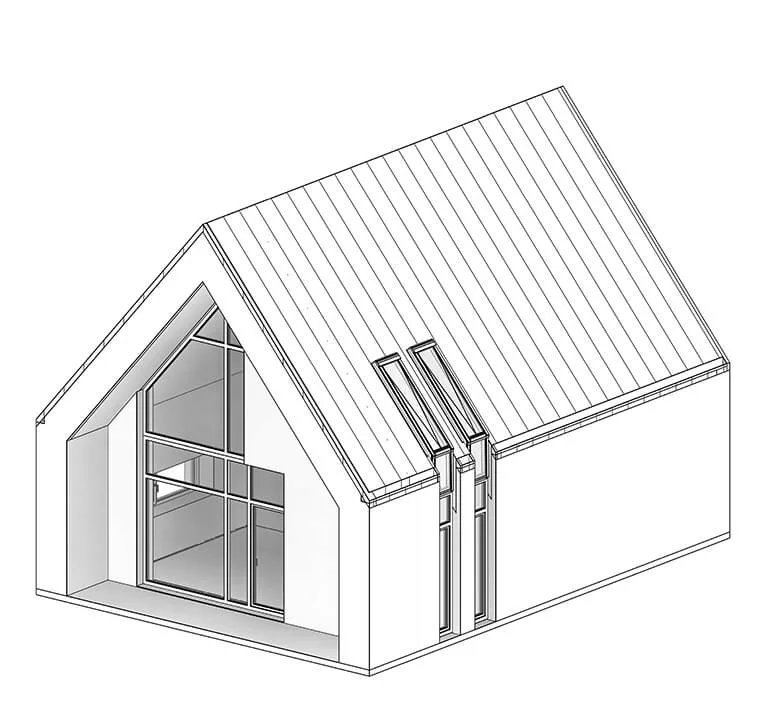

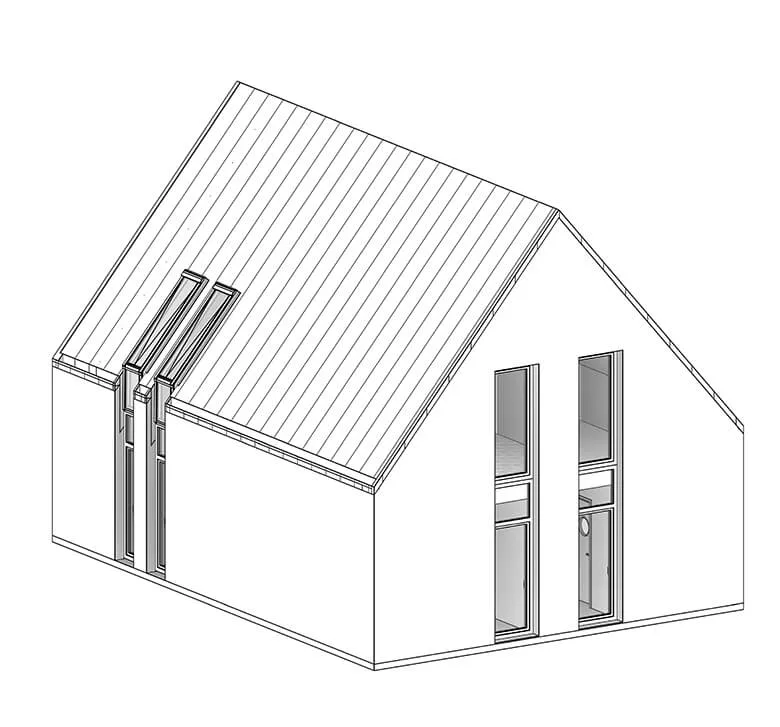

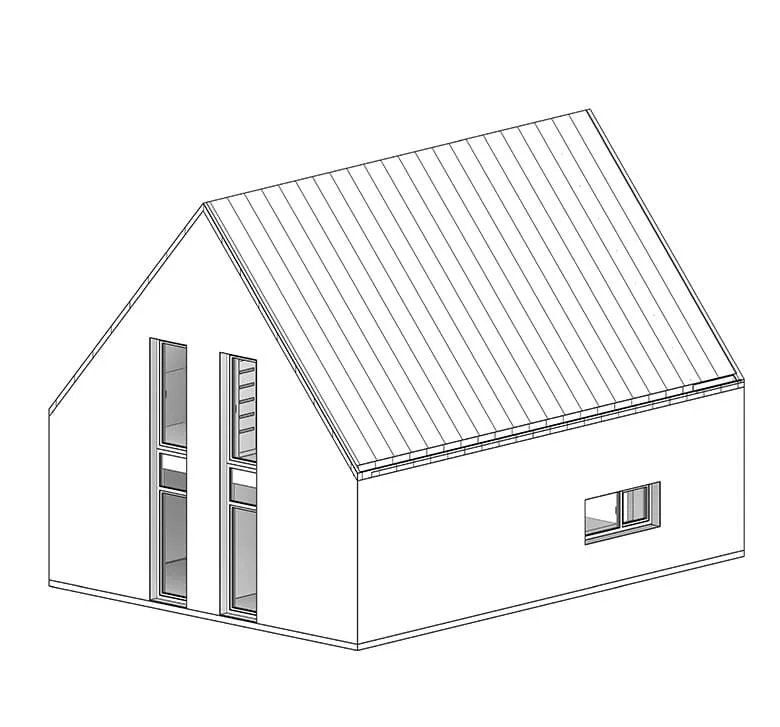

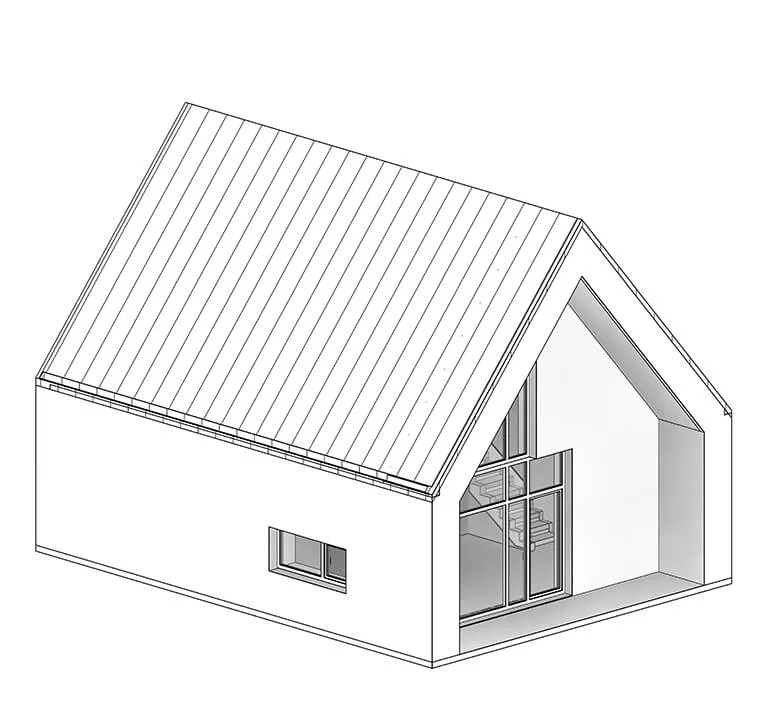

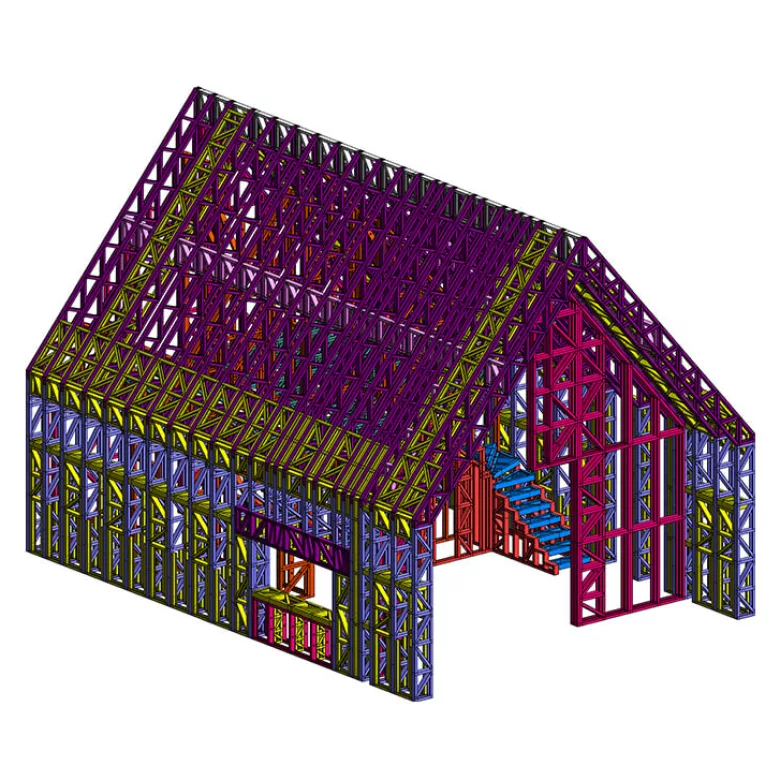

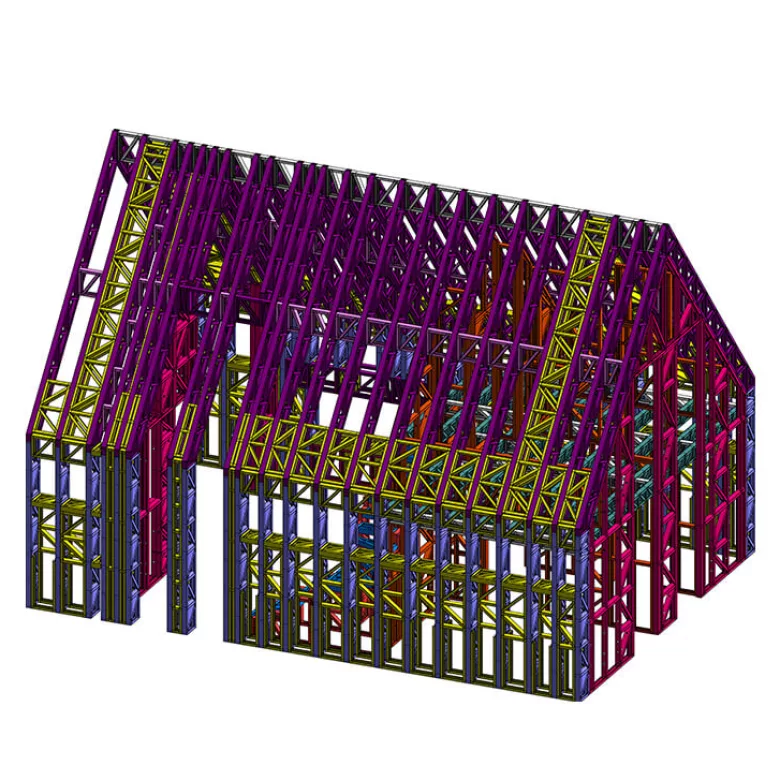

