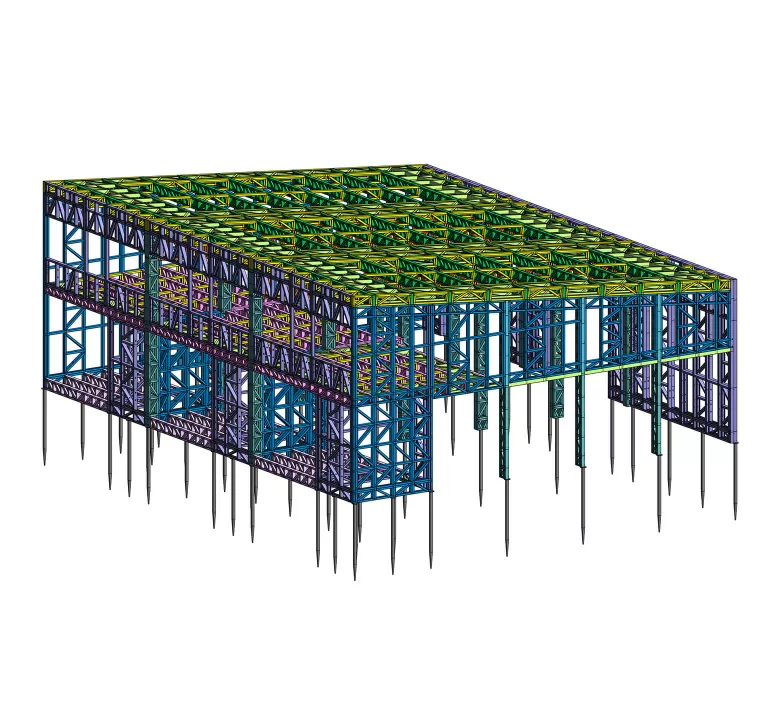

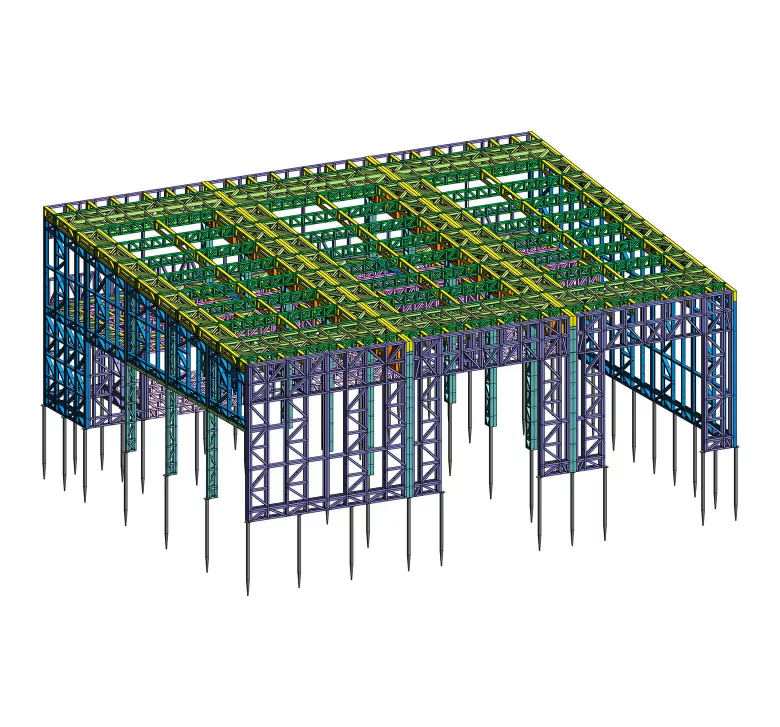

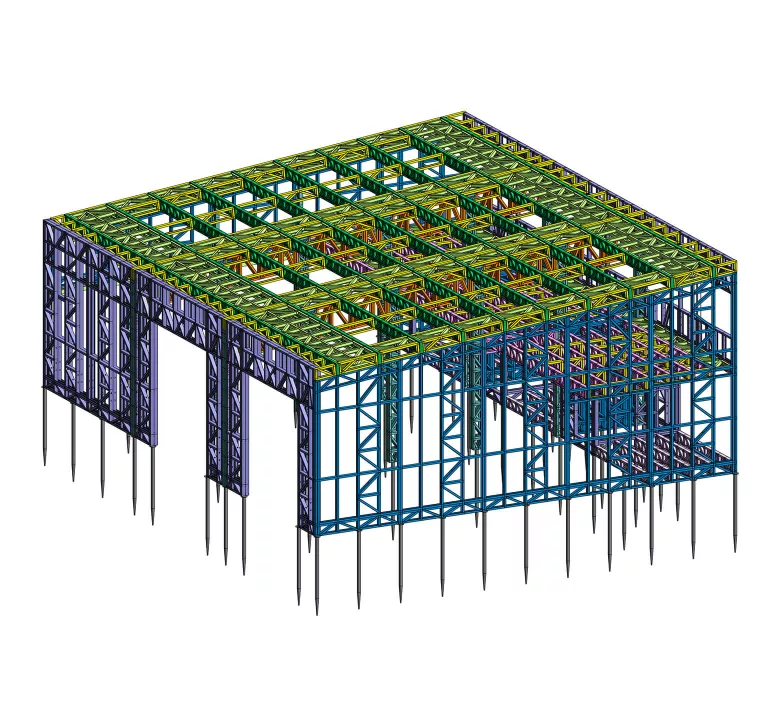

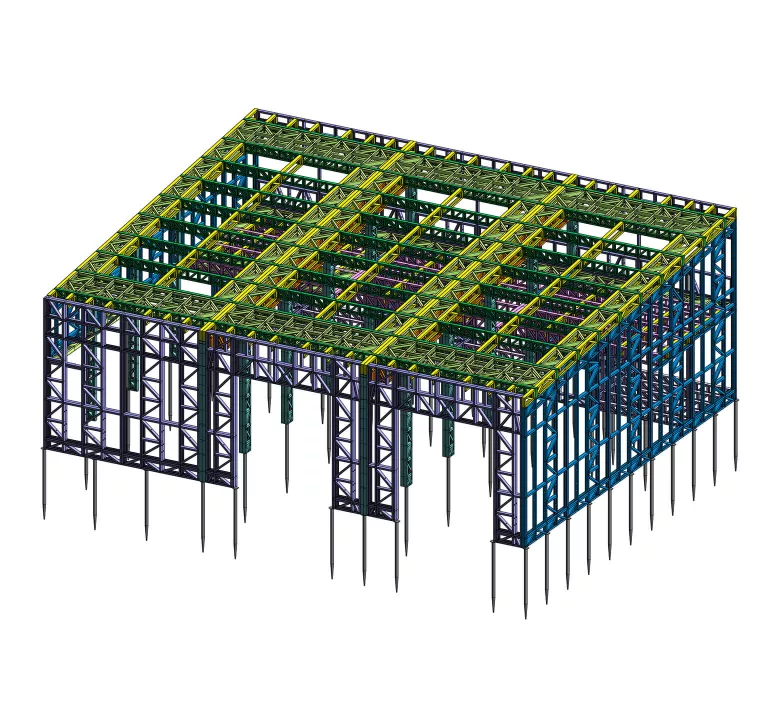

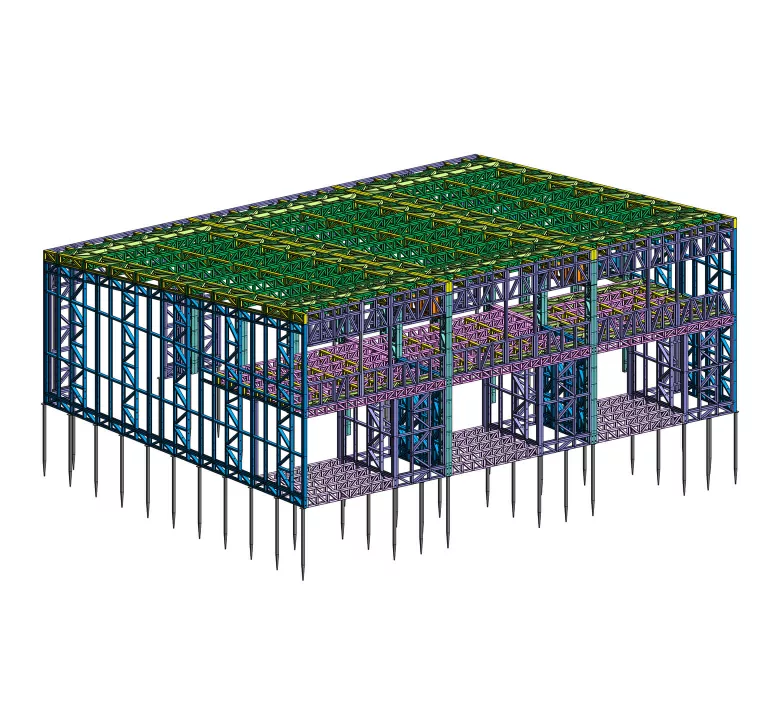

