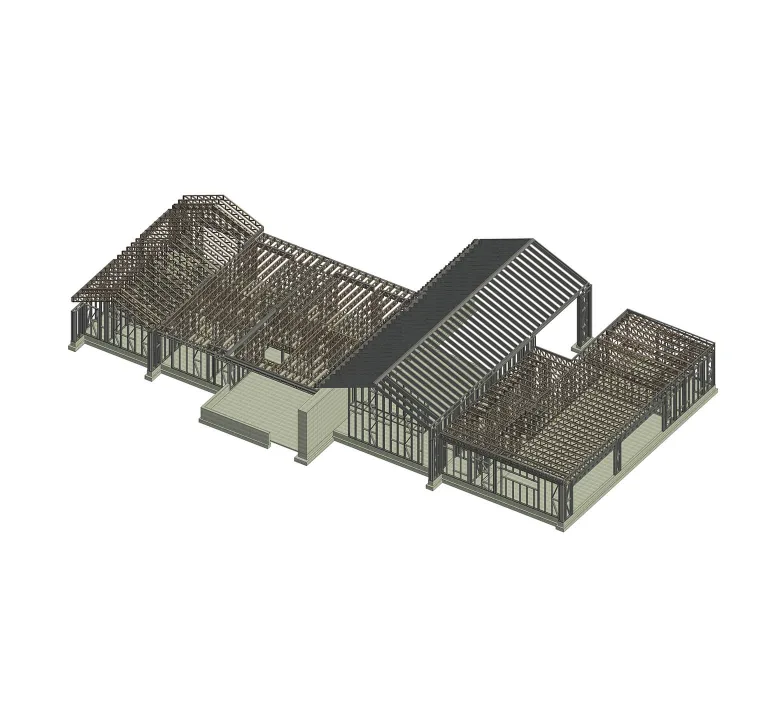

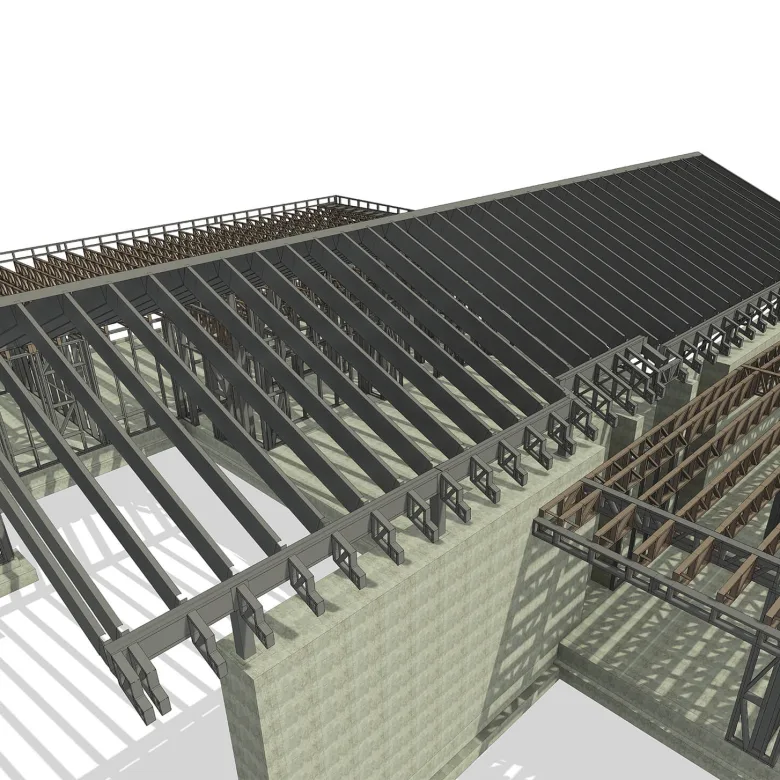

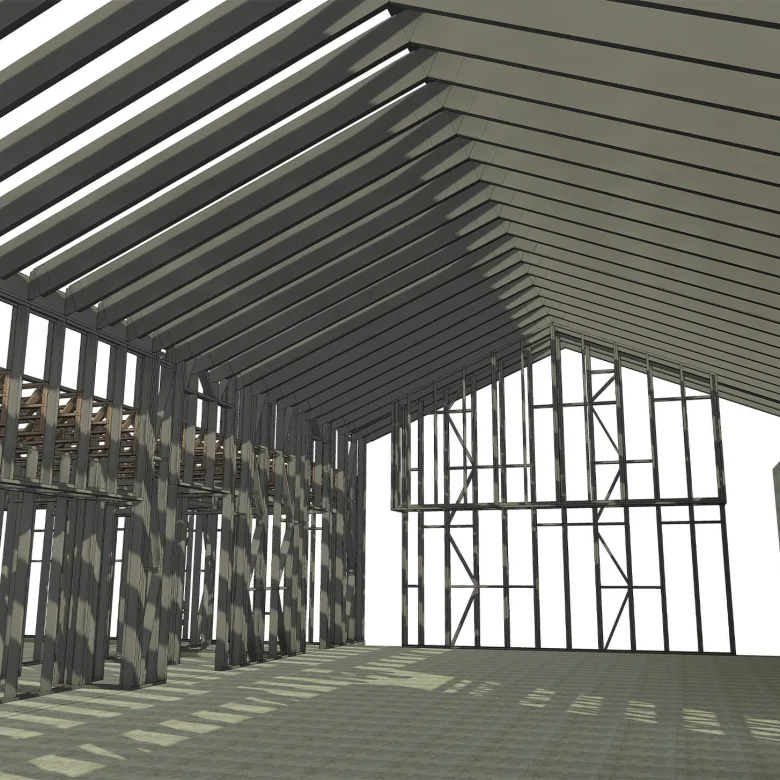

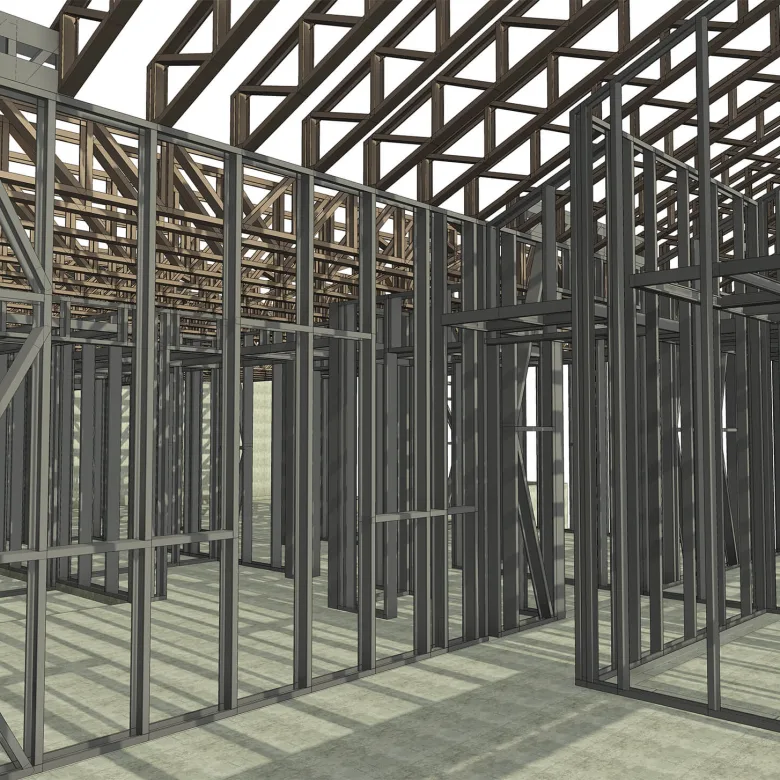

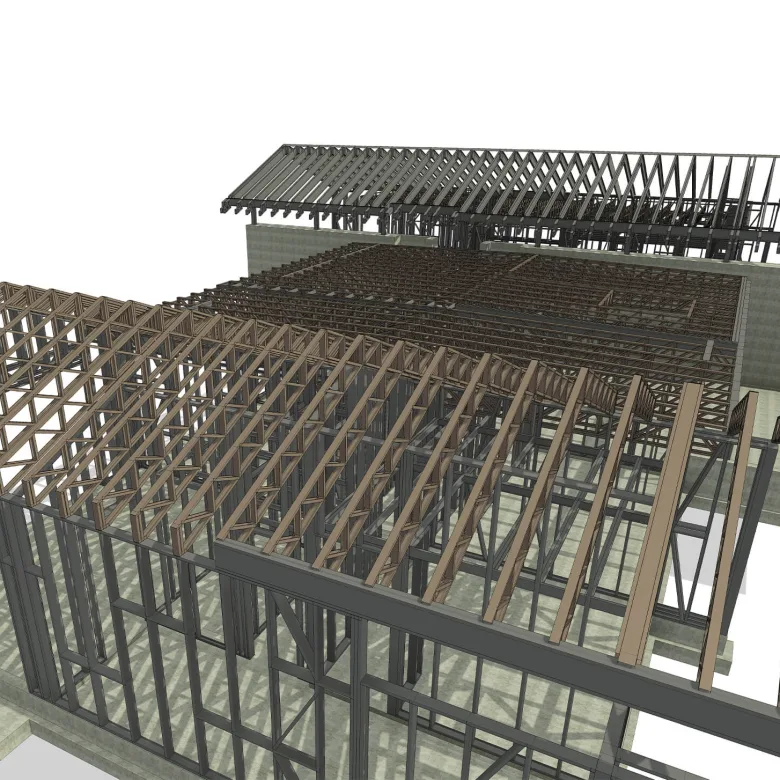

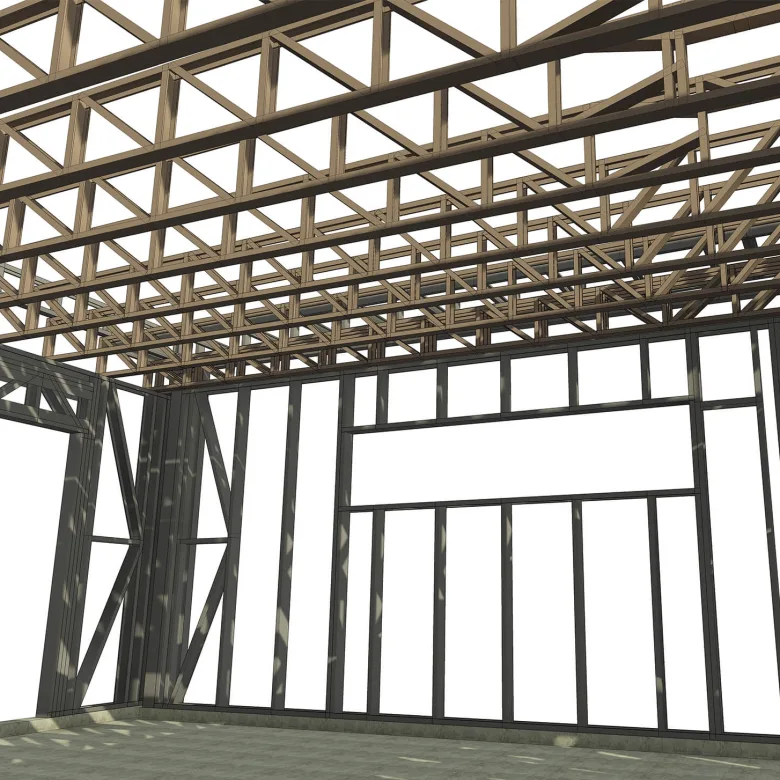

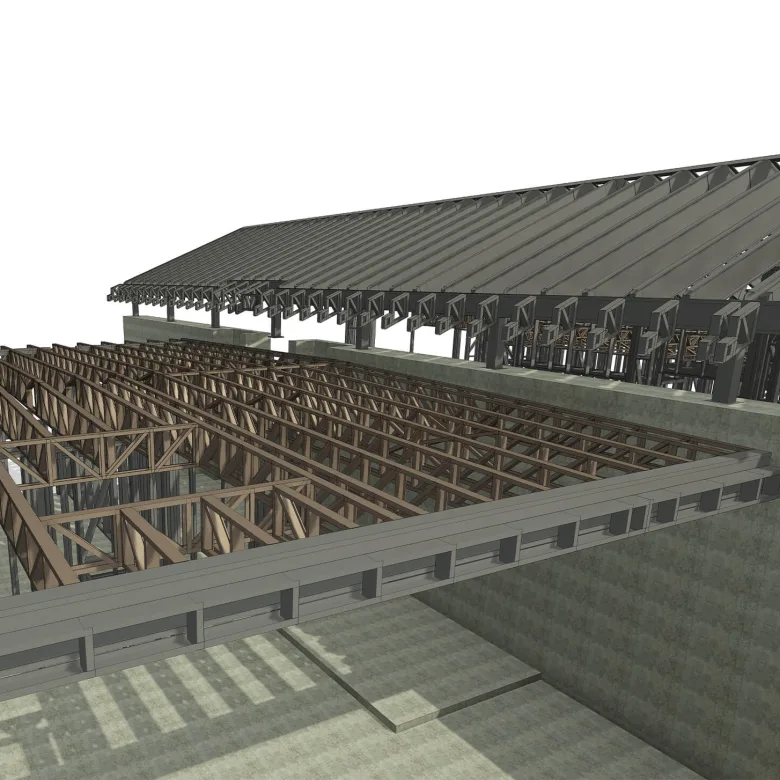