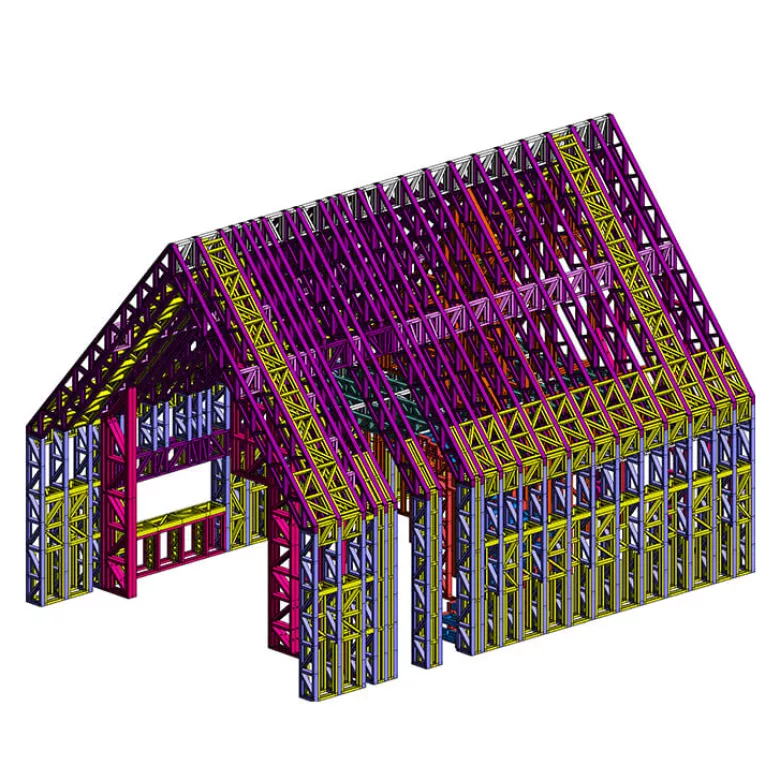

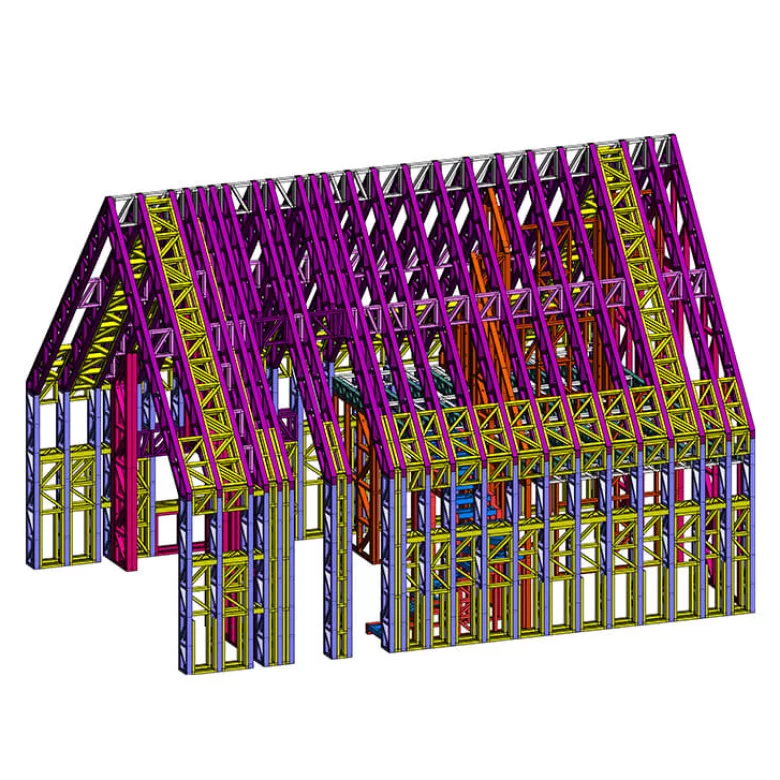

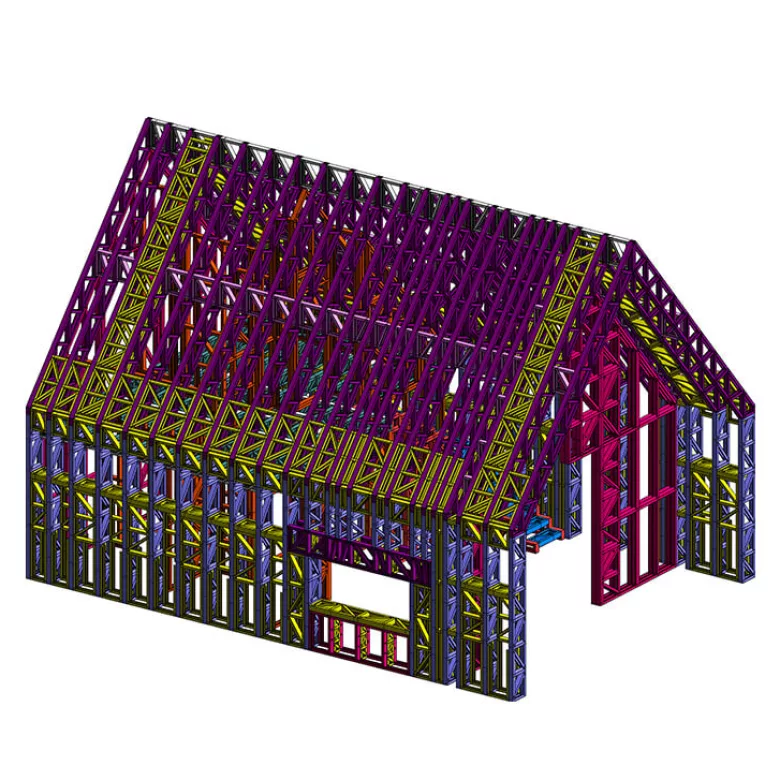

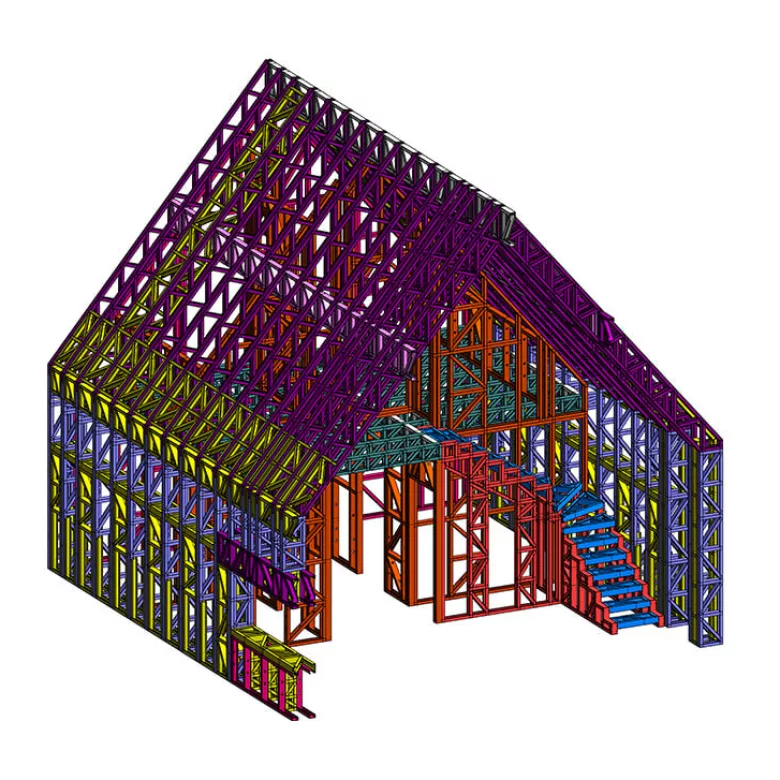

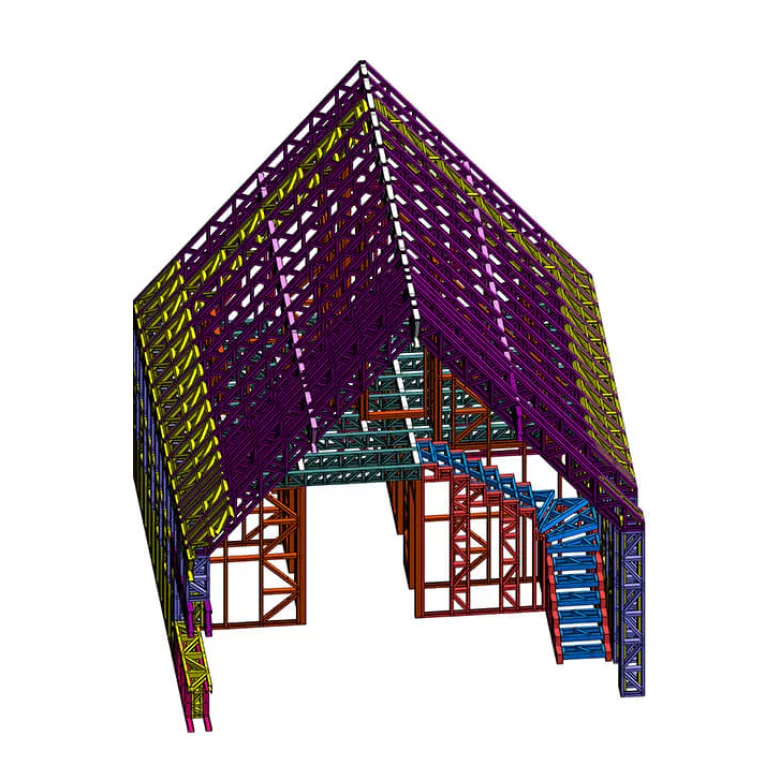

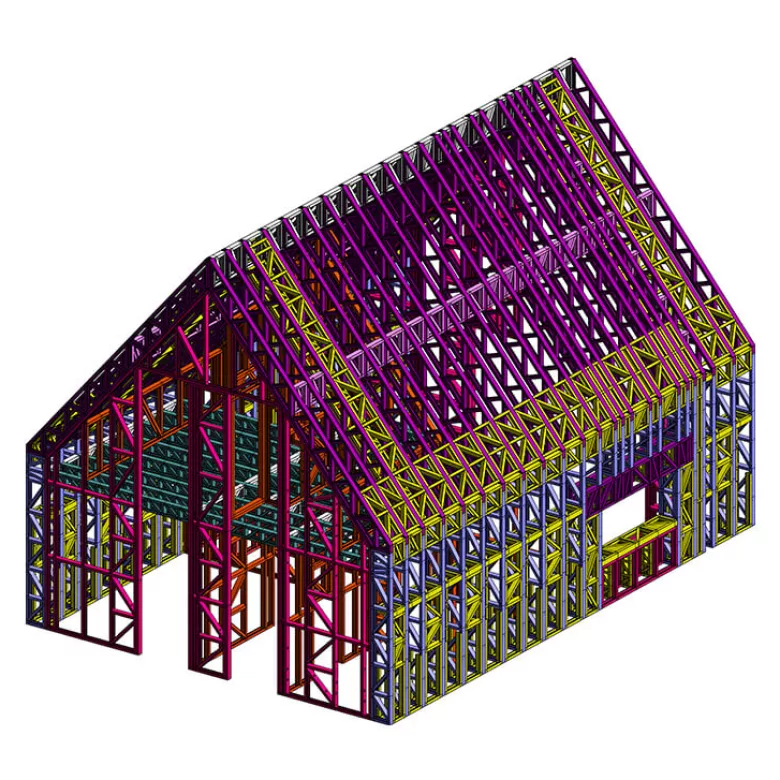

