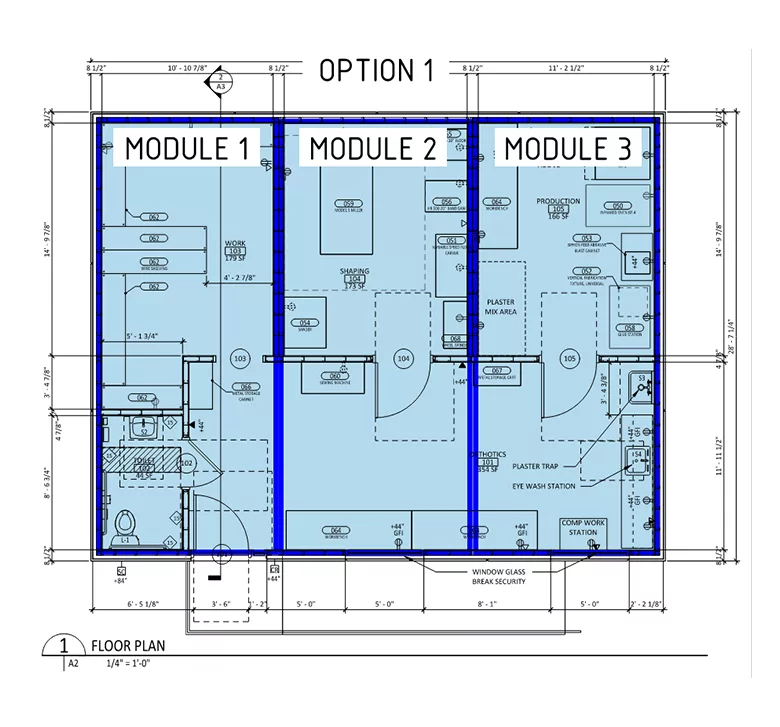

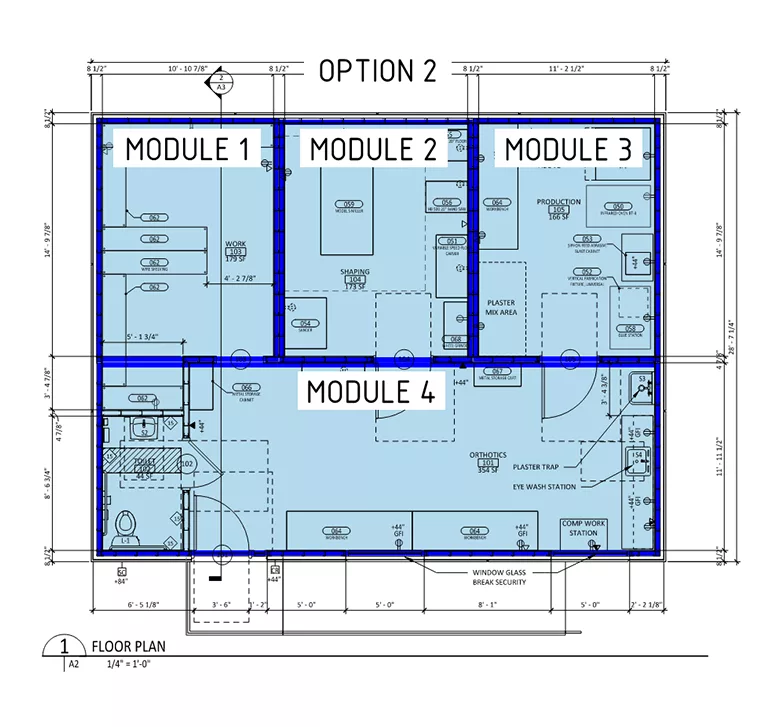

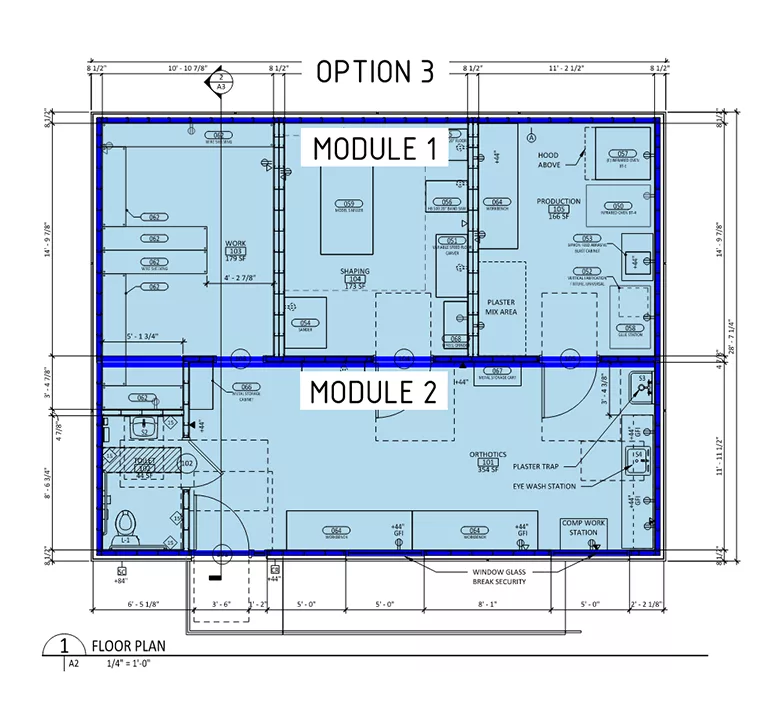

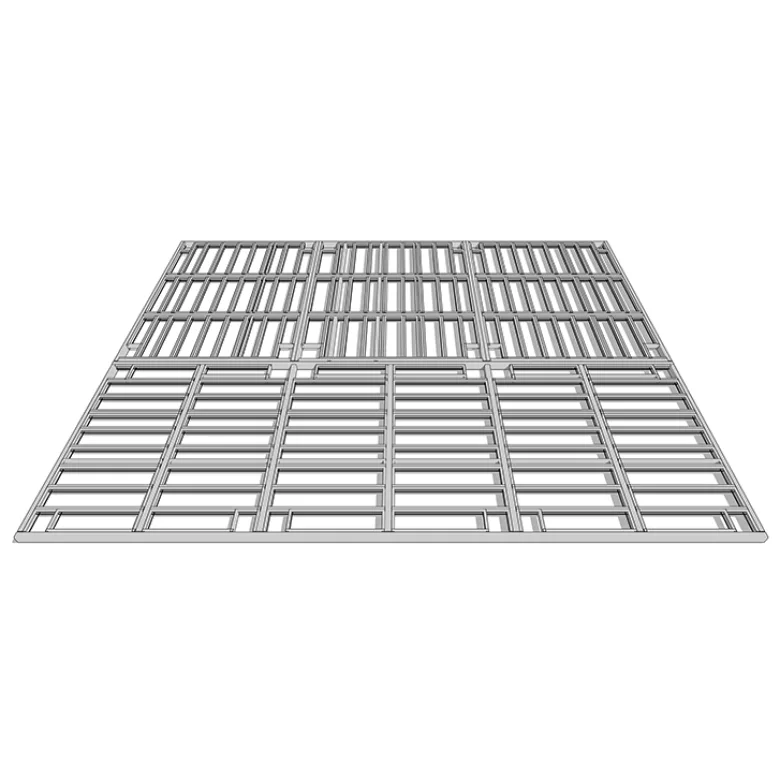

