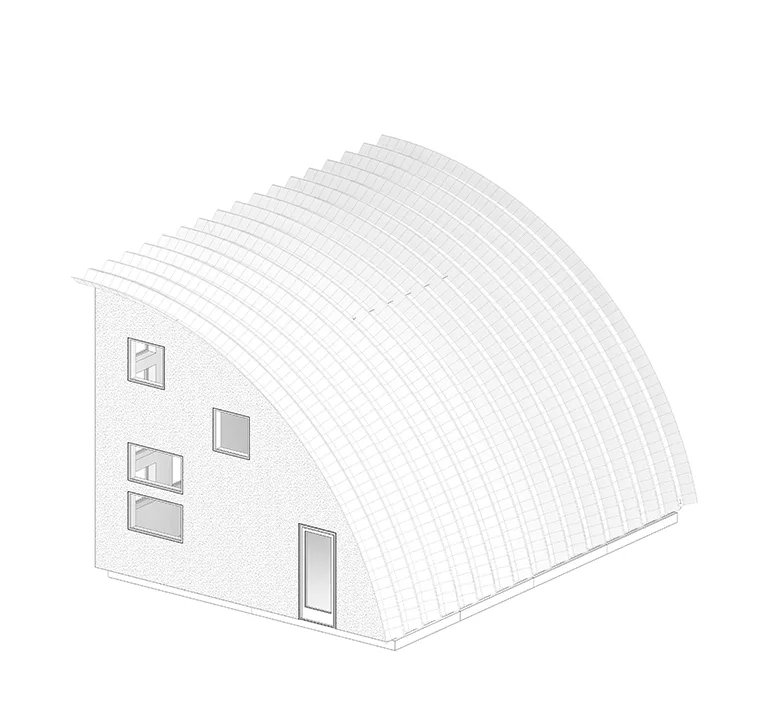

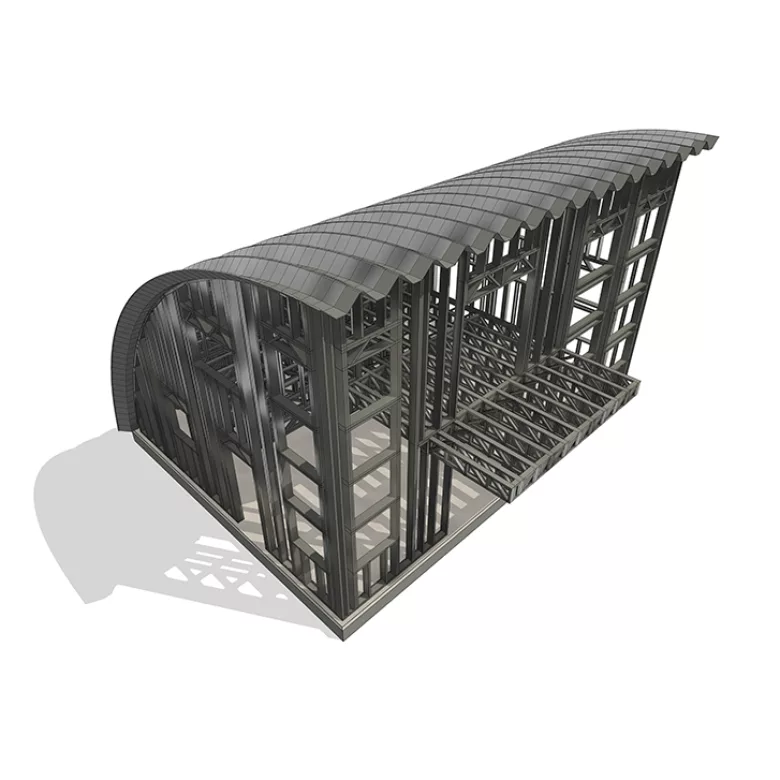

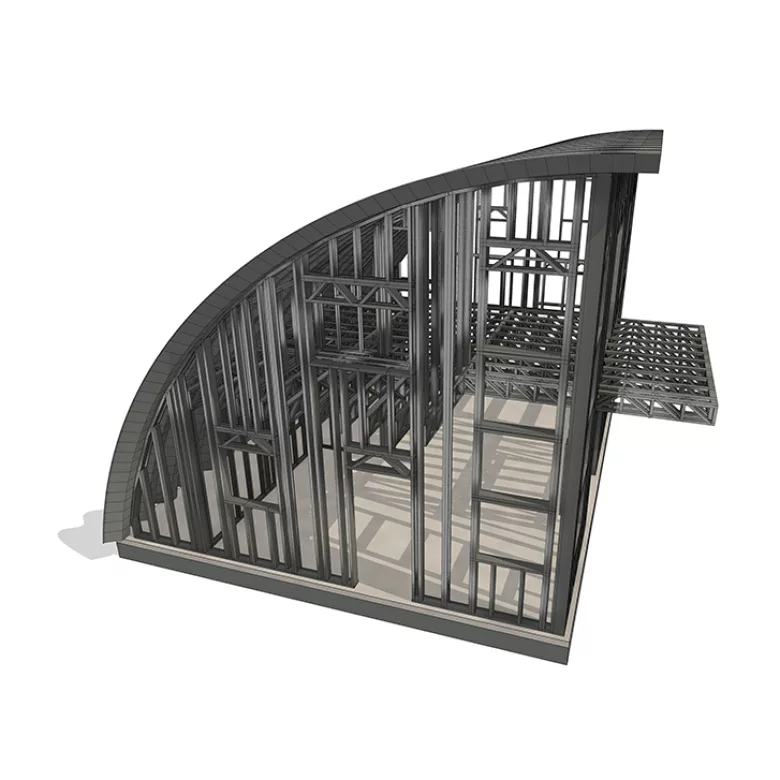

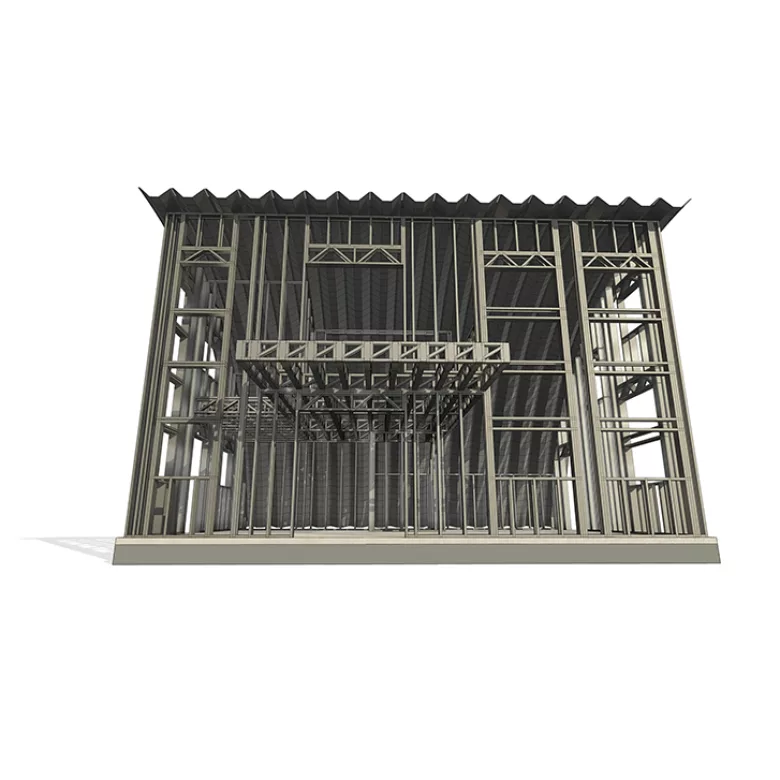

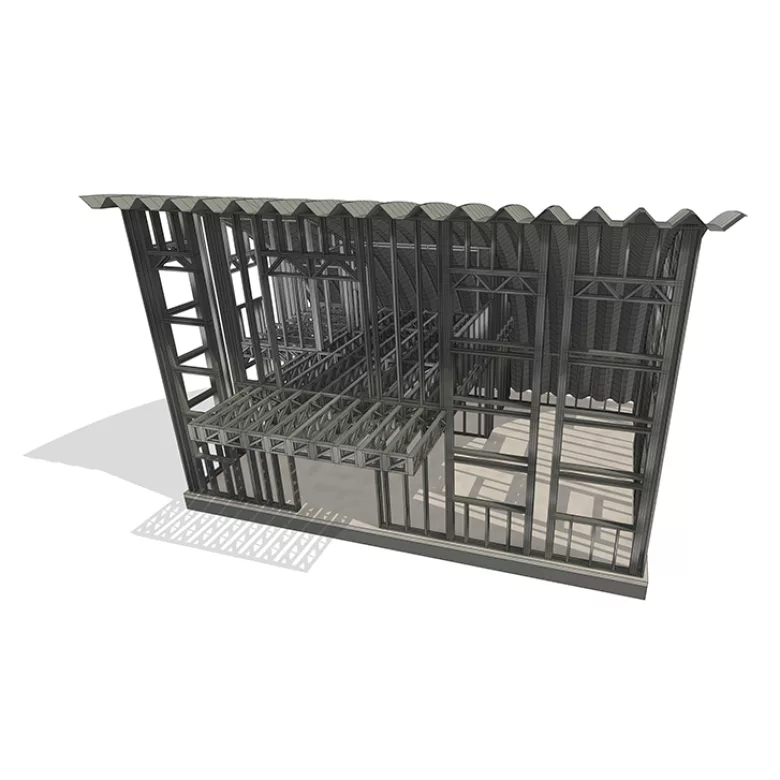