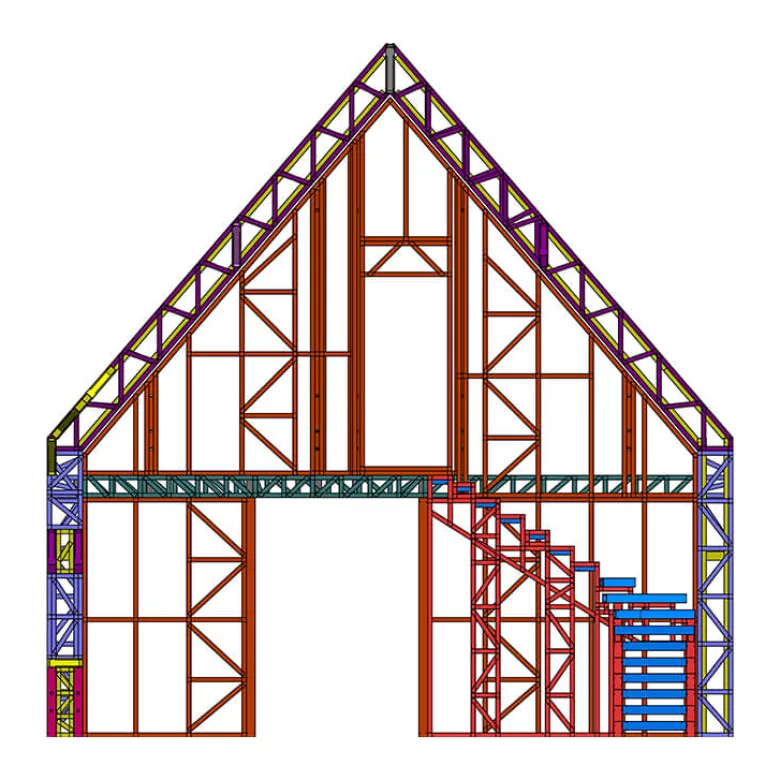

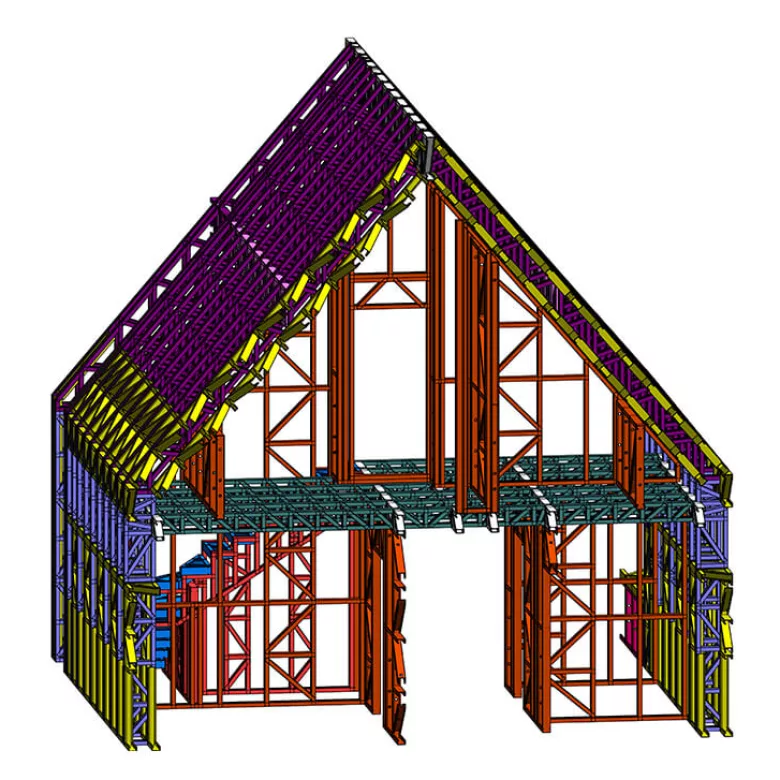

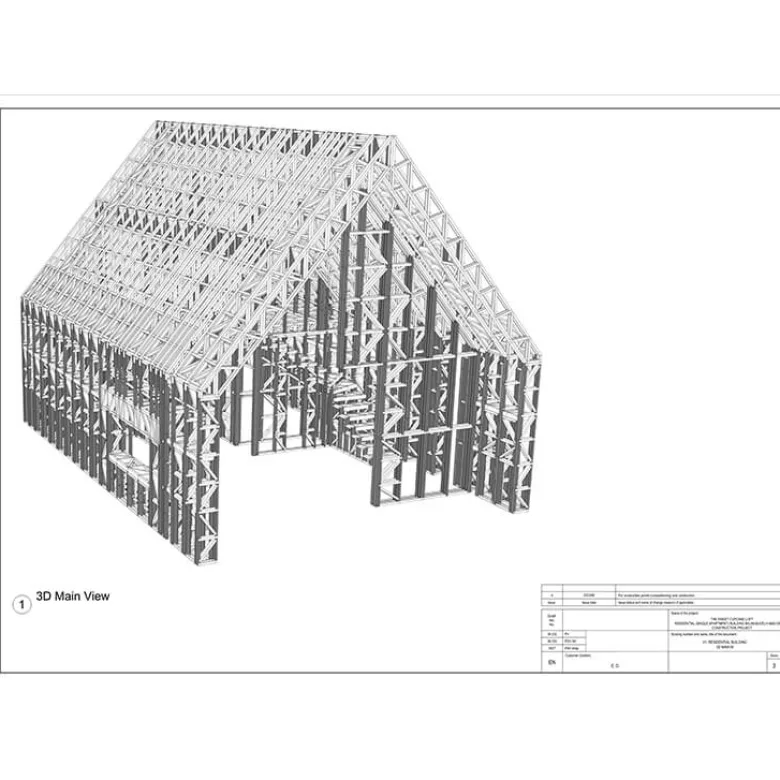

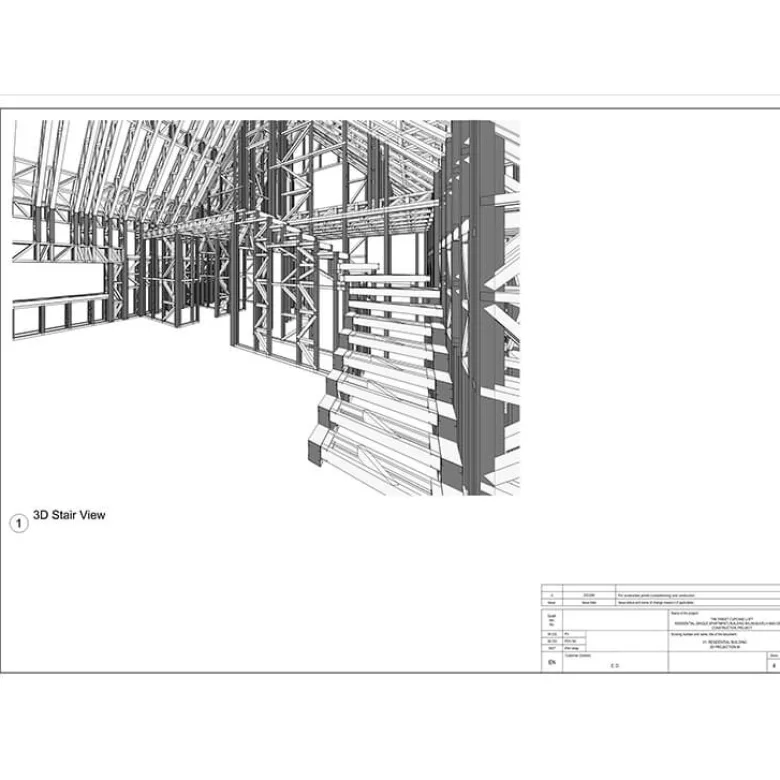

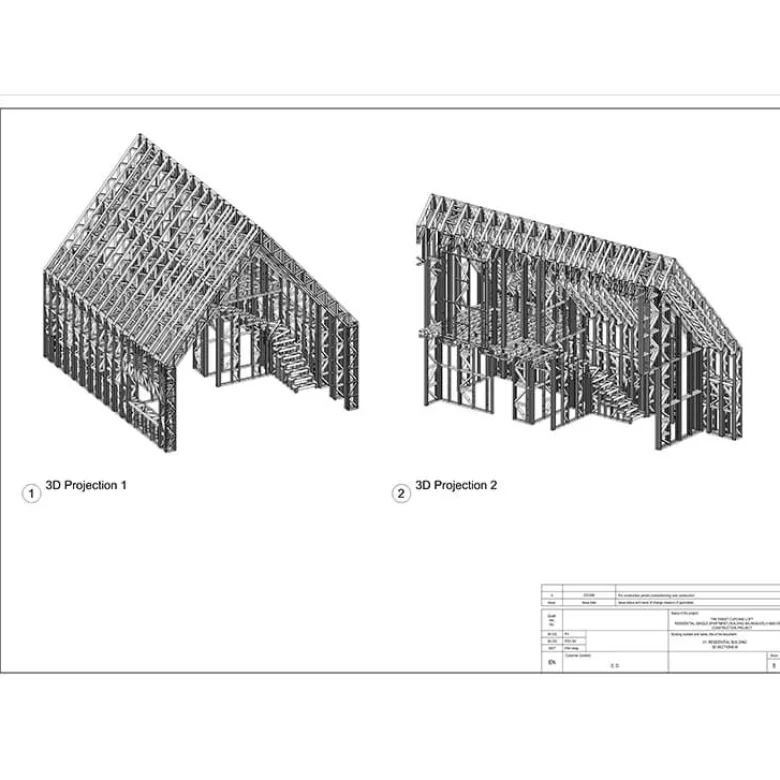

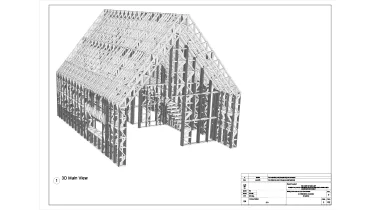