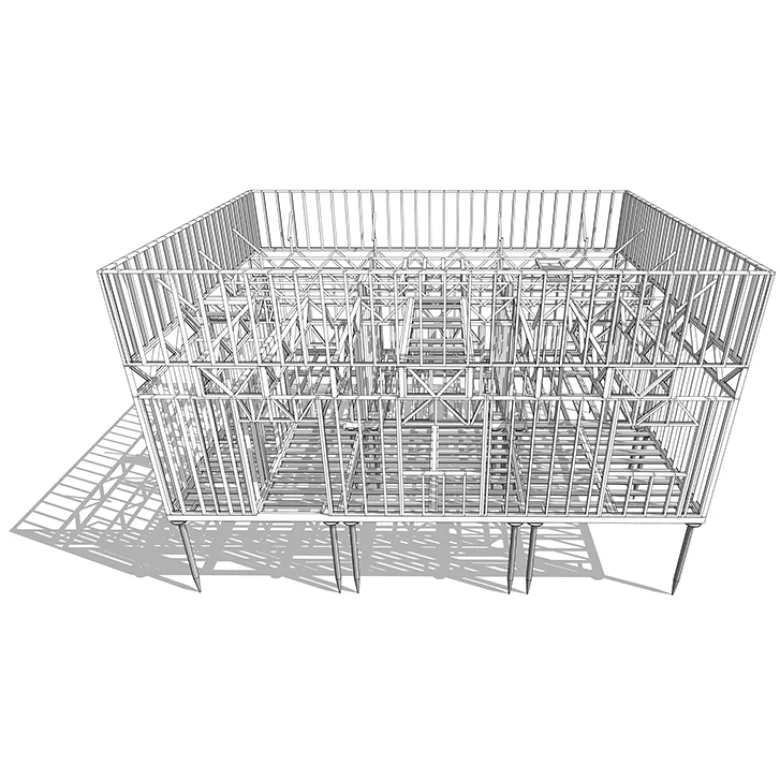

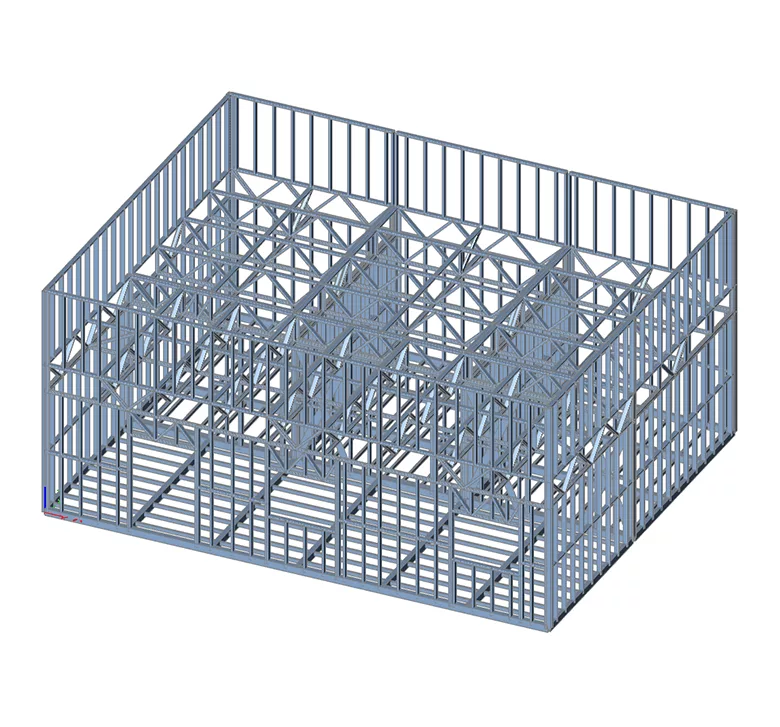

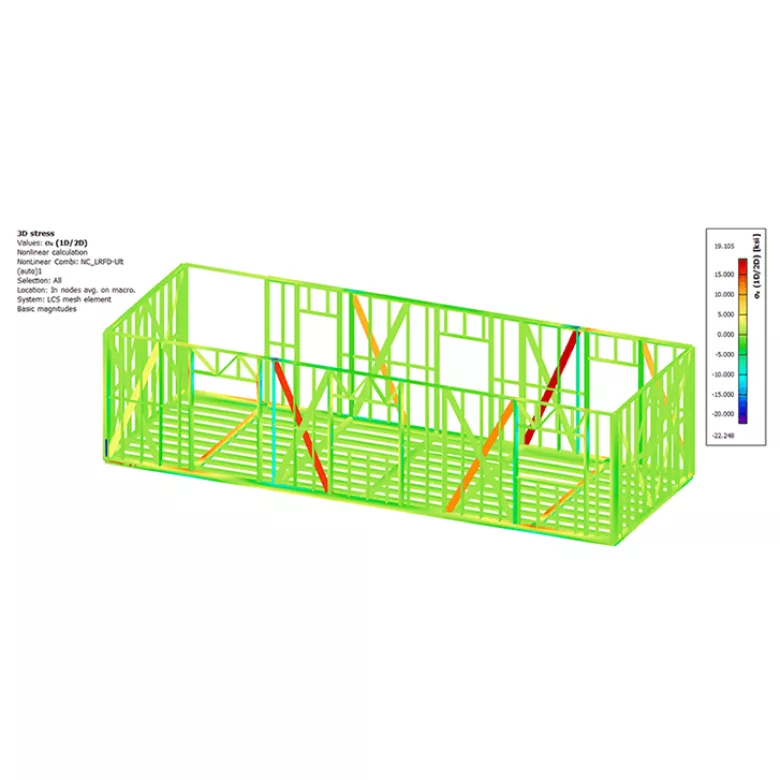

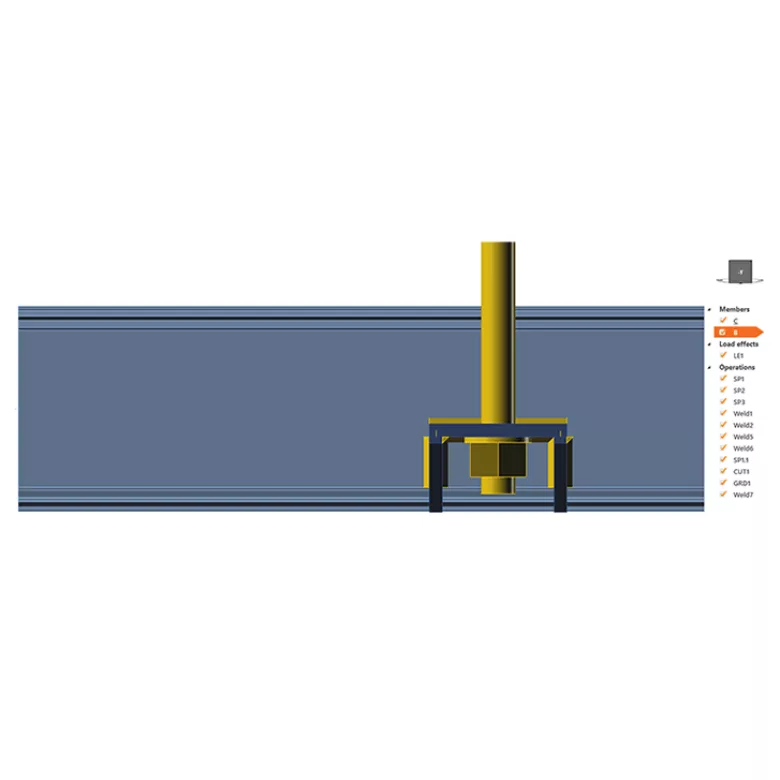

