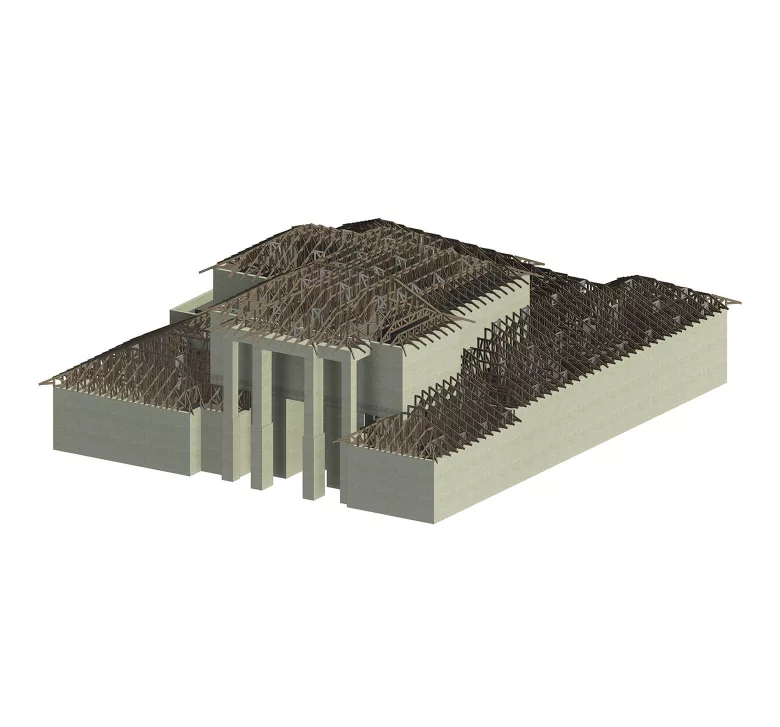

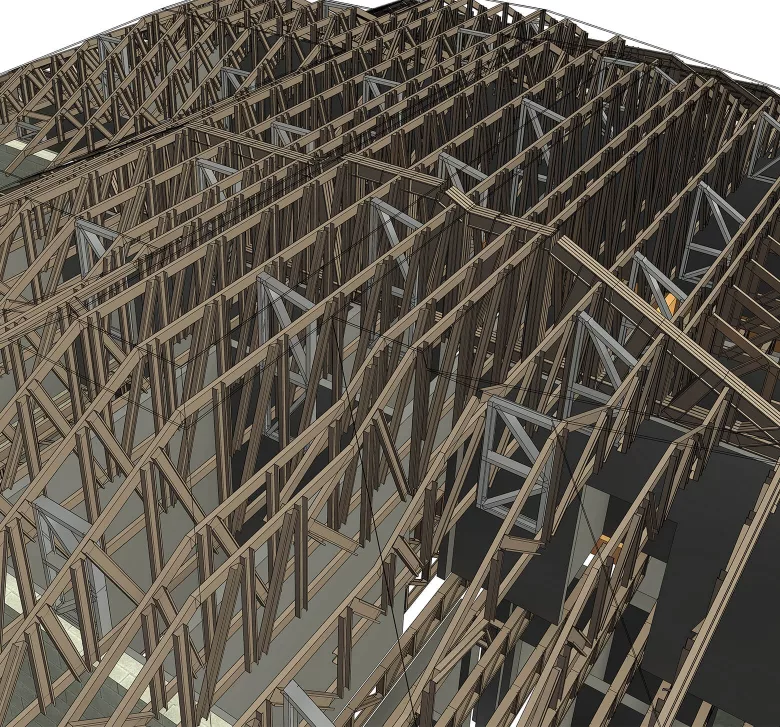

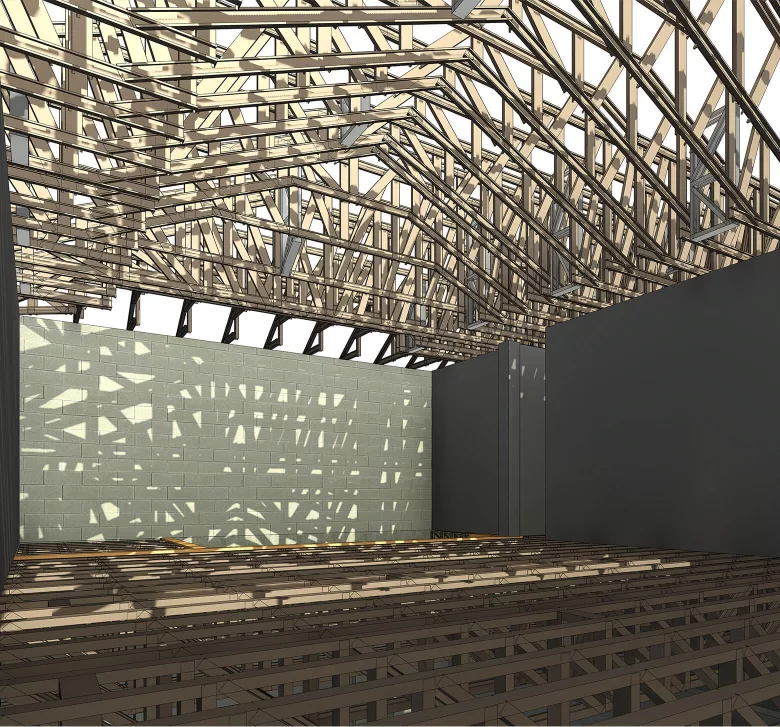

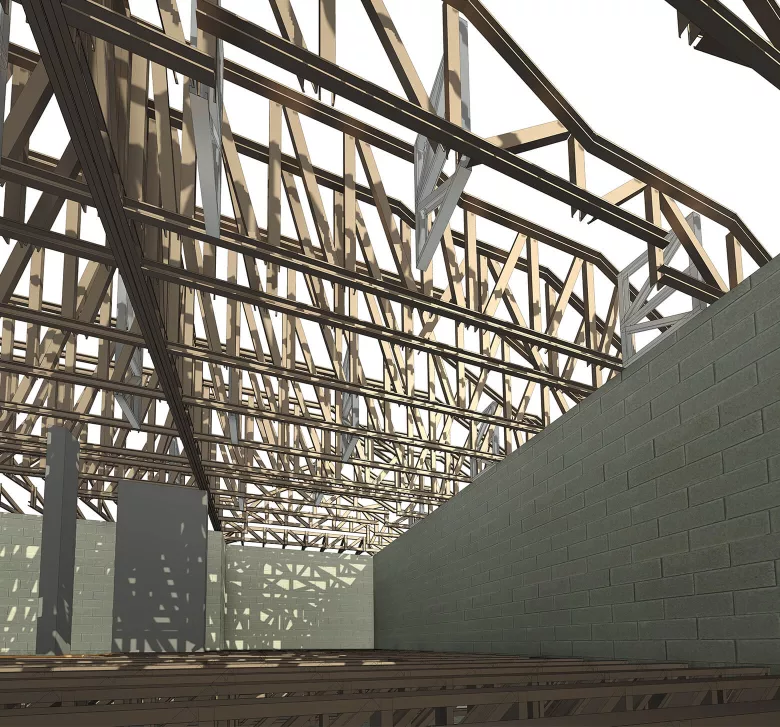

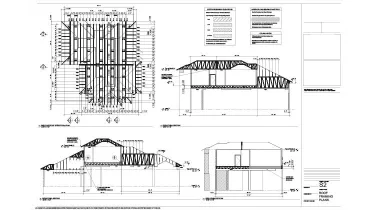

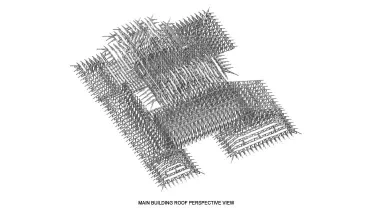

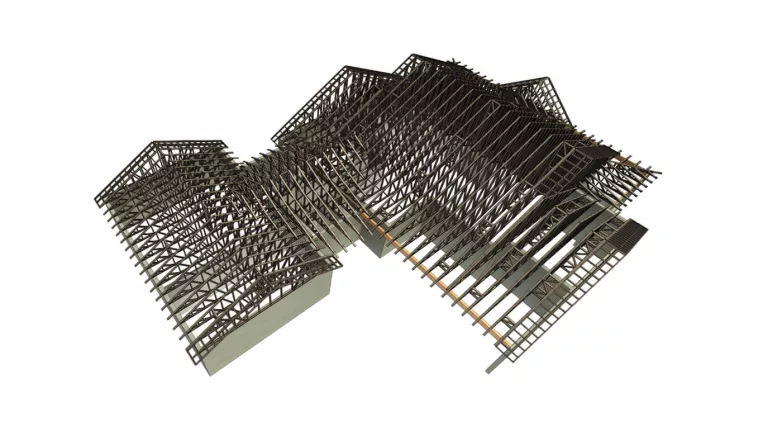

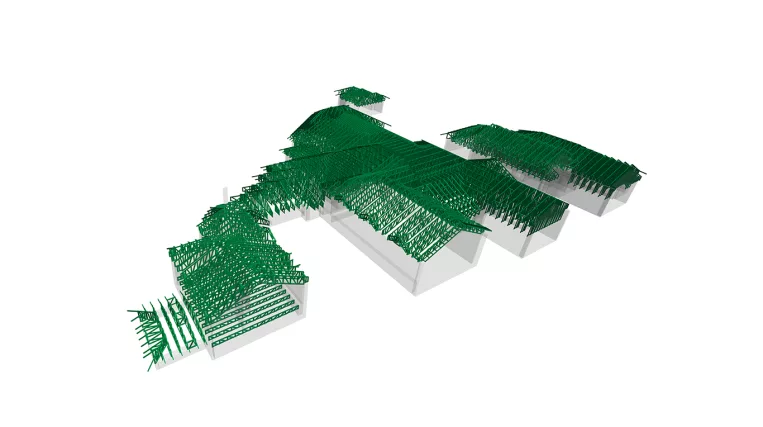

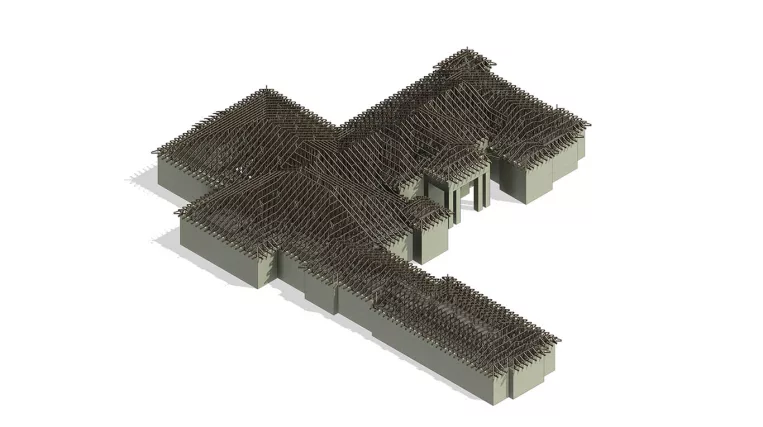