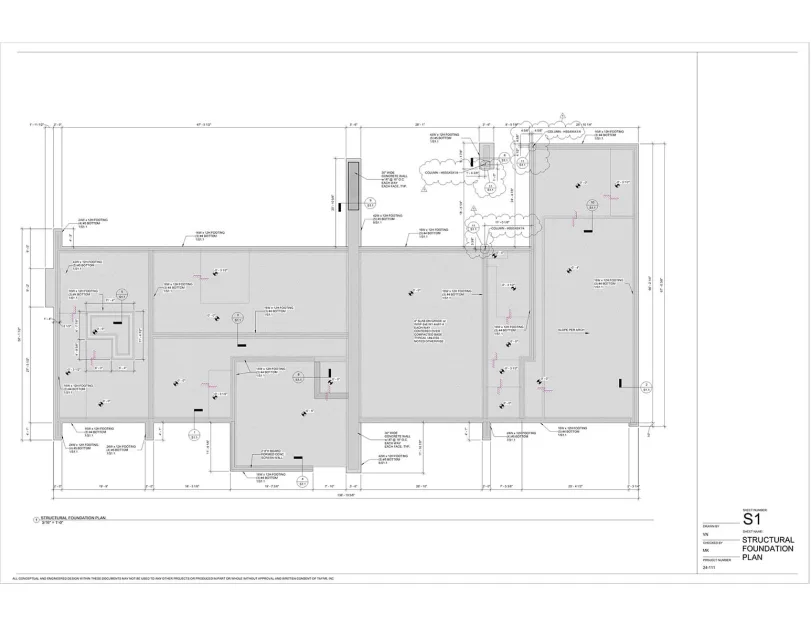

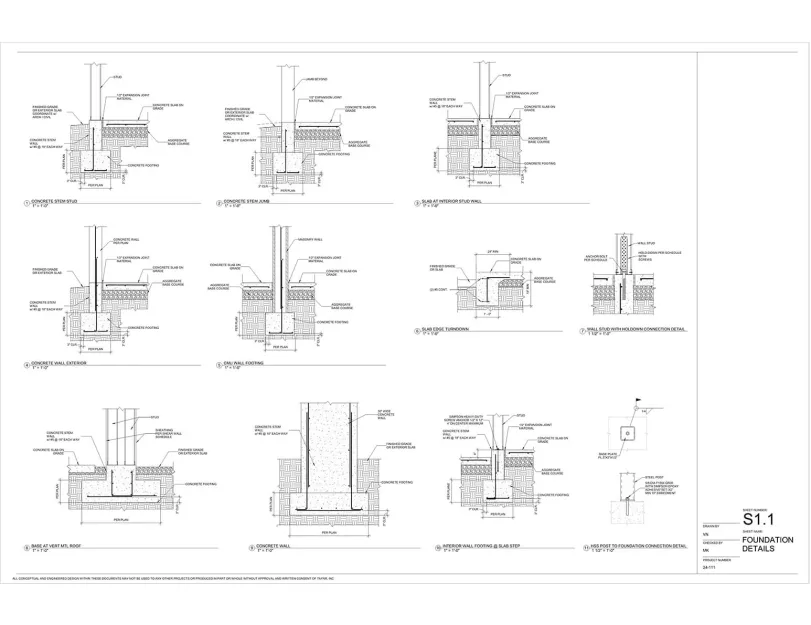

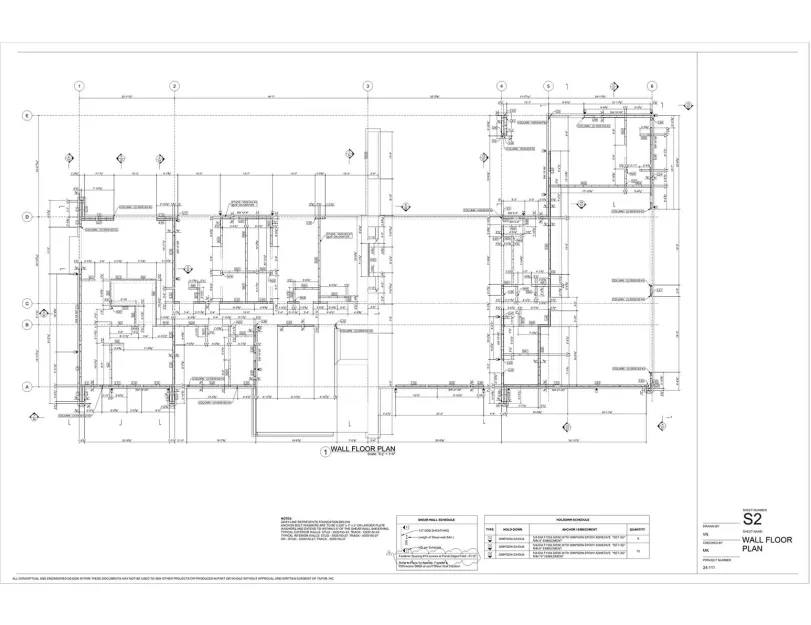

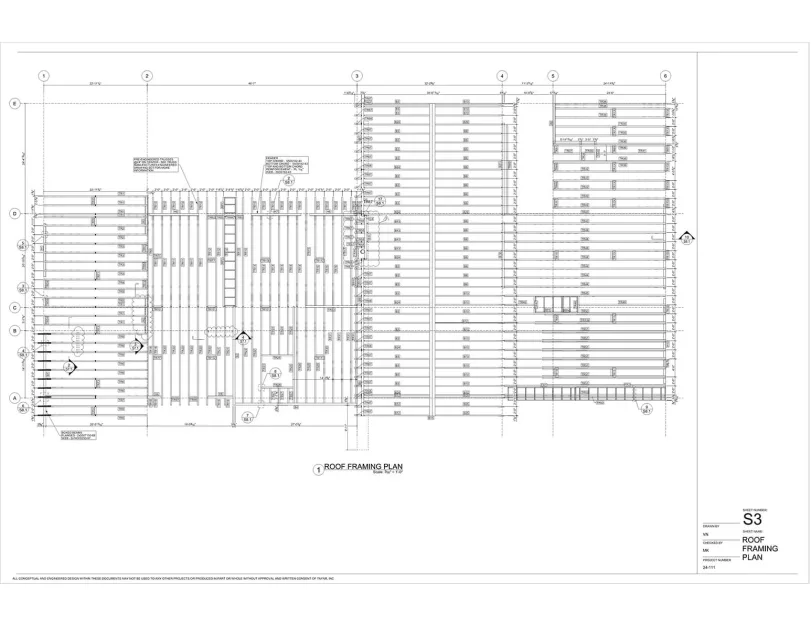

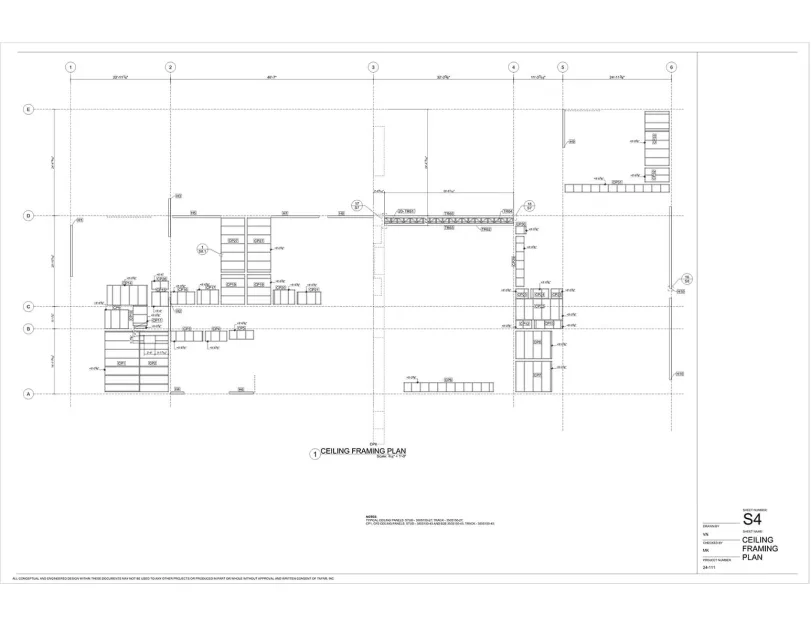

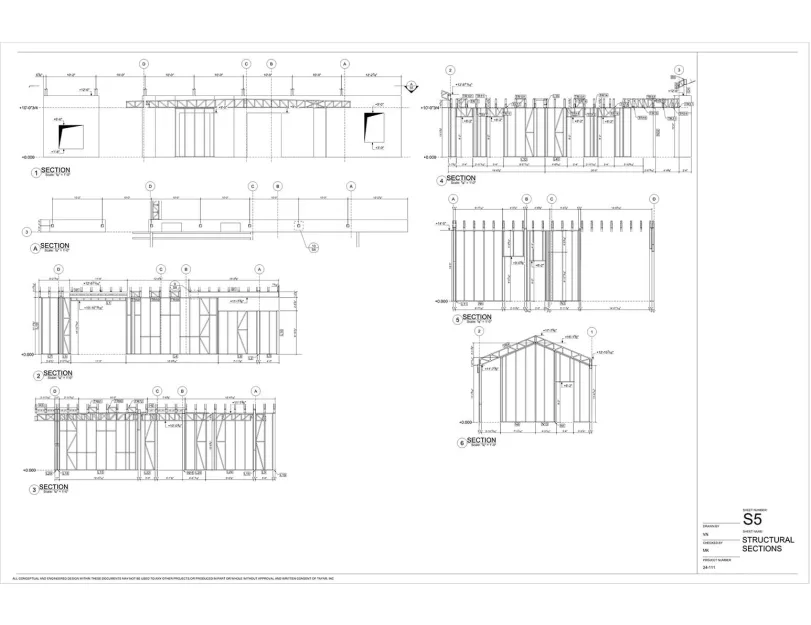

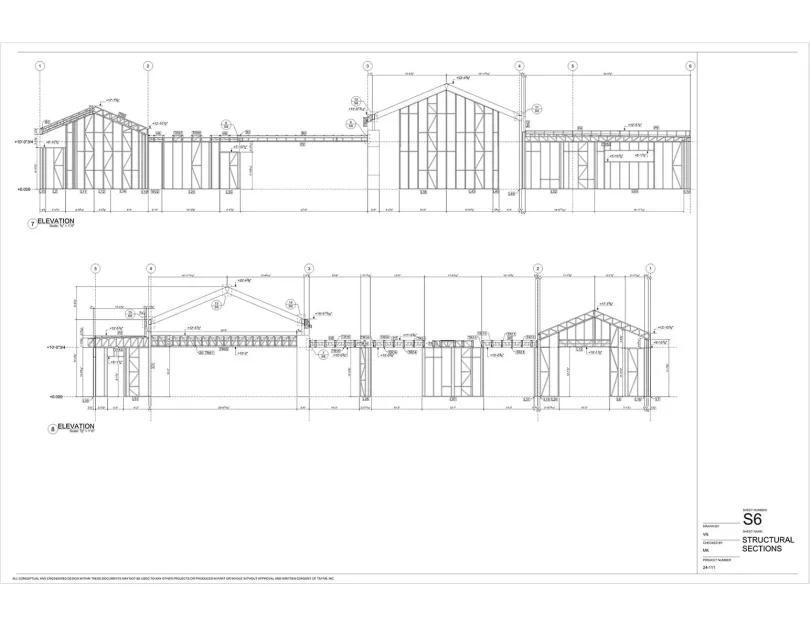

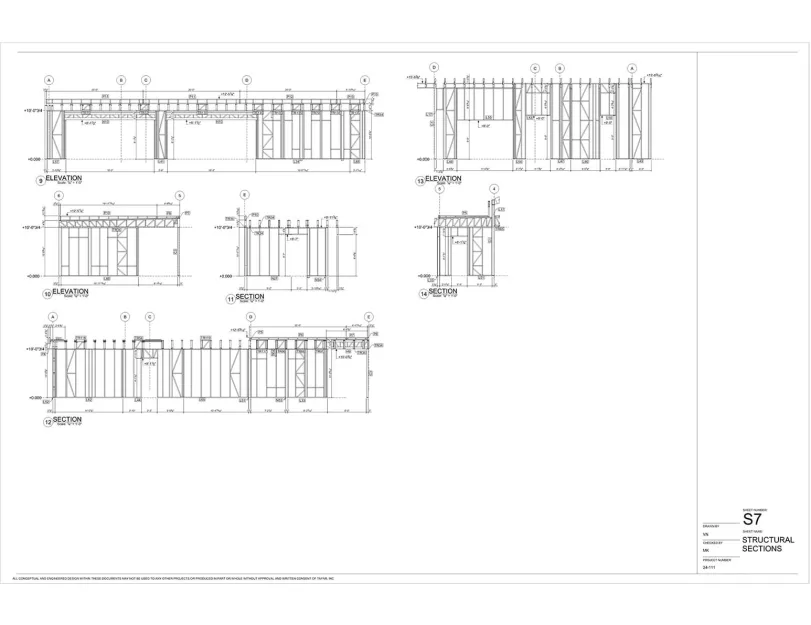

