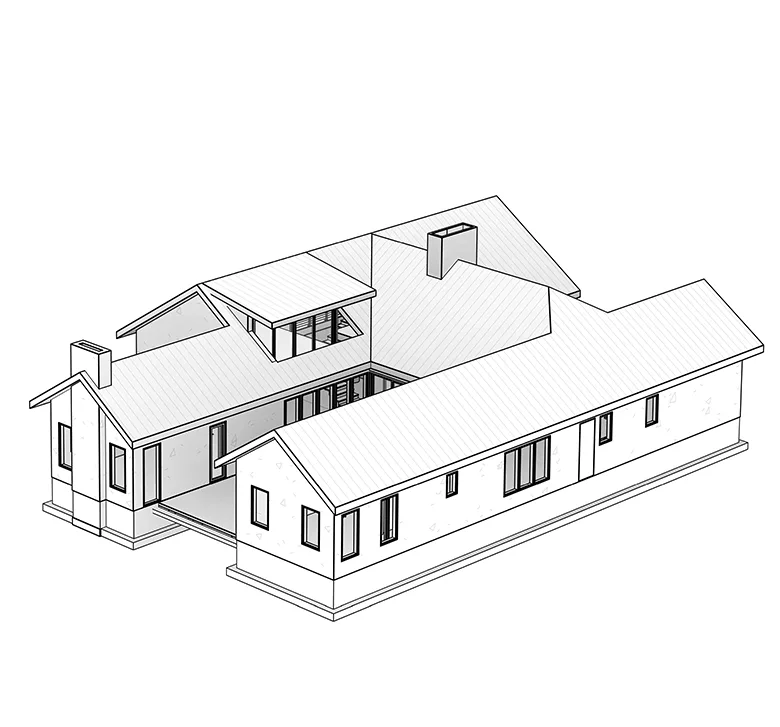

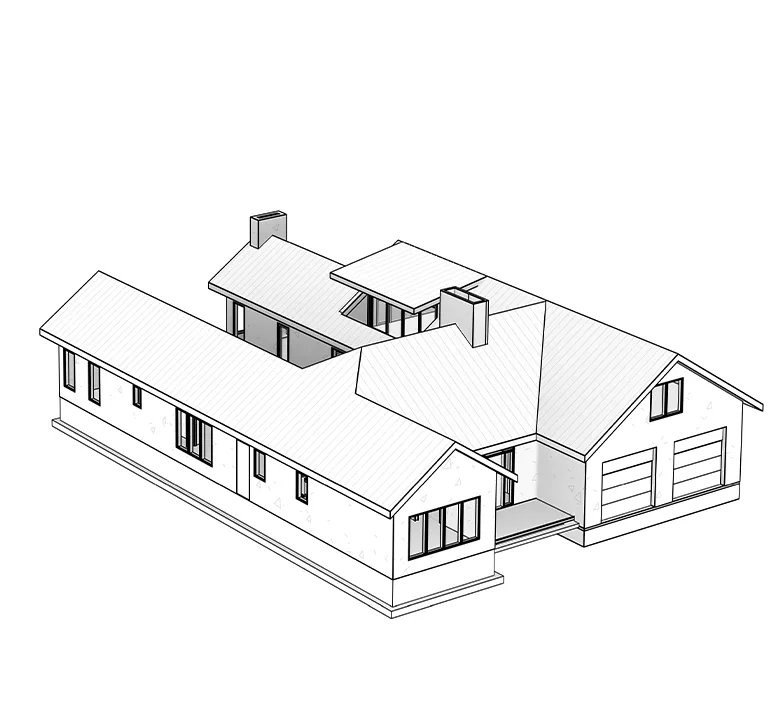

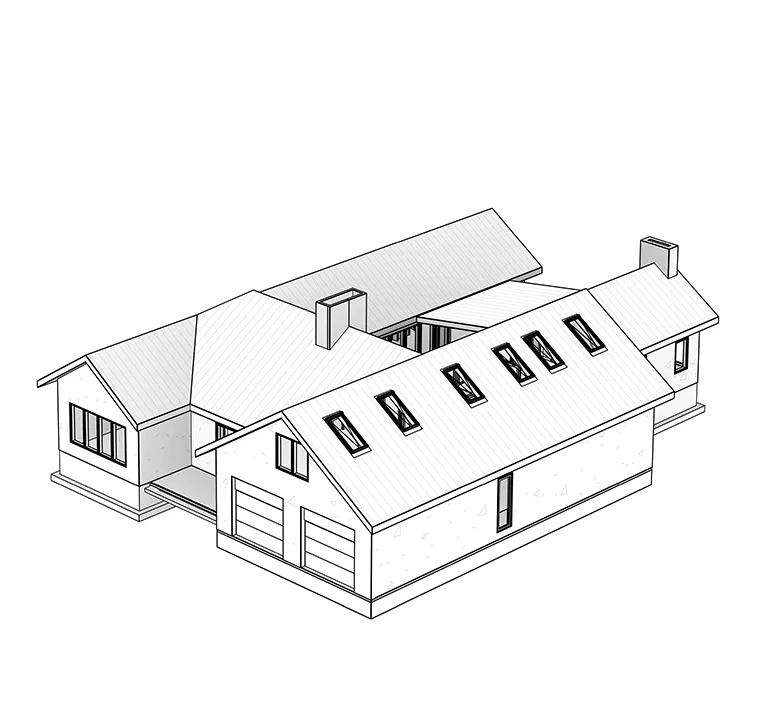

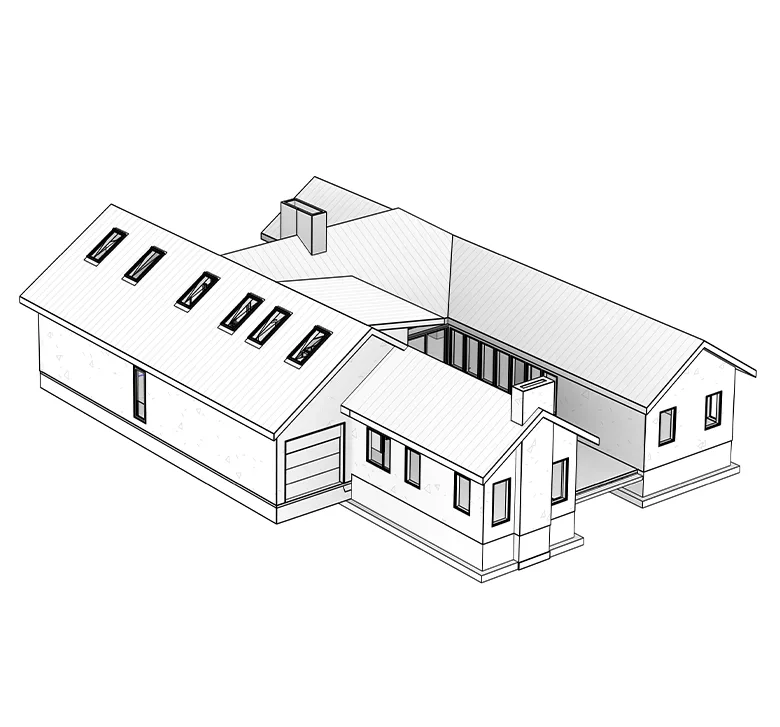

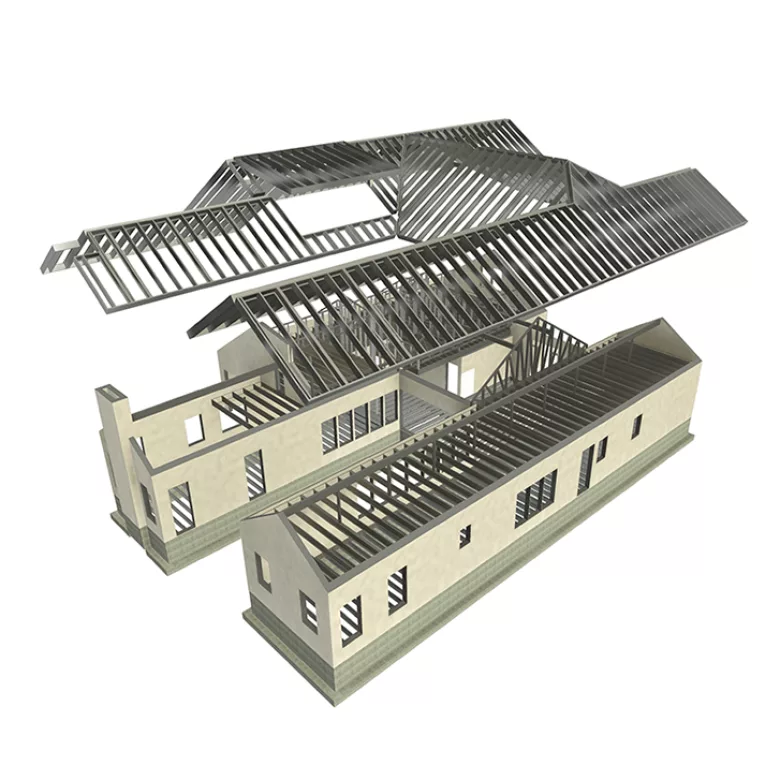

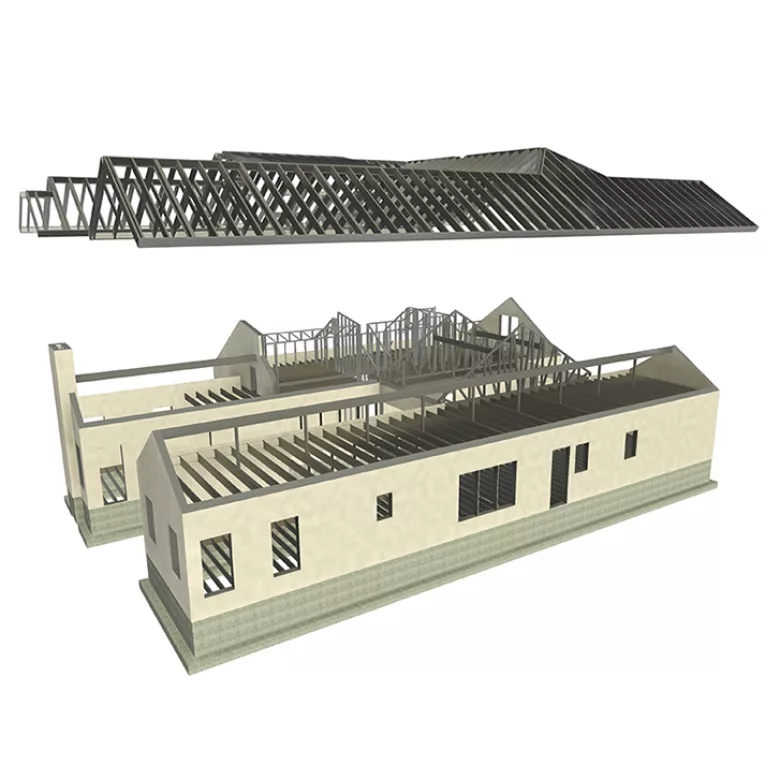

