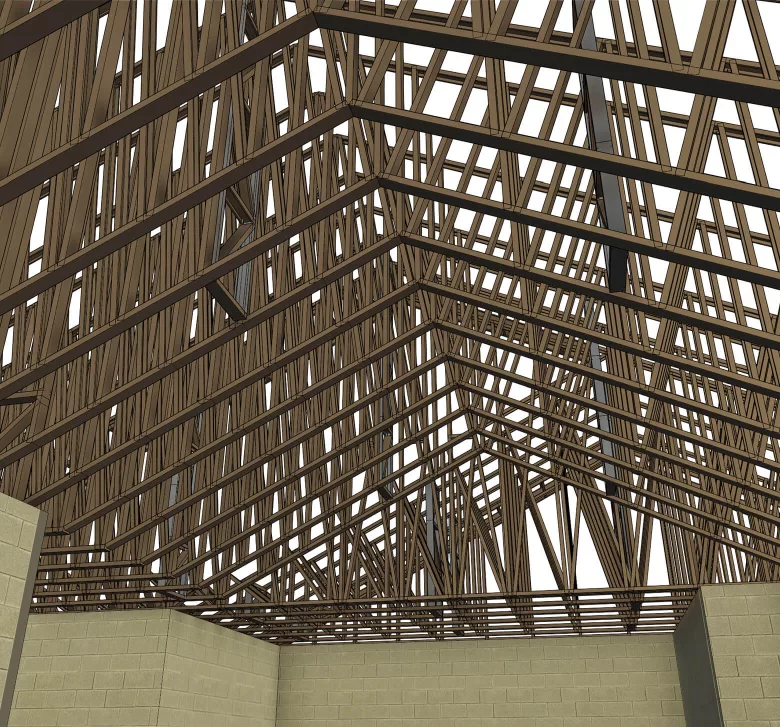

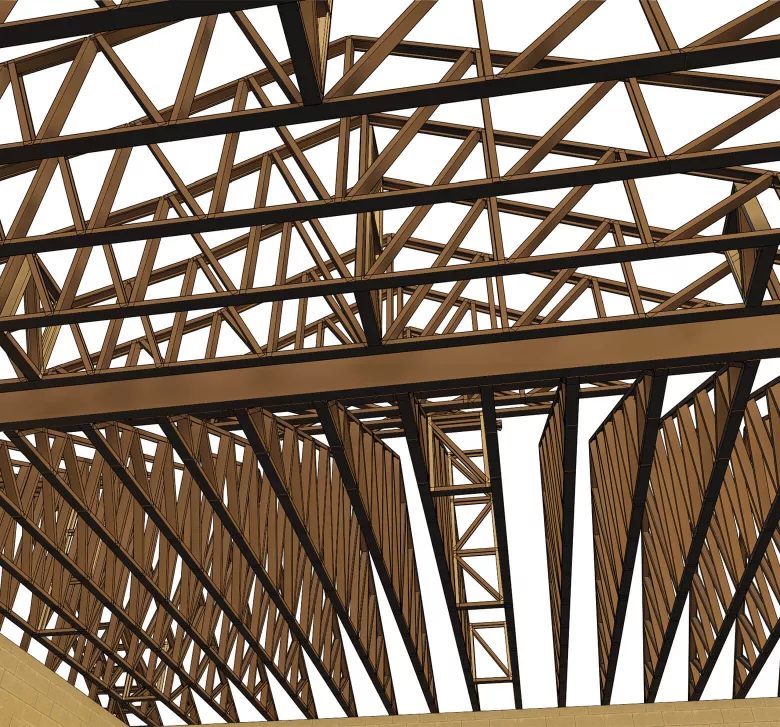

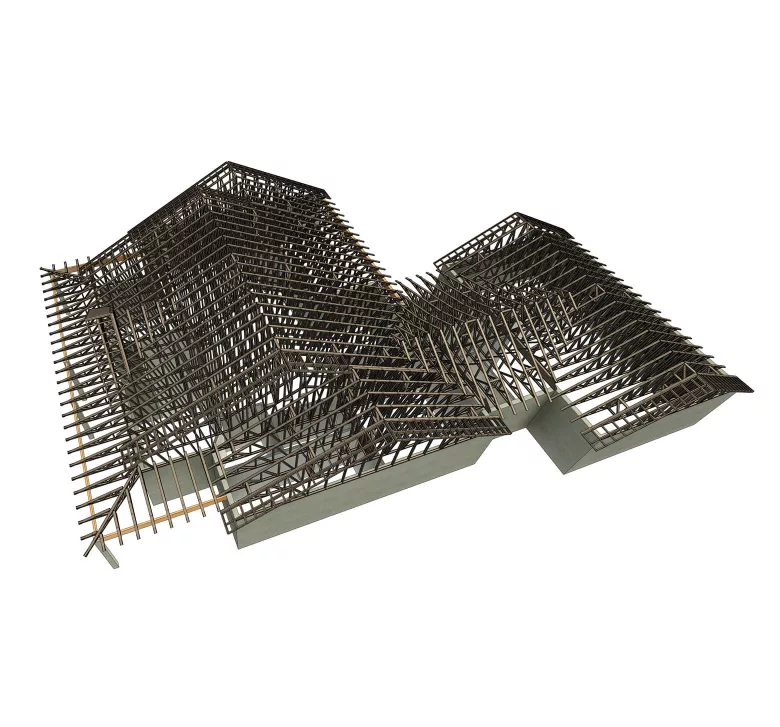

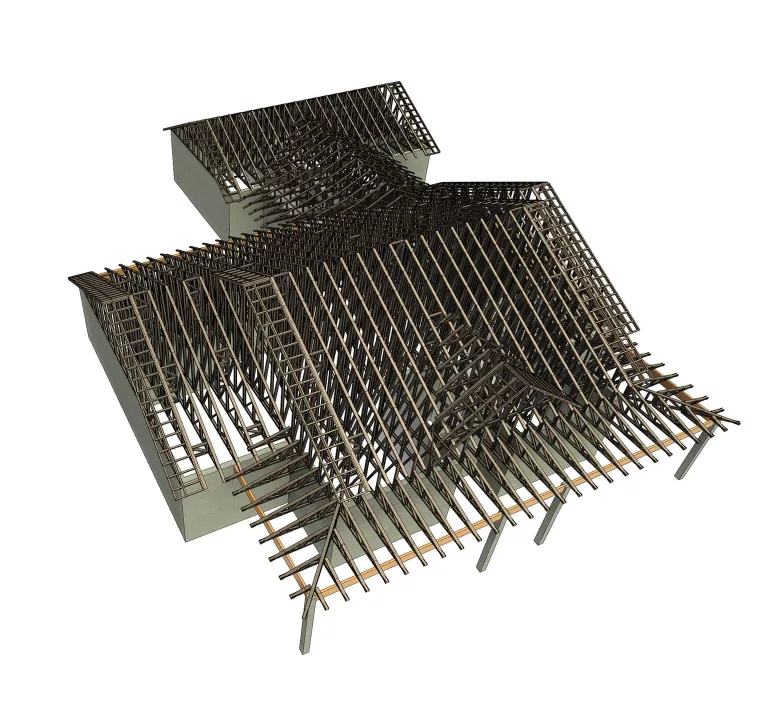

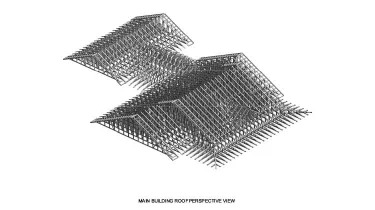

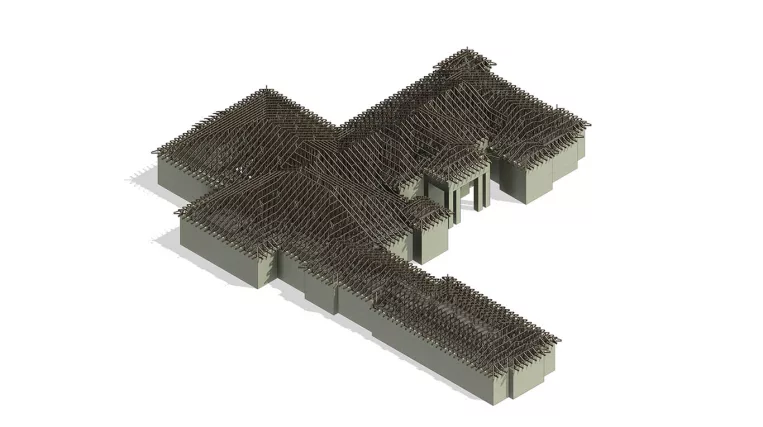