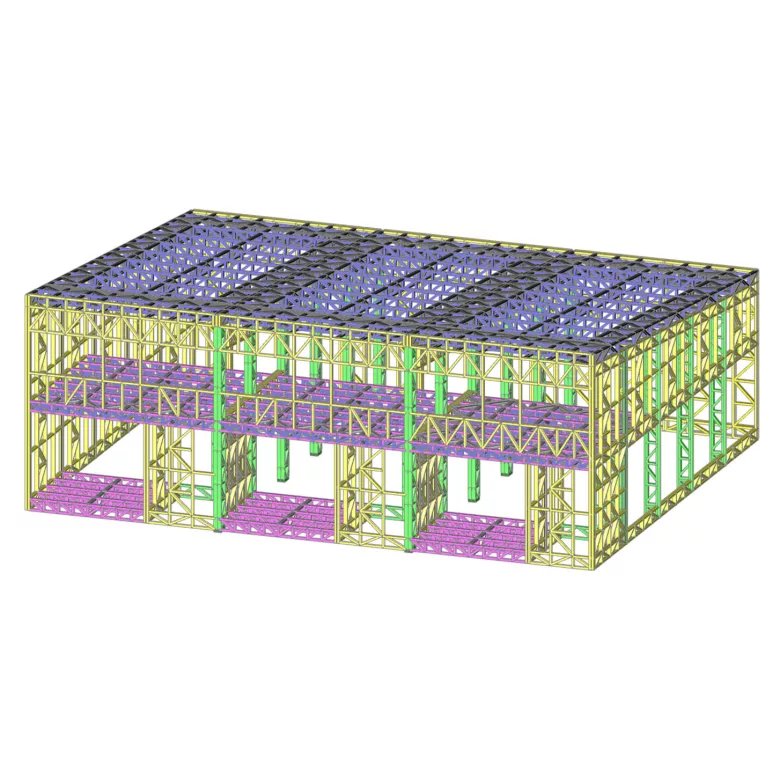

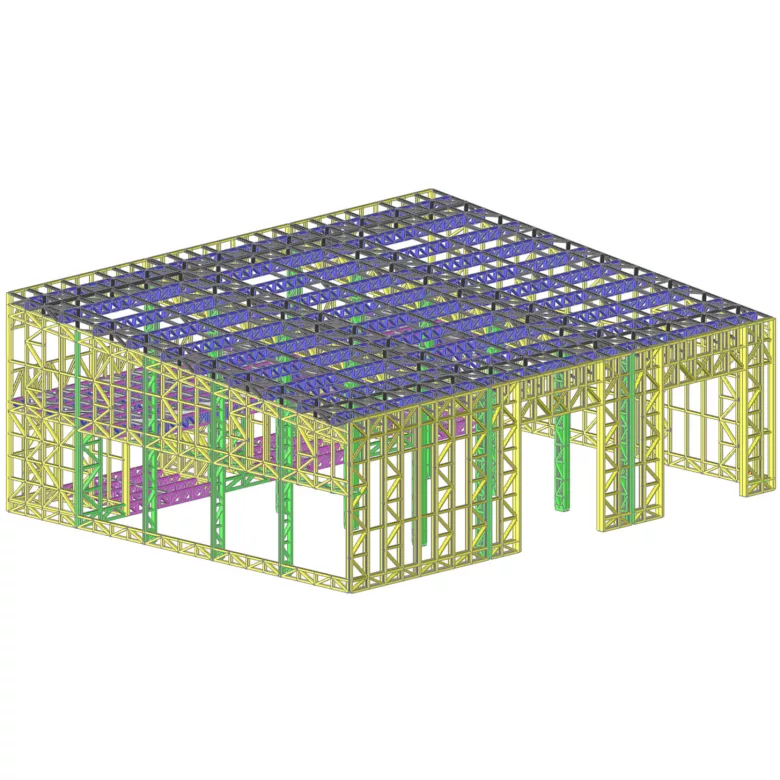

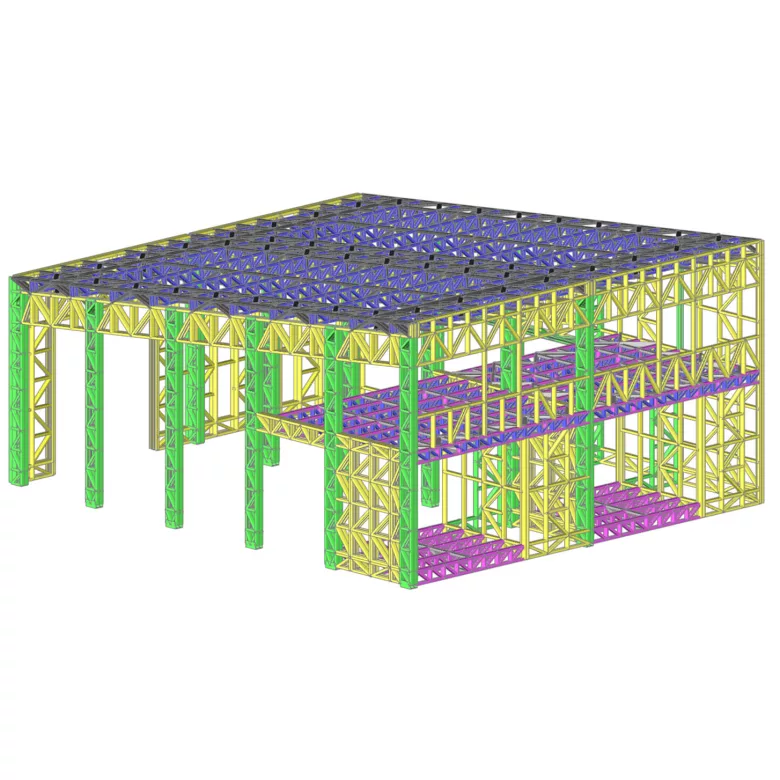

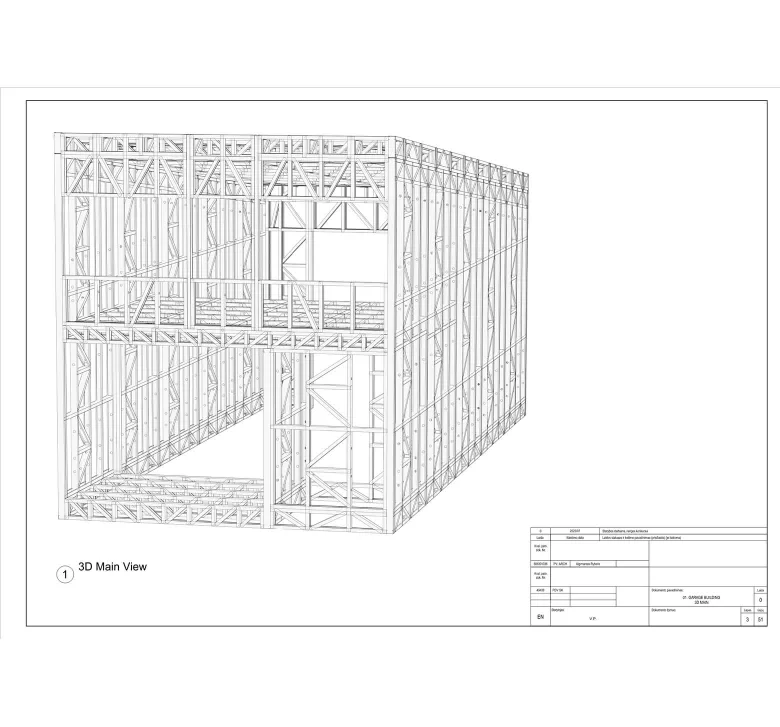

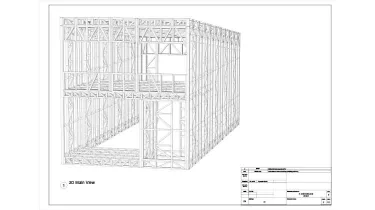