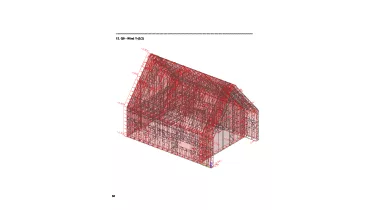

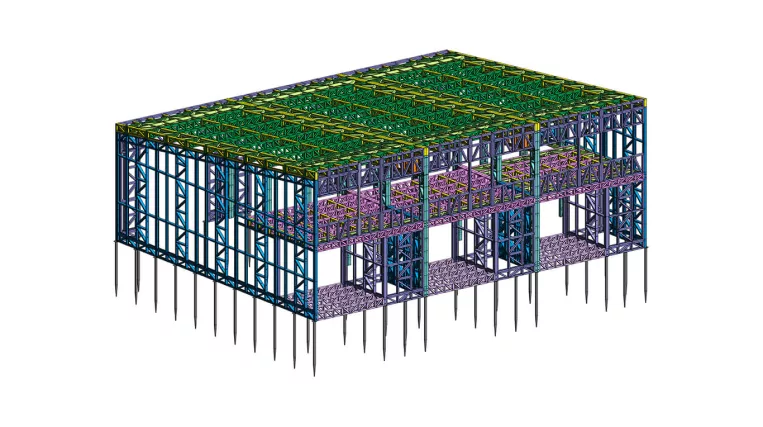

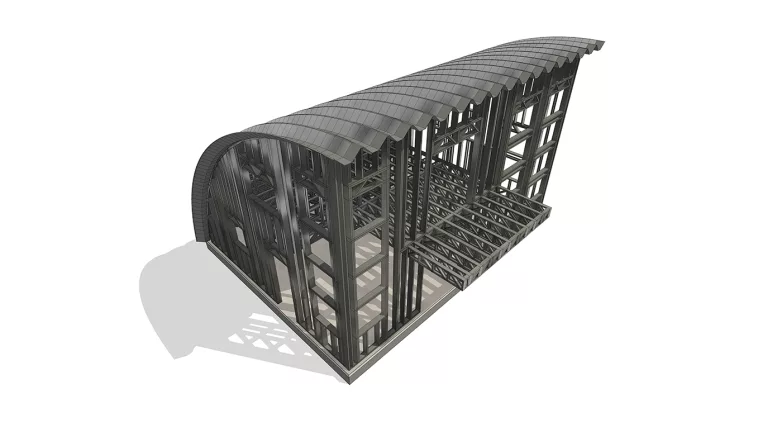

The project entailed designing a two-story residential A-Frame house, commonly known as a barn house.