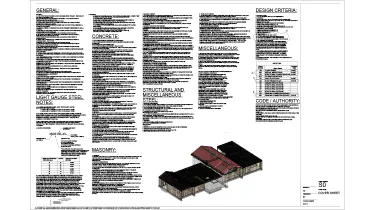

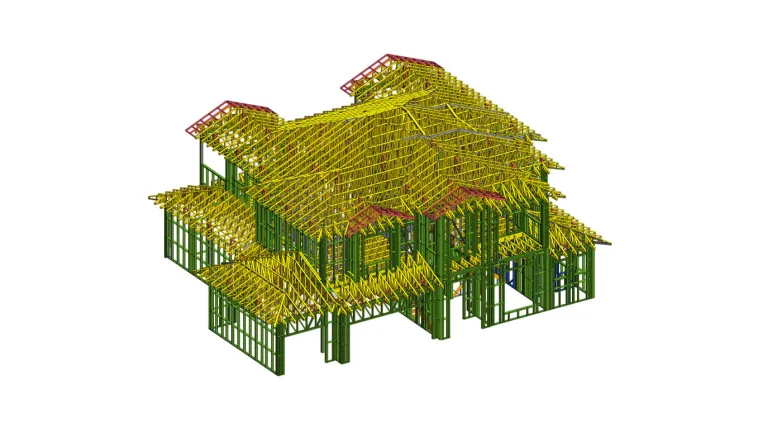

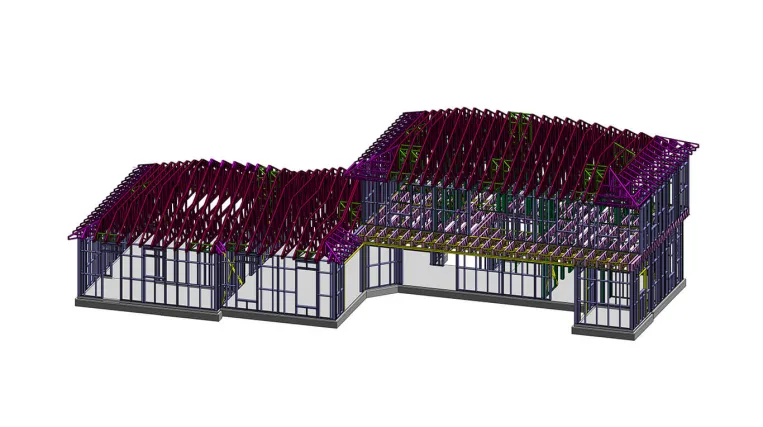

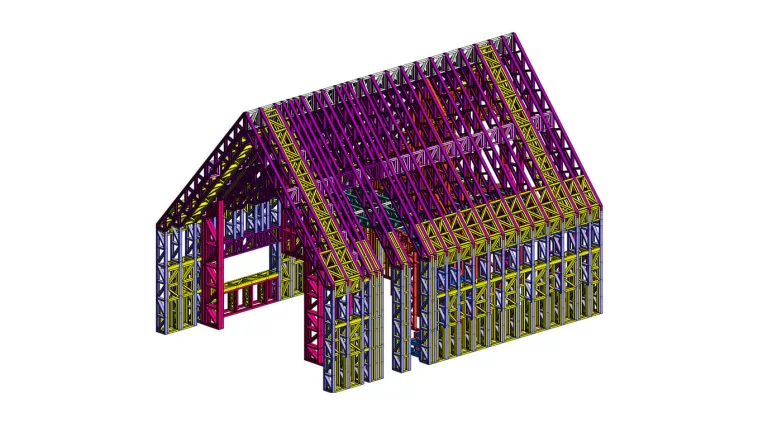

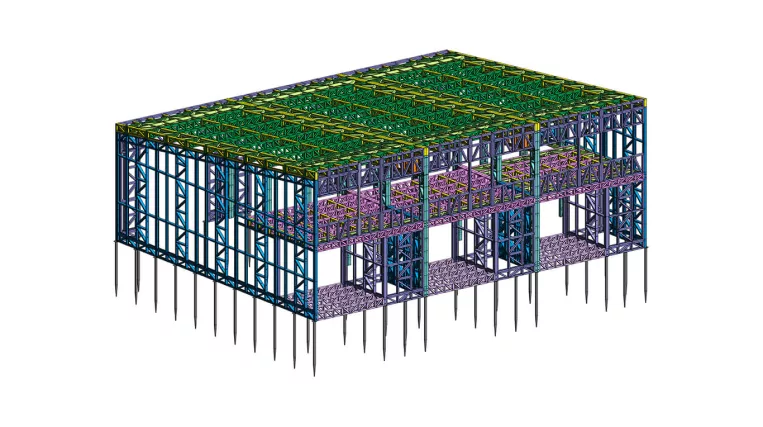

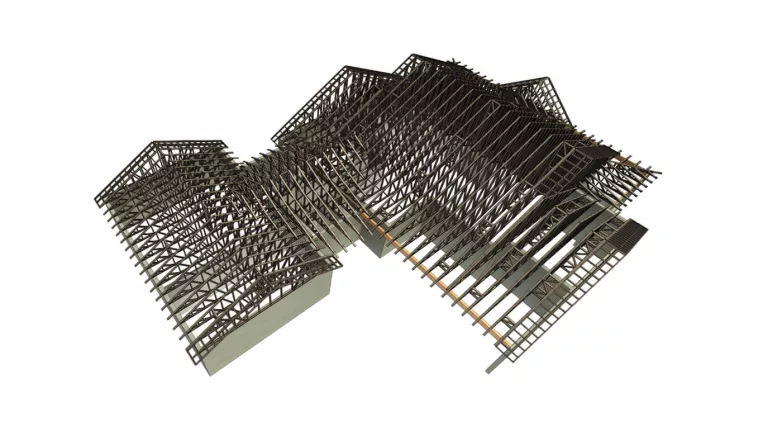

The project features a one-story residential building with a uniquely complex and spacious floor plan, measuring 138′-1.5″ in length and 66′-3″ in width. As part of the scope, the ORIGIN team had to analyze the architectural drawings and deliver a comprehensive set of deliverables, ranging from structural drawings to CNC files for LGS panels production.