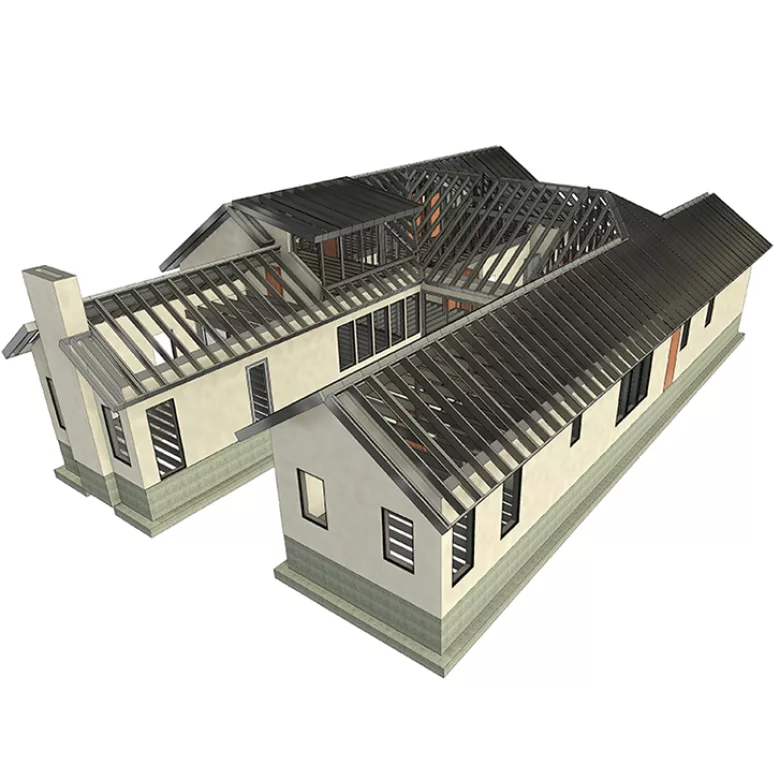

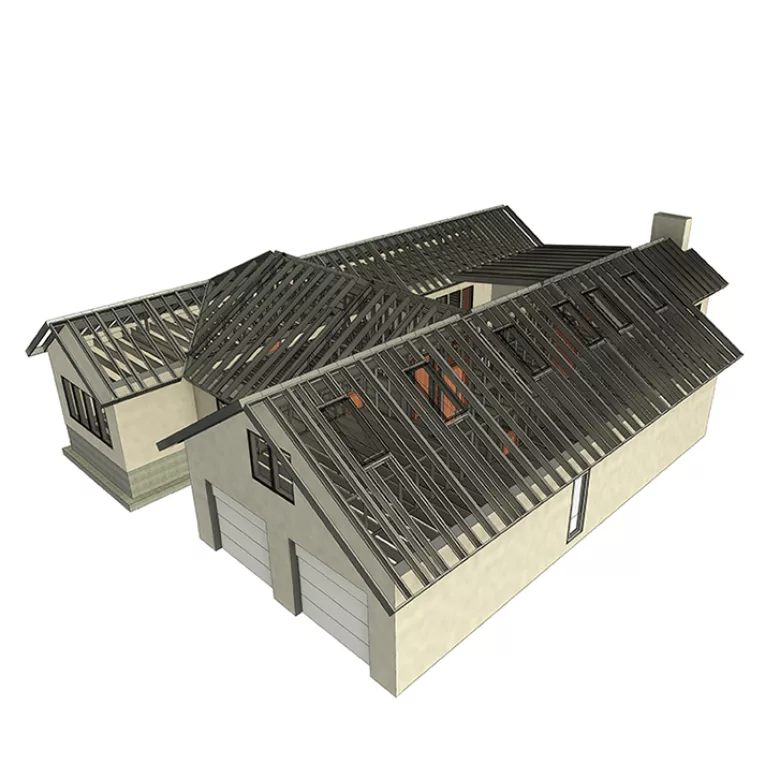

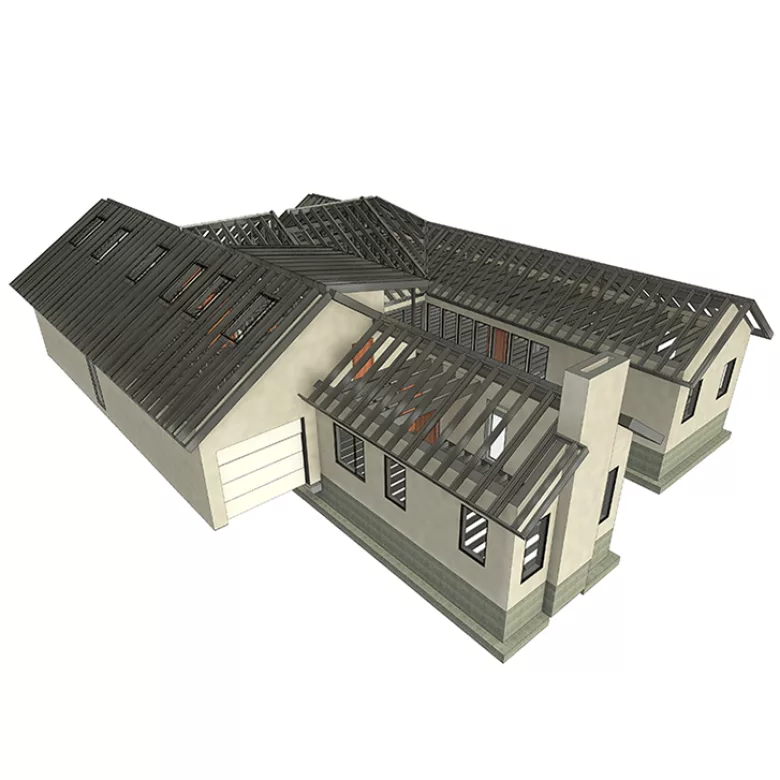

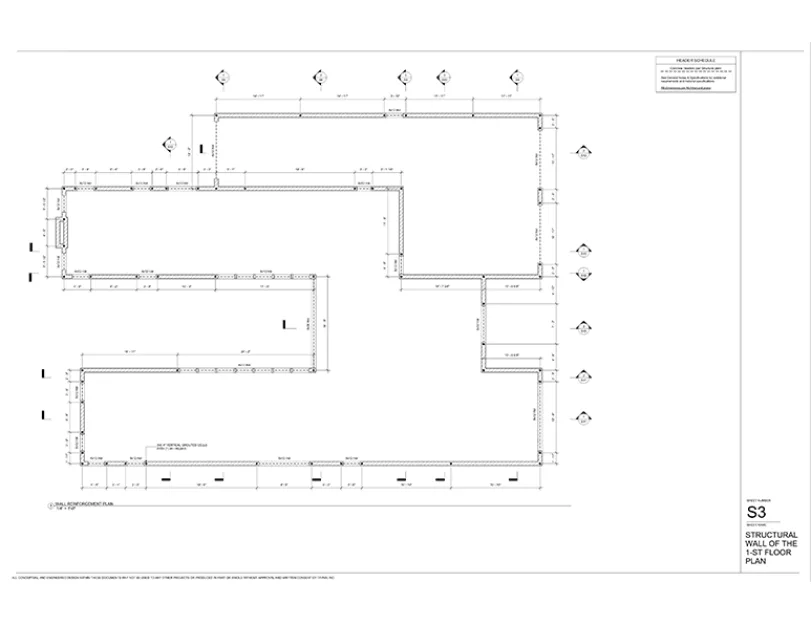

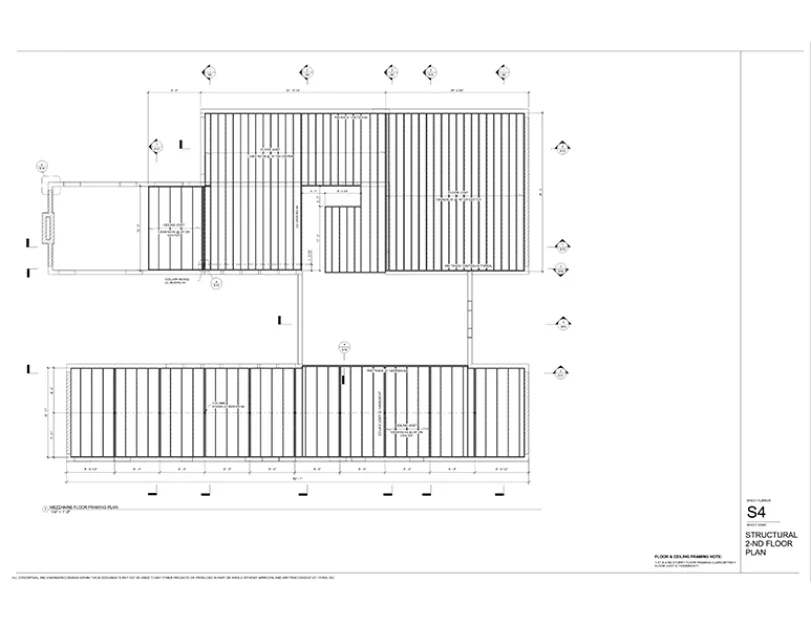

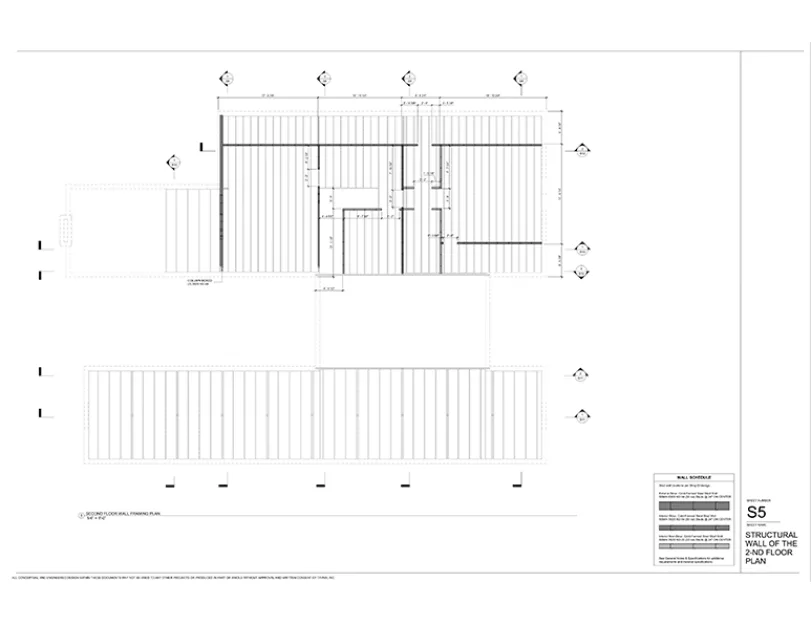

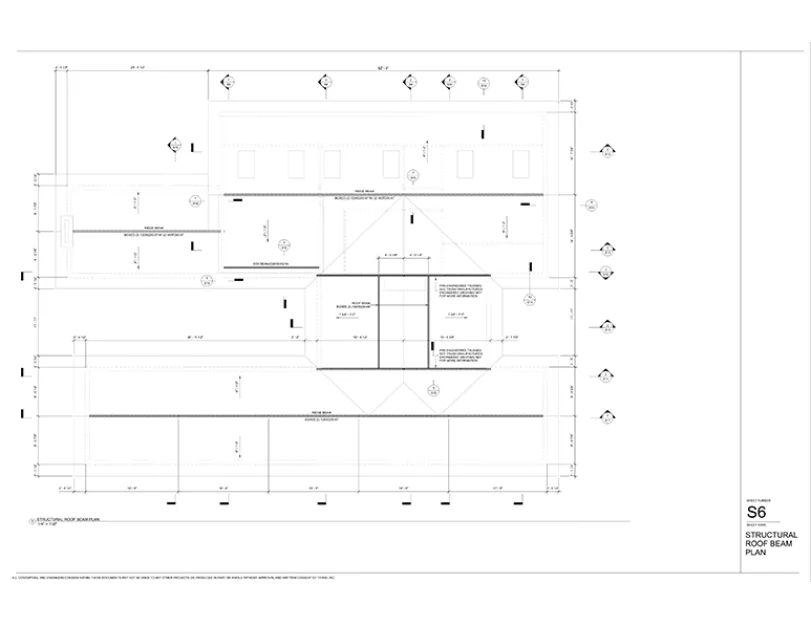

