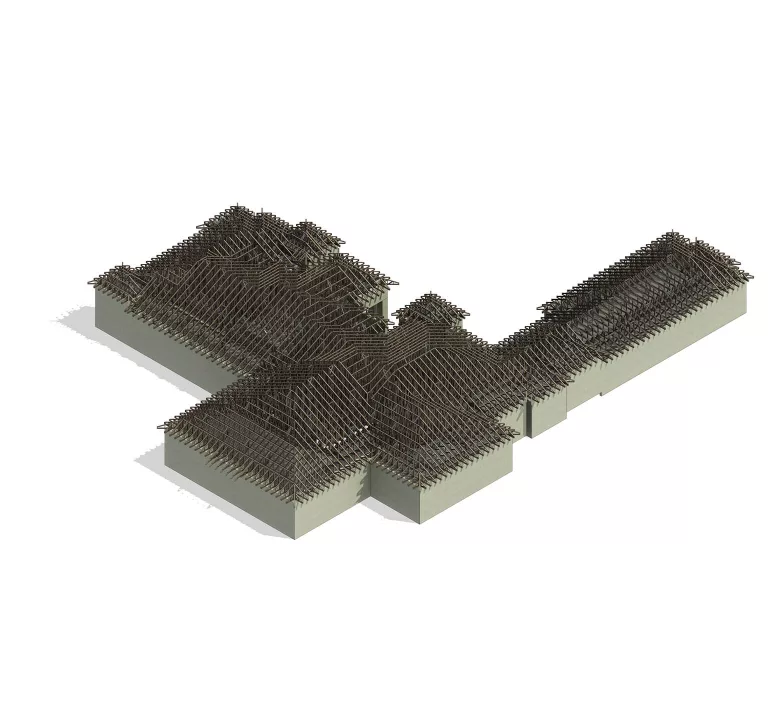

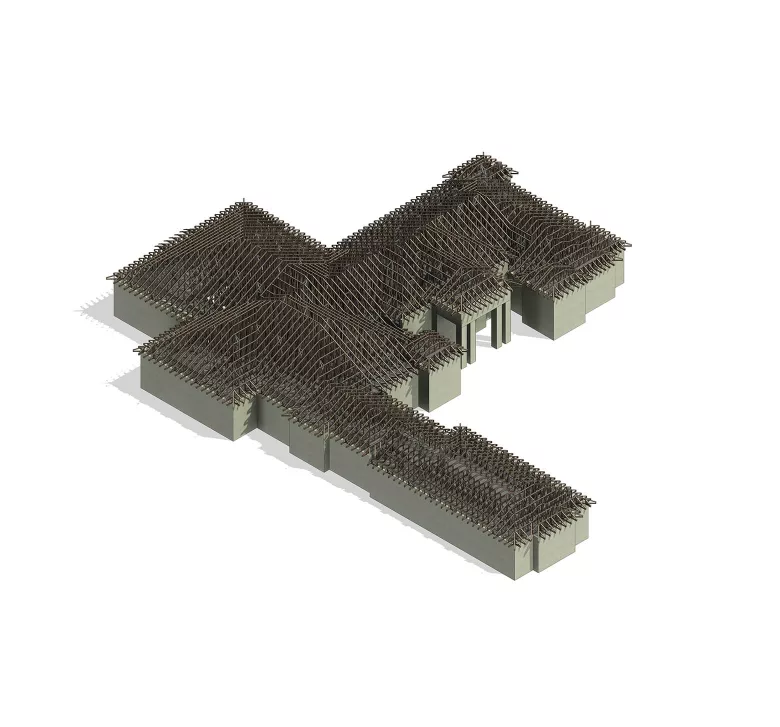

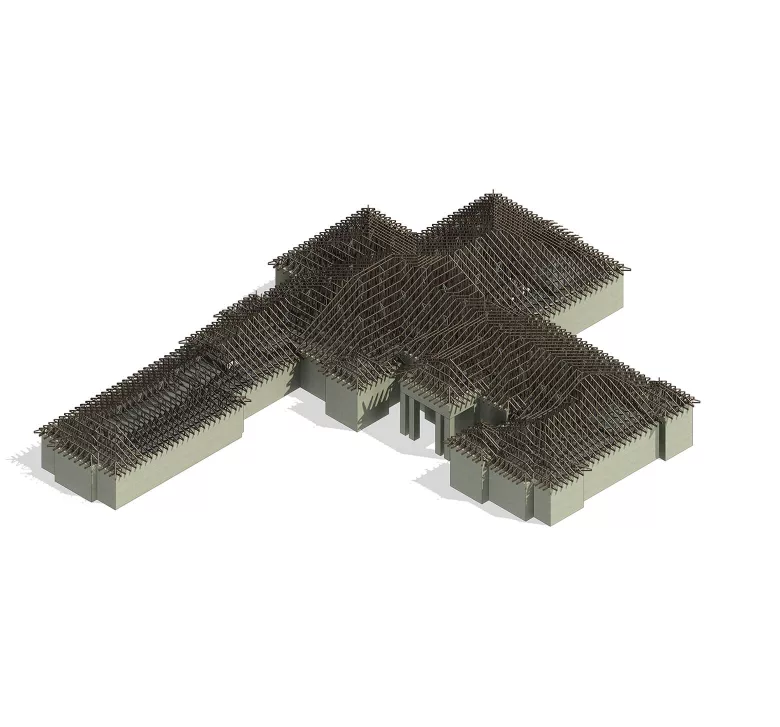

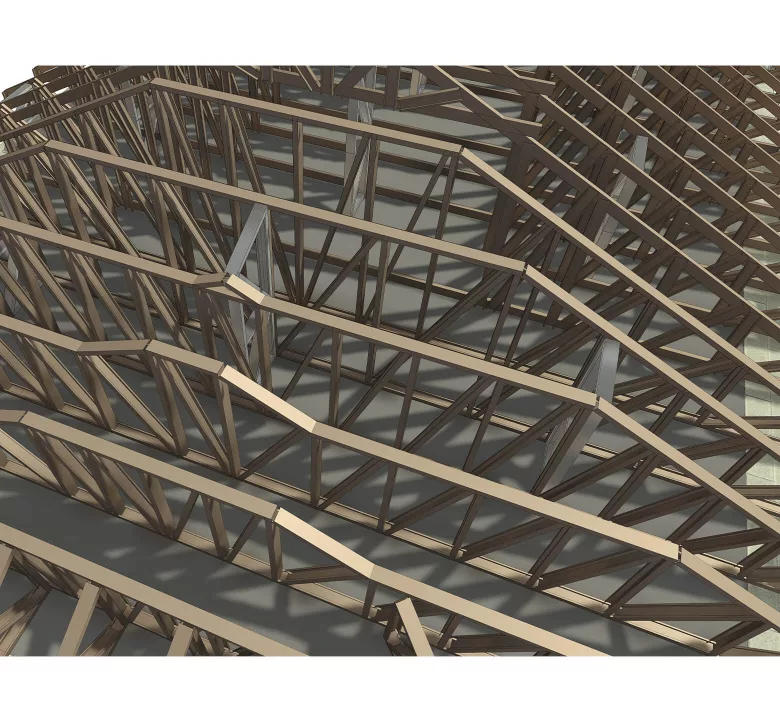

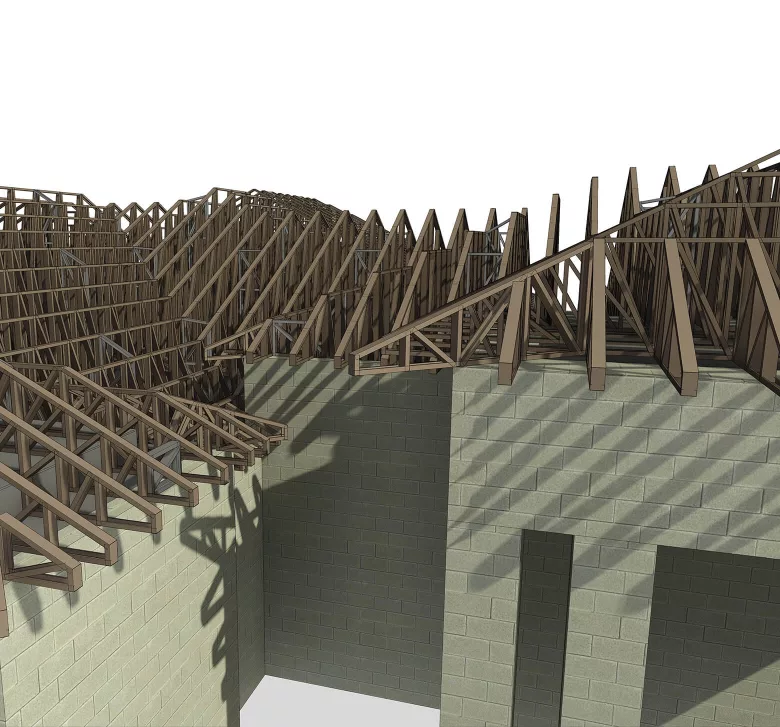