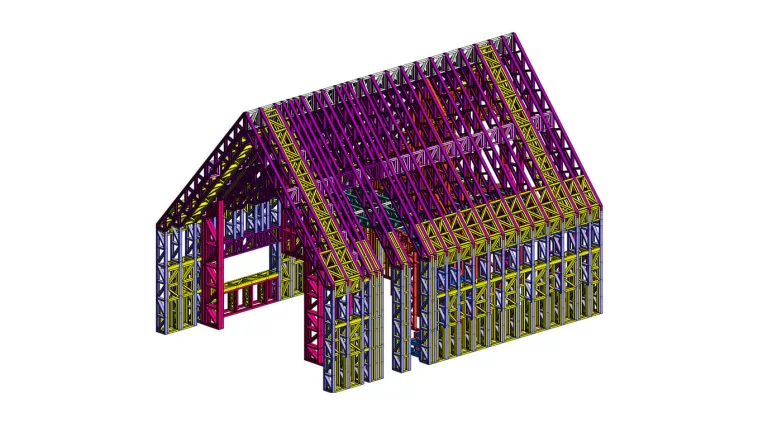

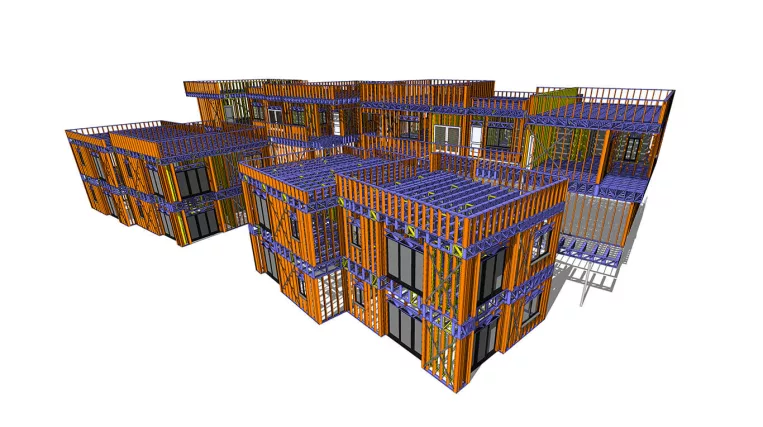

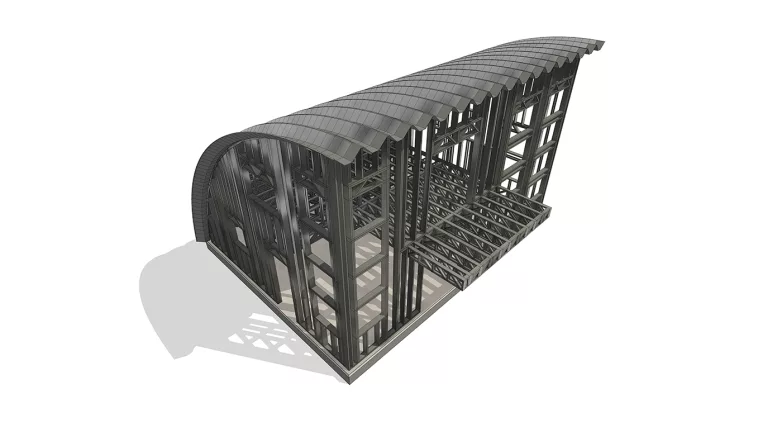

The project involved designing and detailing a warehouse building with a 2-story office space.