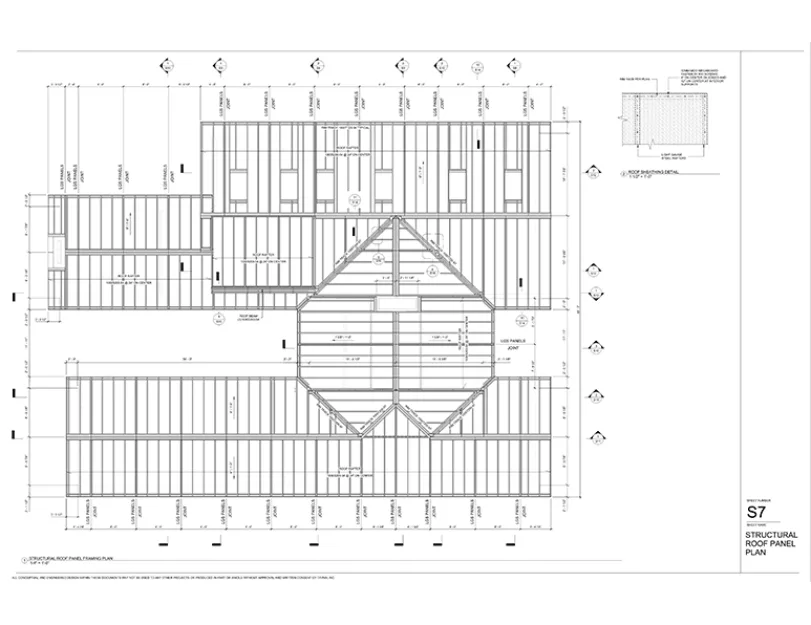

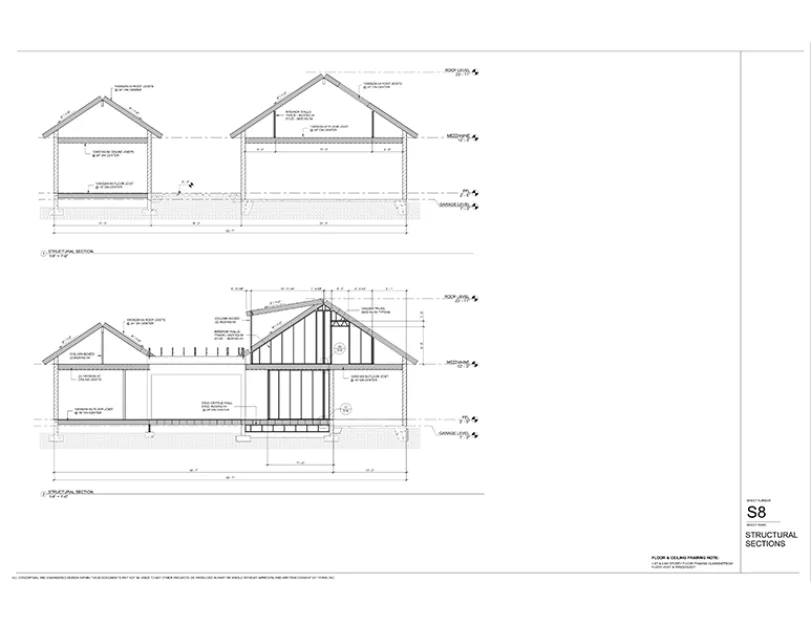

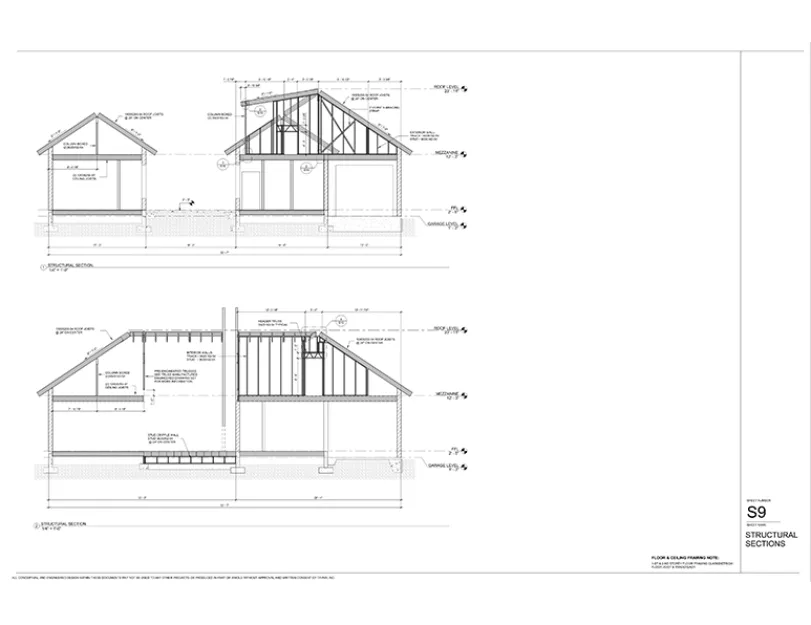

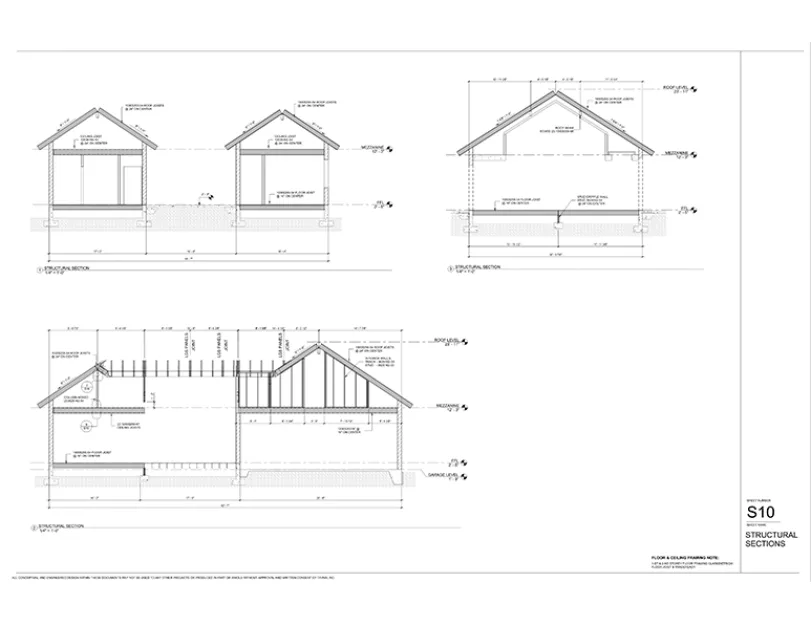

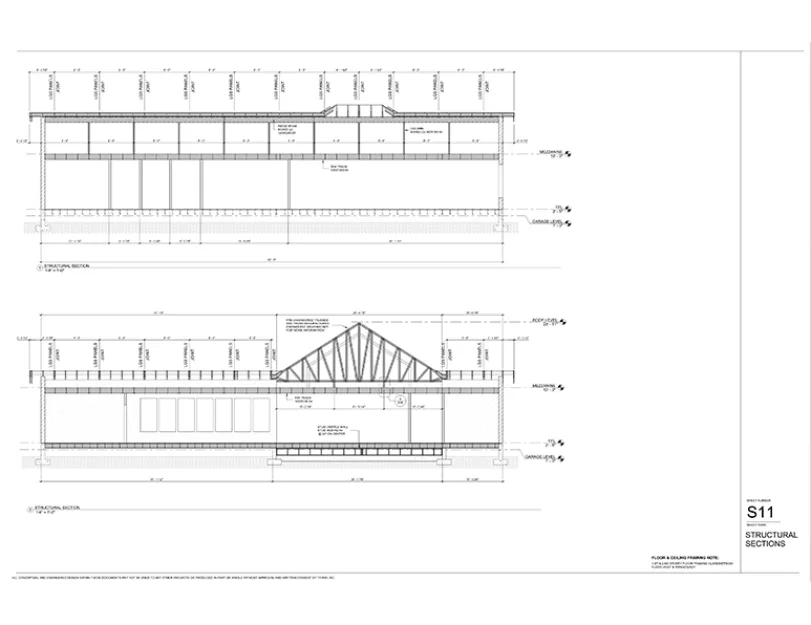

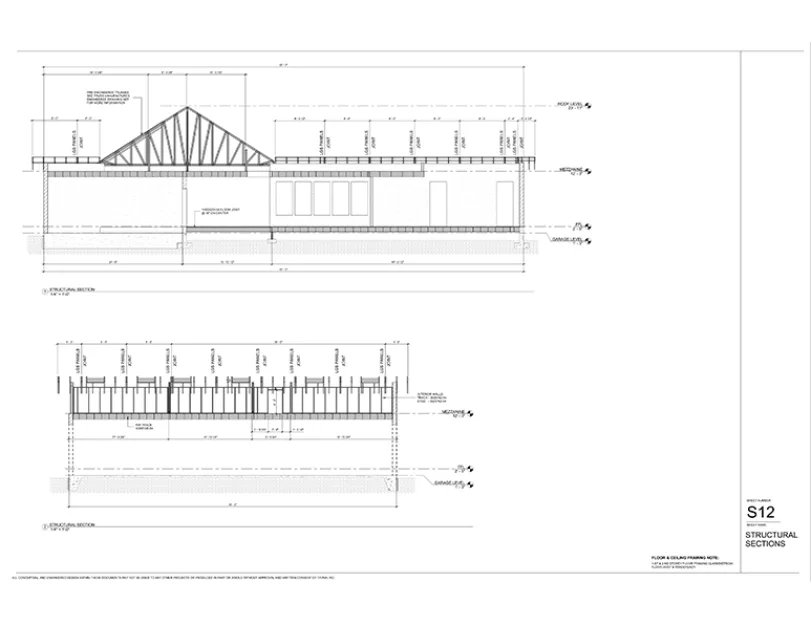