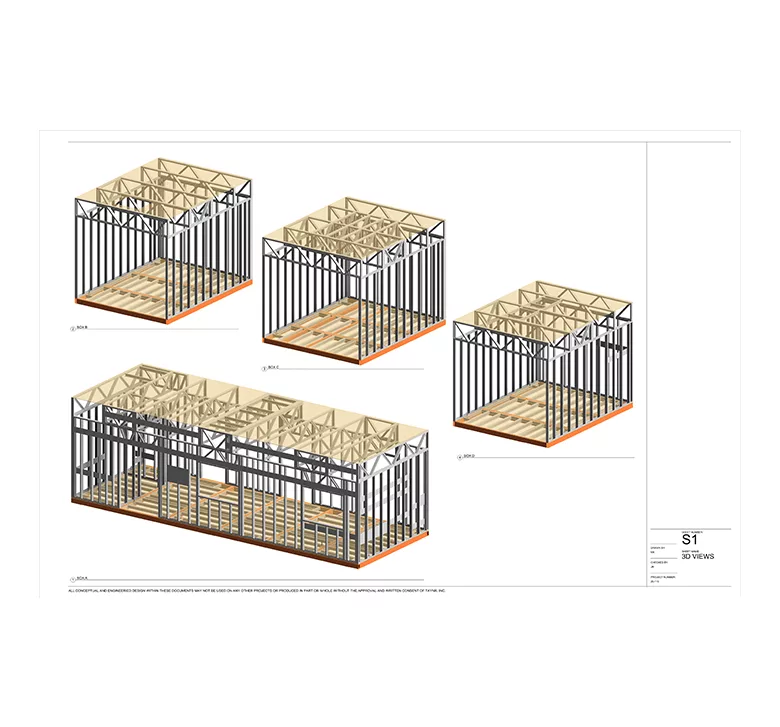

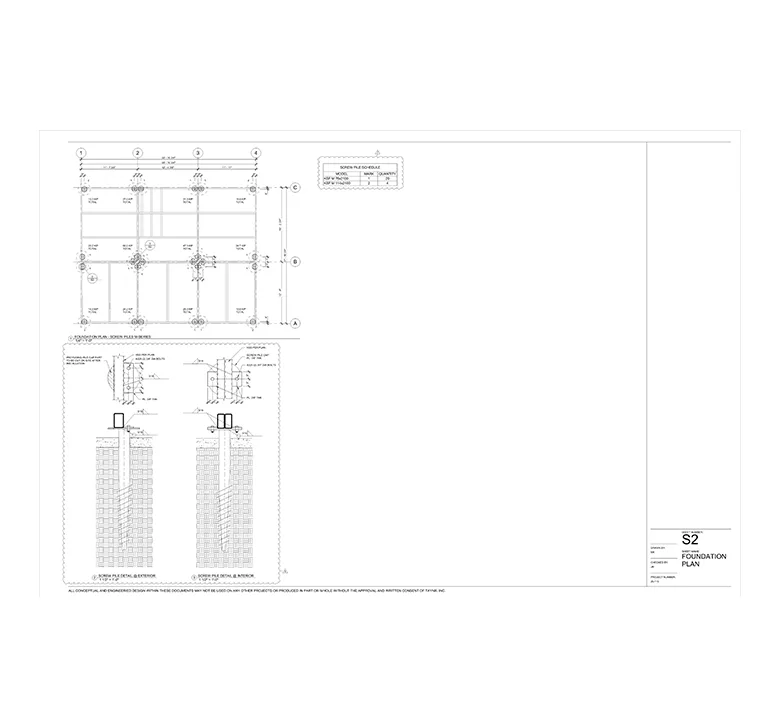

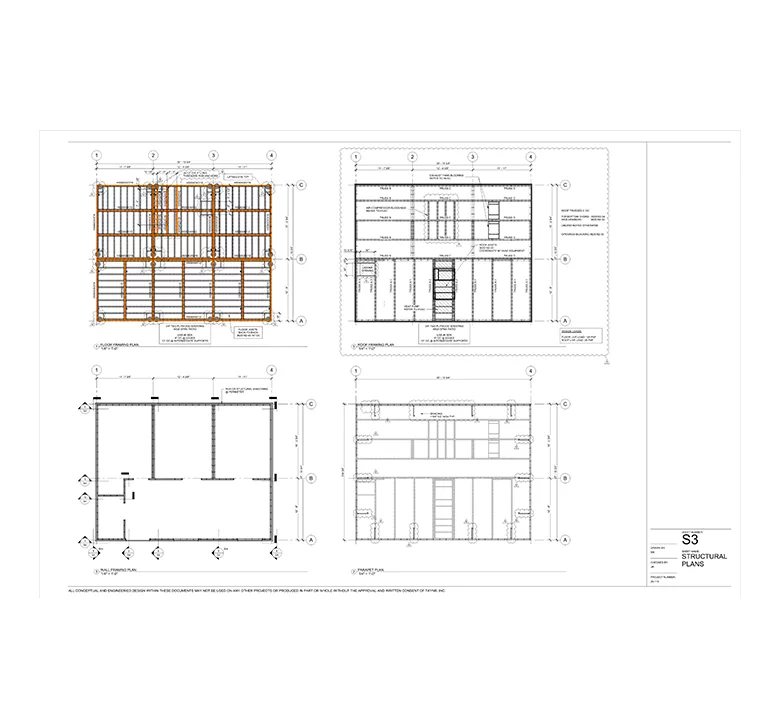

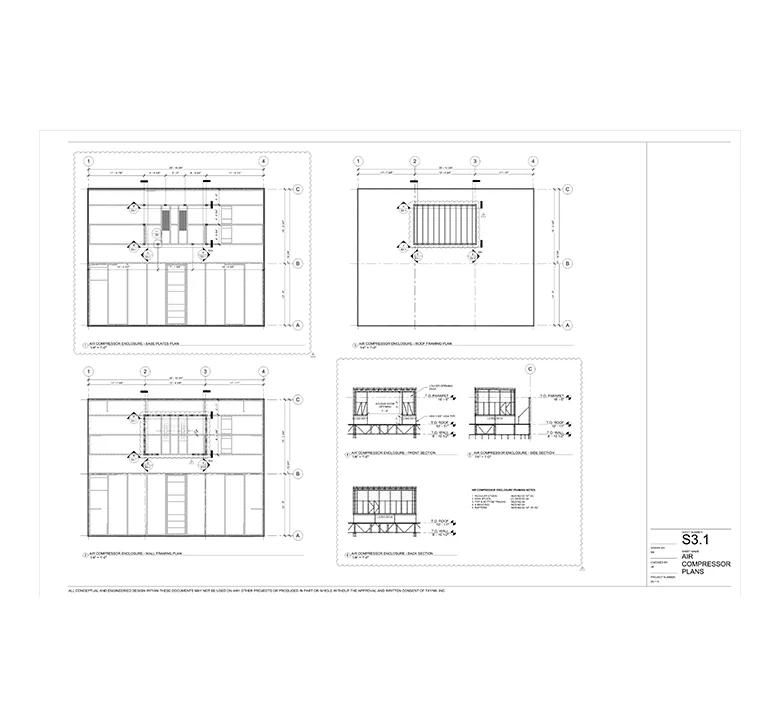