Input: Architectural drawings set

Project deliverables:

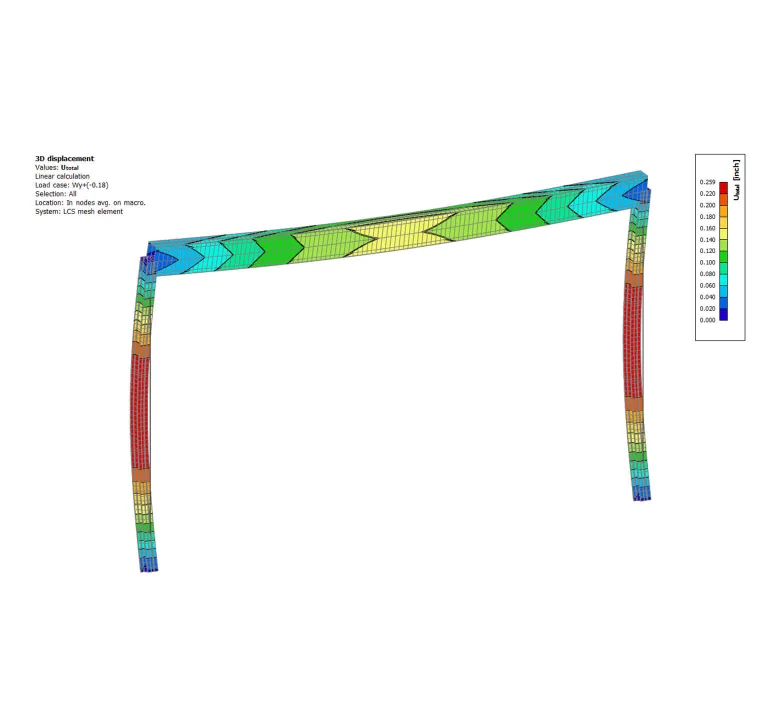

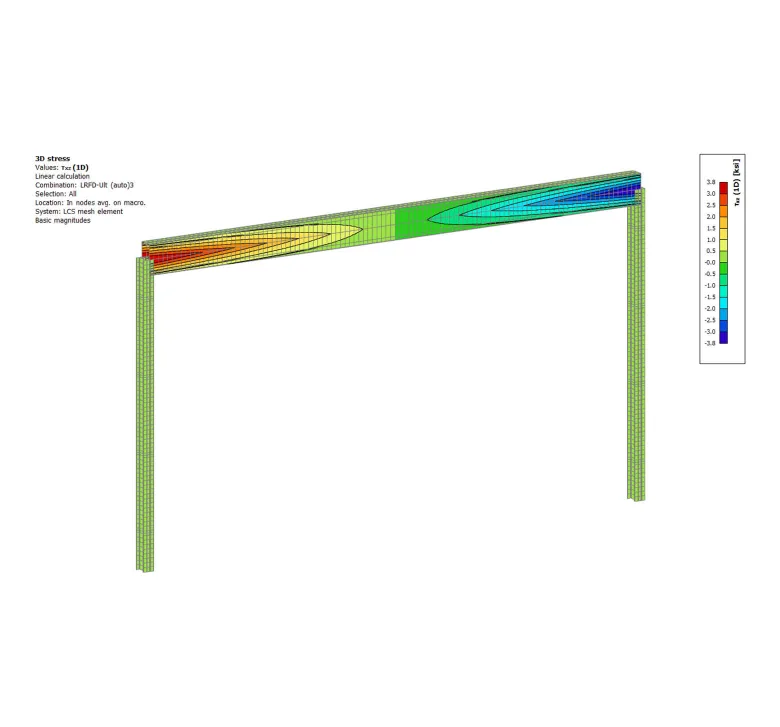

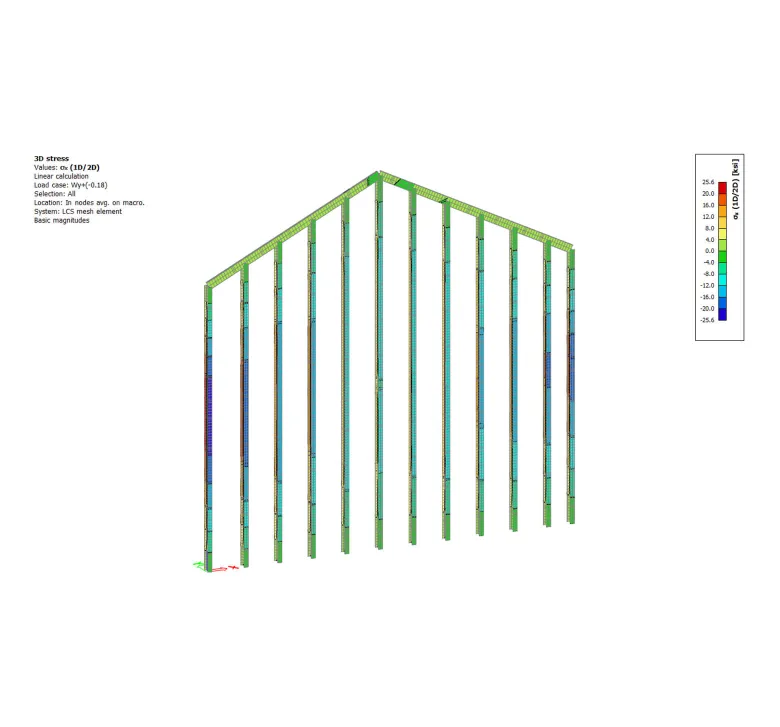

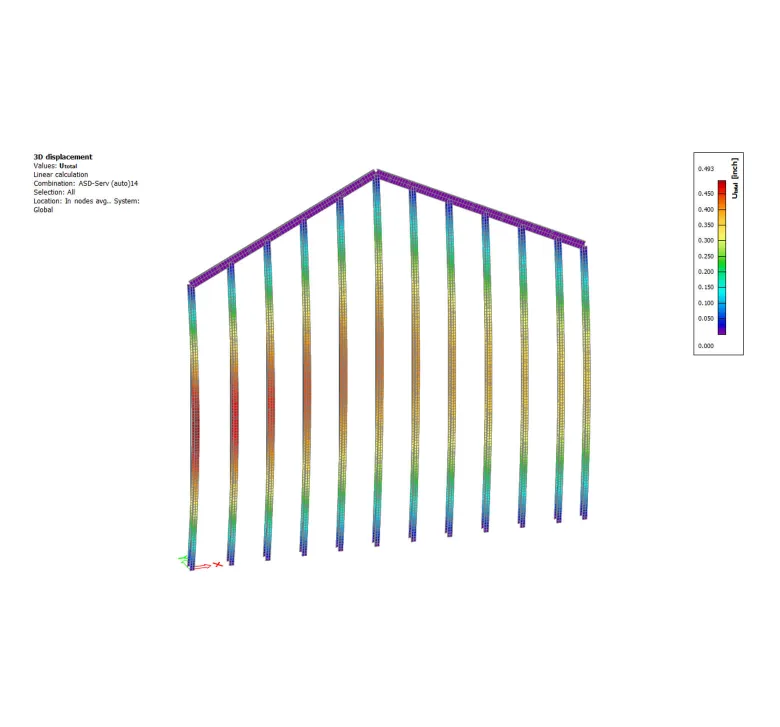

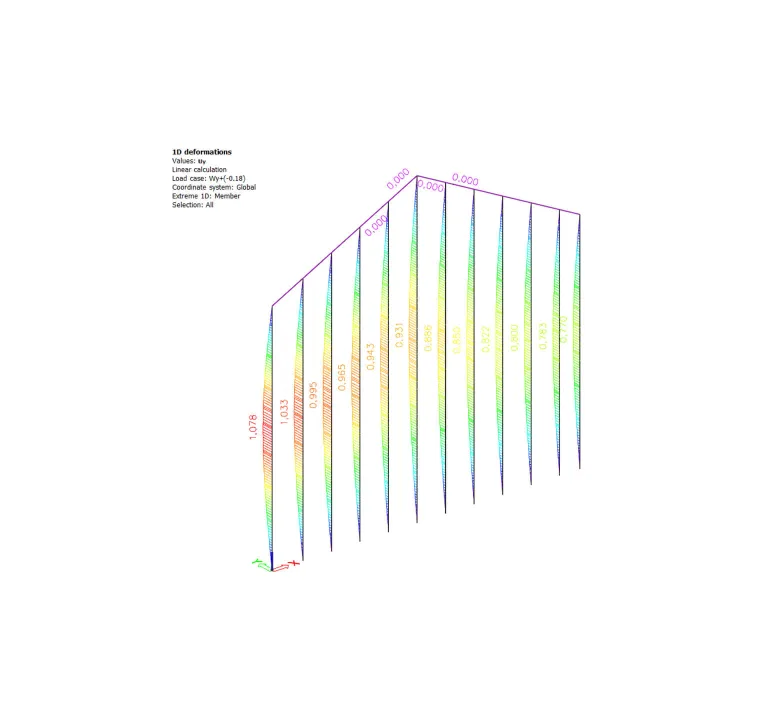