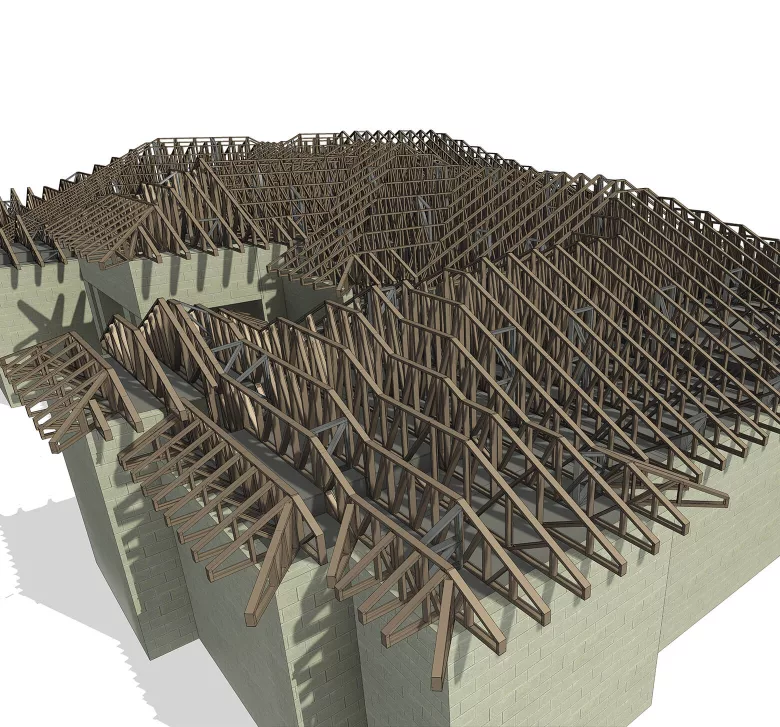

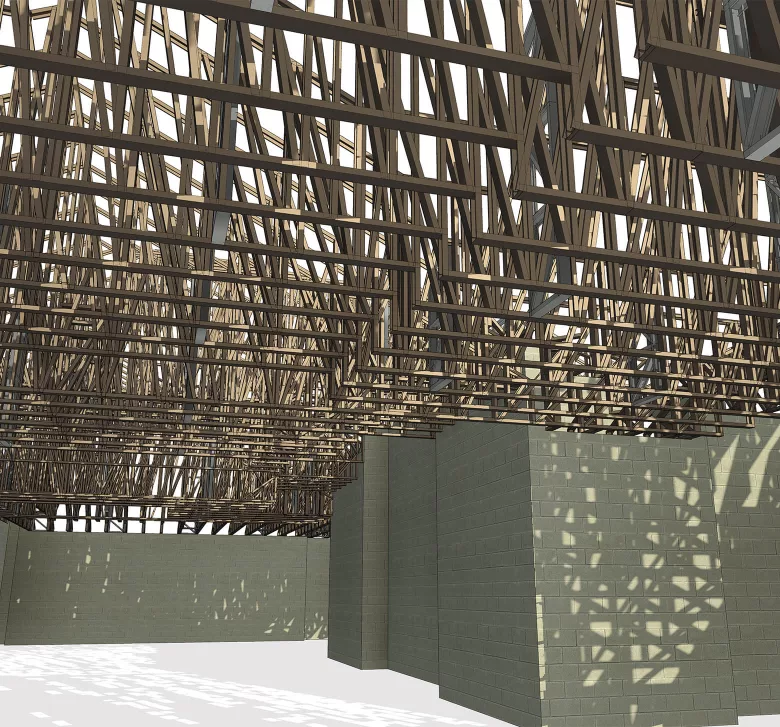

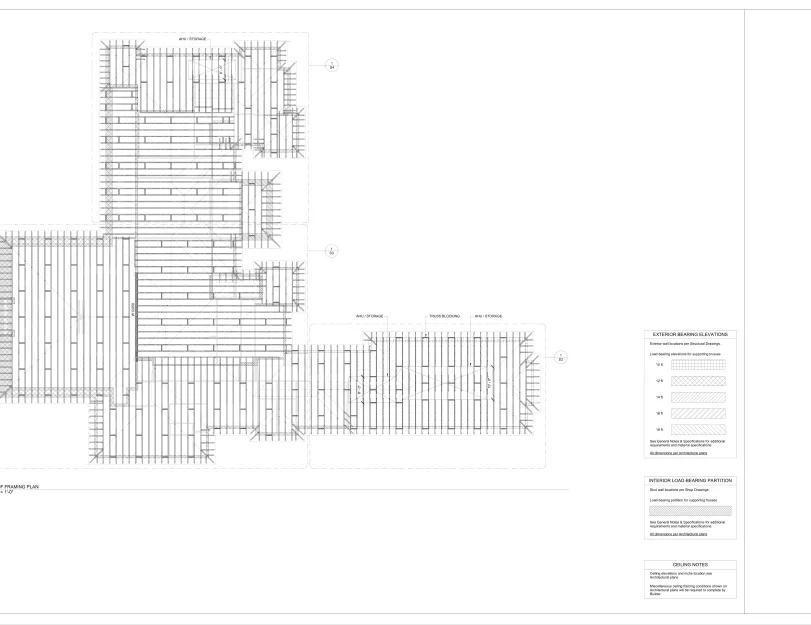

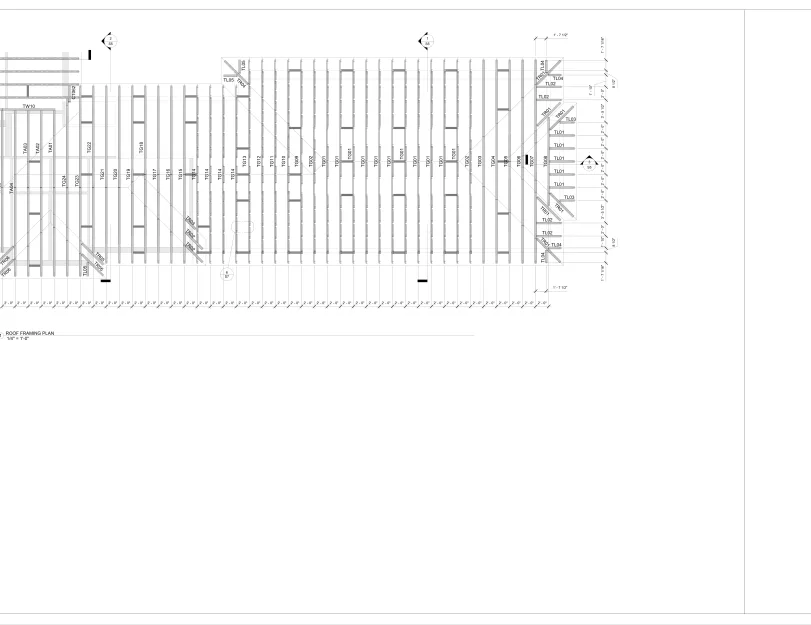

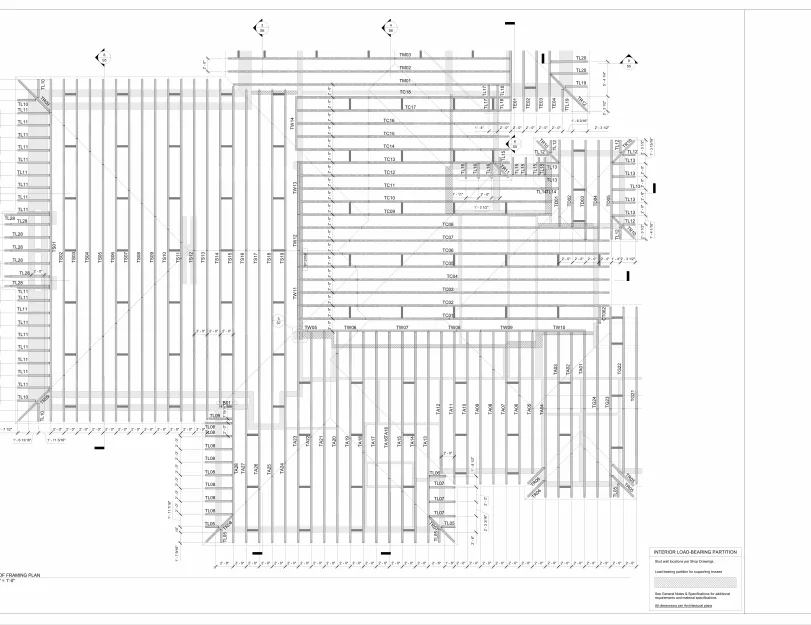