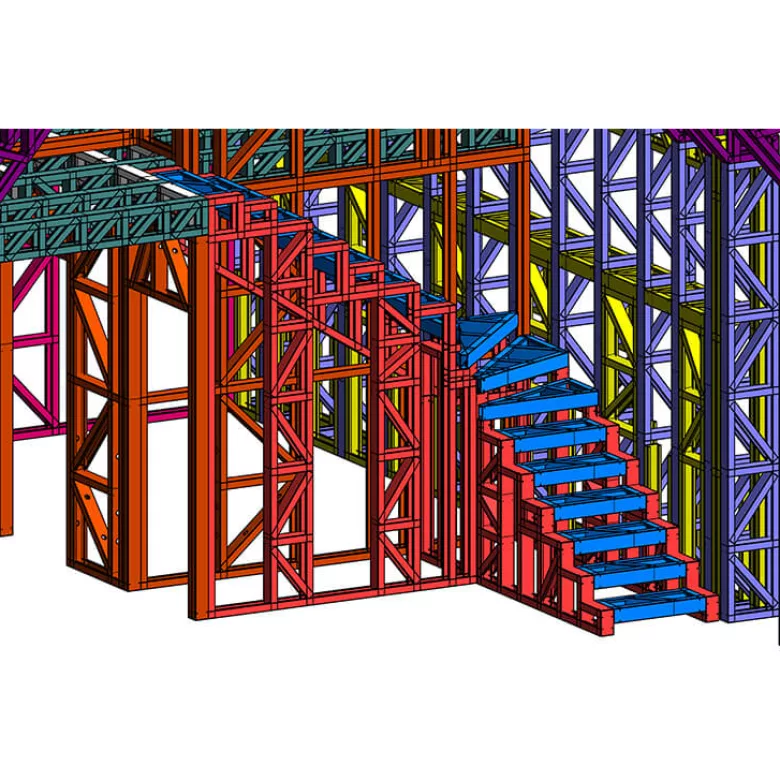

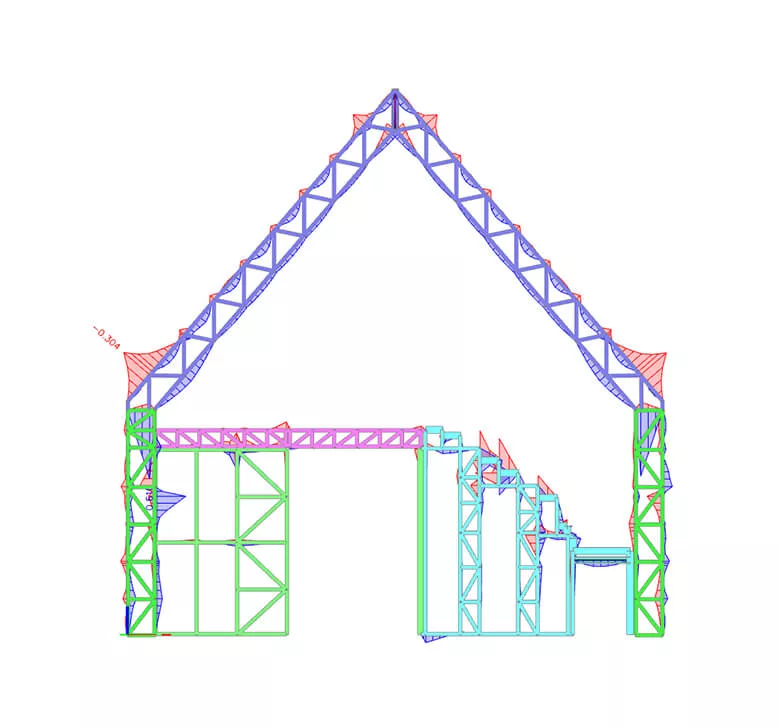

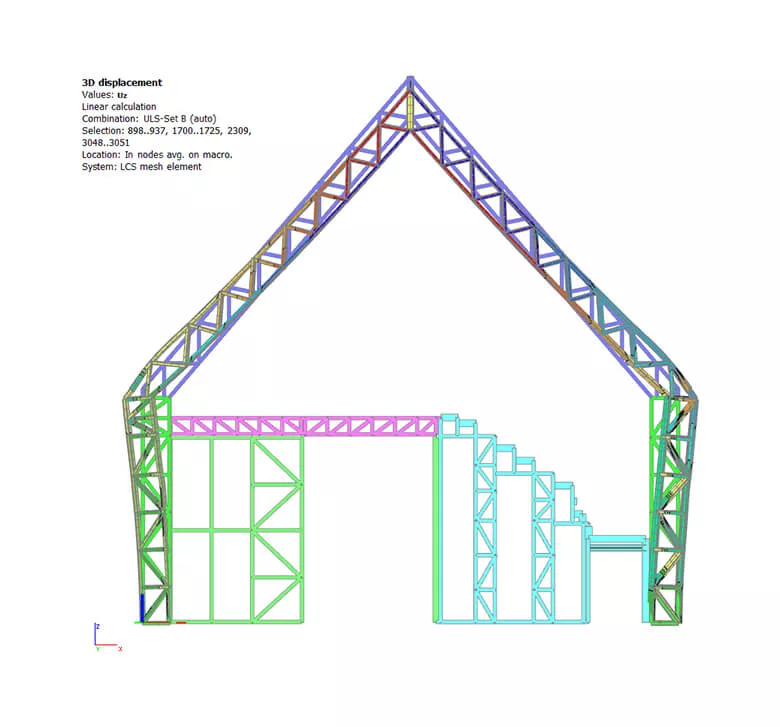

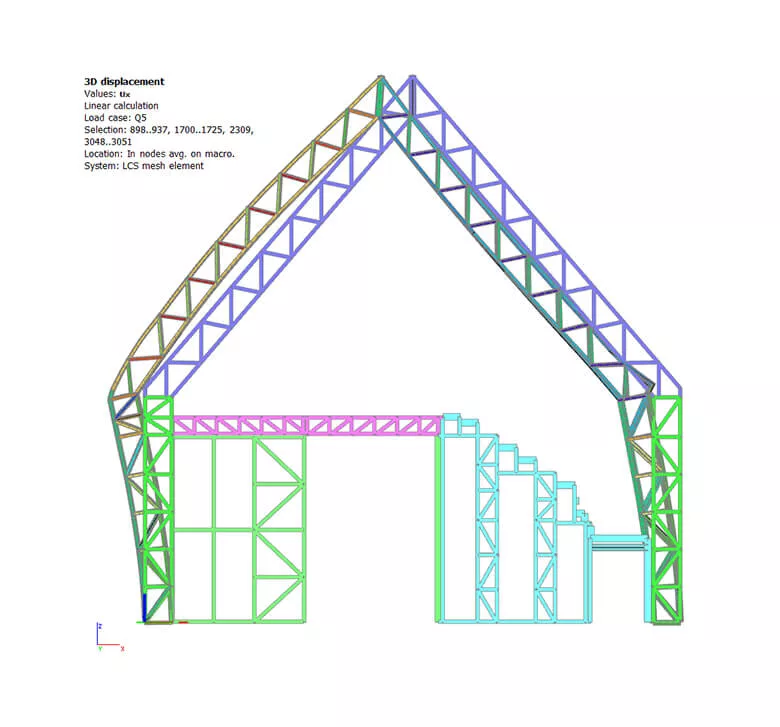

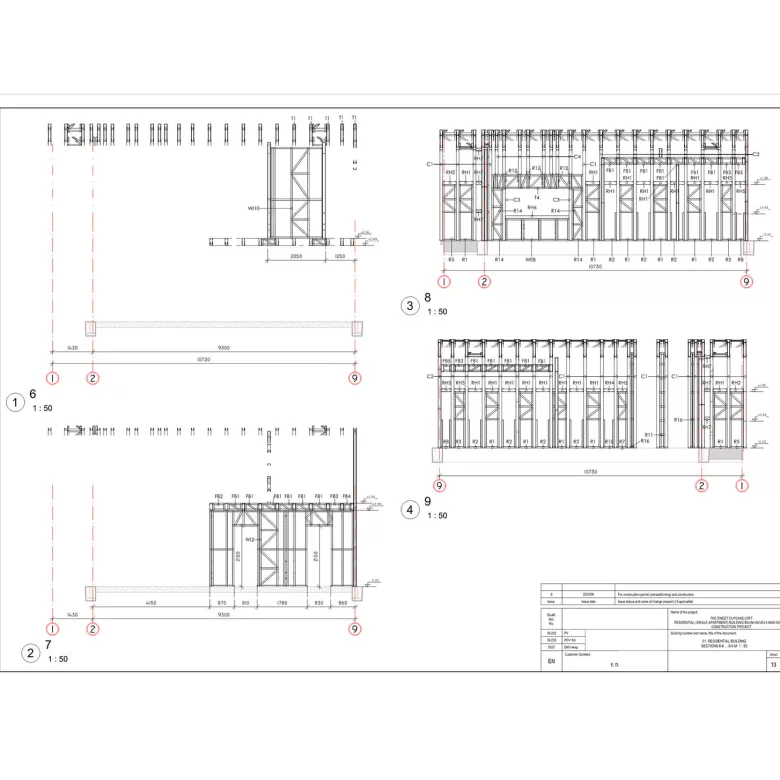

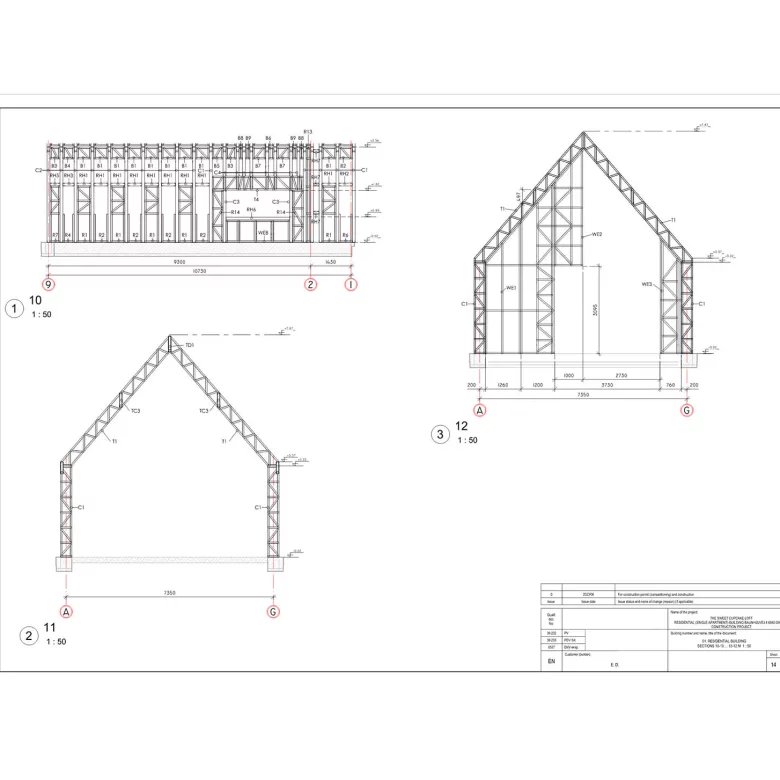

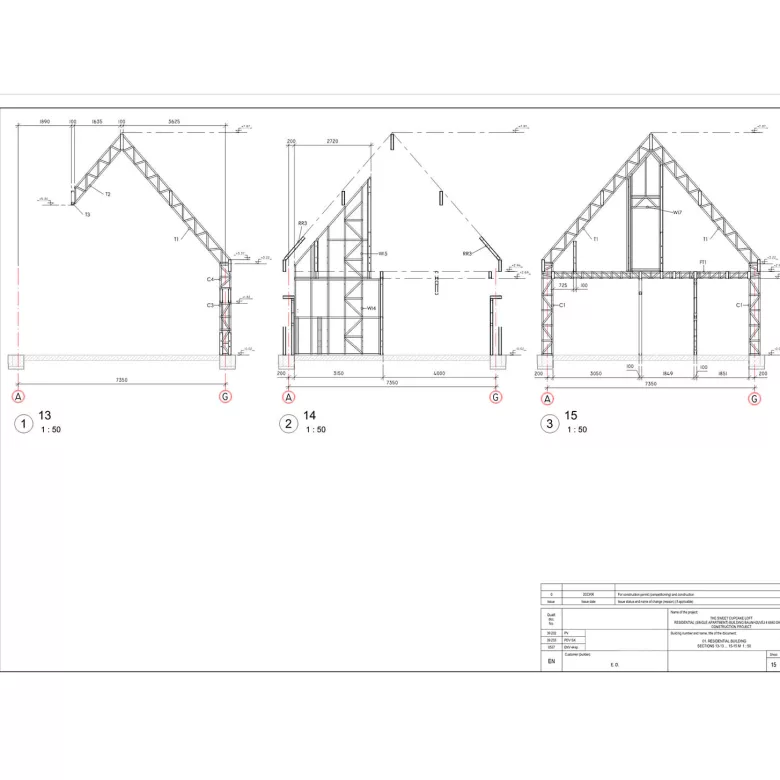

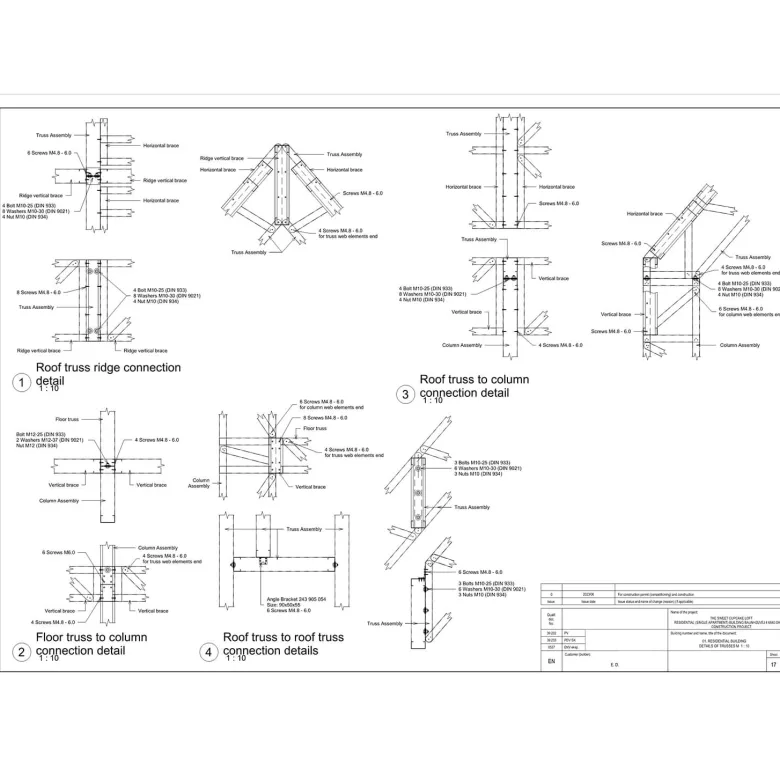

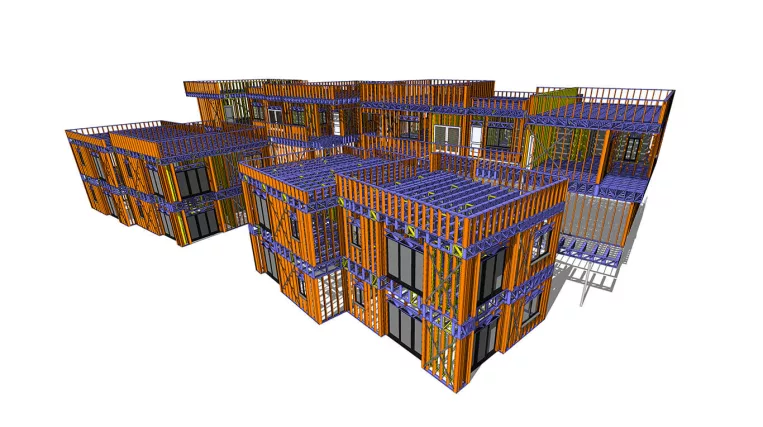