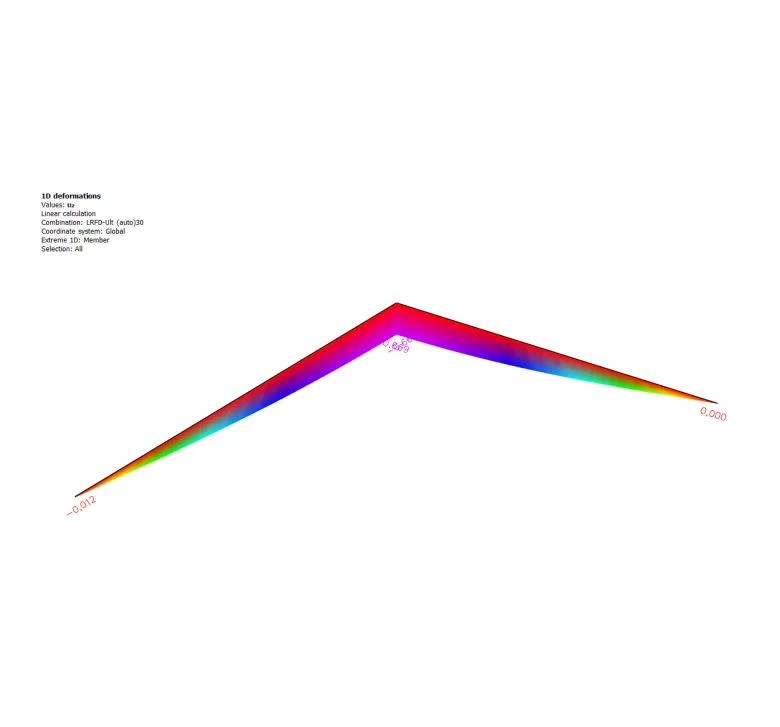

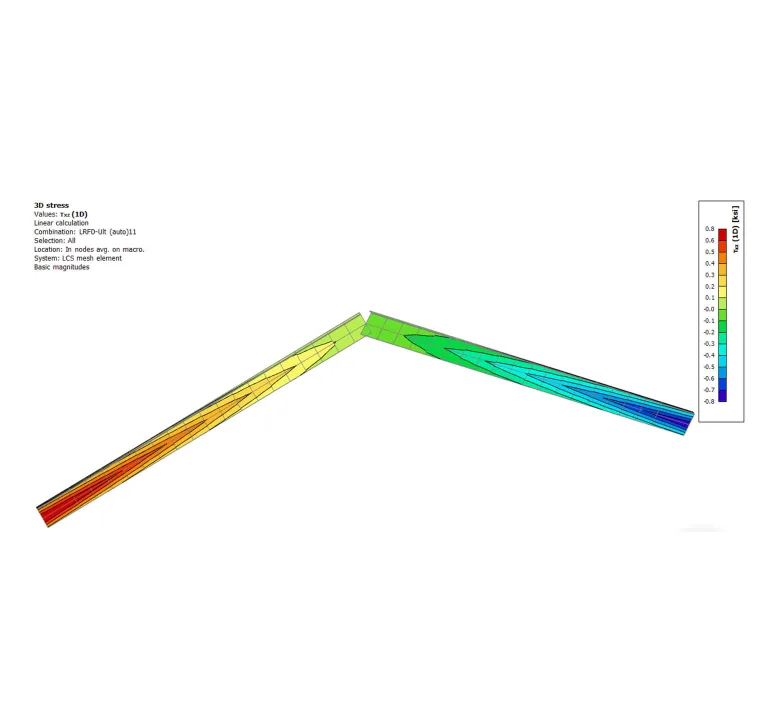

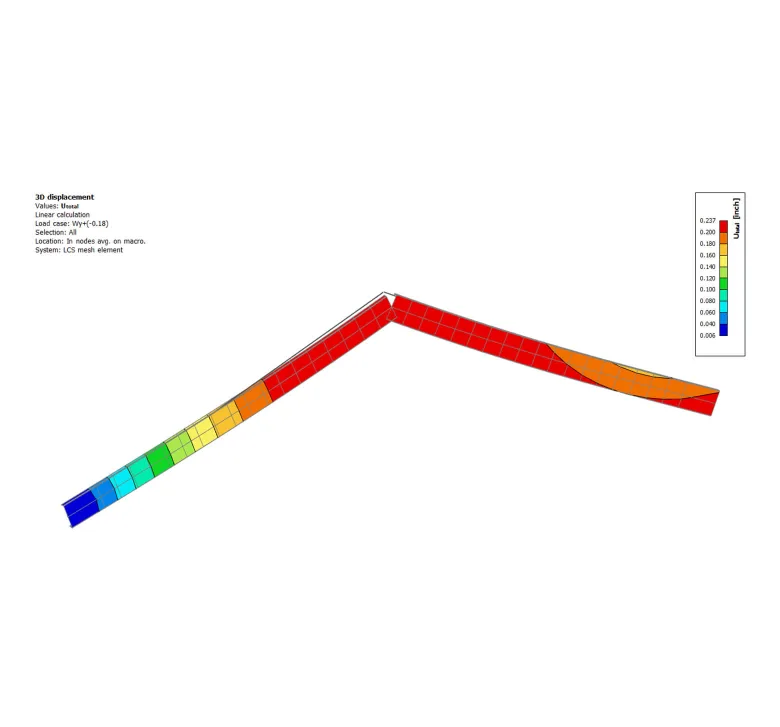

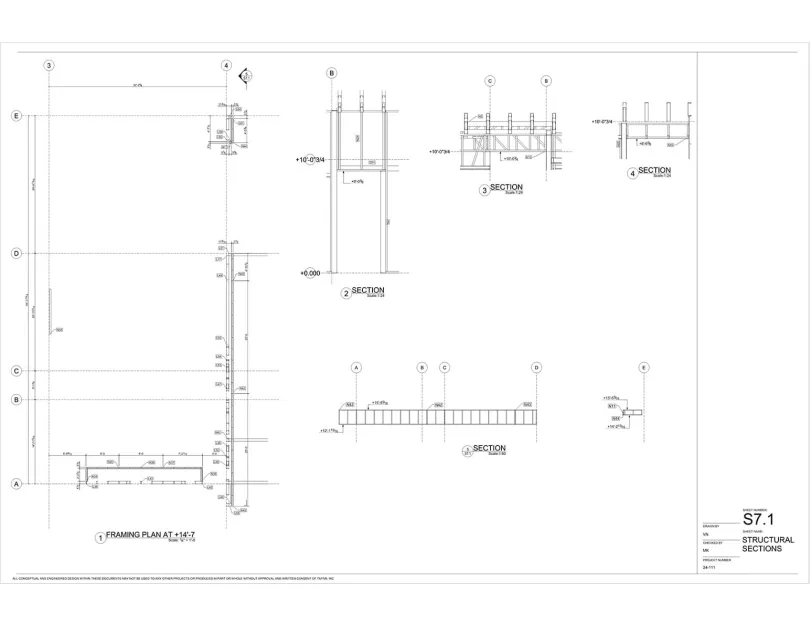

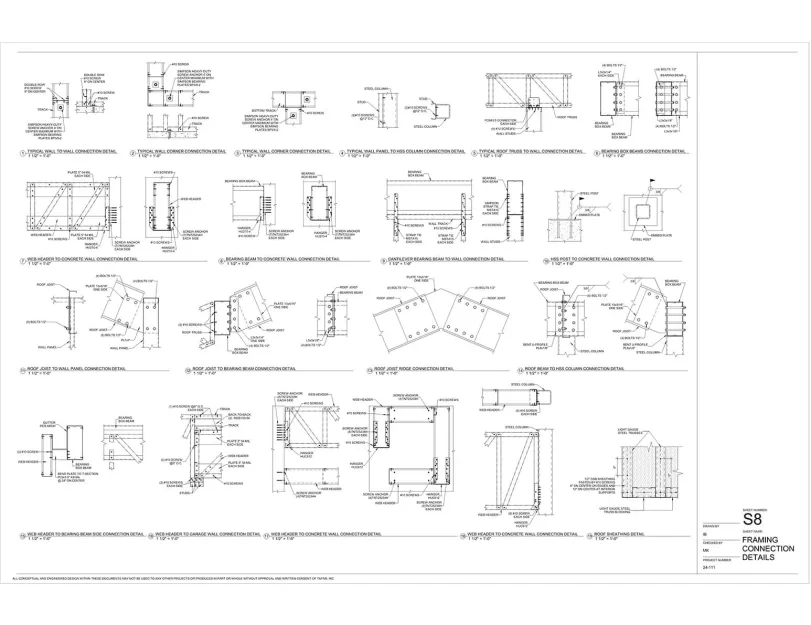

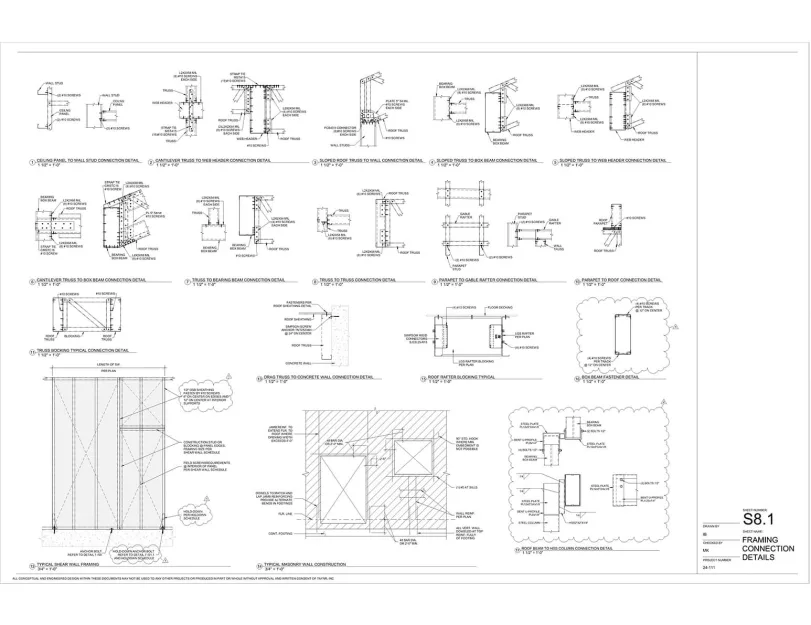