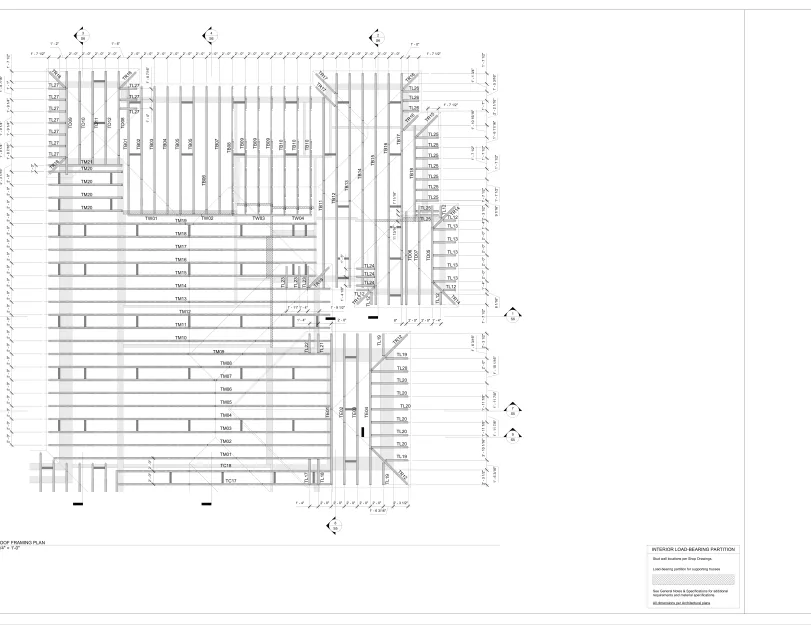

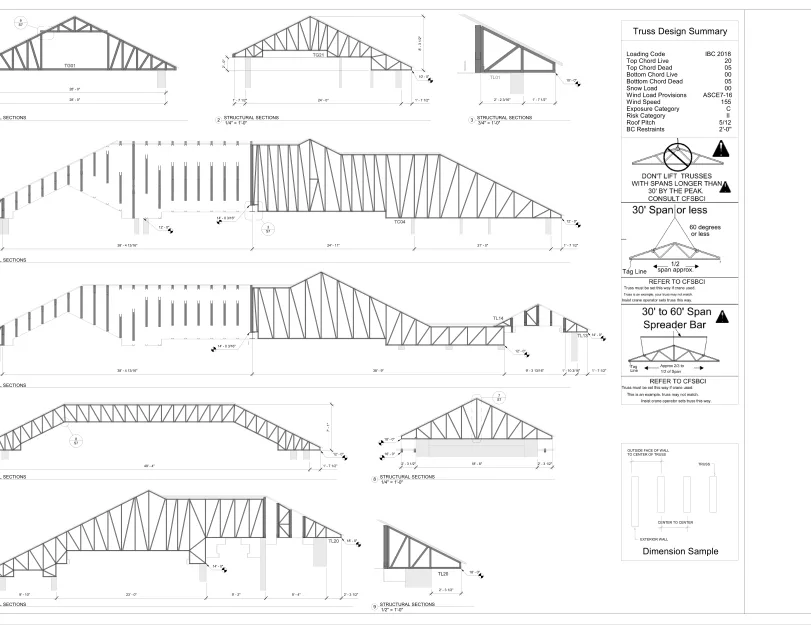

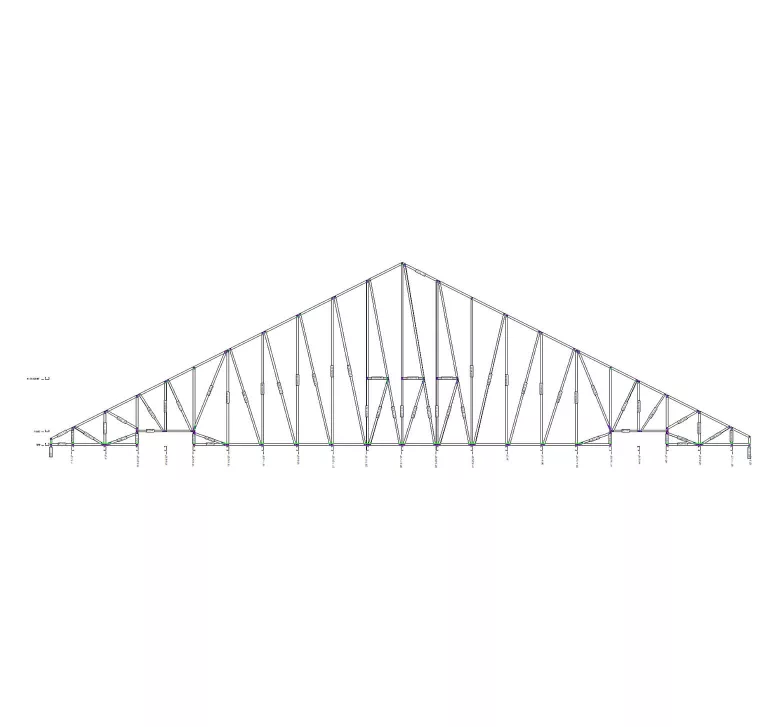

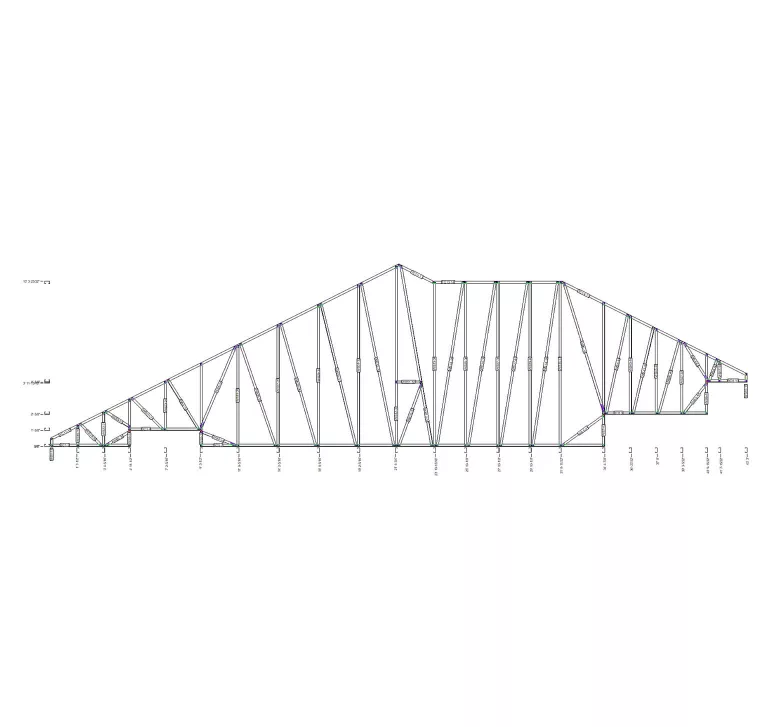