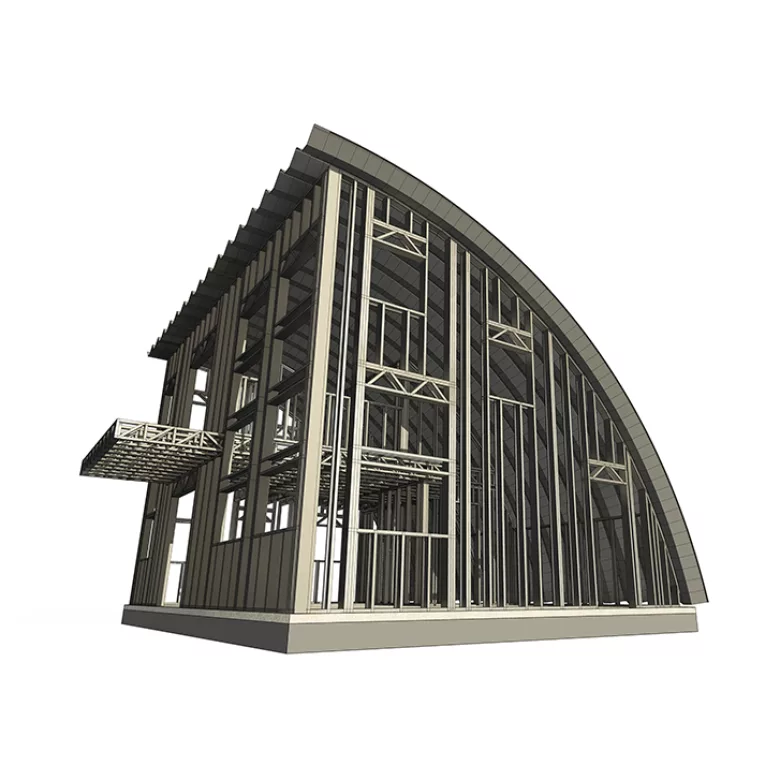

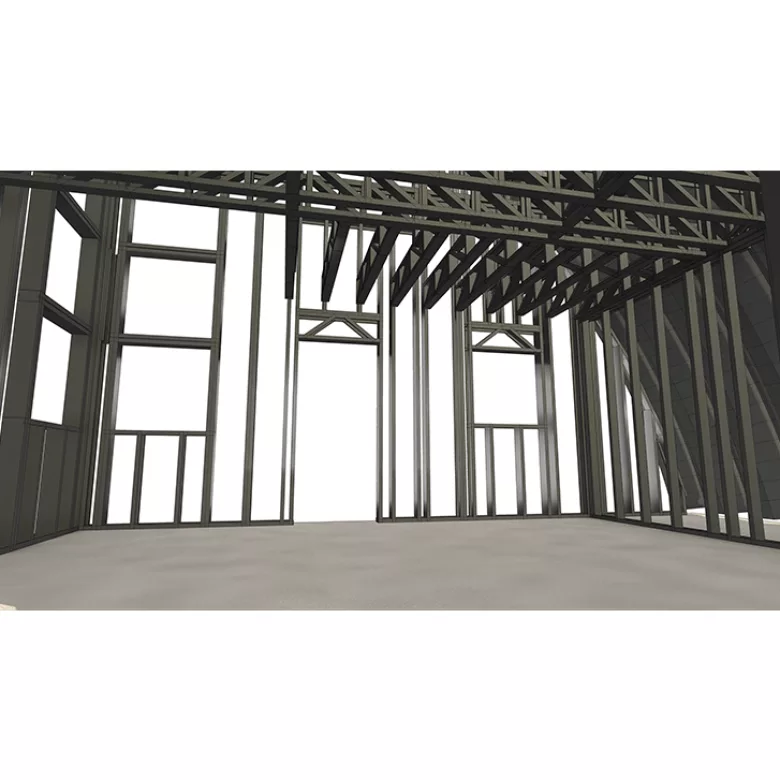

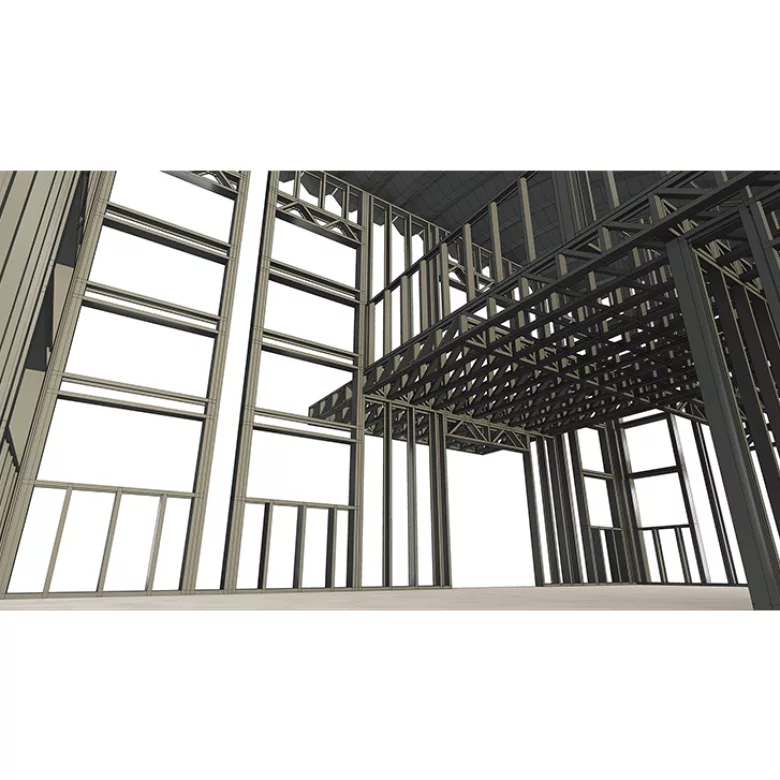

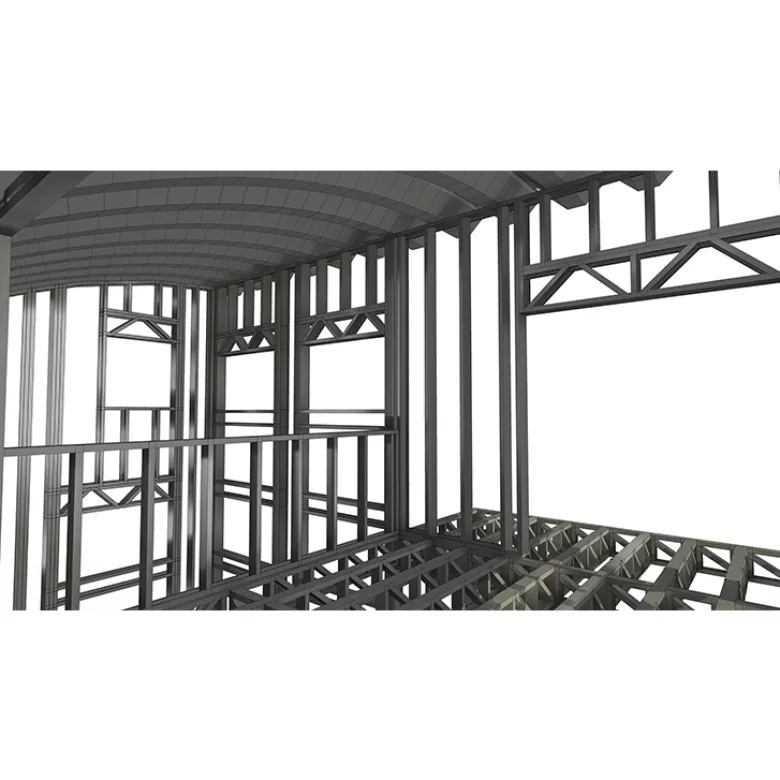

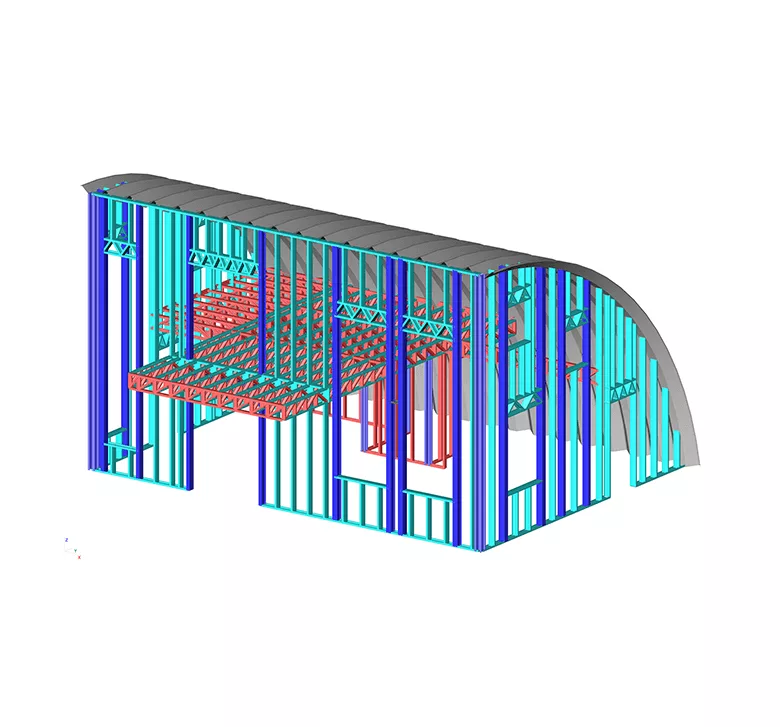