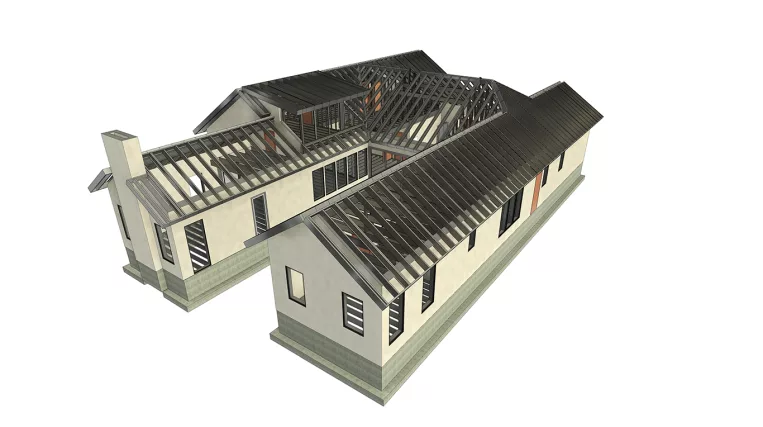

The goal of this project was to design LGS roof framing for a single-family residential house spanning 520 m² / 5600 ft² LGS framing.

ORIGIN was asked to ensure the truss design was compatible with the FRAMECAD rollformer, enabling seamless fabrication and streamlined production. Well-versed with this technology, the ORIGIN team committed to efficient execution.