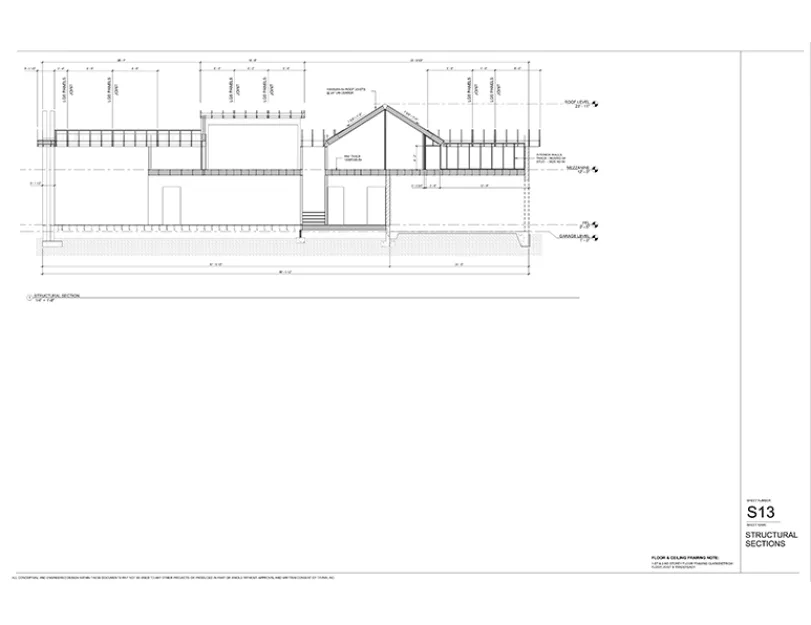

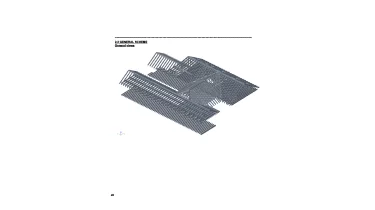

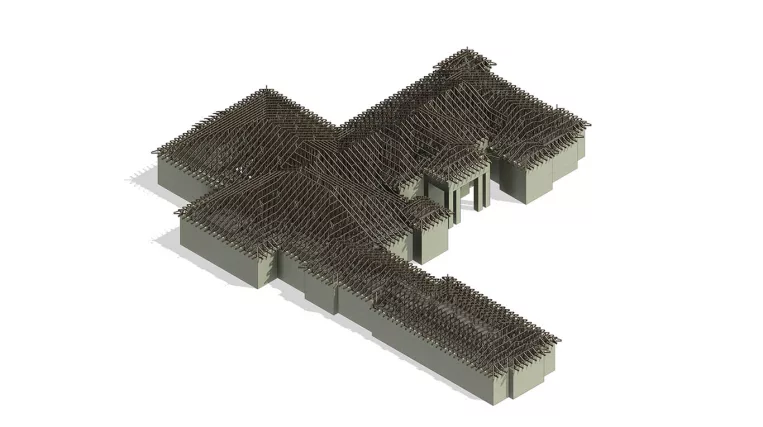

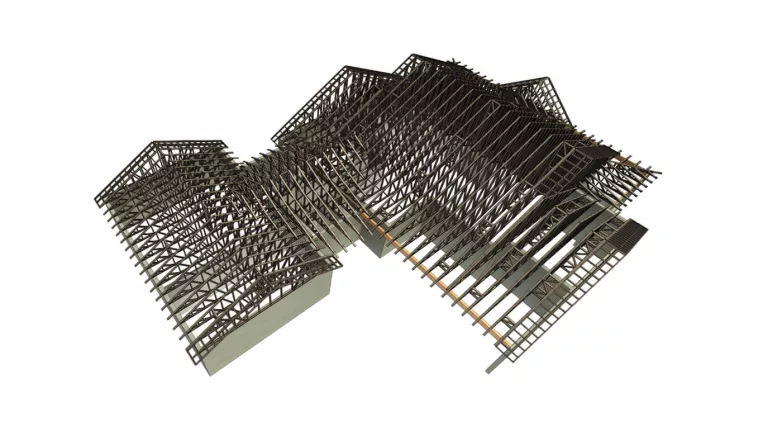

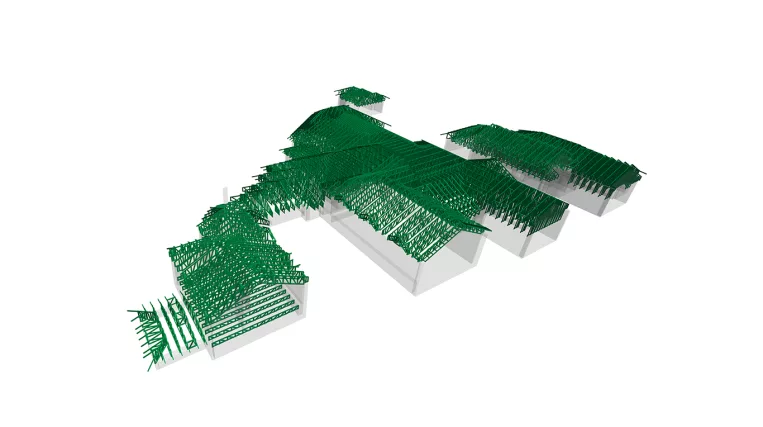

This project entails a two-story residential house, composed of two wings with a joining hall between them.