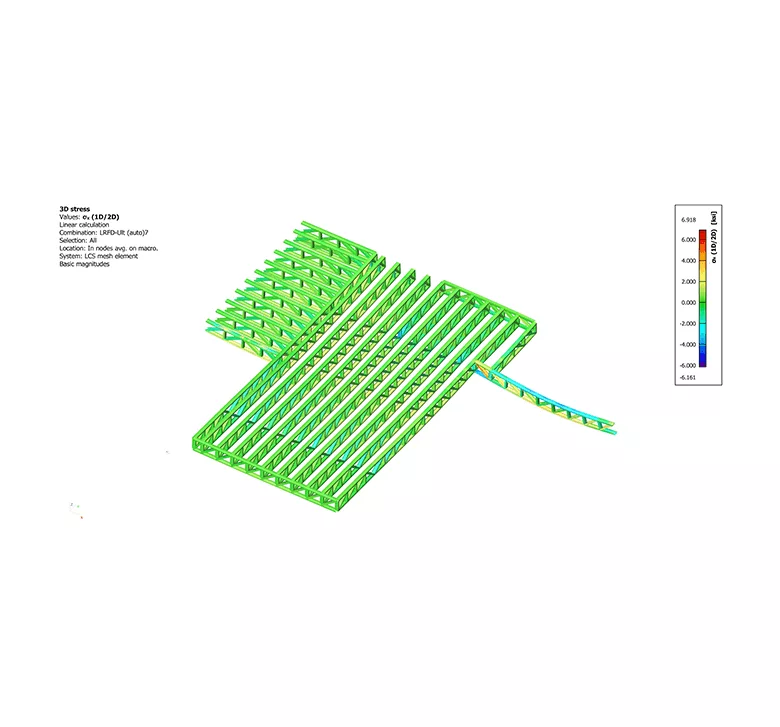

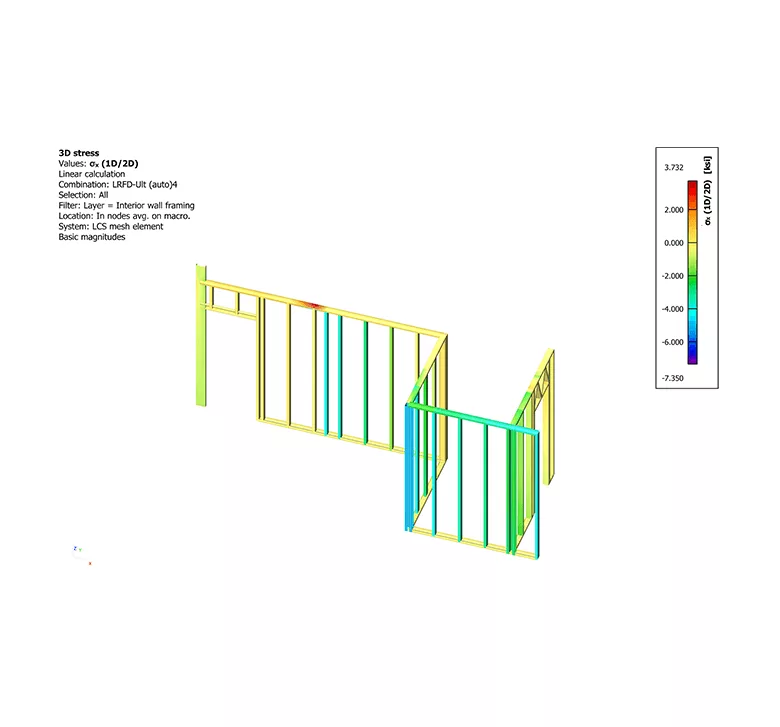

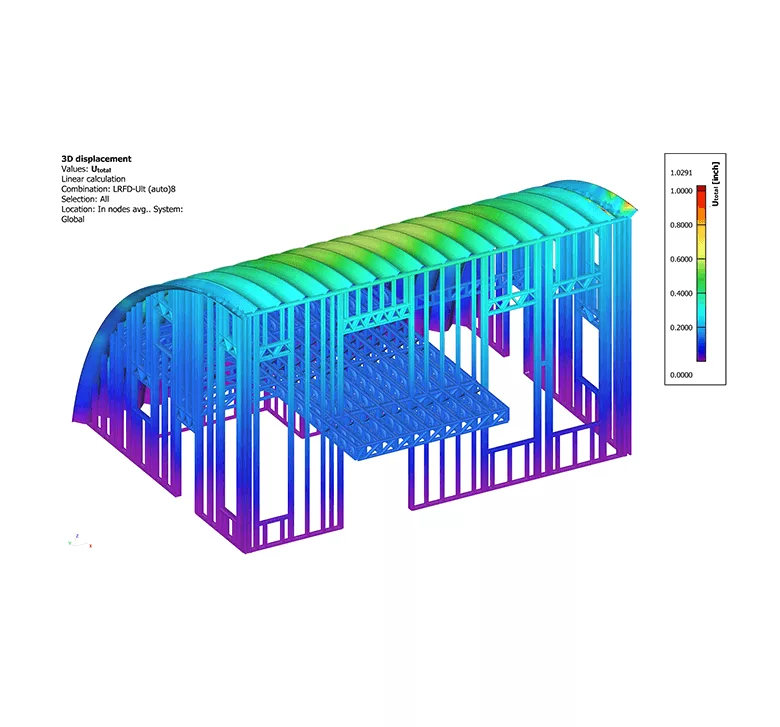

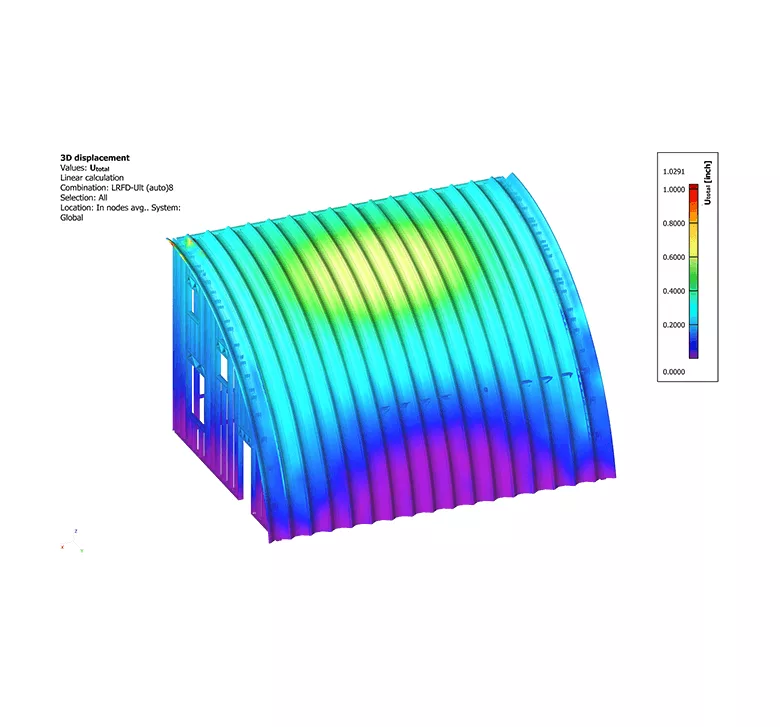

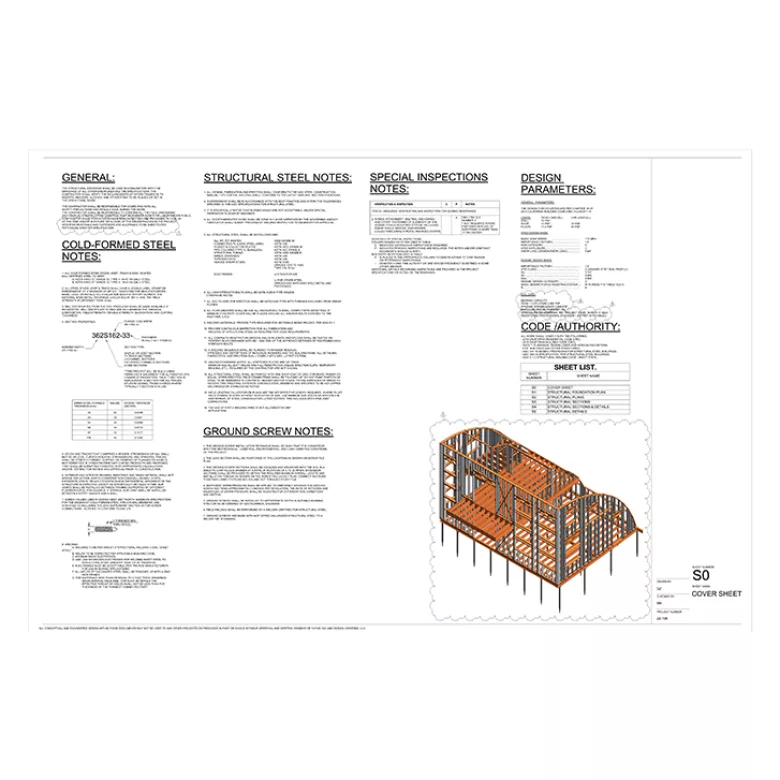