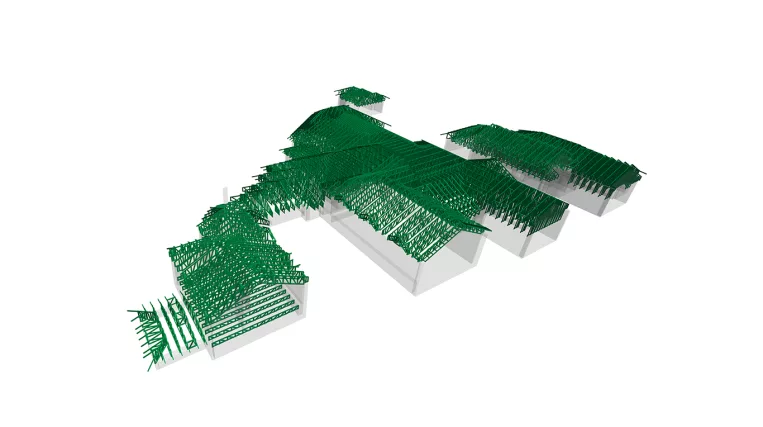

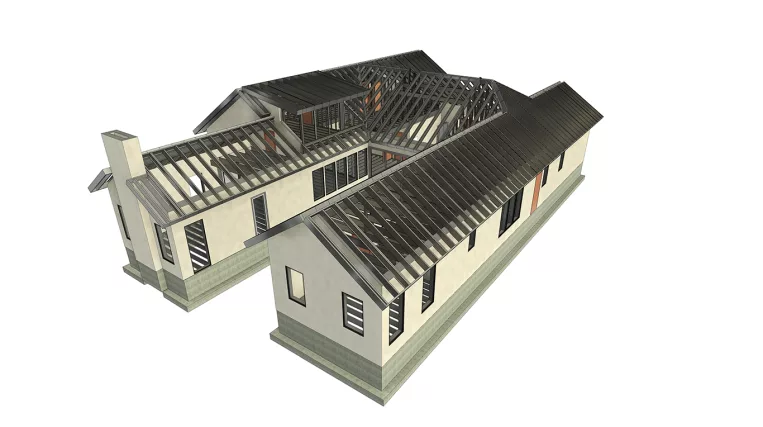

On this project, the ORIGIN team designed the LGS roof framing of a residential building.

One of the most crucial aspects of the project requirements was ensuring that the truss design was suitable for further fabrication using a FRAMECAD rollformer.

Well-familiar with this efficient construction practice, the ORIGIN team knew well how to meet these requirements.

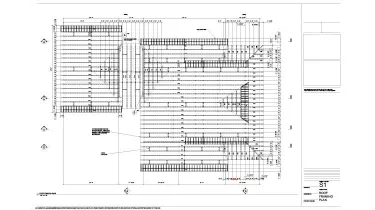

Input: Structural drawings set.