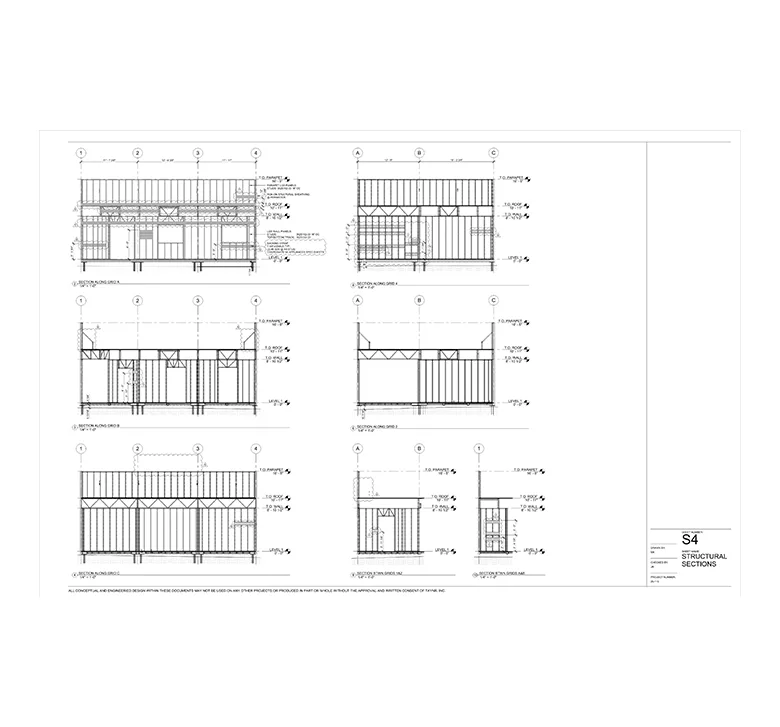

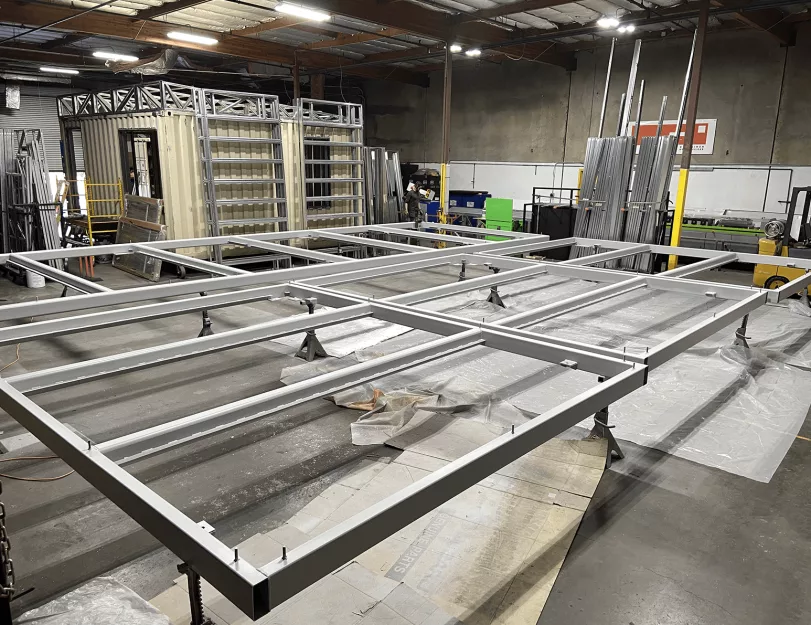

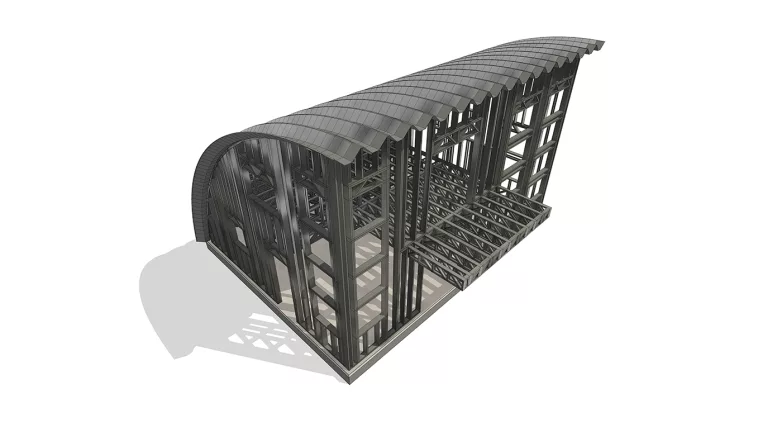

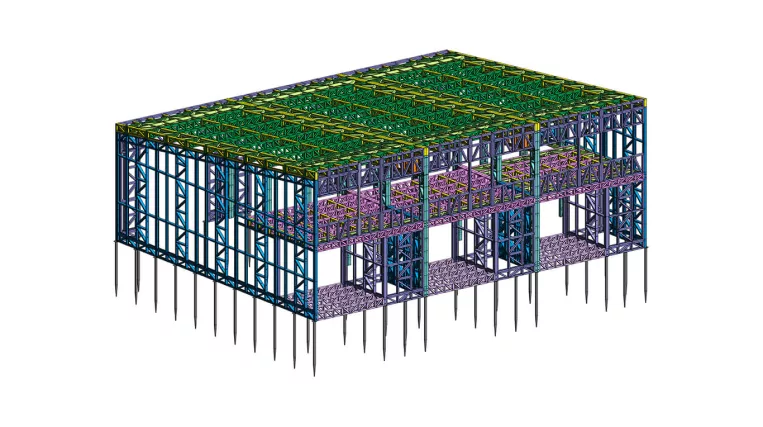

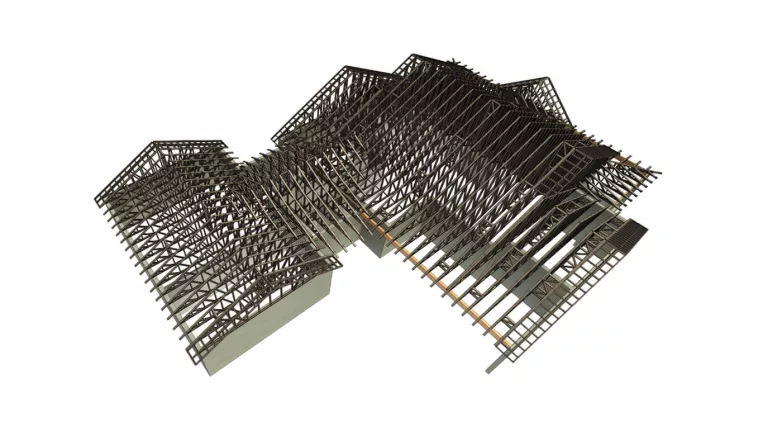