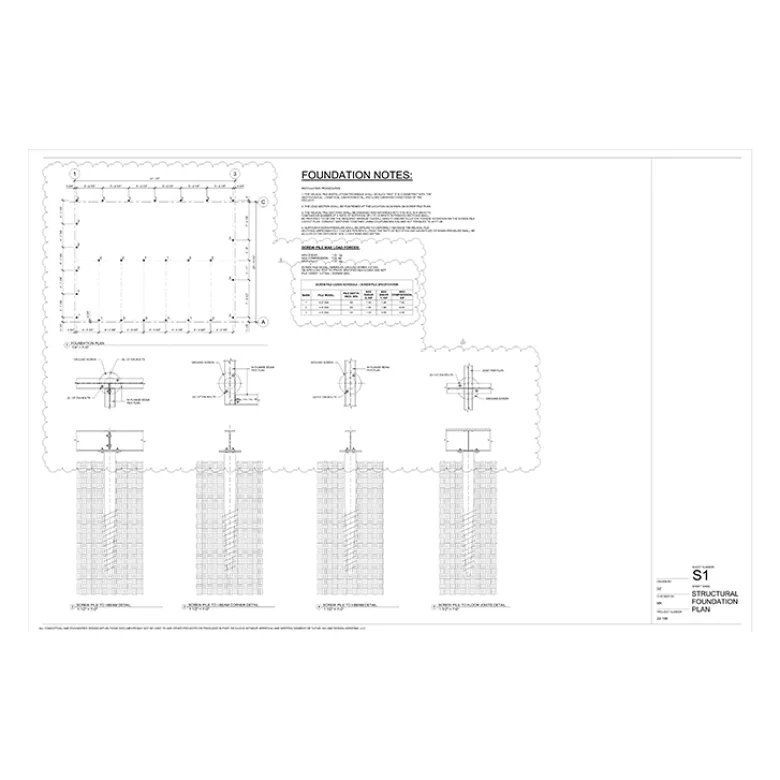

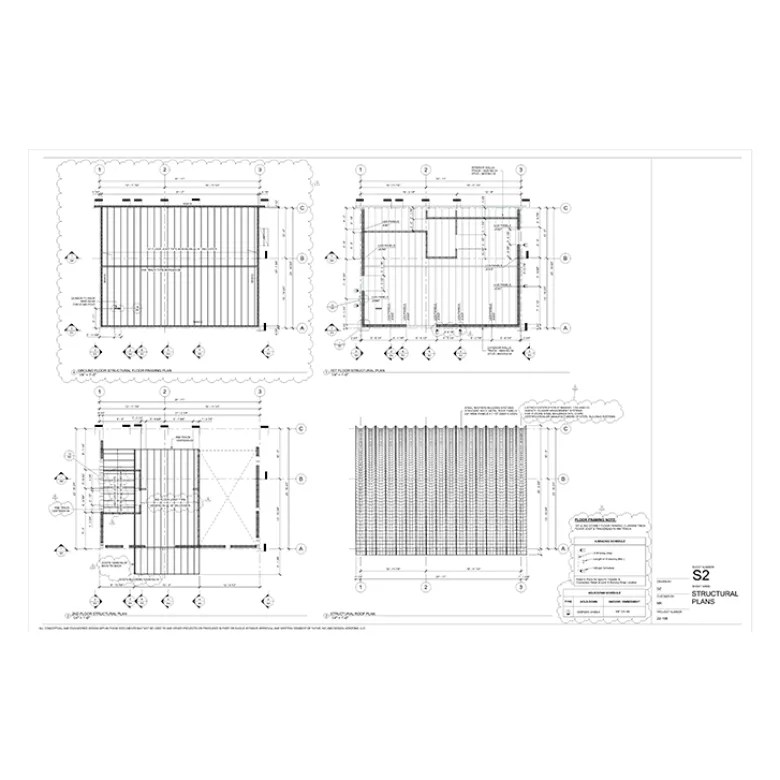

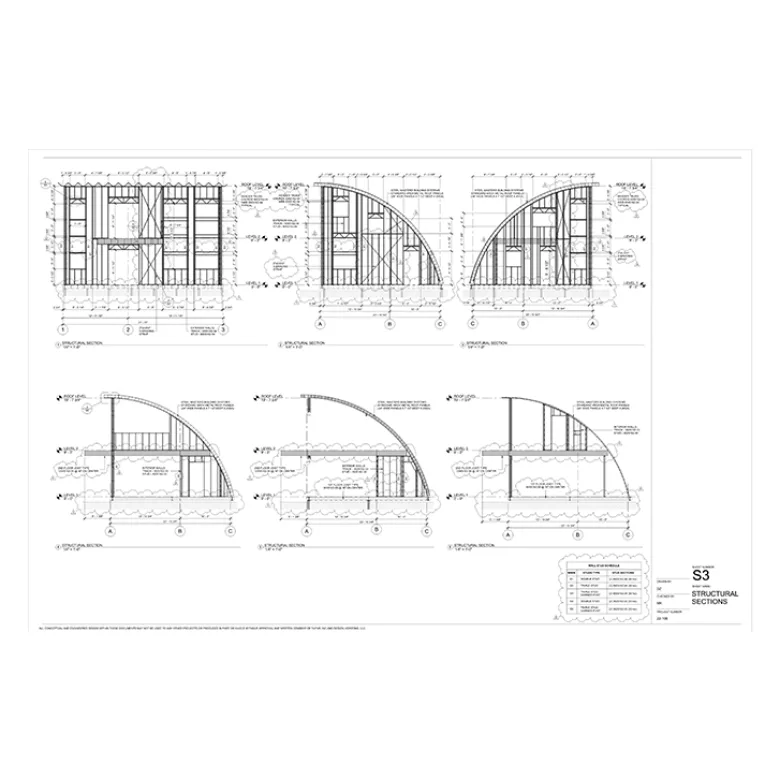

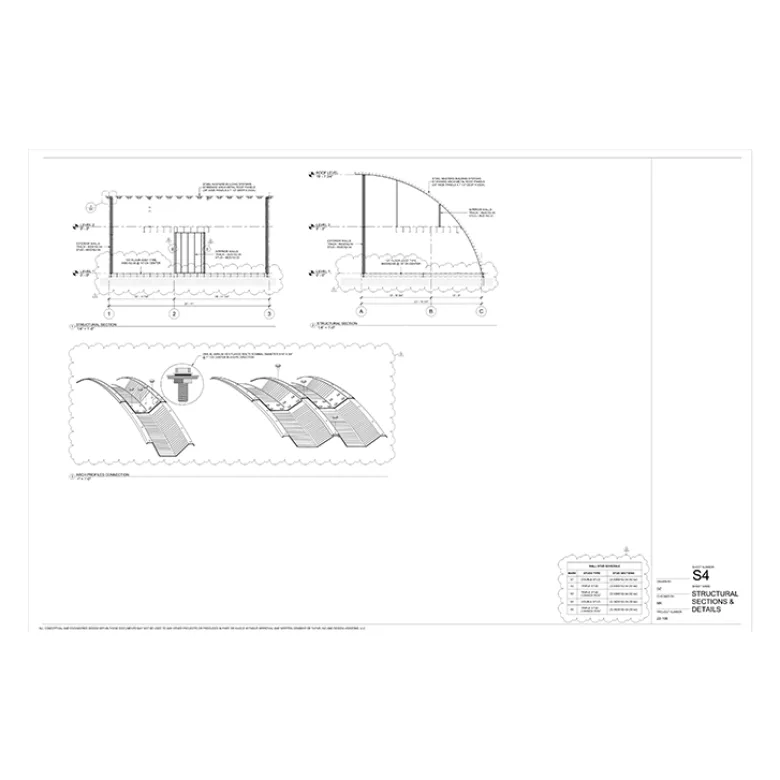

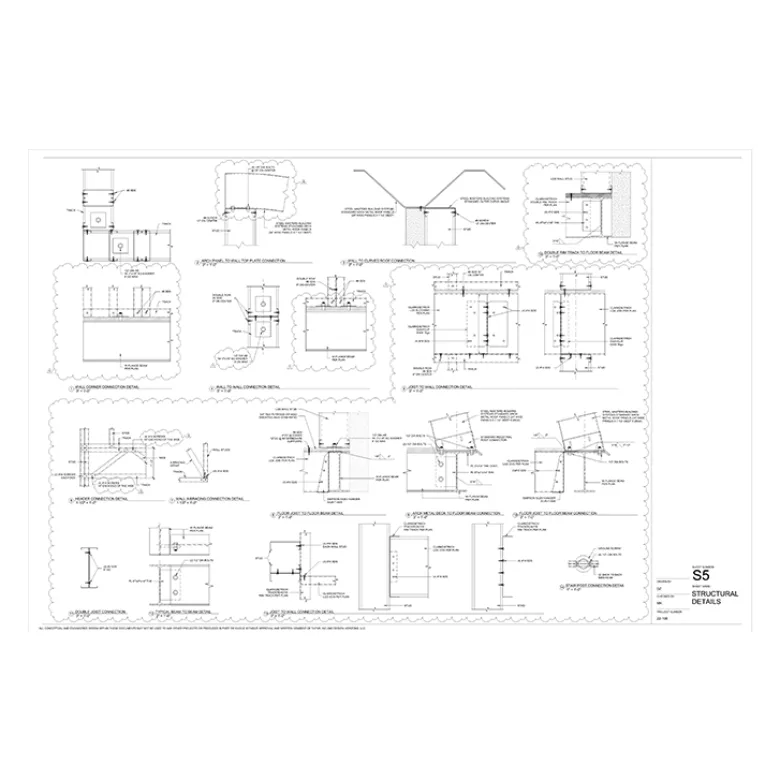