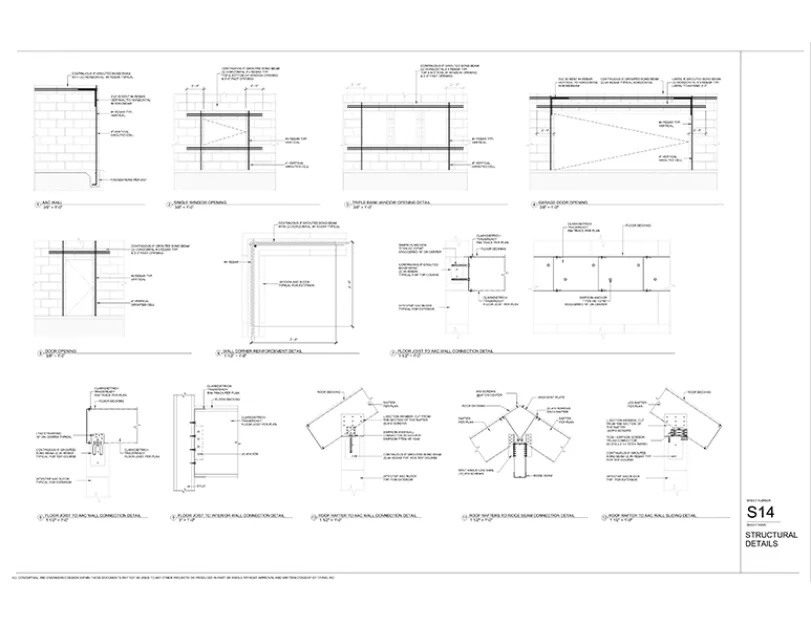

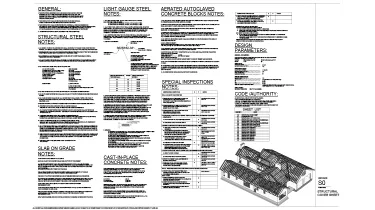

ORIGIN was enlisted to develop structural construction drawings and to conduct a structural analysis of the LGS framing and the building’s foundation.