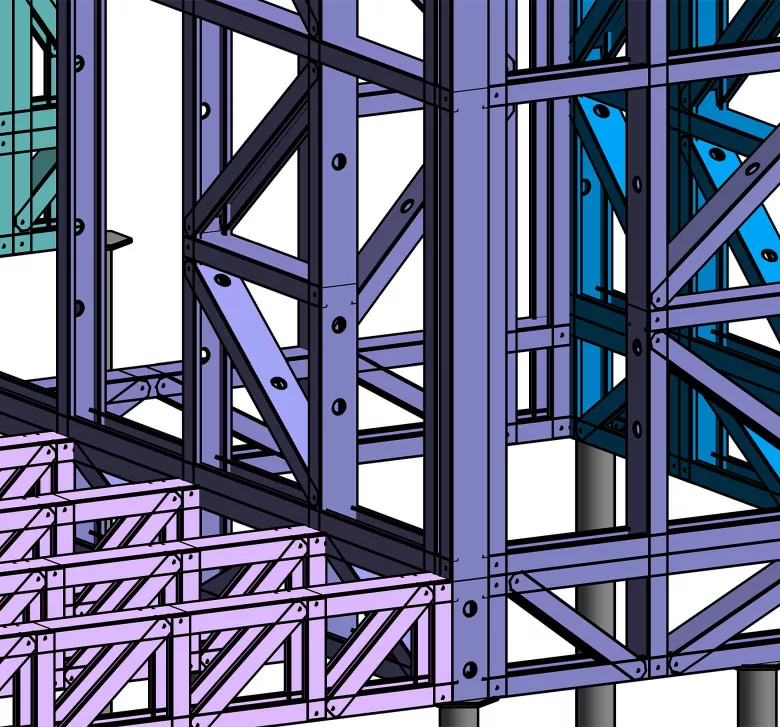

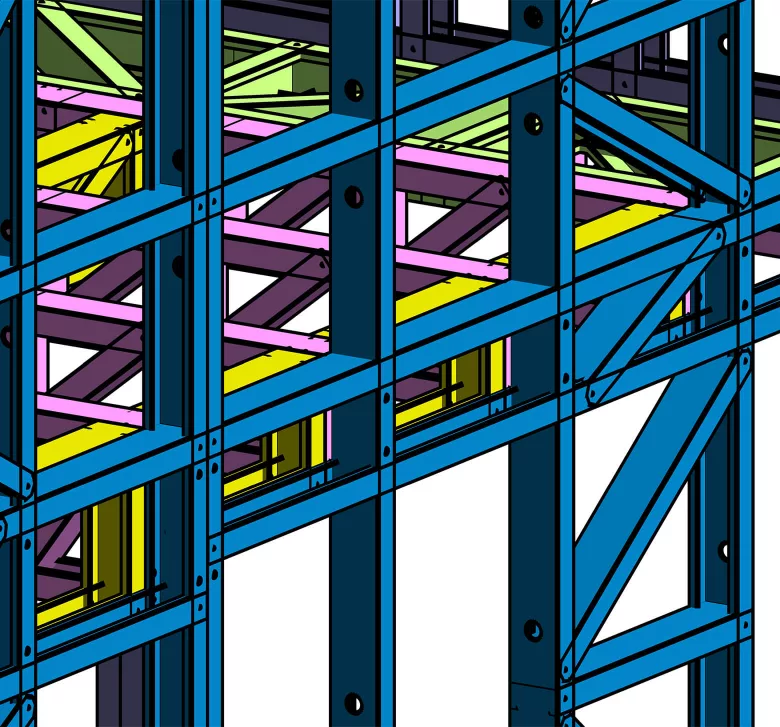

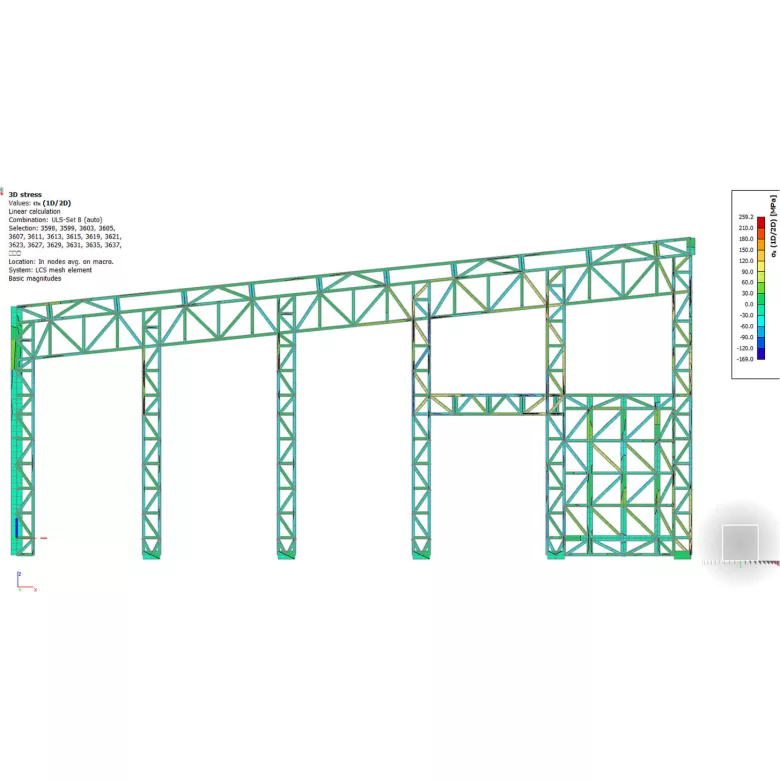

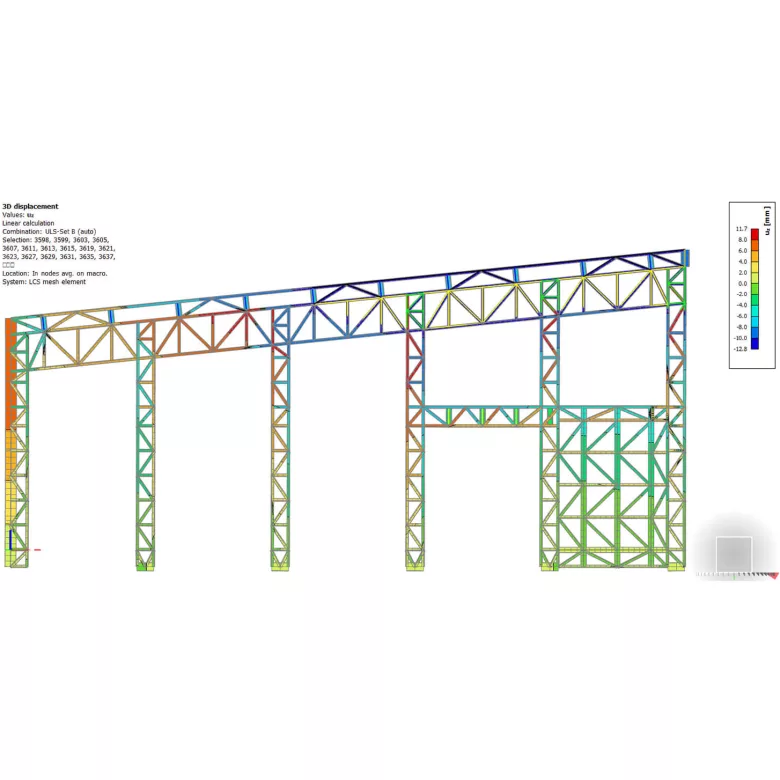

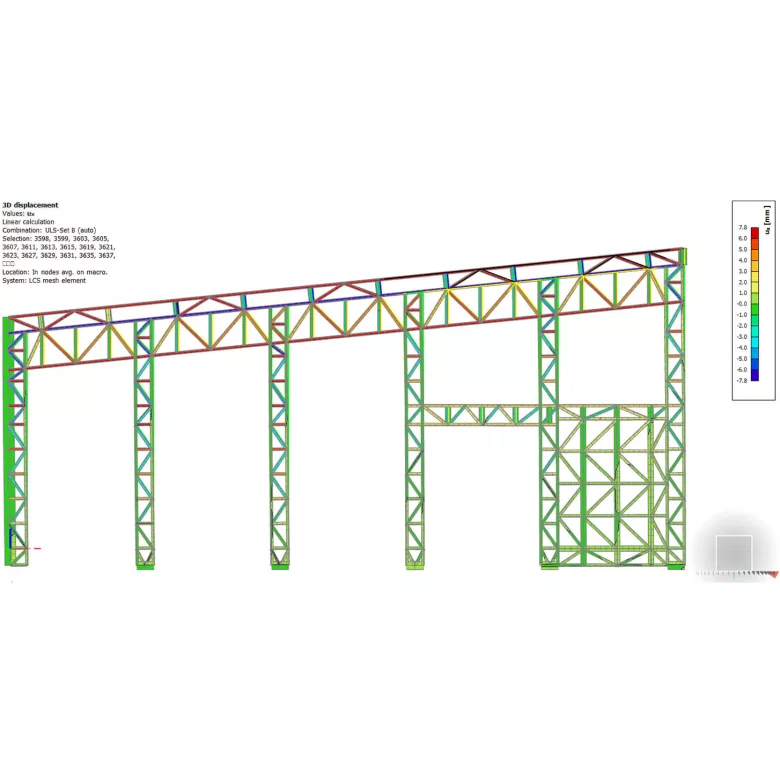

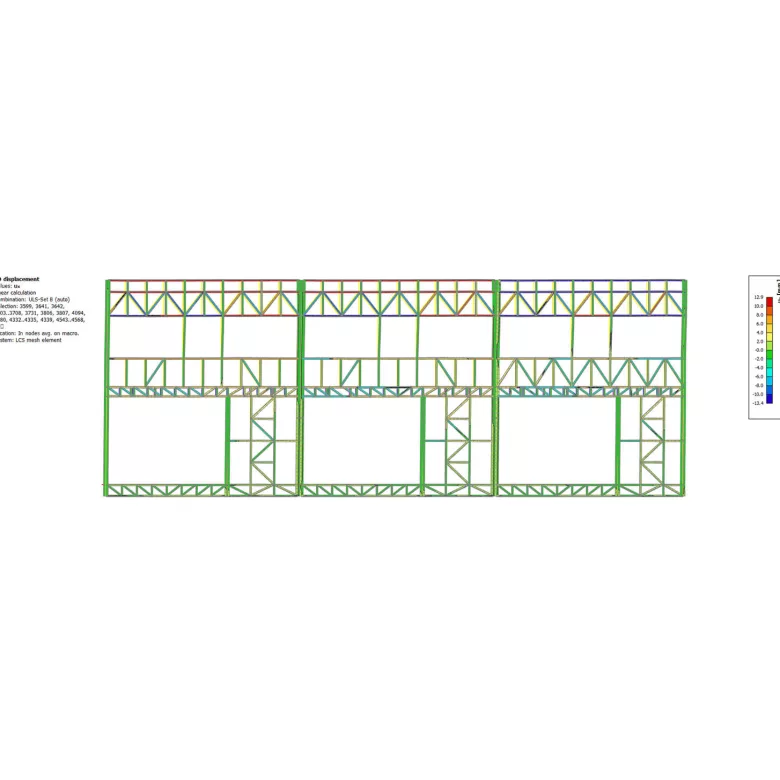

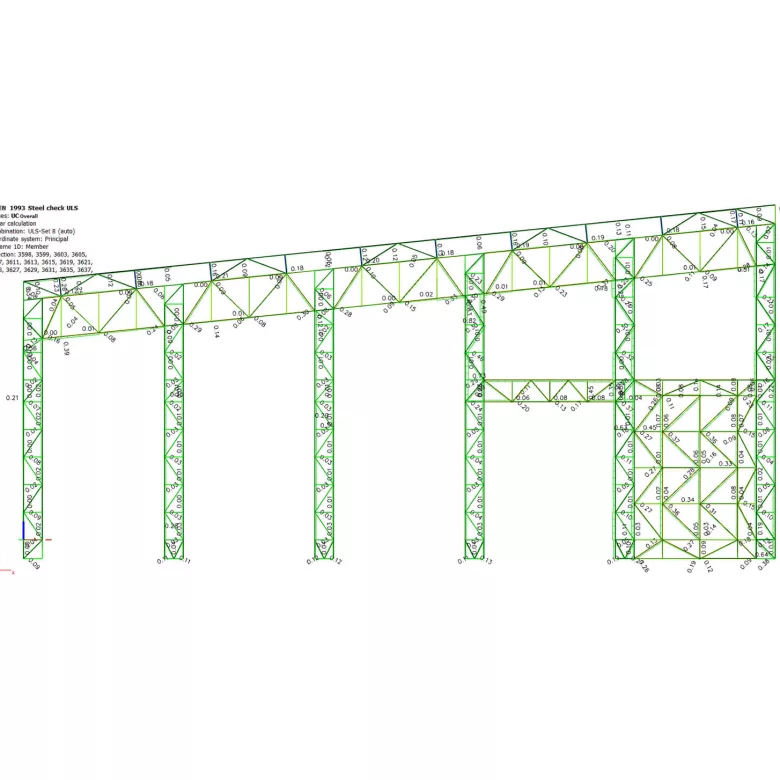

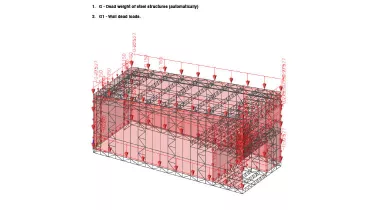

The ORIGIN team was requested to develop structural construction drawings and perform a structural analysis of the building’s LGS framing and foundation.

Since the project builder had the Howick rollformer, ORIGIN also had to prepare CNC files for LGS panel production.

Input: Architectural drawings set.

Project deliverables:

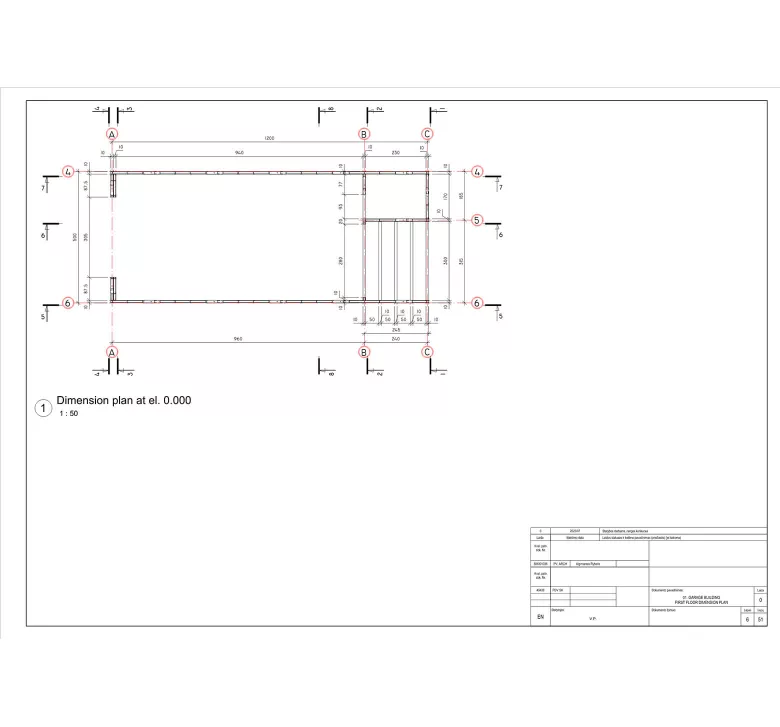

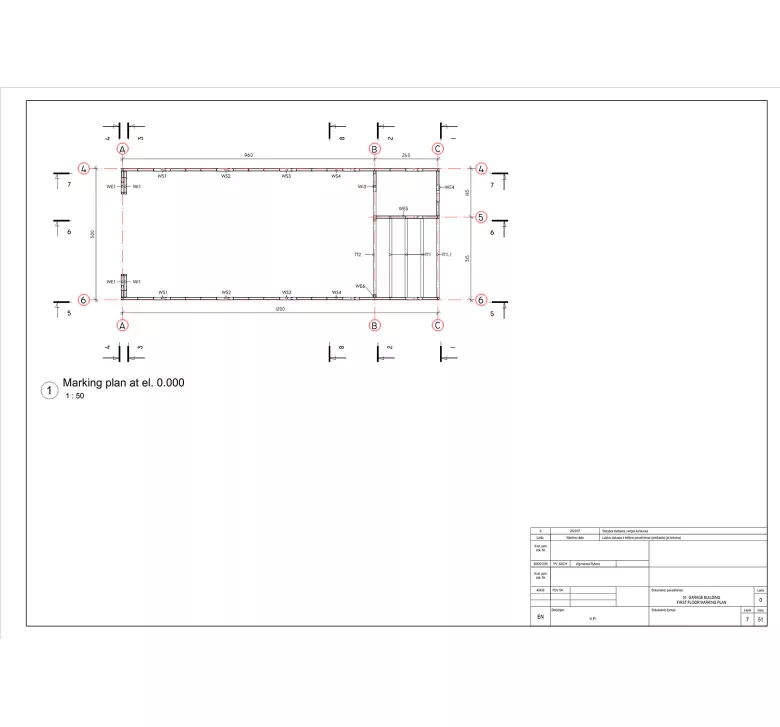

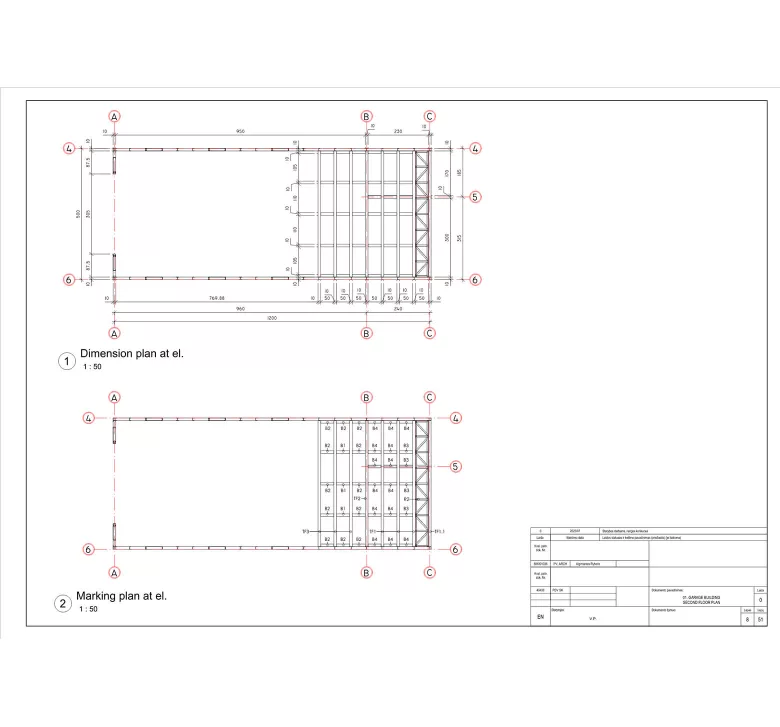

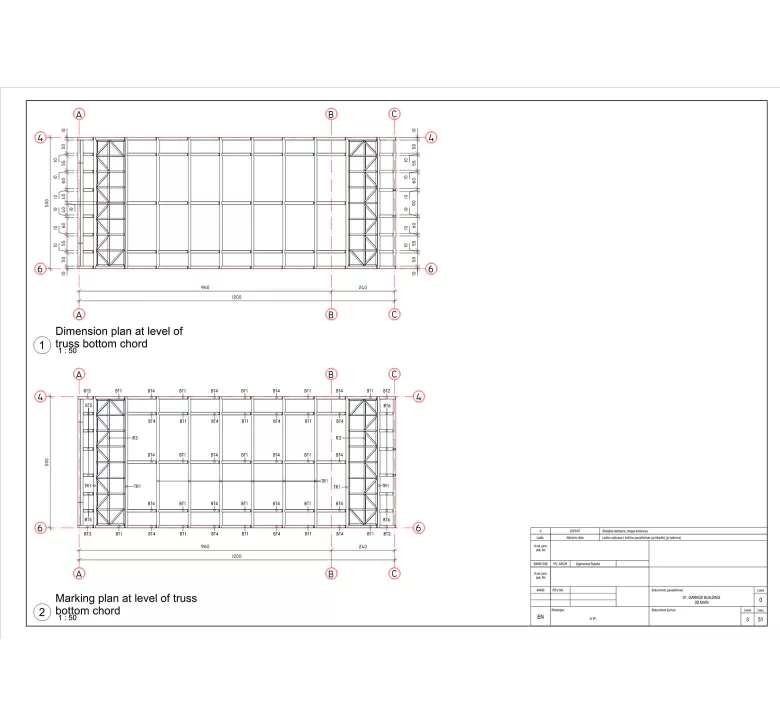

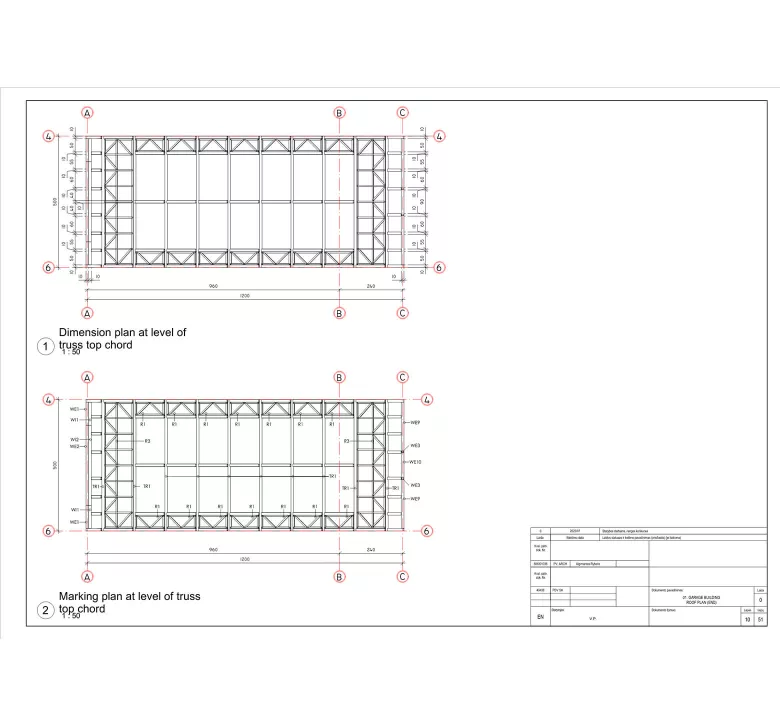