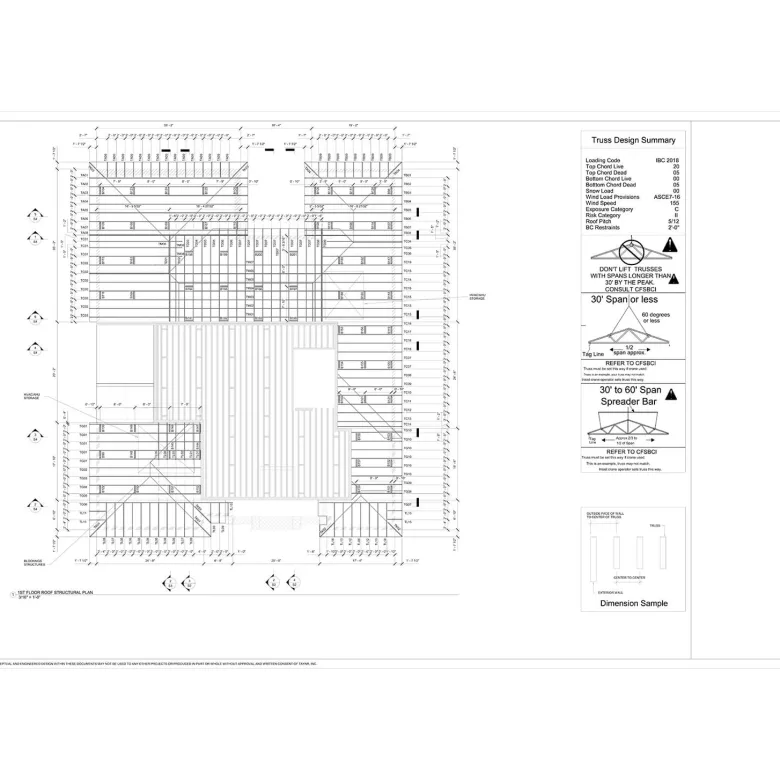

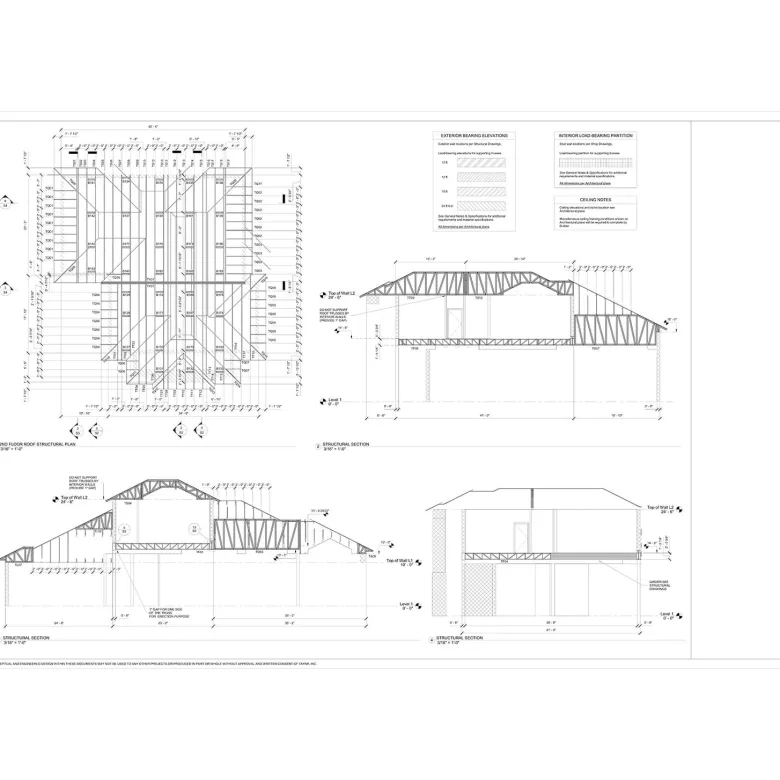