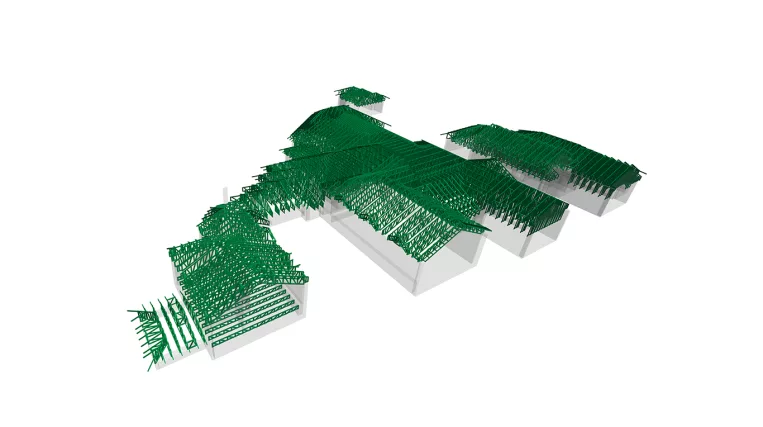

This project is a workshop for a medical hospital. A notable feature of this building is that it is prefabricated. Comprising four modules constructed off-site and delivered to the location, this construction method was chosen by the owner to reduce noise levels near the hospital. Additionally, geoscrews were selected as the foundation method to minimize on-site construction time. The use of geoscrews enables the completion of foundation work within a day.