Project deliverables:

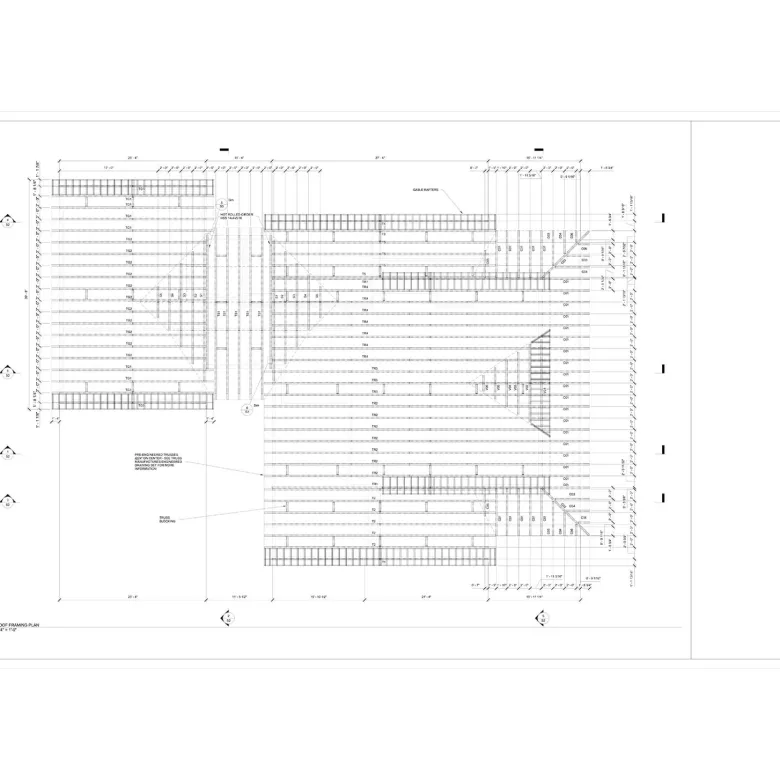

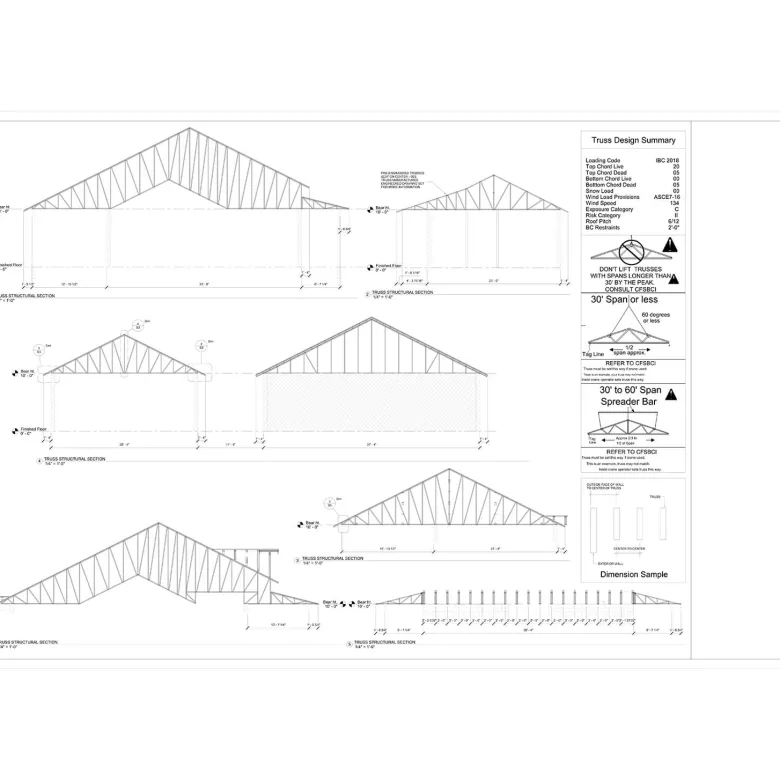

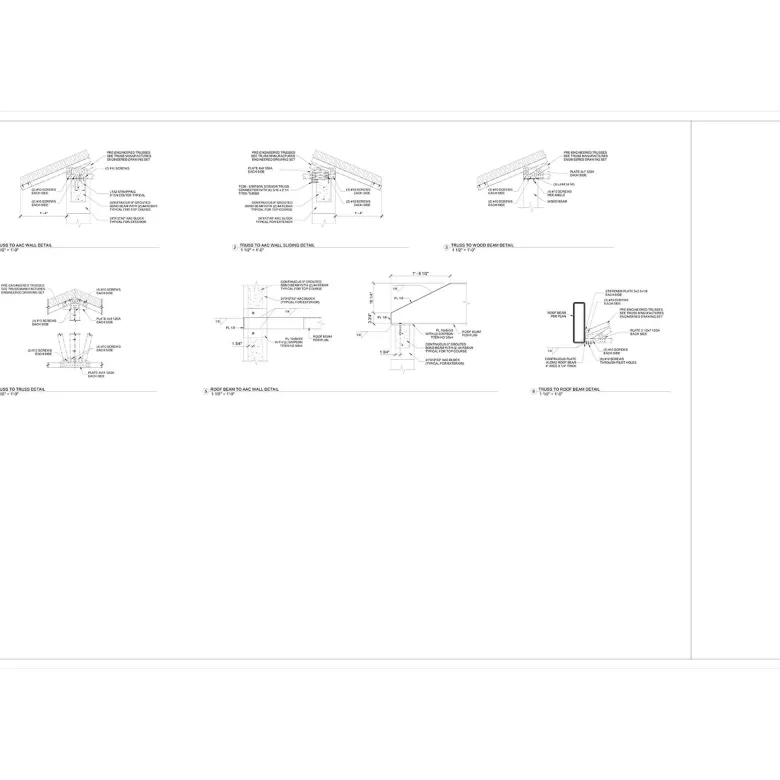

- Roof trusses layout;

