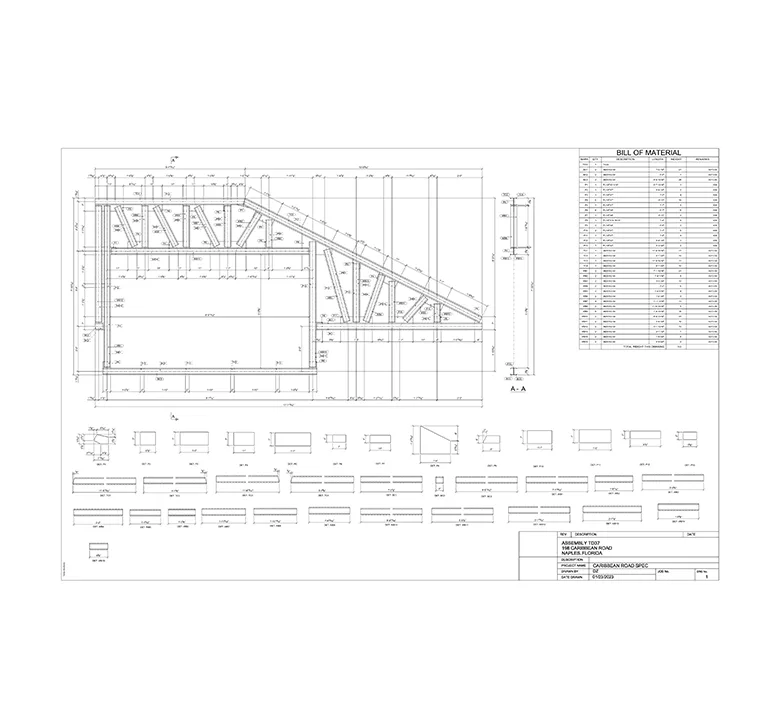

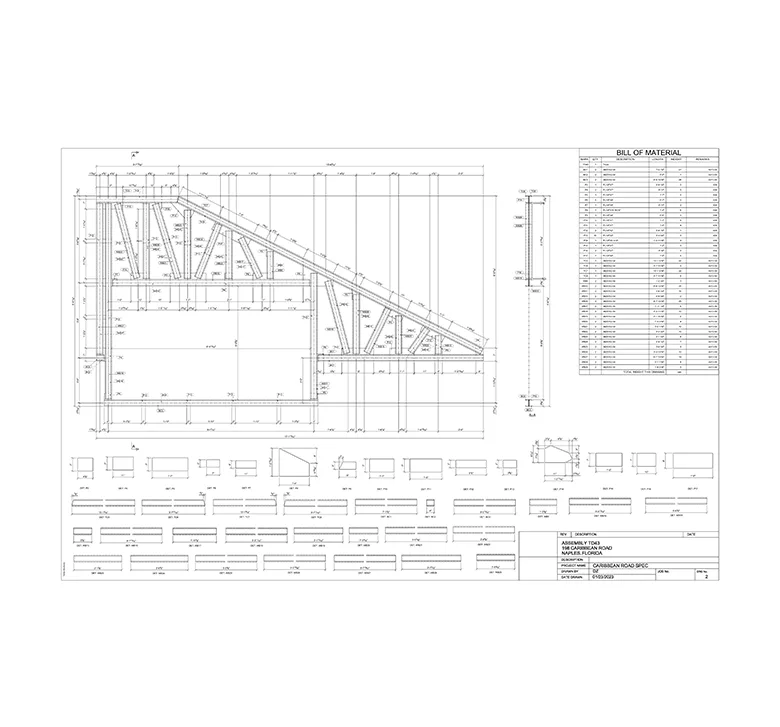

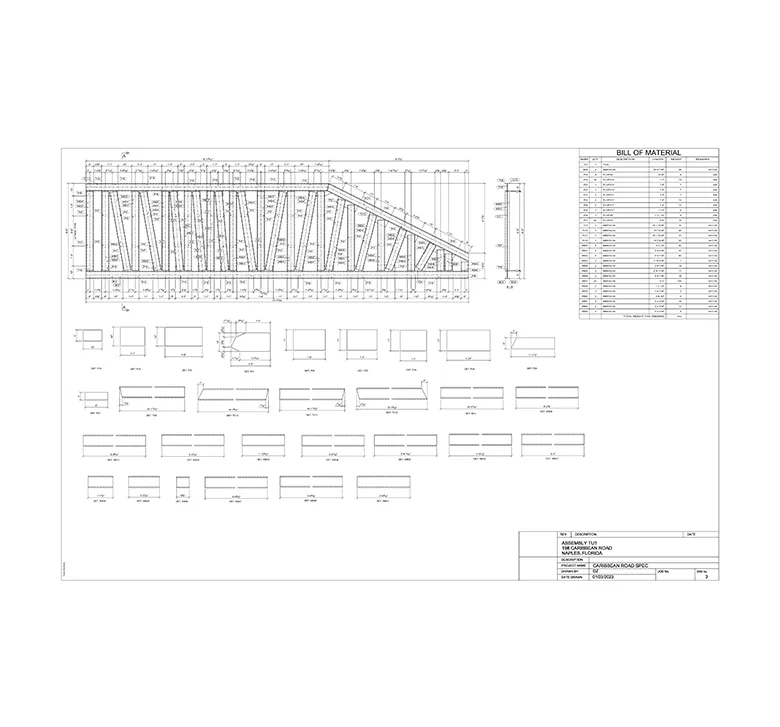

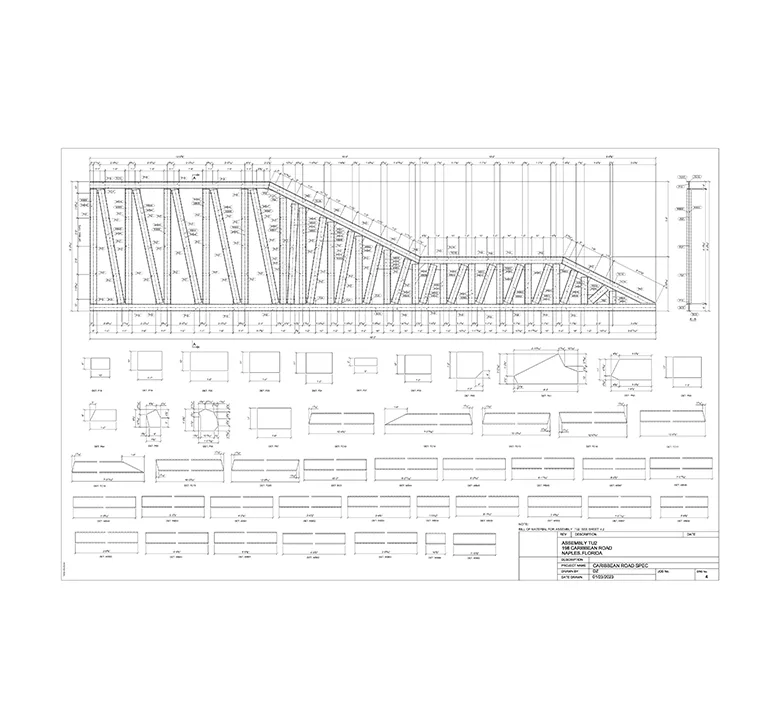

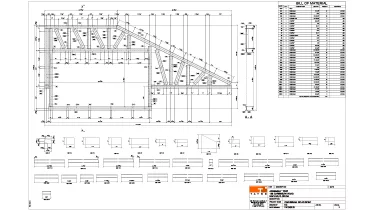