The ORIGIN team’s goal was to develop structural construction drawings and perform structural analysis of the building’s LGS framing and foundation.

Since the project builder had the Howick rollformer, CNC files for LGS panel production were also requested.

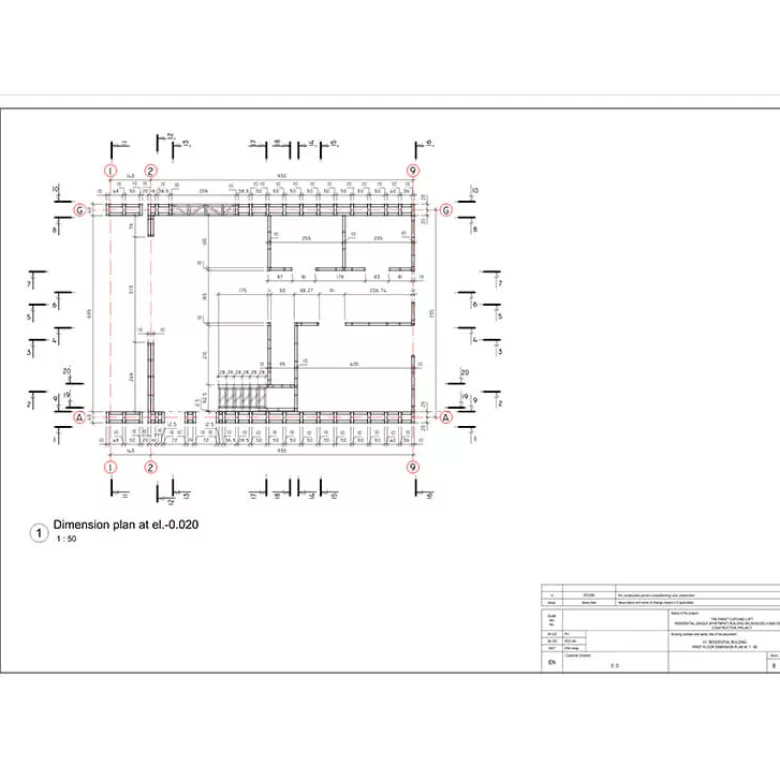

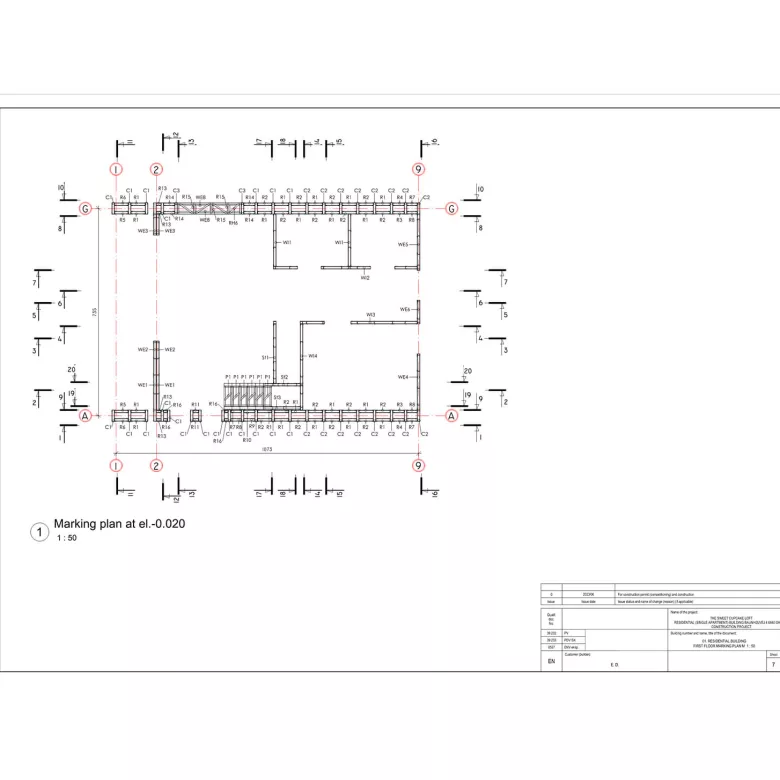

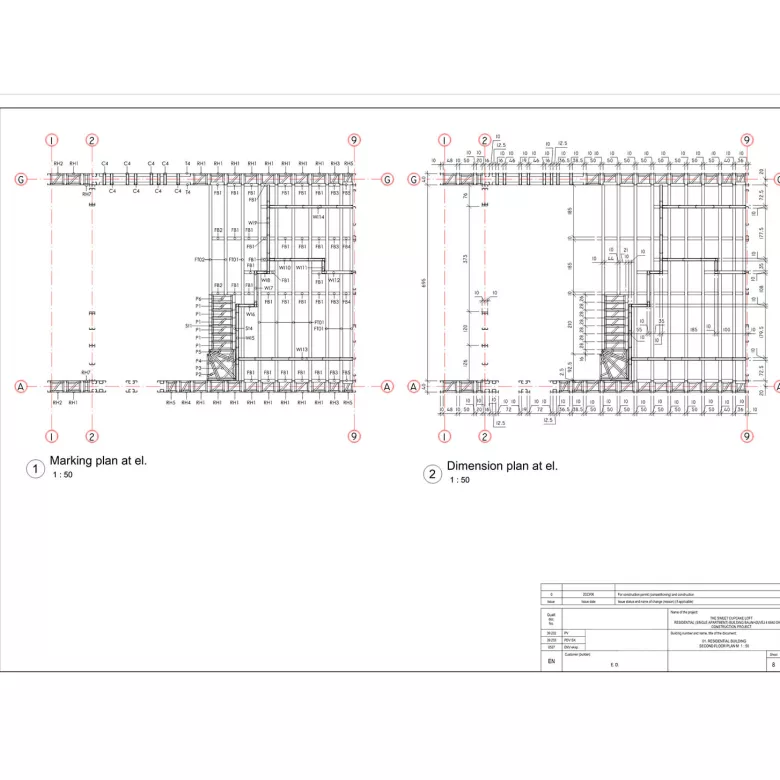

Input: Architectural drawings set.