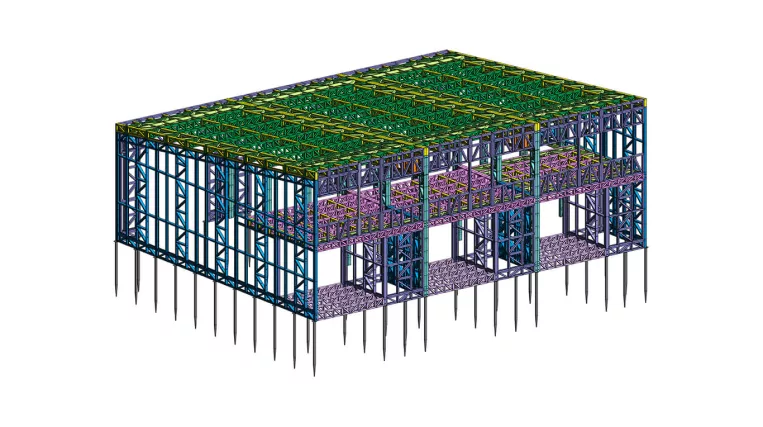

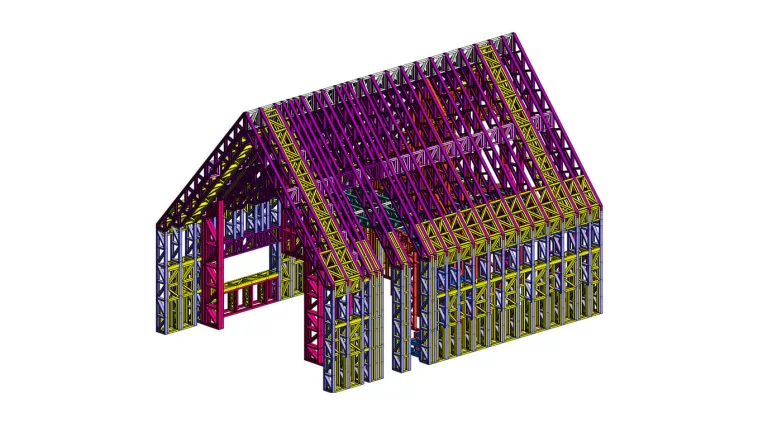

This project involves a two-story residential house distinctively characterized by its Quonset hut roofline, a lightweight prefabricated structure made of corrugated galvanized steel with a semi-cylindrical cross-section. The exterior and interior walls, as well as the first floor, are constructed using LGS framing.