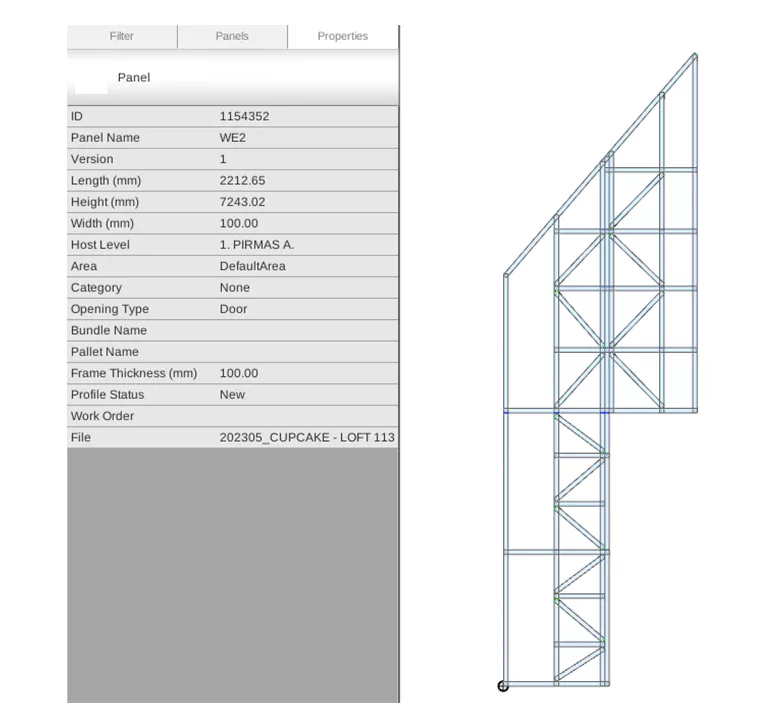

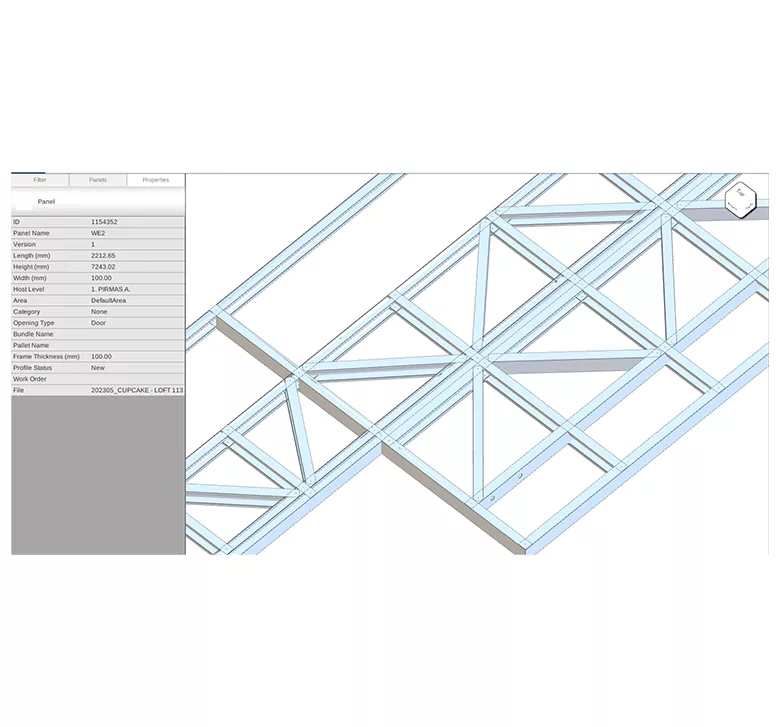

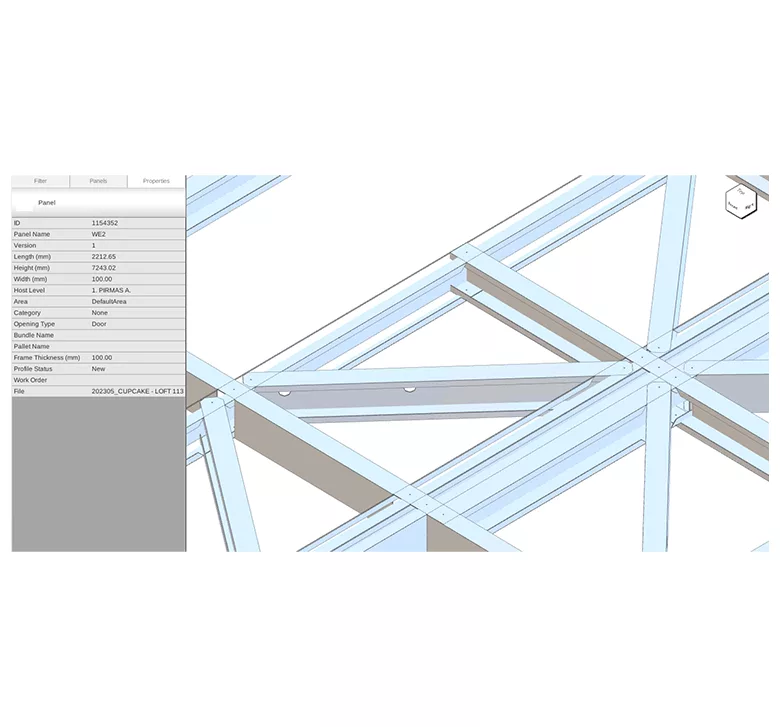

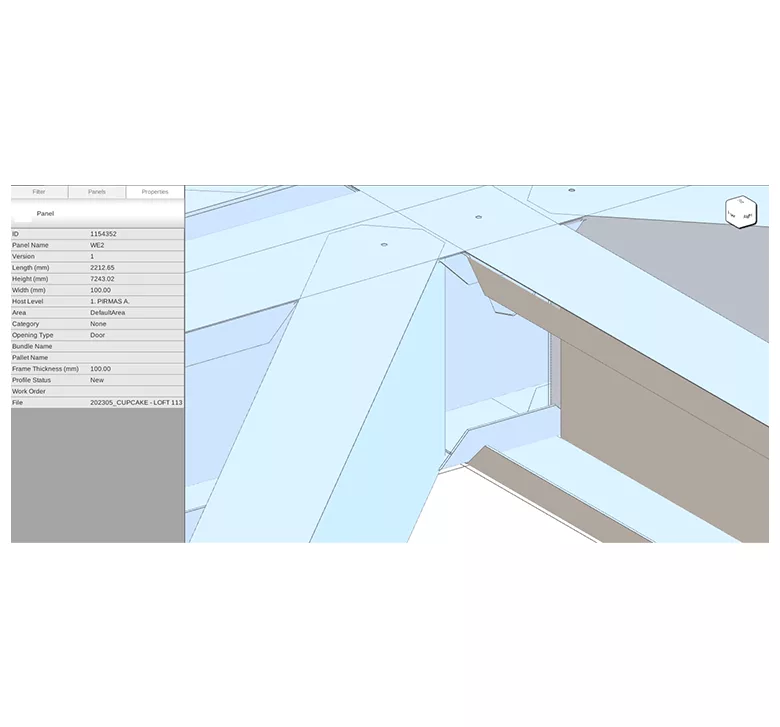

Given the builder’s possession of a Framecad rollformer, CNC files for LGS panel production were also a requirement.