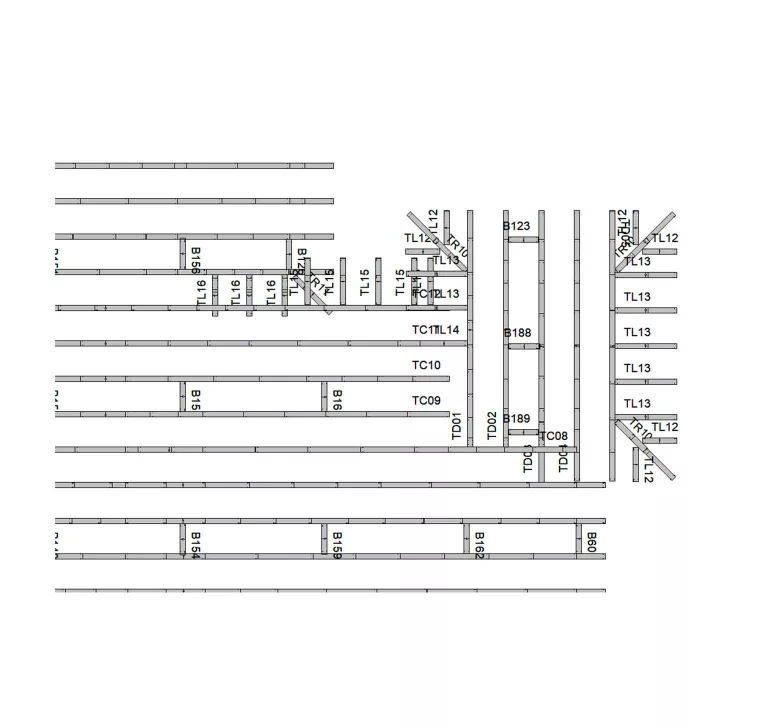

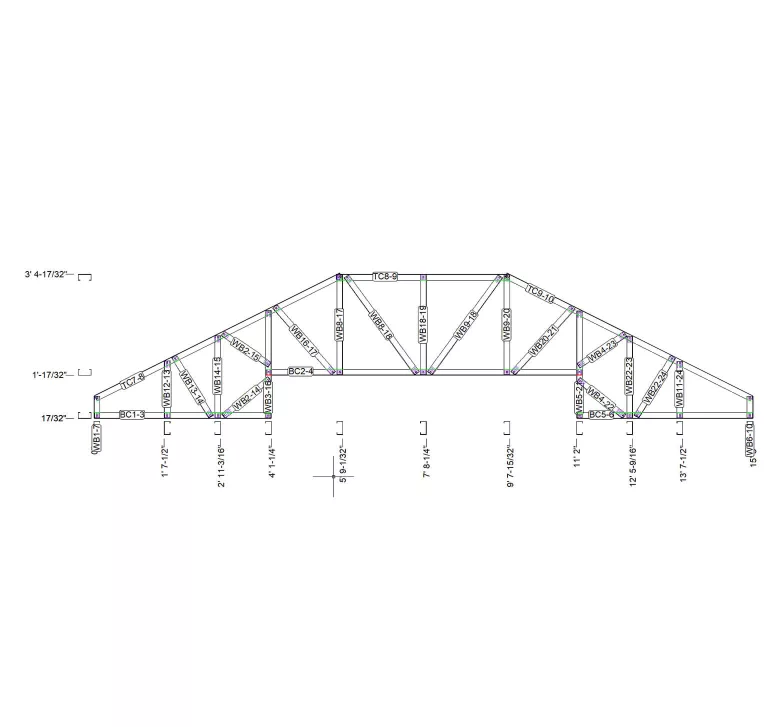

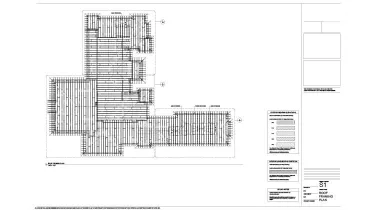

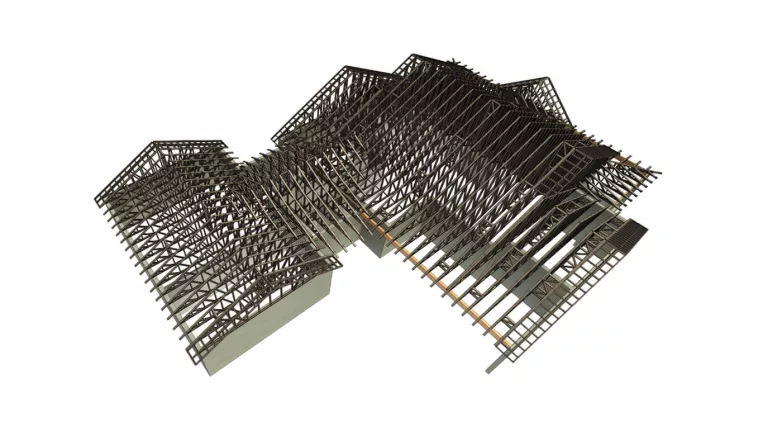

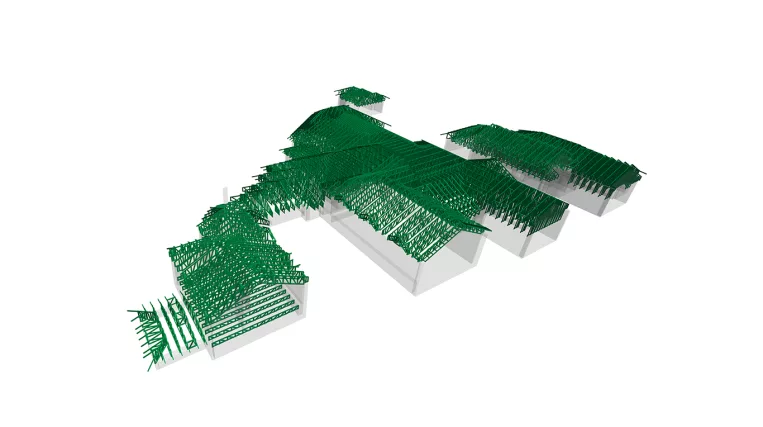