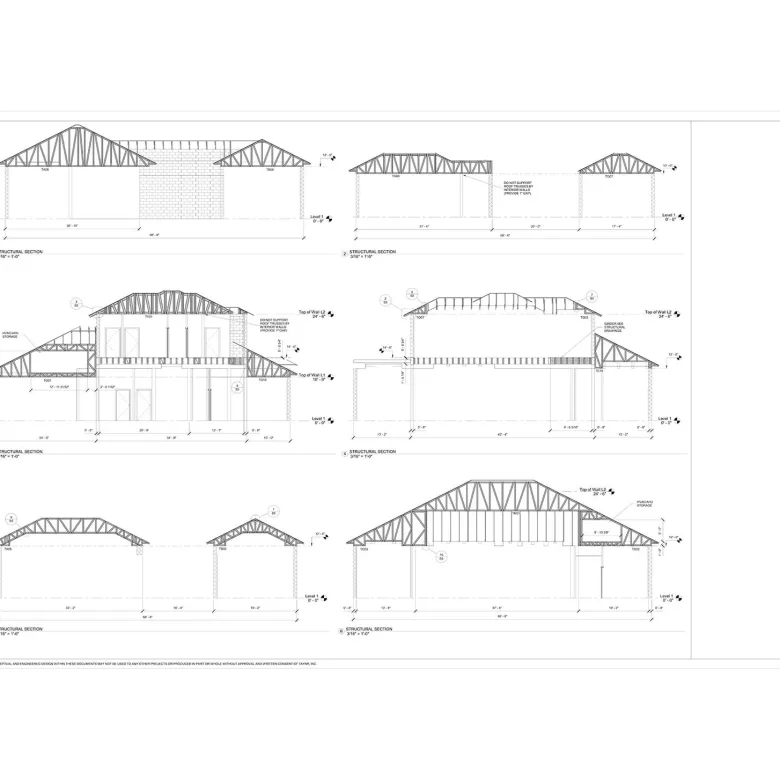

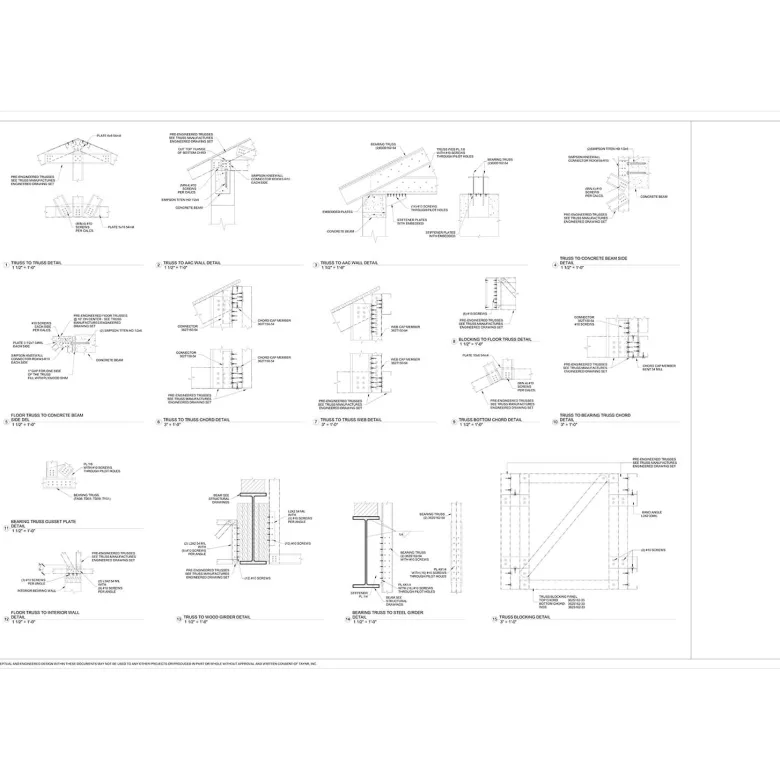

Input: Structural drawings set.