Input: Architectural drawing set.

Project deliverables:

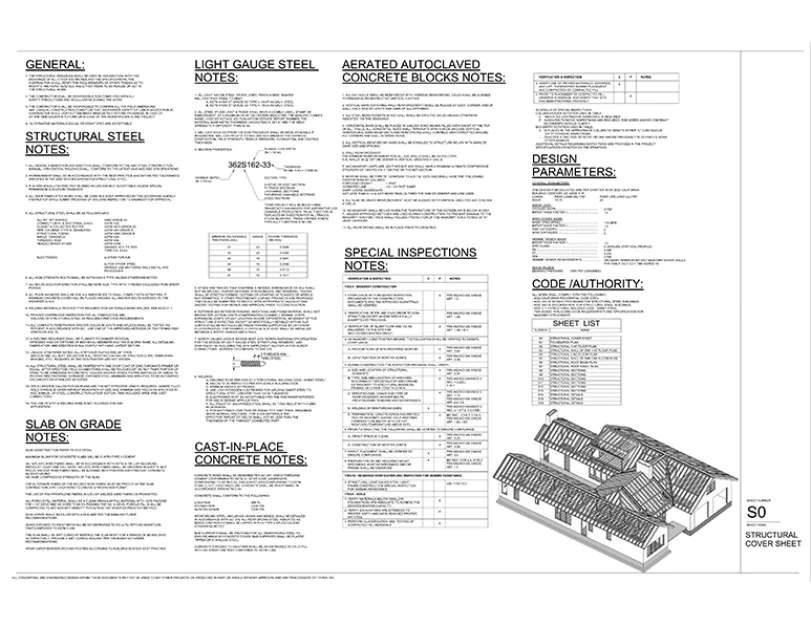

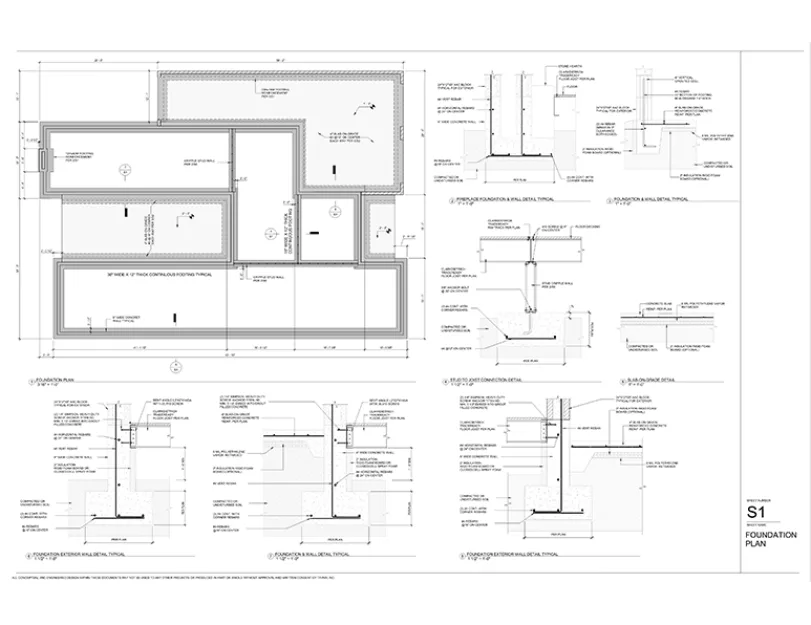

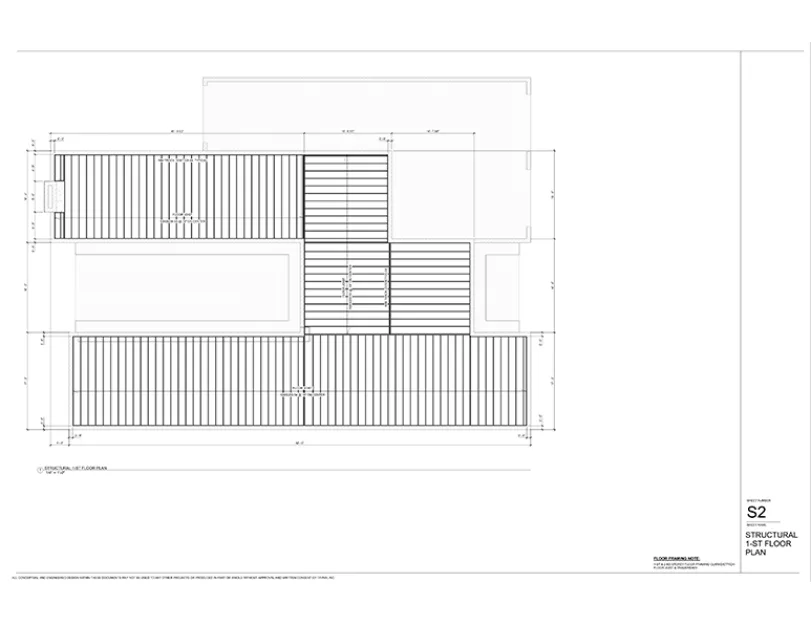

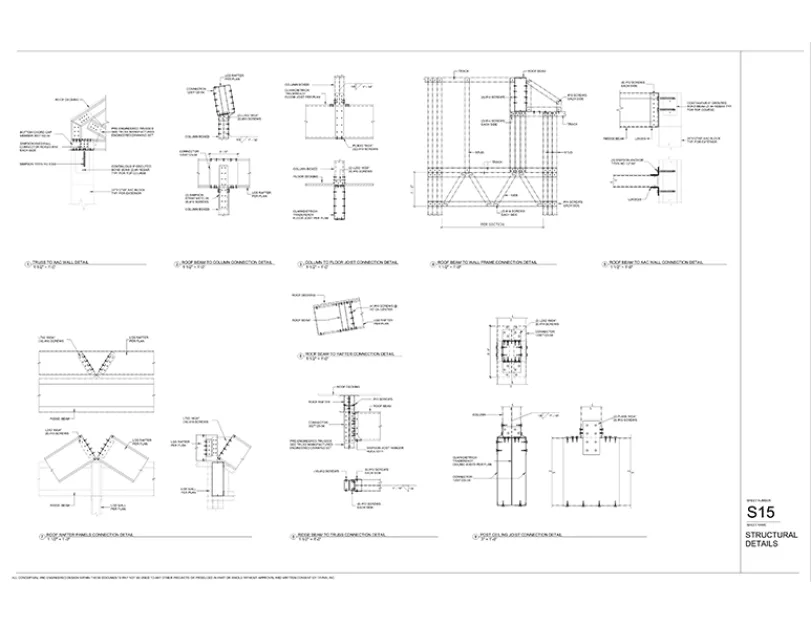

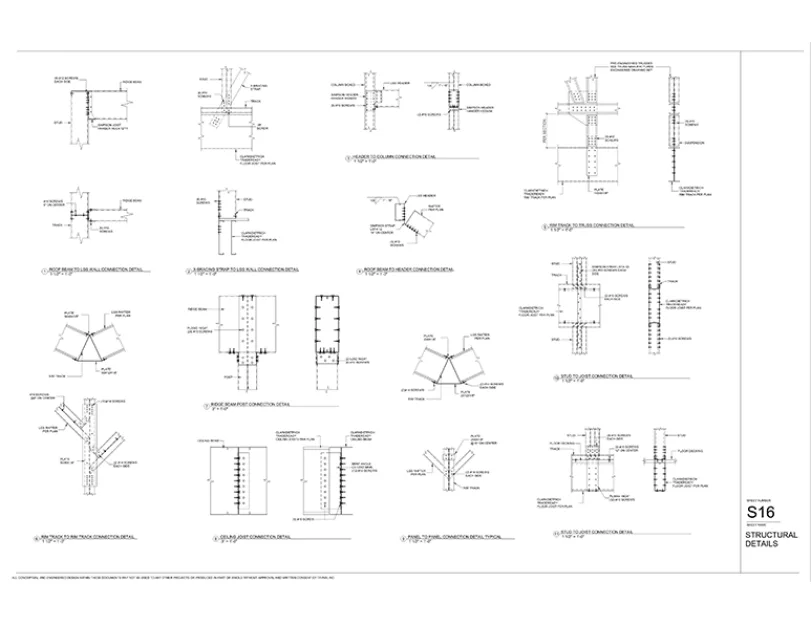

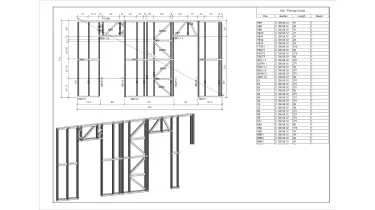

- Structural drawing set;