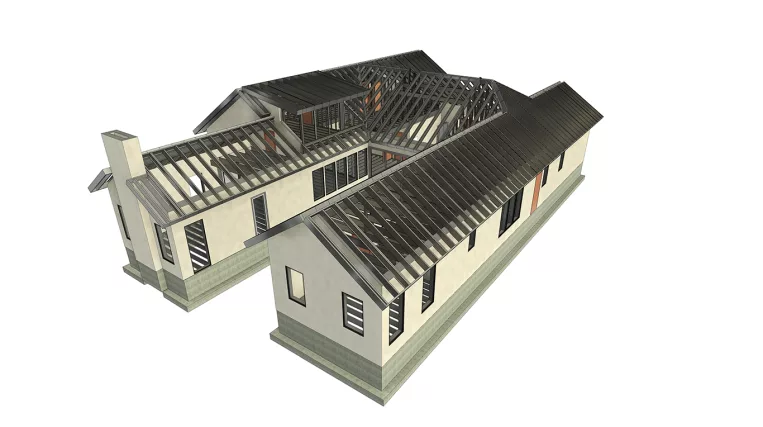

This project required the ORIGIN team to design LGS roof framing for a single-family residential building, with the condition that the truss design be suitable for further fabrication using a FRAMECAD rollformer. This would ensure a streamlined fabrication process and enhanced construction efficiency.

Input: Structural drawings set.

Project deliverables:

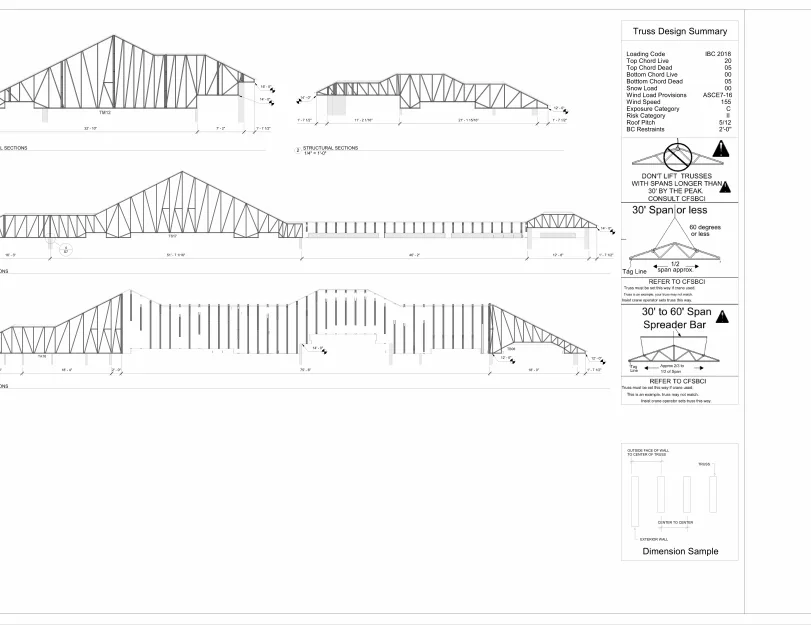

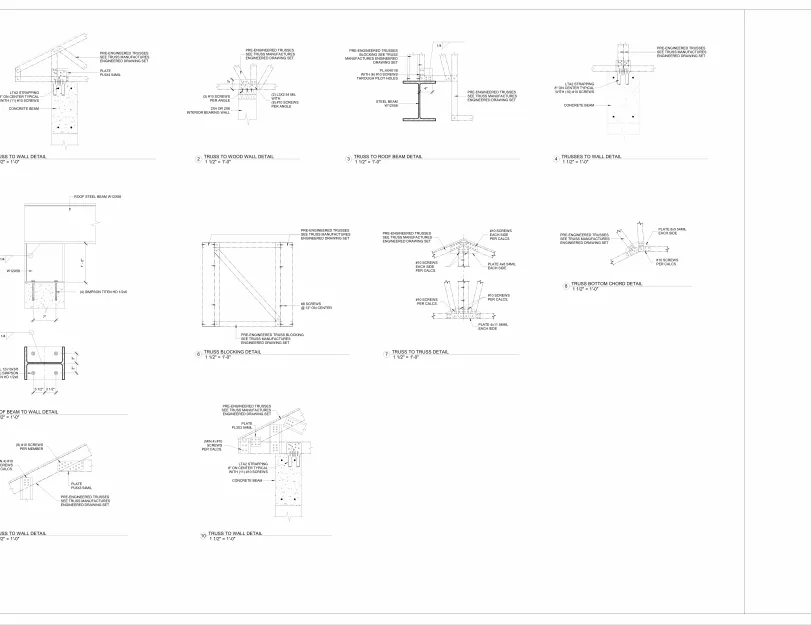

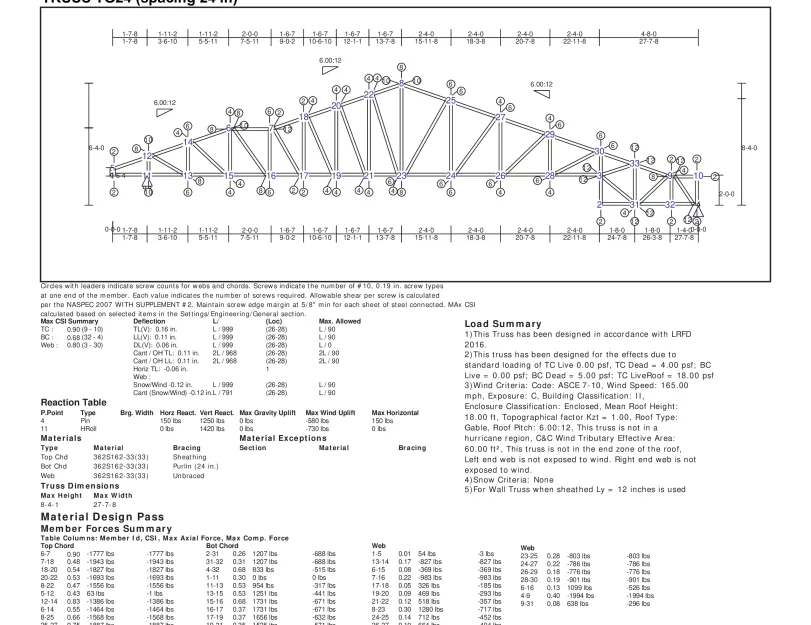

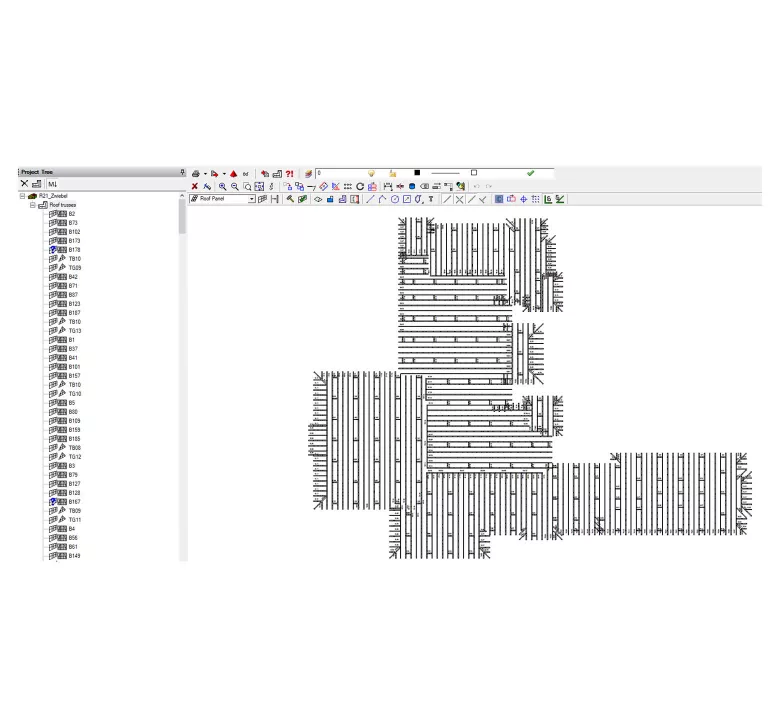

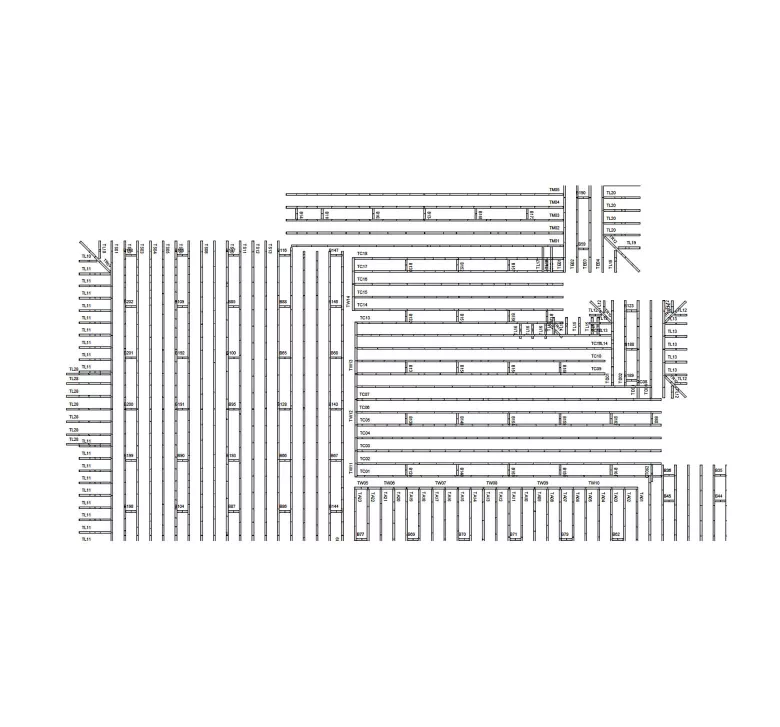