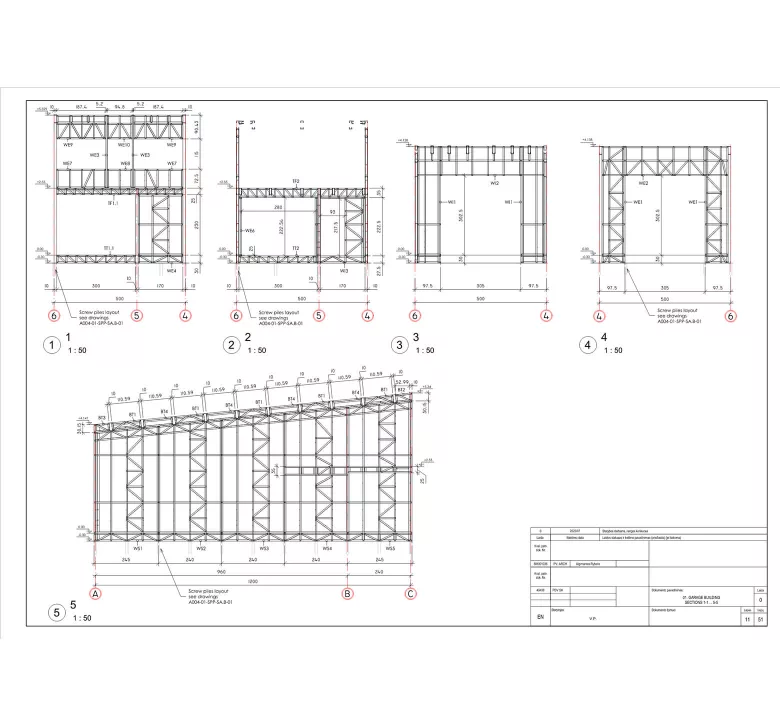

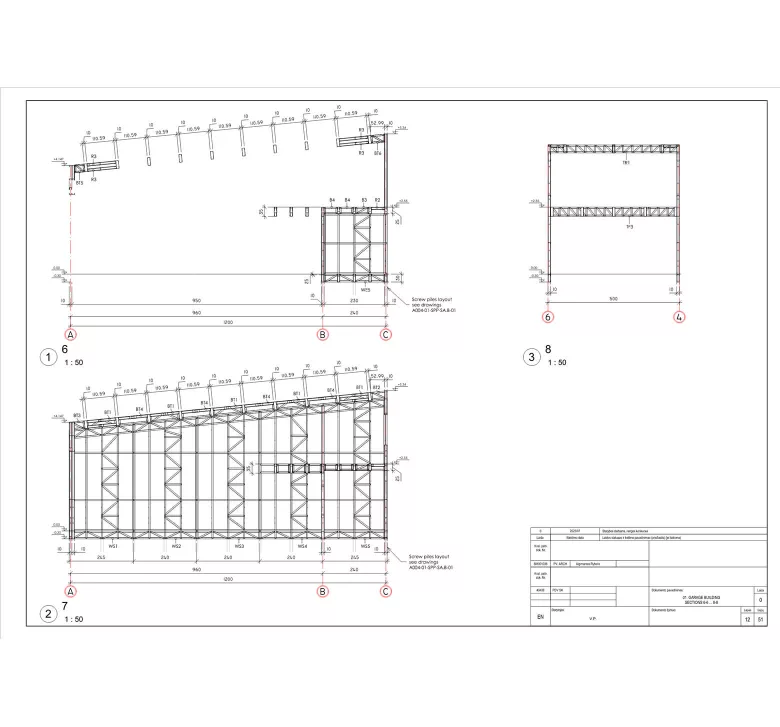

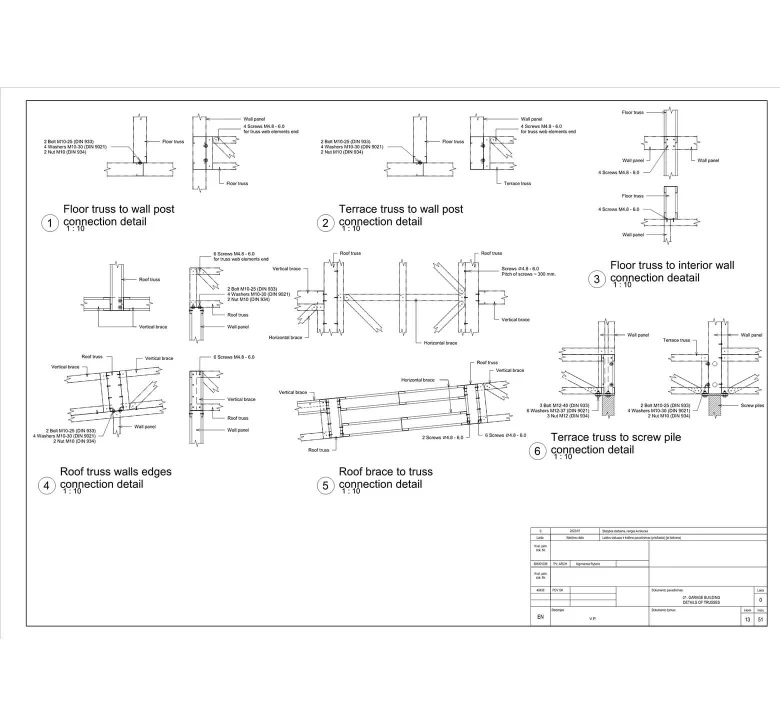

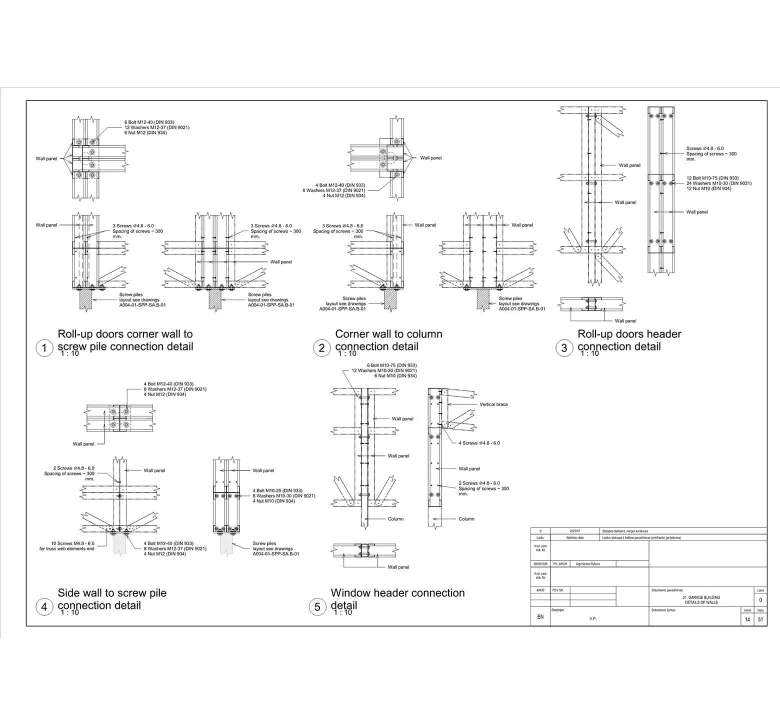

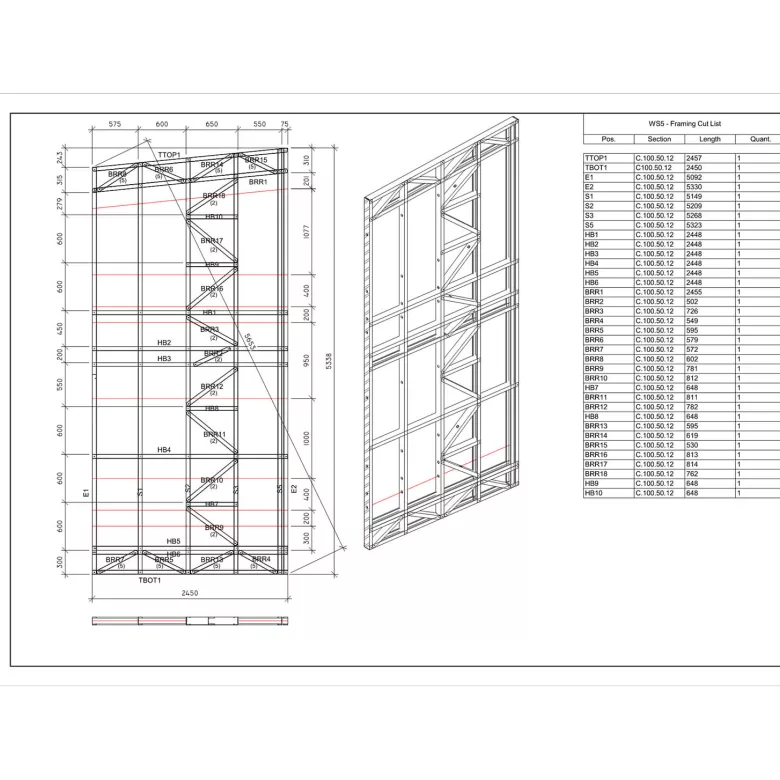

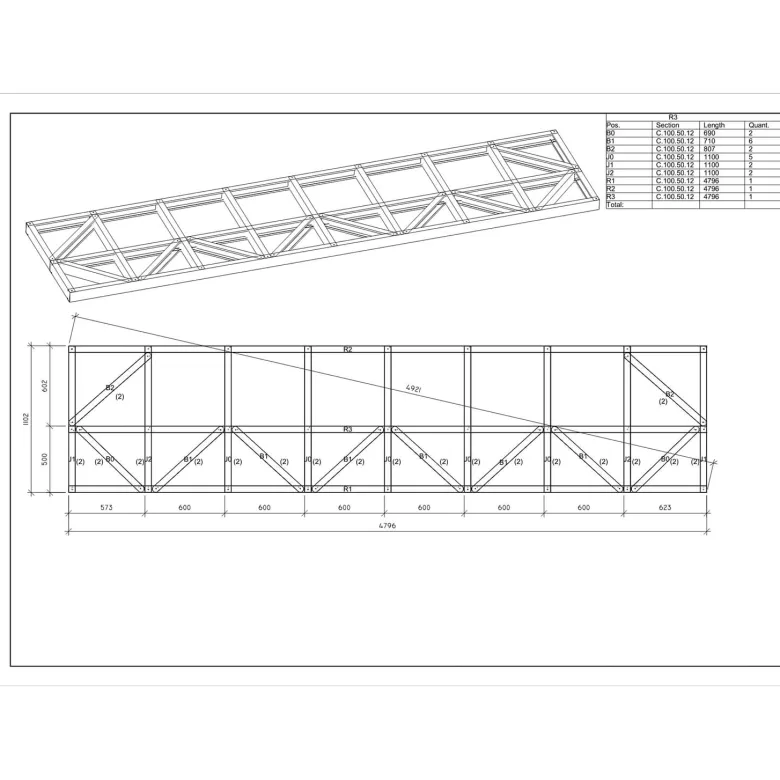