Project deliverables:

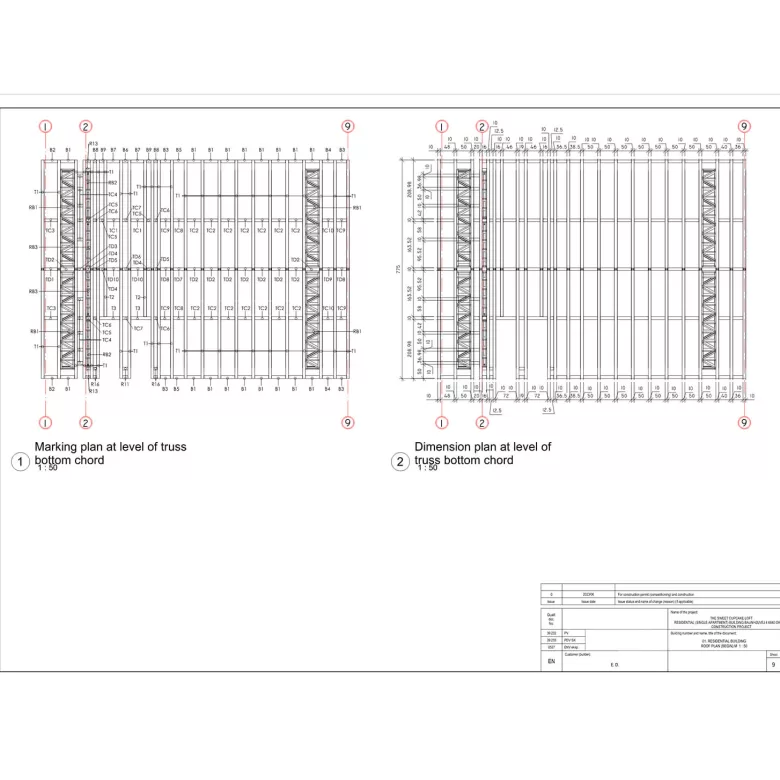

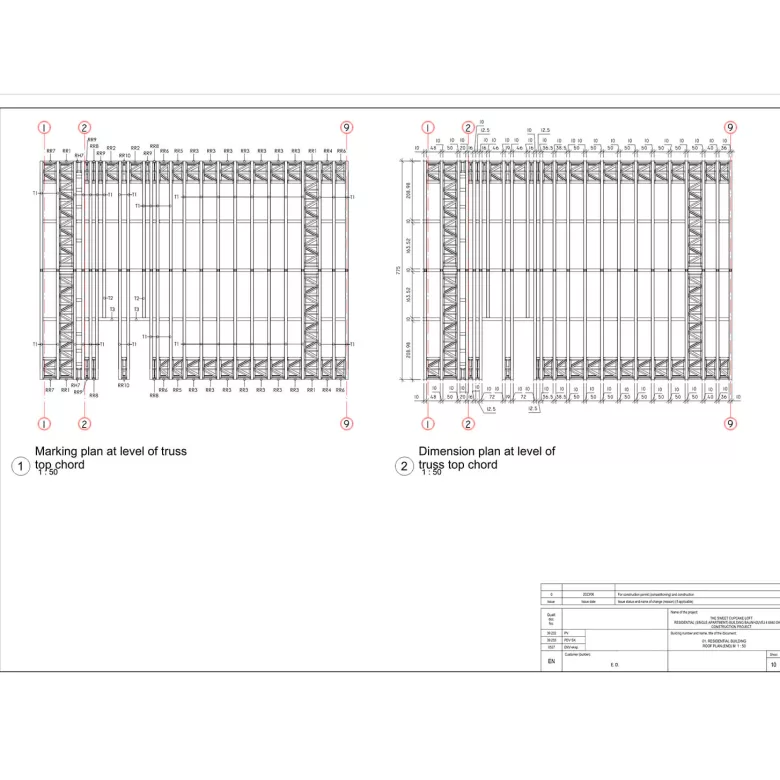

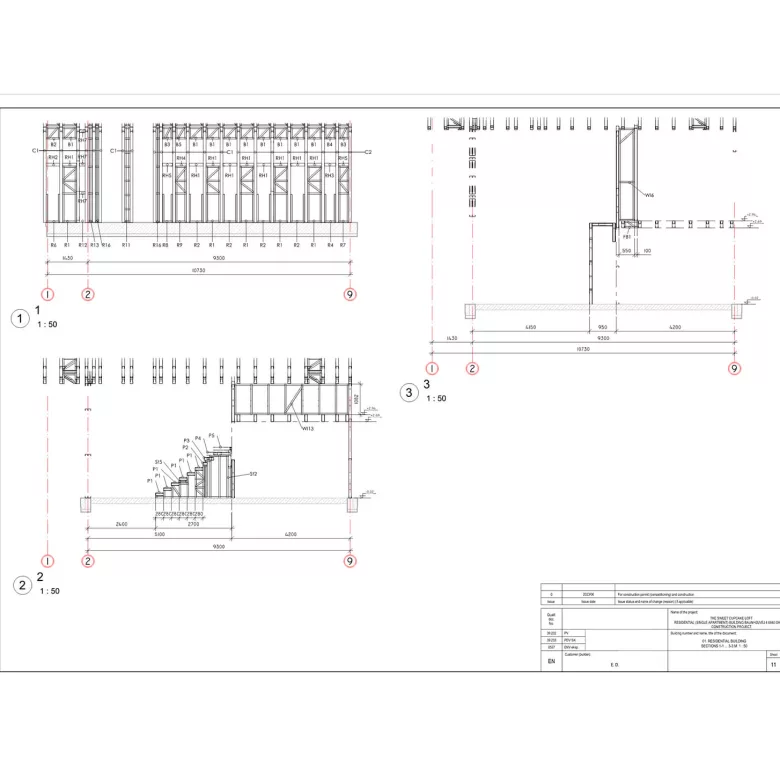

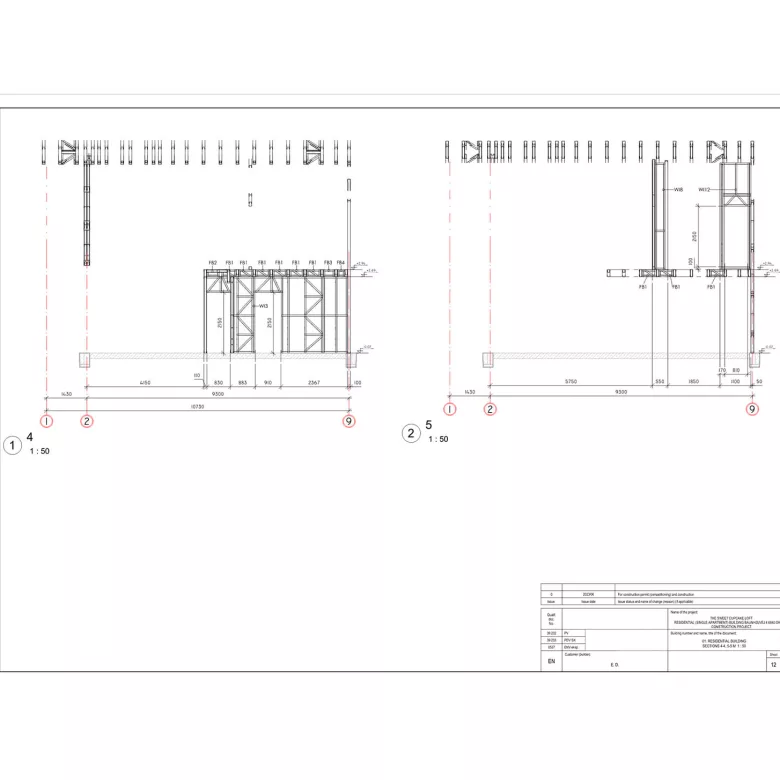

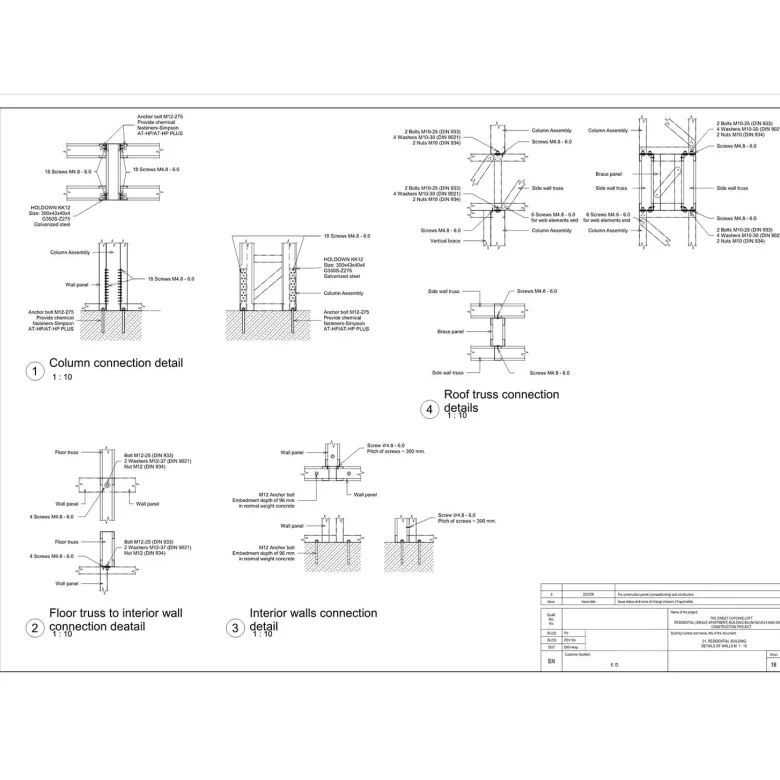

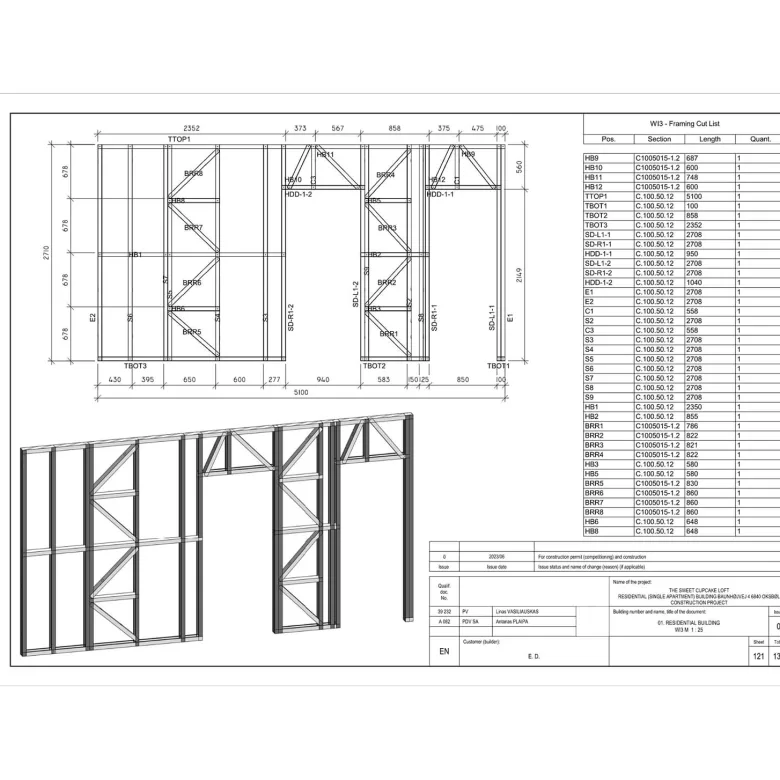

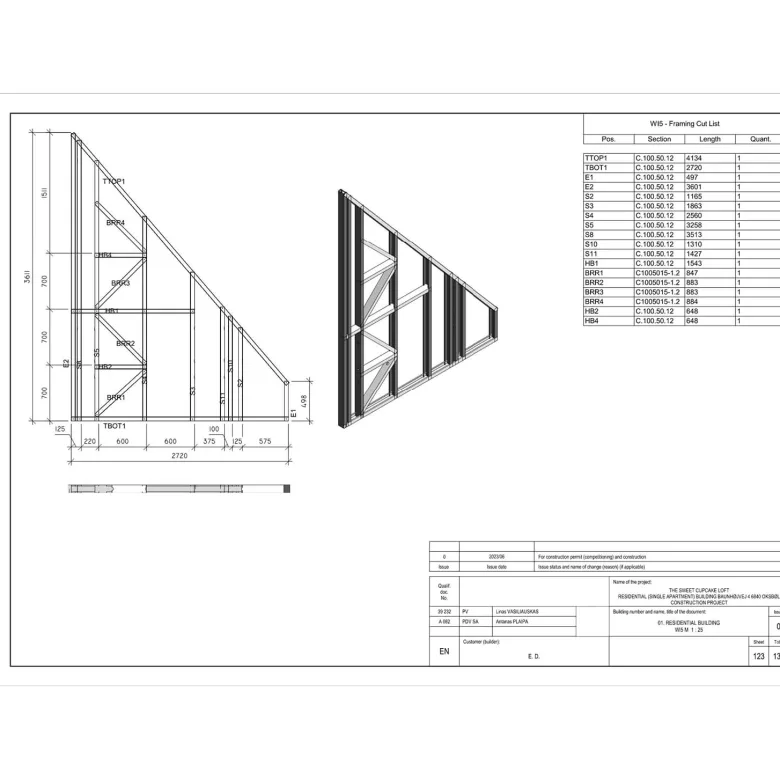