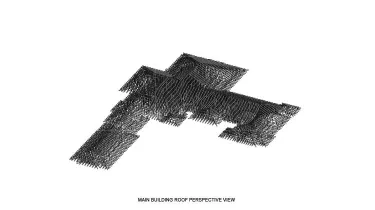

- Roof trusses layout;

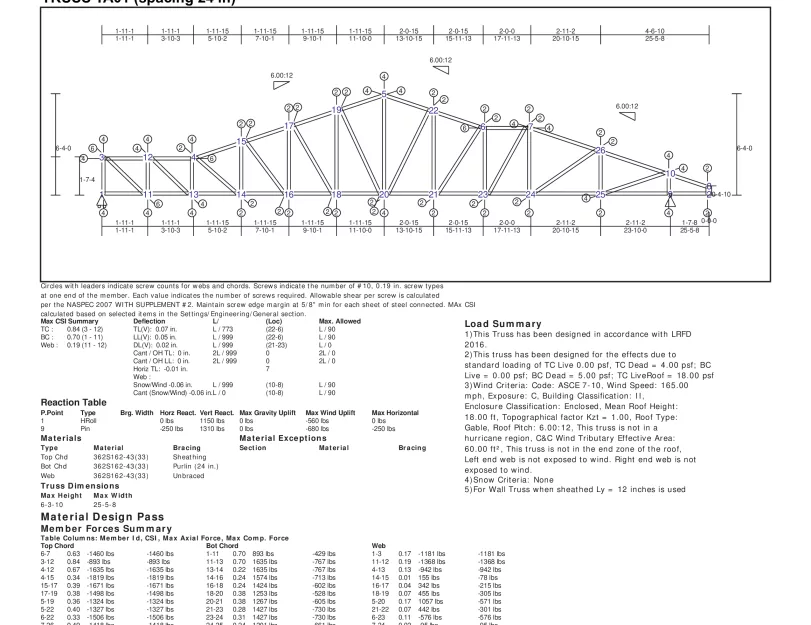

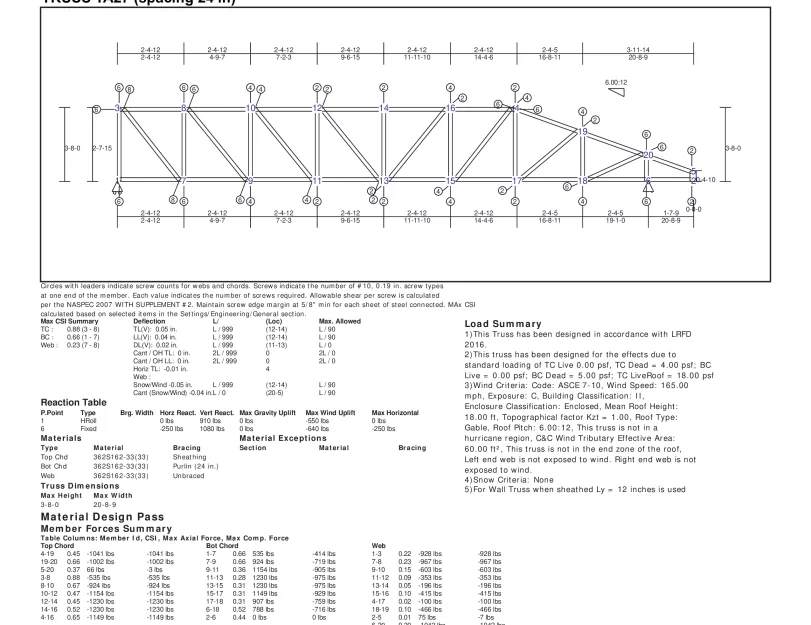

- Truss reports;

- FRAMECAD CNC files for LGS panels production.