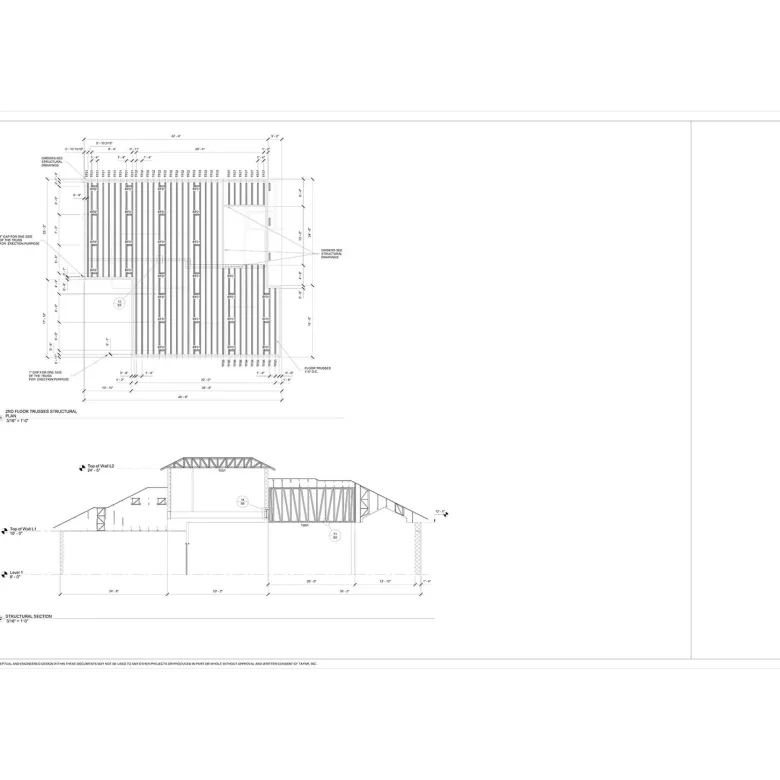

Project deliverables:

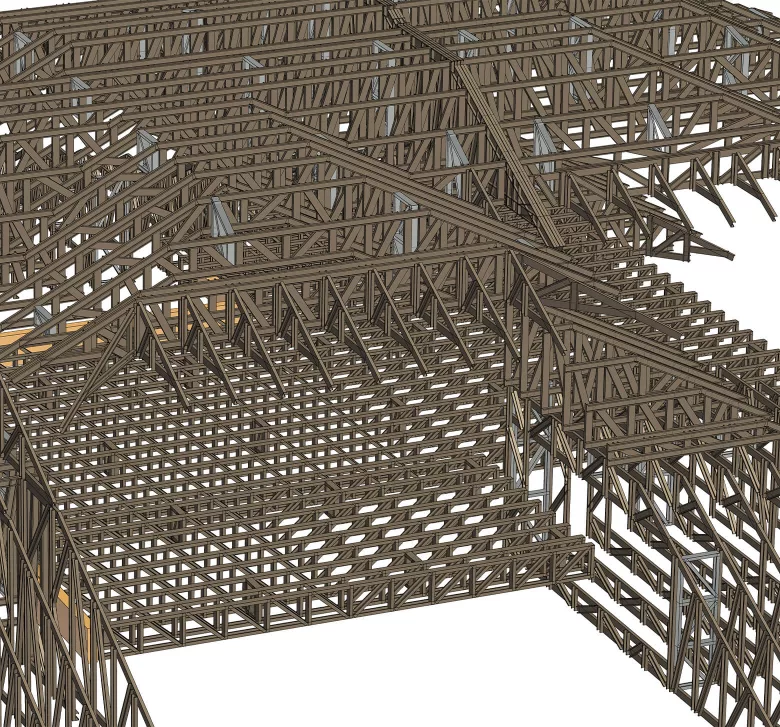

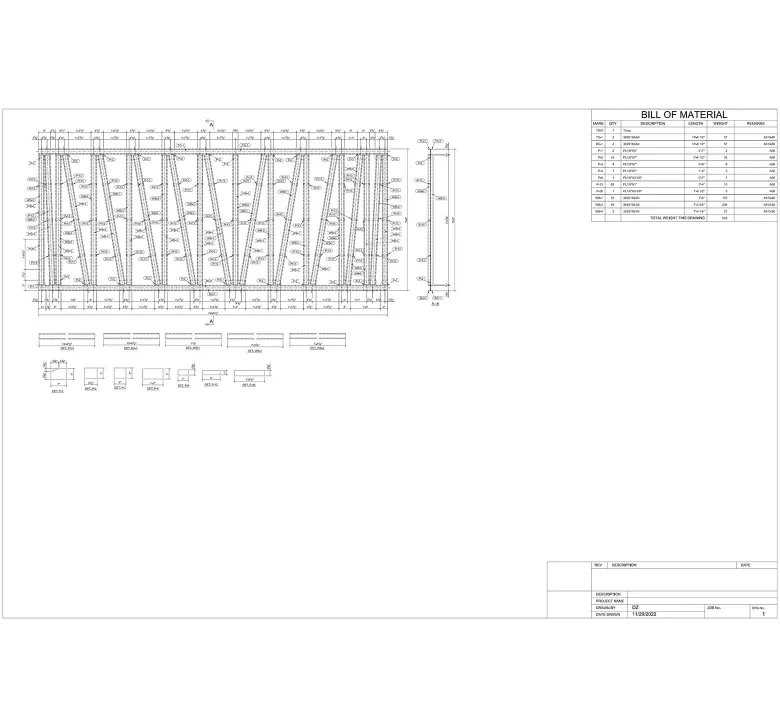

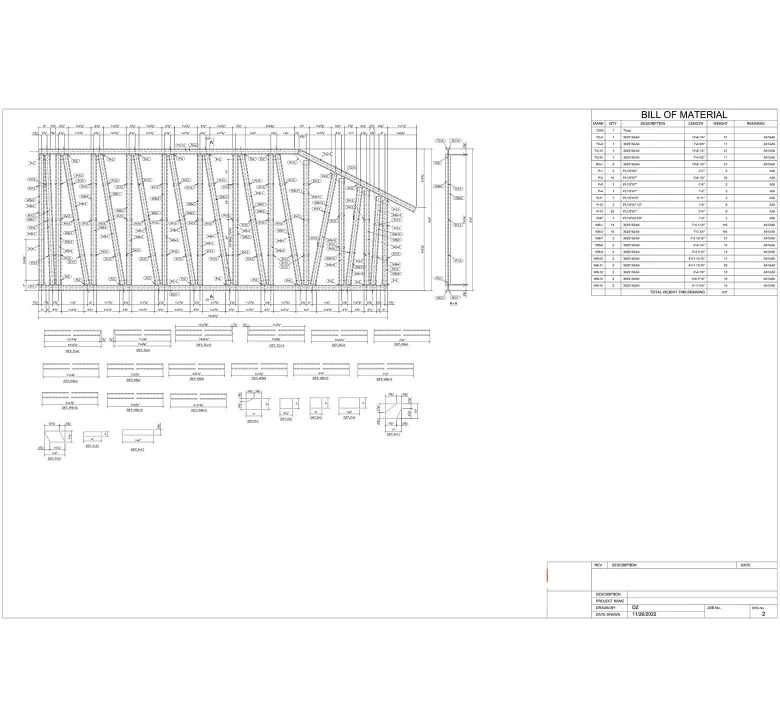

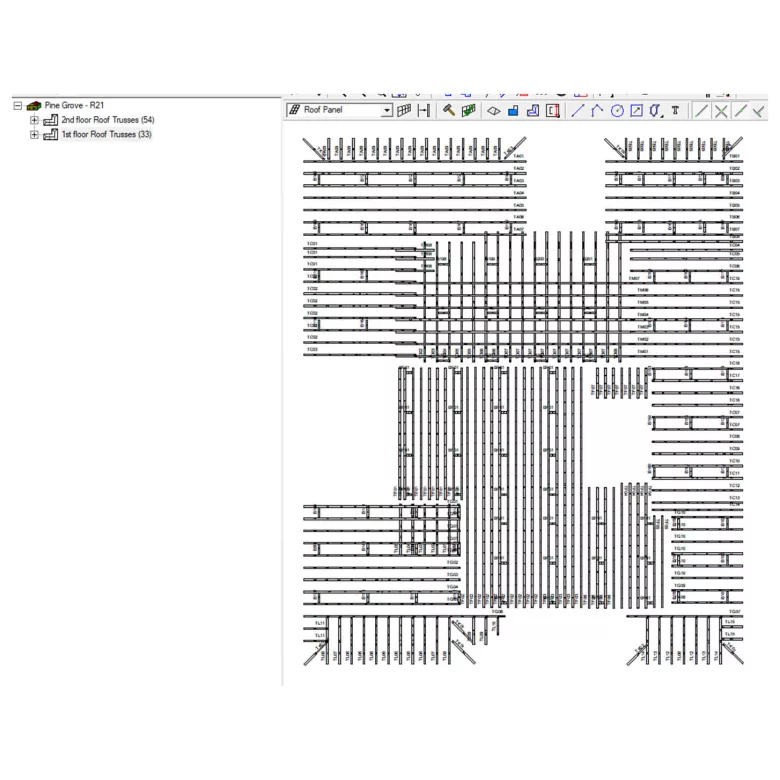

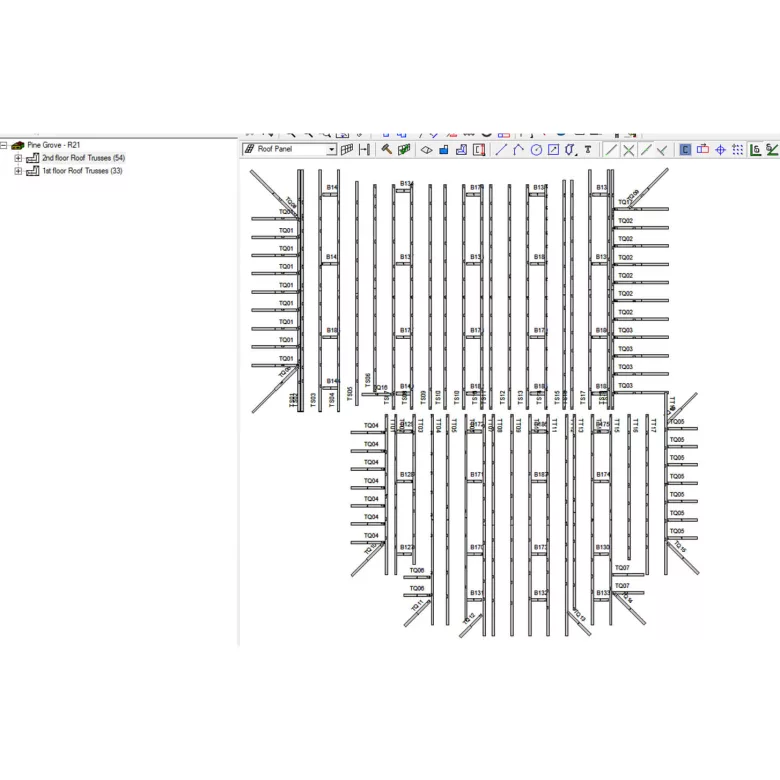