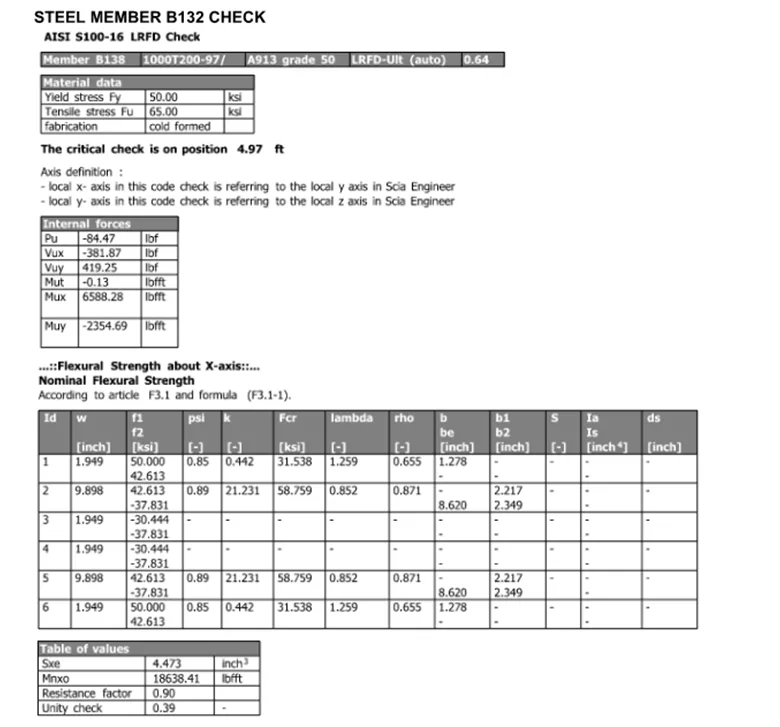

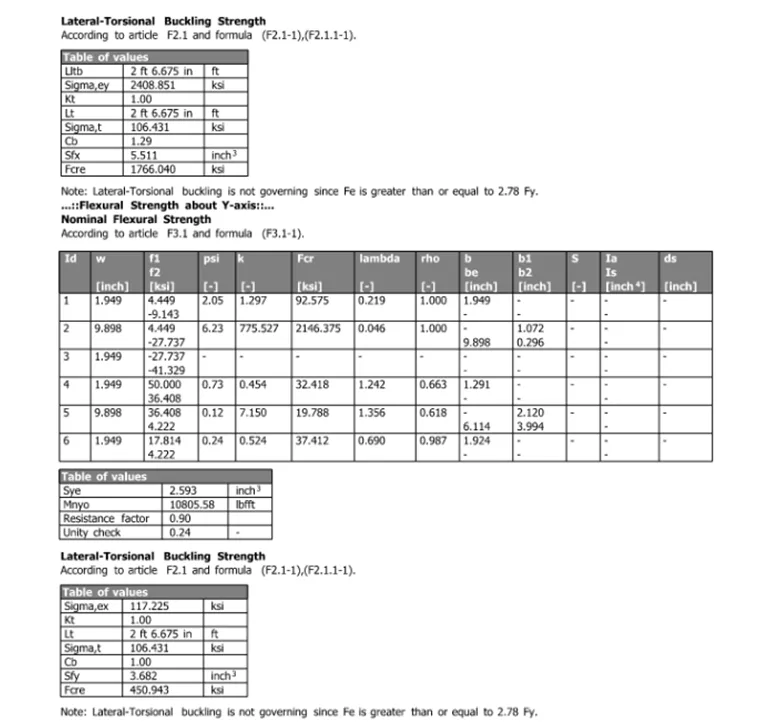

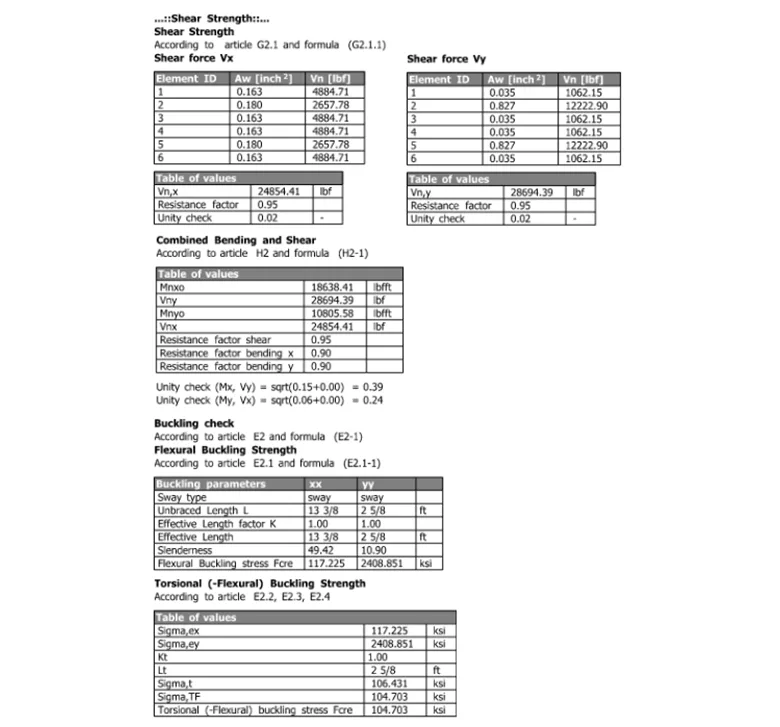

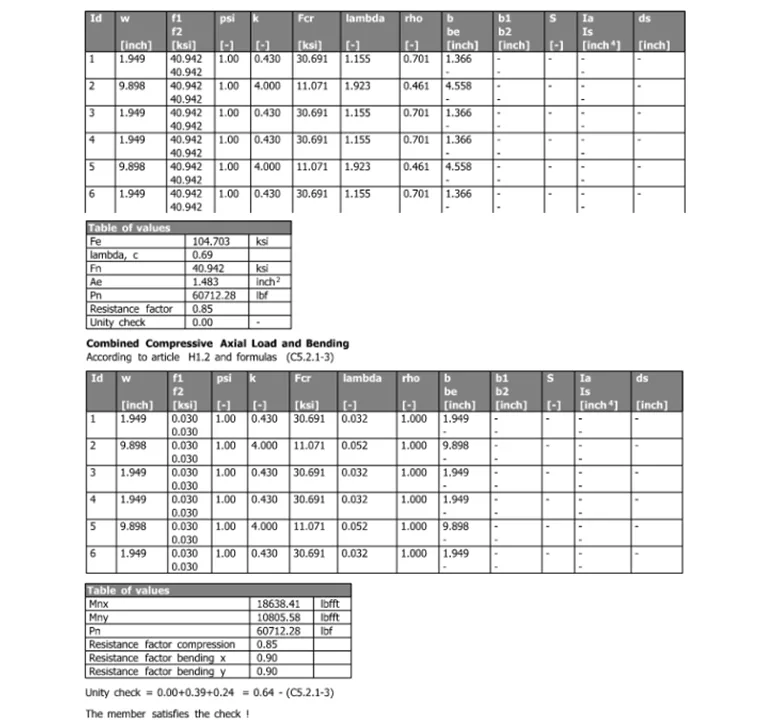

- Structural analysis report;

- LGS shop drawings;

- Framecad CNC files for LGS panel production.