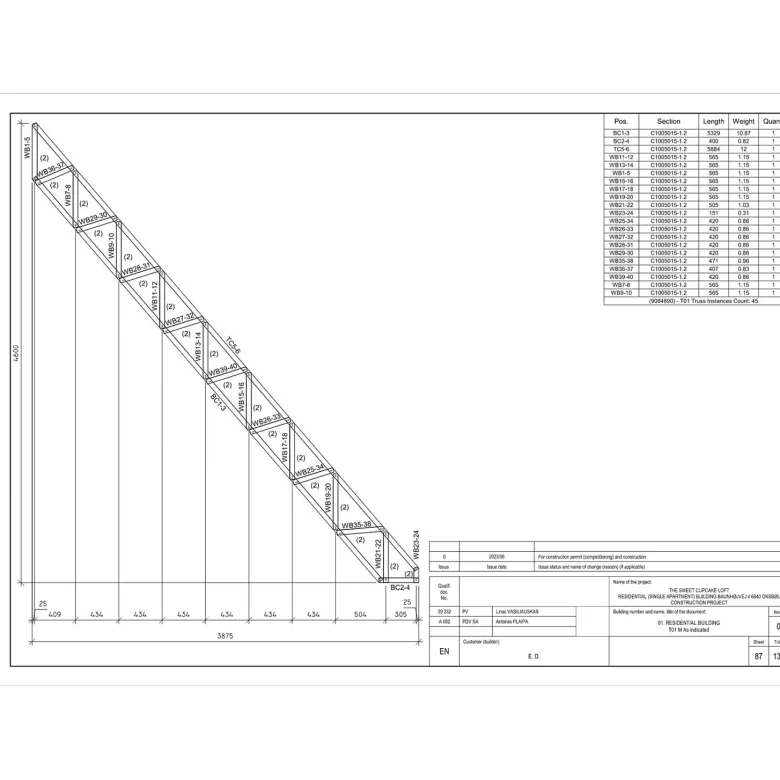

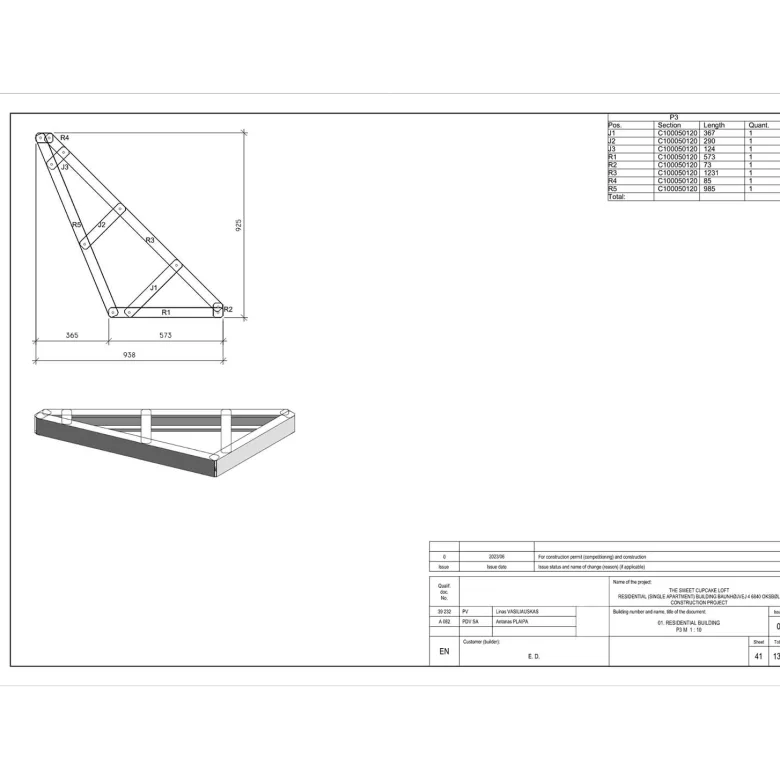

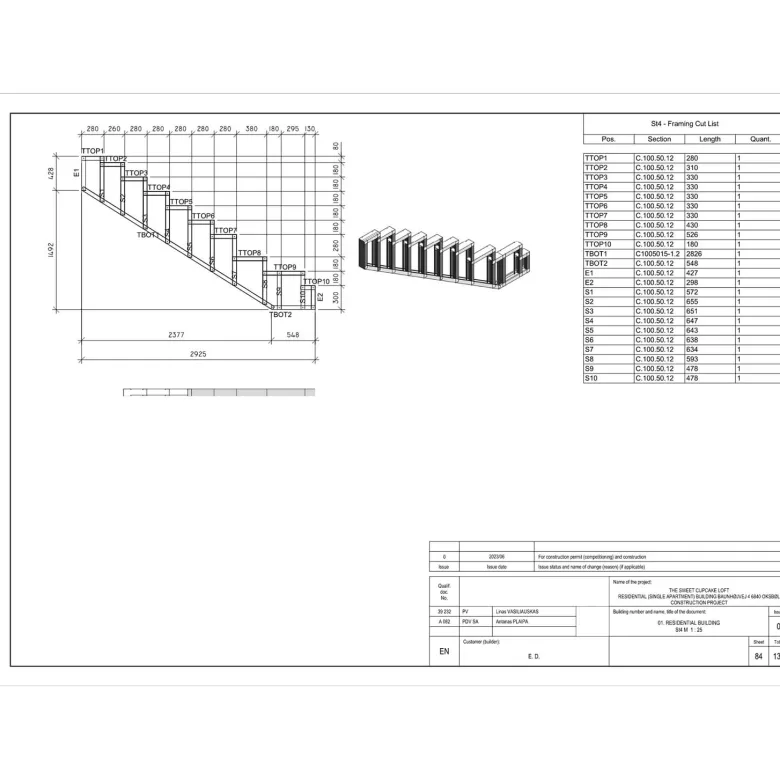

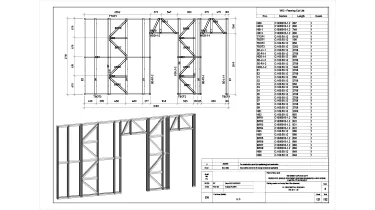

- Structural drawings set;

- Structural analysis report;

- LGS shop drawings;

- Howick CNC files for LGS panels production.