- Shop drawings for complex LGS trusses incompatible with the FRAMECAD system;

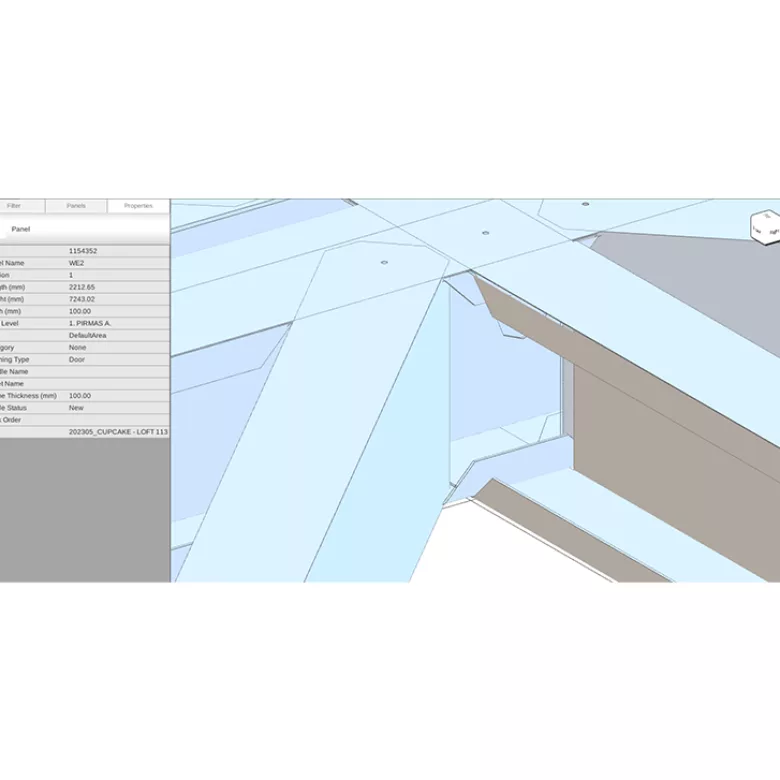

- FRAMECAD CNC files for LGS panels production.