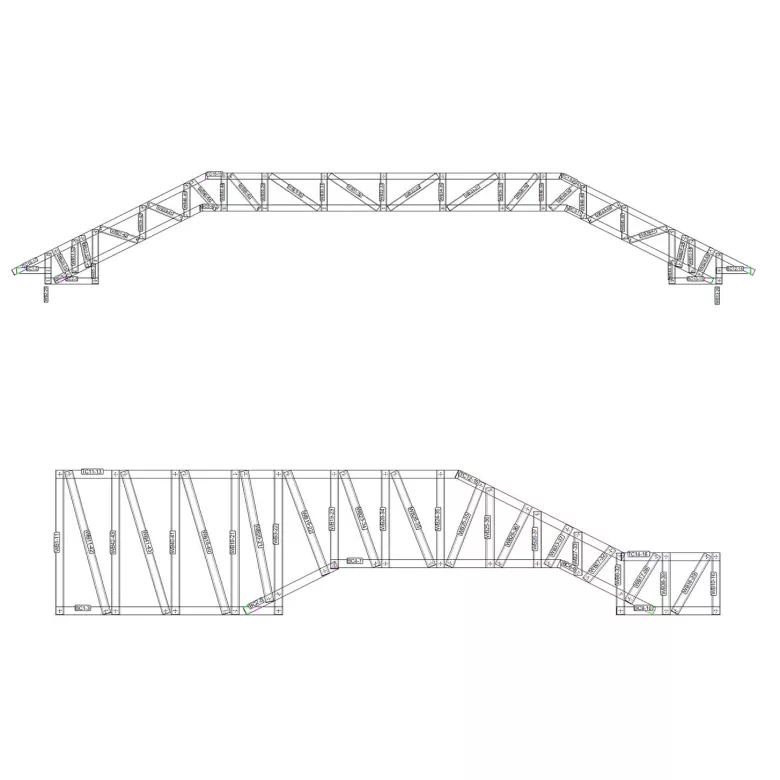

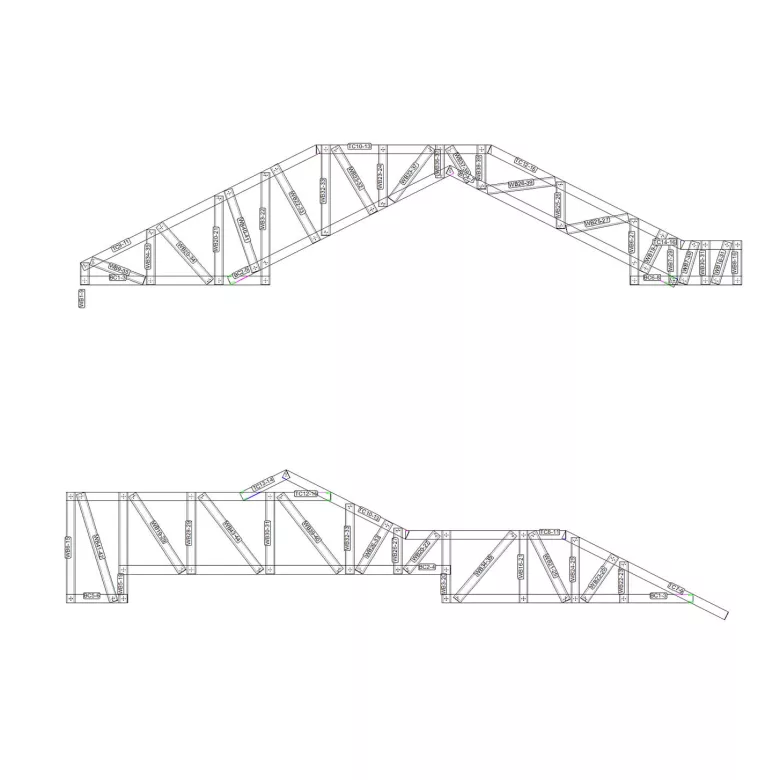

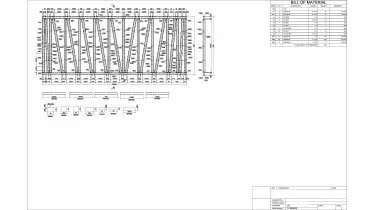

- Roof trusses layout;

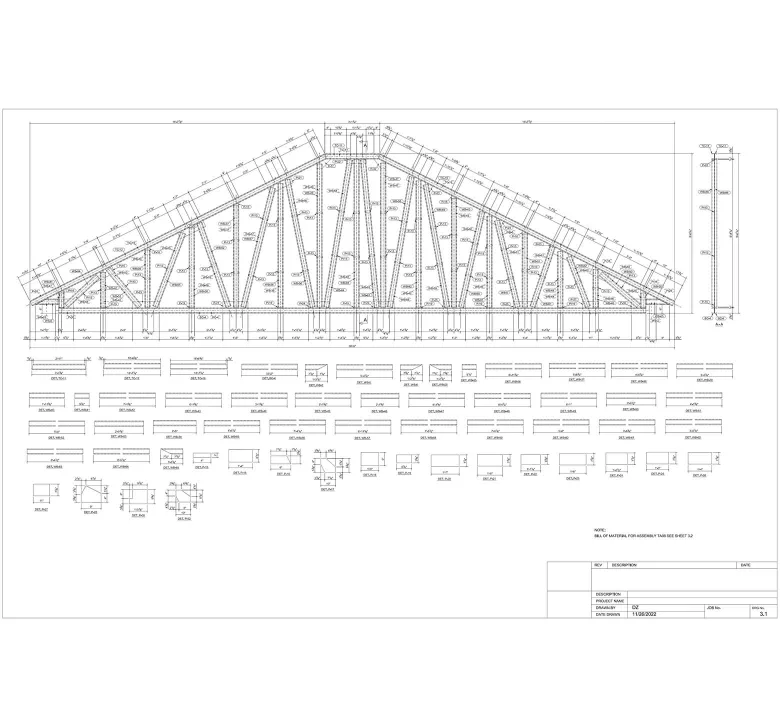