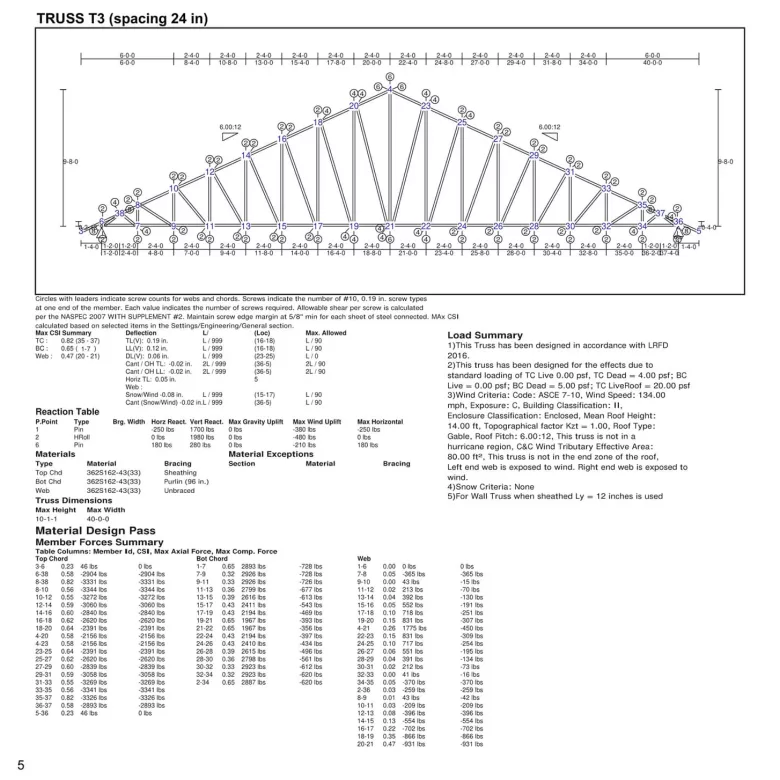

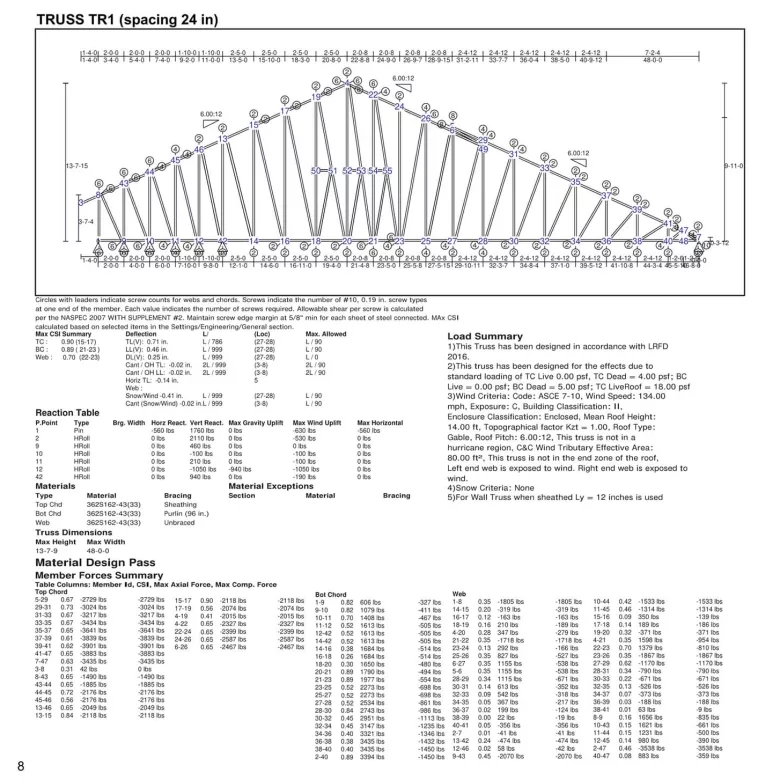