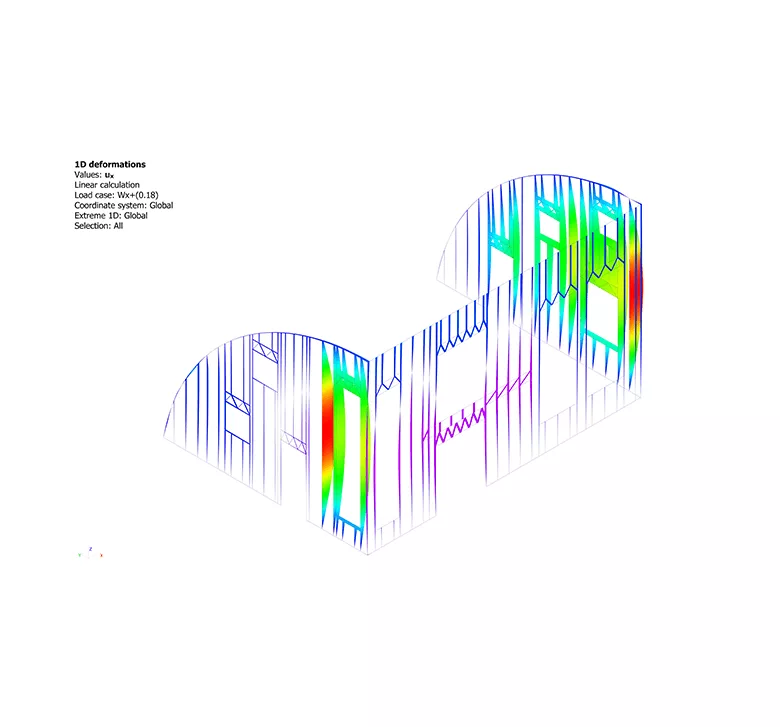

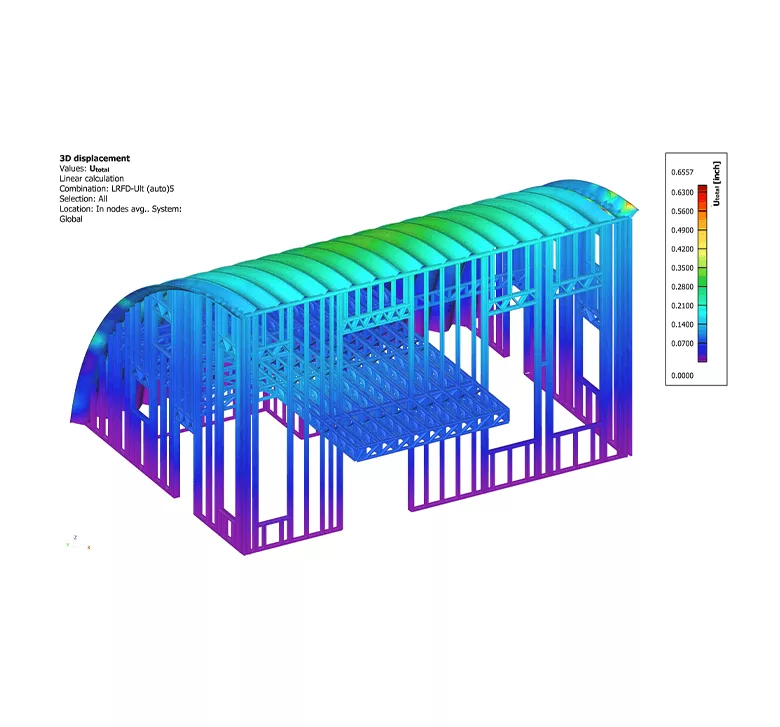

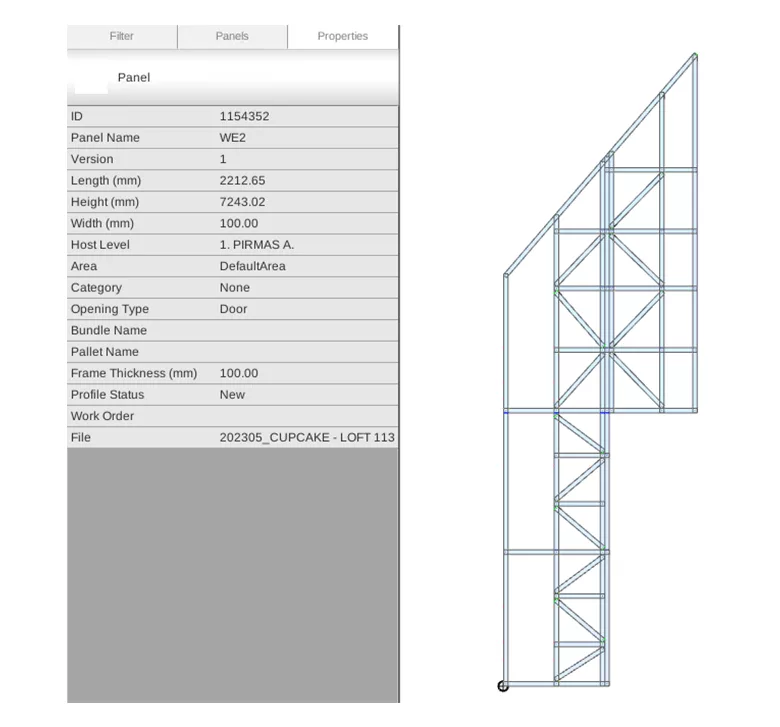

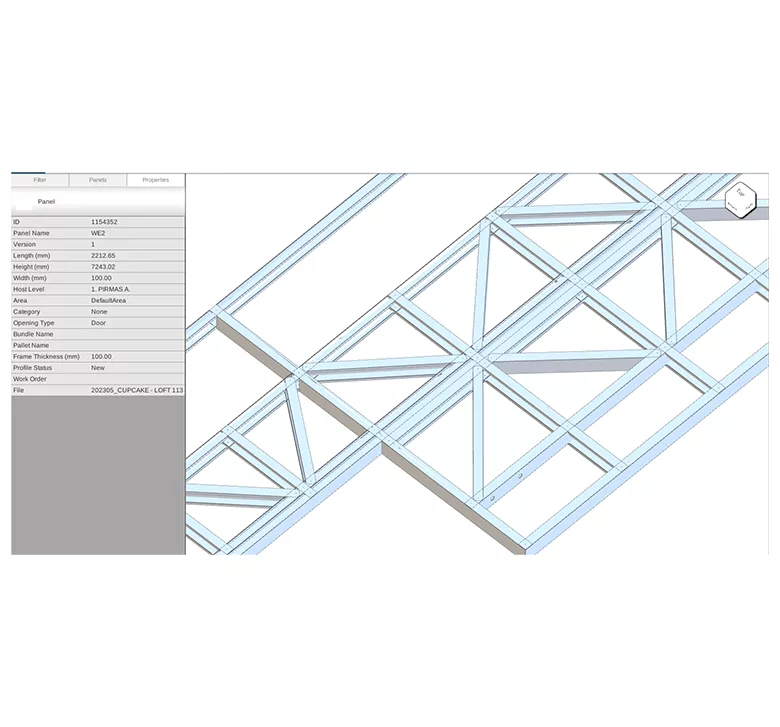

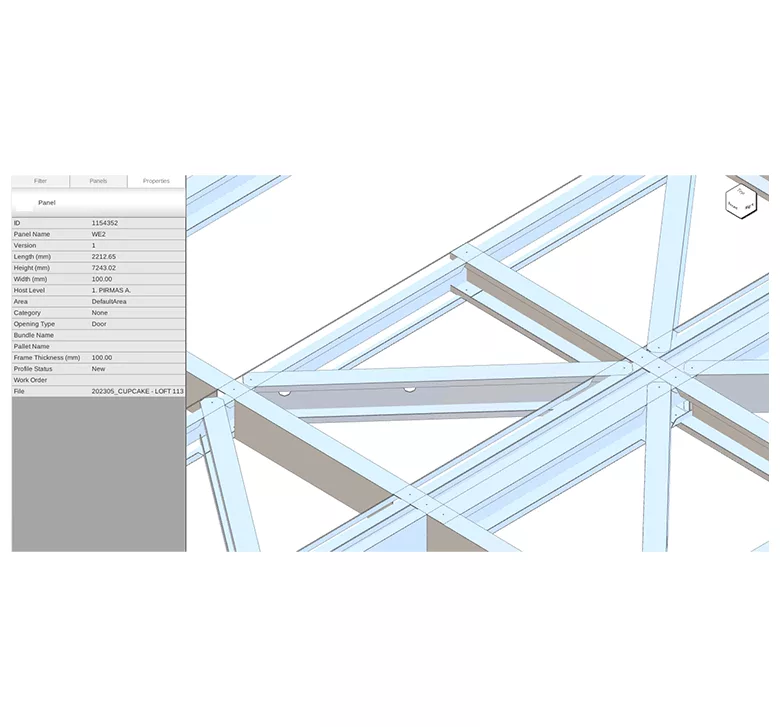

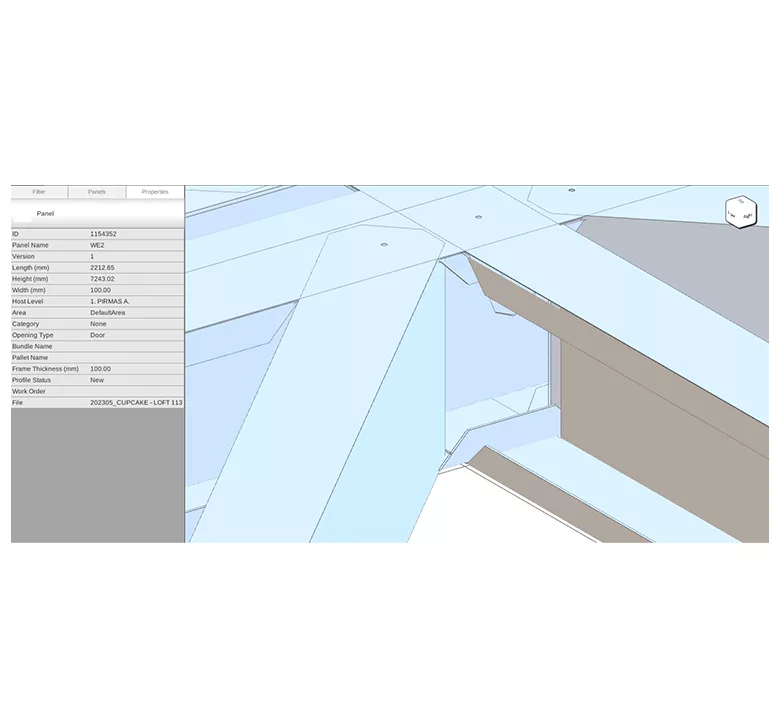

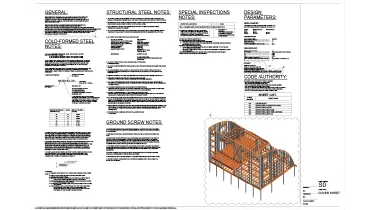

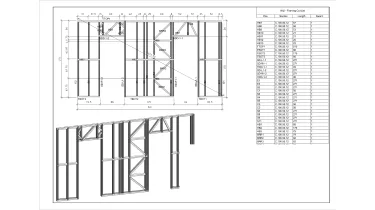

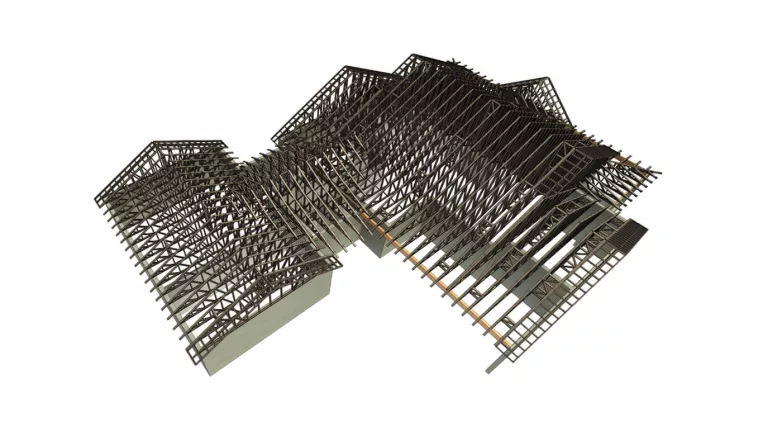

ORIGIN was commissioned to create structural construction drawings and conduct a structural analysis of the LGS framing and foundation of the building. Given that the project’s builder owns a Framecad rollformer, the production of CNC files for LGS panels was also required.

Input: A set of architectural drawings.

Project Deliverables:

- Structural drawing set;

- Structural analysis report;

- LGS shop drawings;

- Framecad CNC files for LGS panel production.