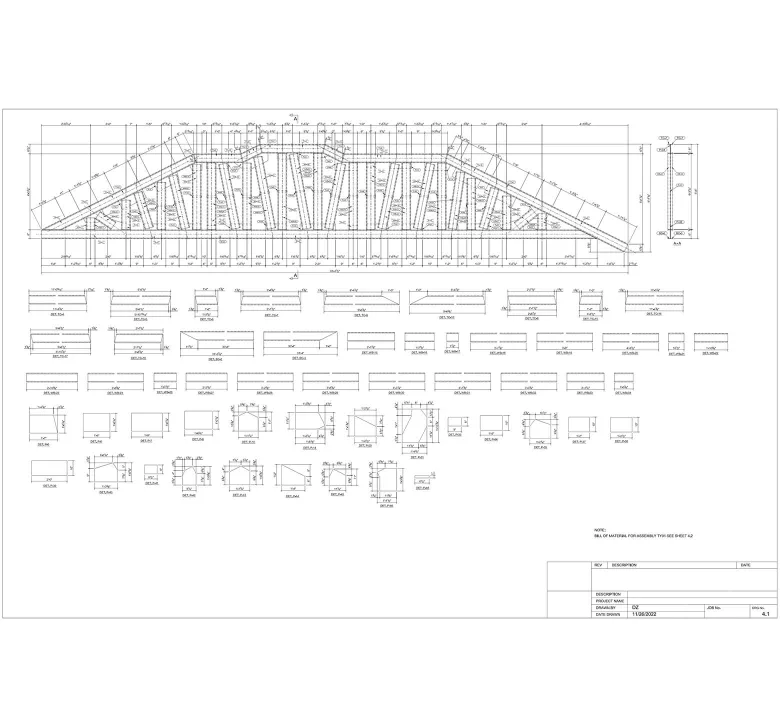

- Truss reports;

- Shop drawings of complex LGS trusses which cannot be fabricated using FRAMECAD system only;

- FRAMECAD CNC files for LGS panels production.