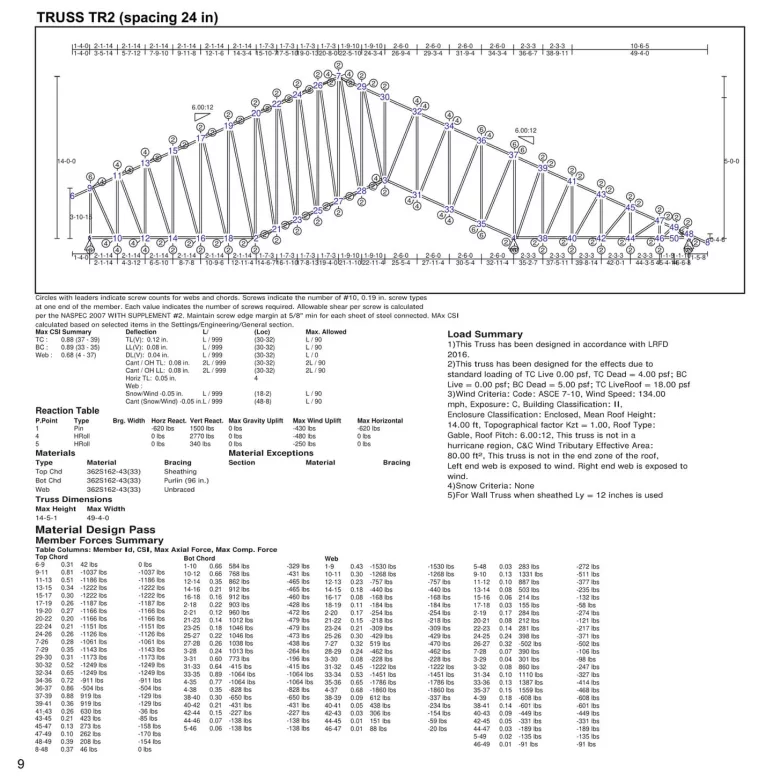

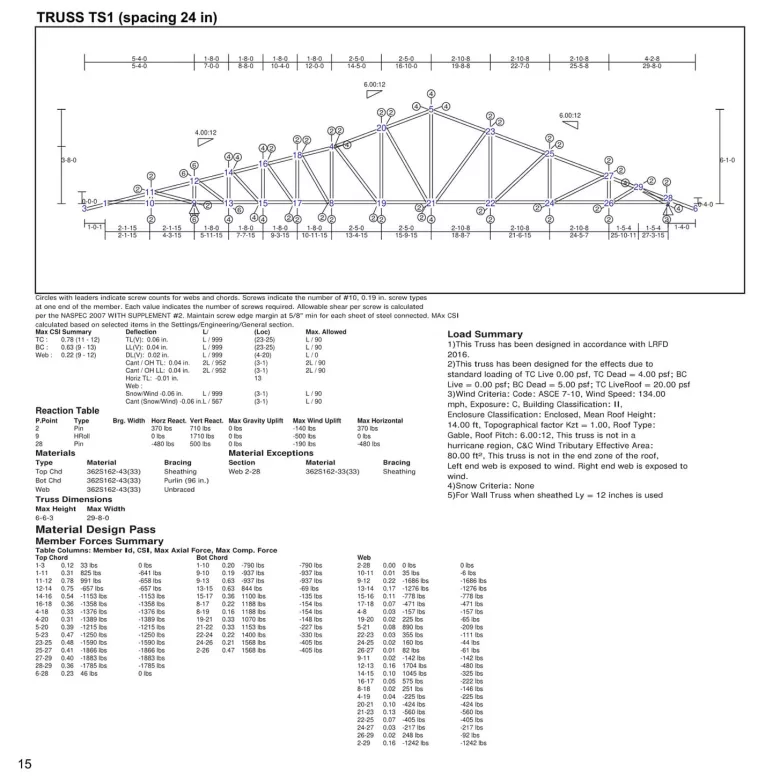