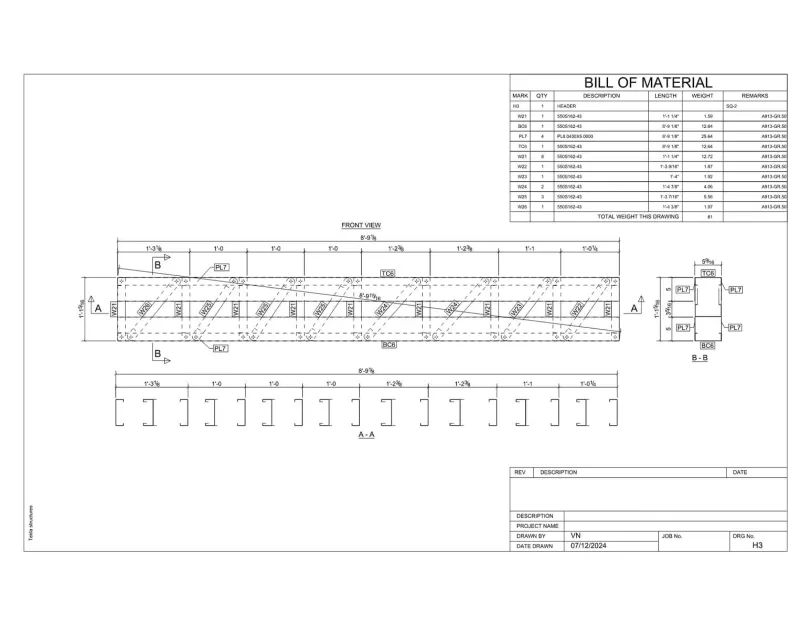

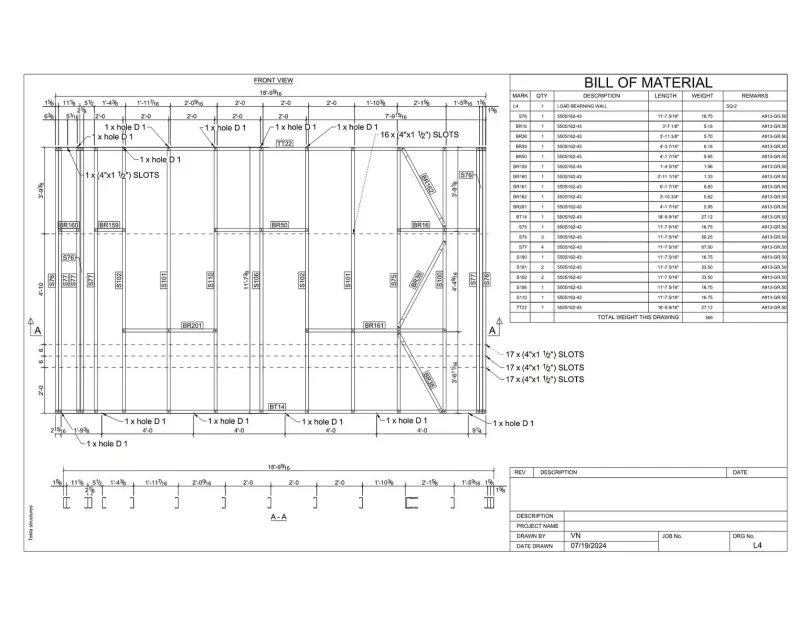

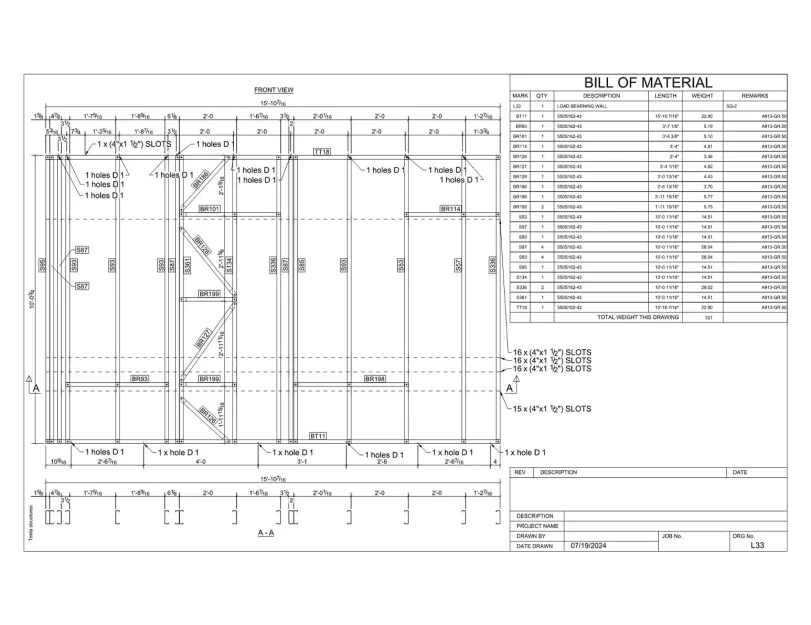

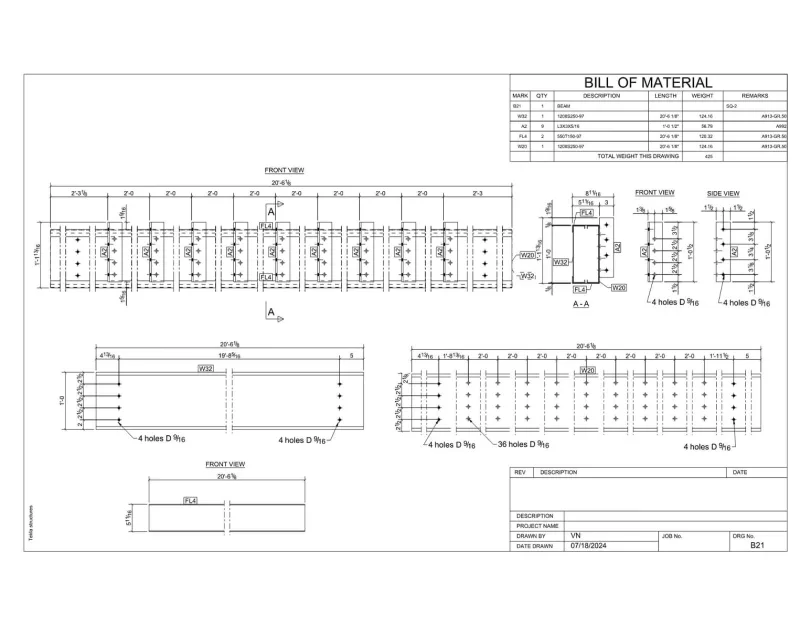

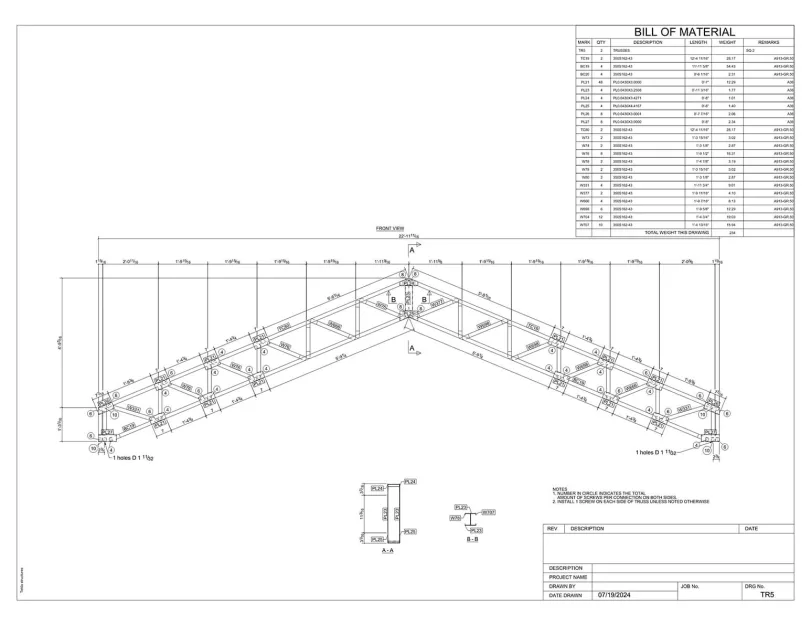

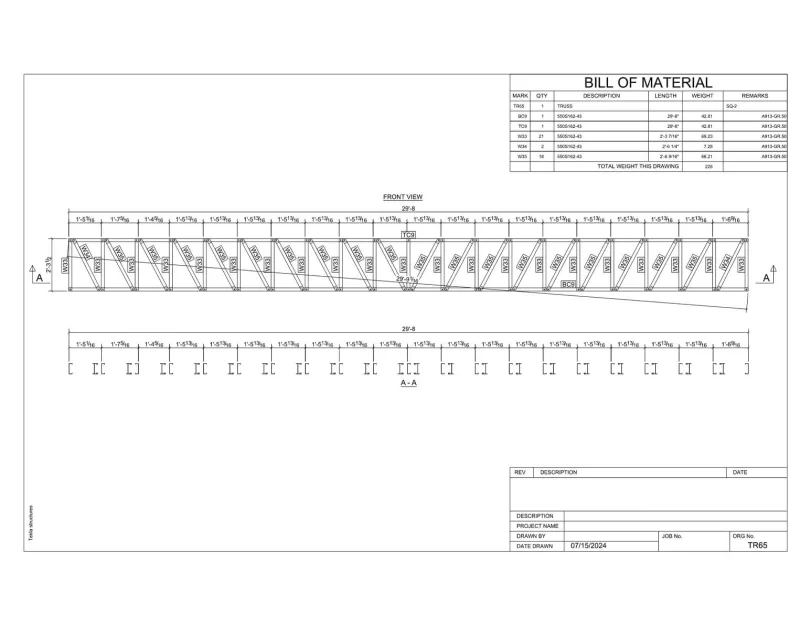

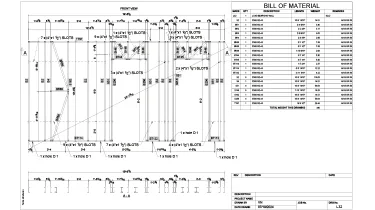