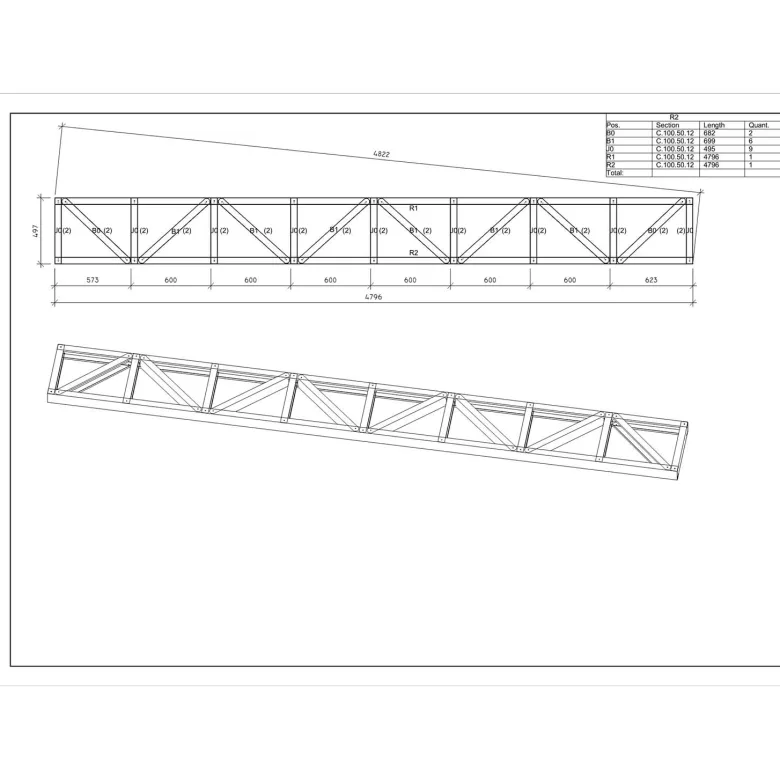

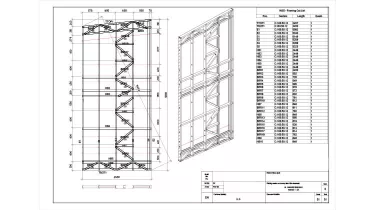

- Structural drawings set;

- Structural analysis report;

- LGS shop drawings;

- Howick CNC files for LGS panels production.