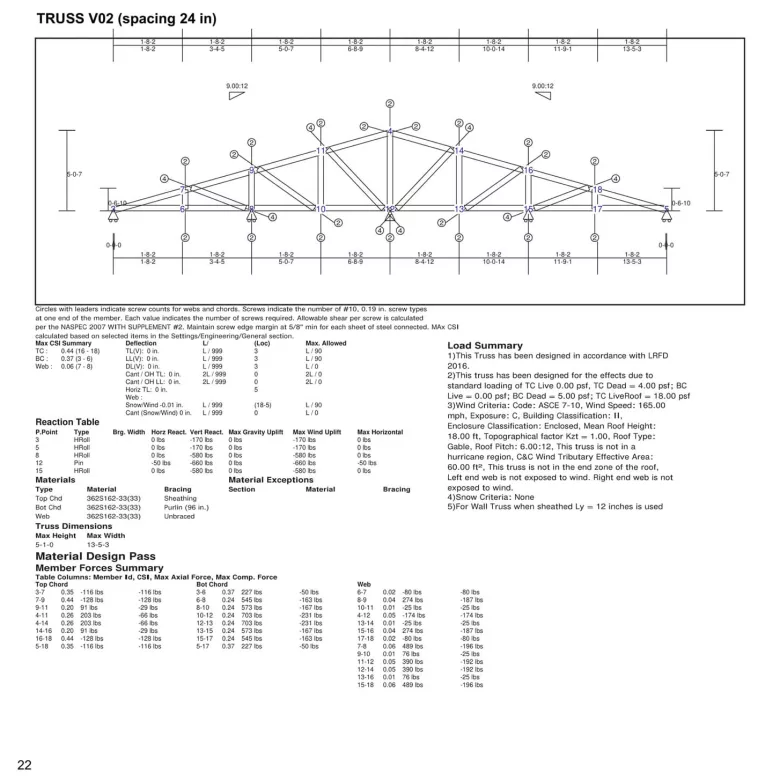

- Truss reports;

- FRAMECAD CNC files for LGS panels production.