- Structural drawings set;

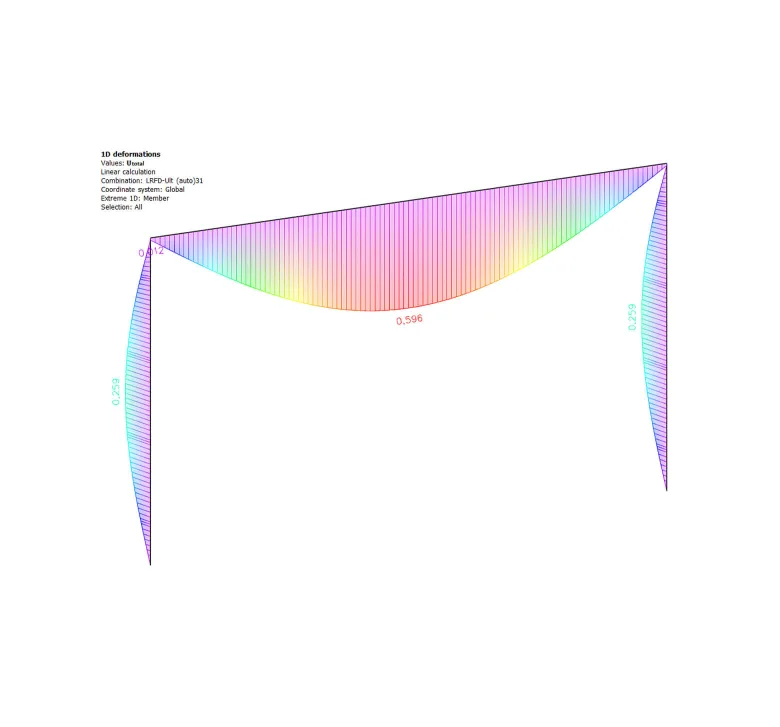

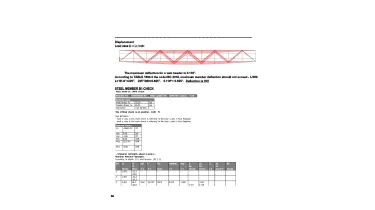

- Structural analysis report;

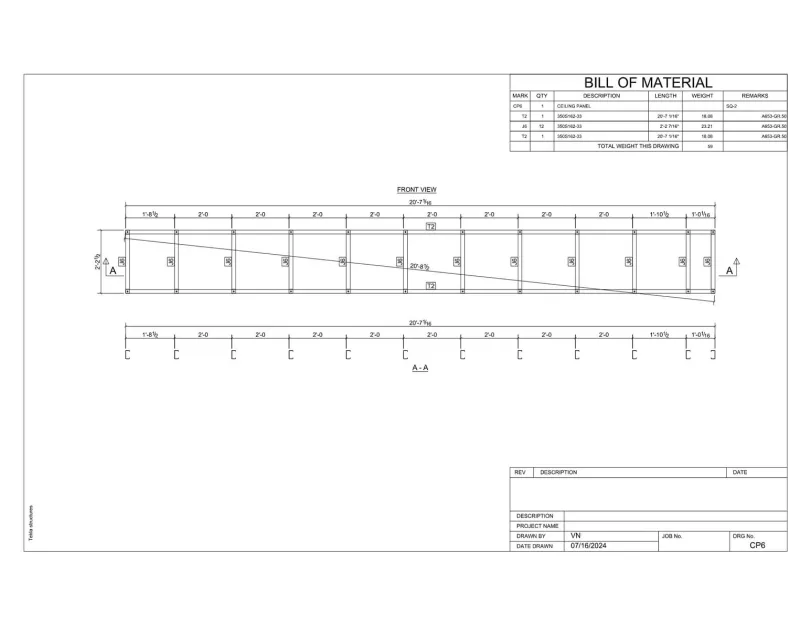

- LGS and hot-rolled steel shop drawings;

- CNC files for LGS panels production.