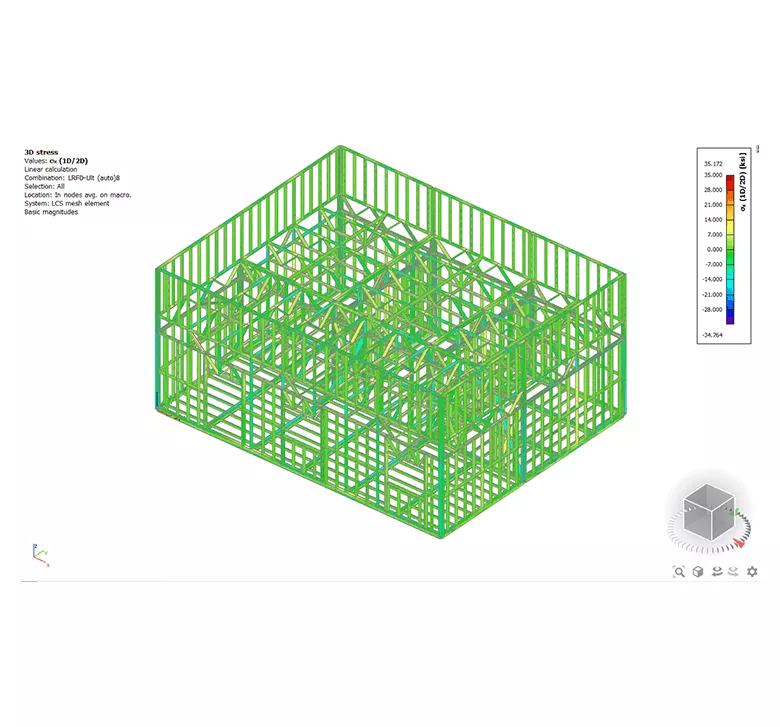

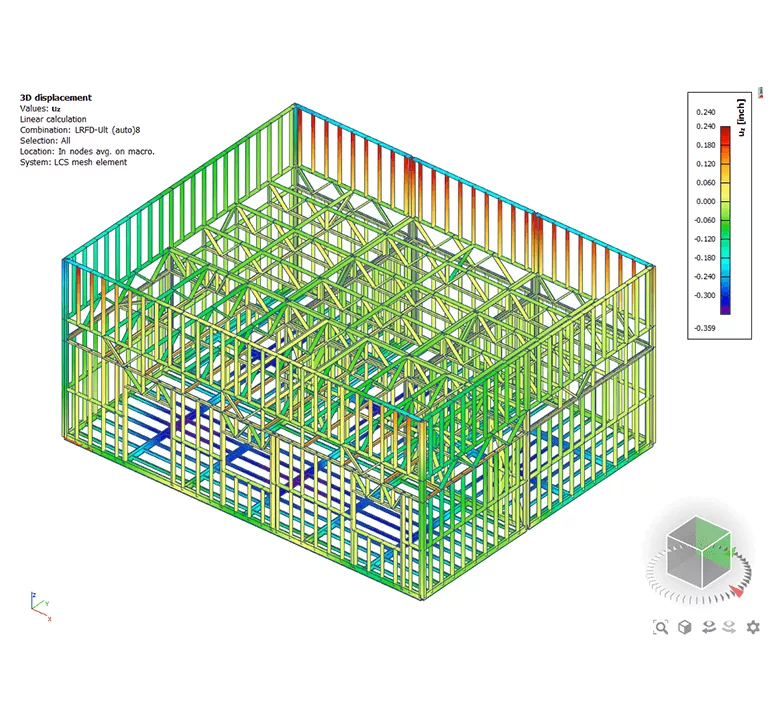

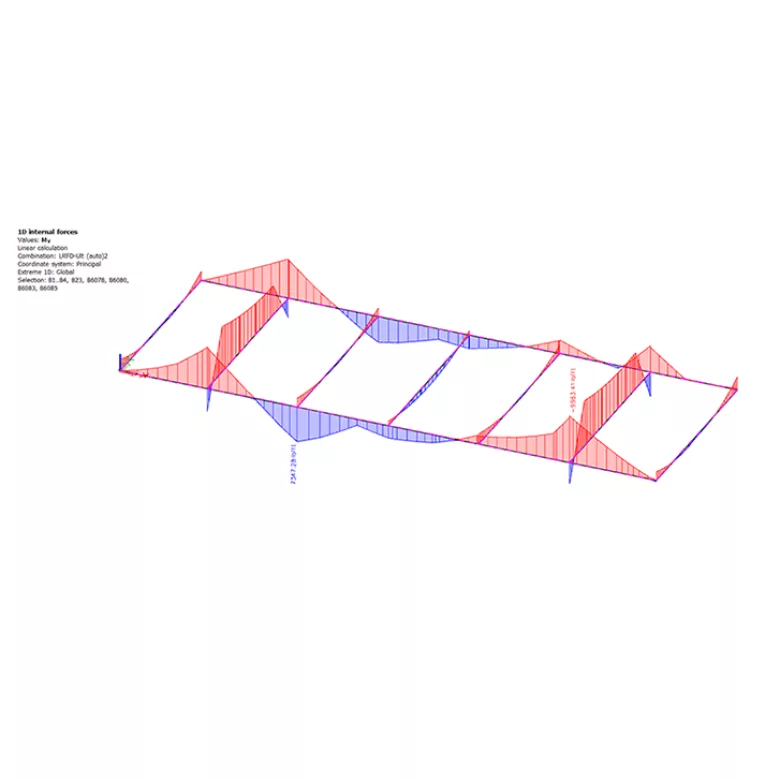

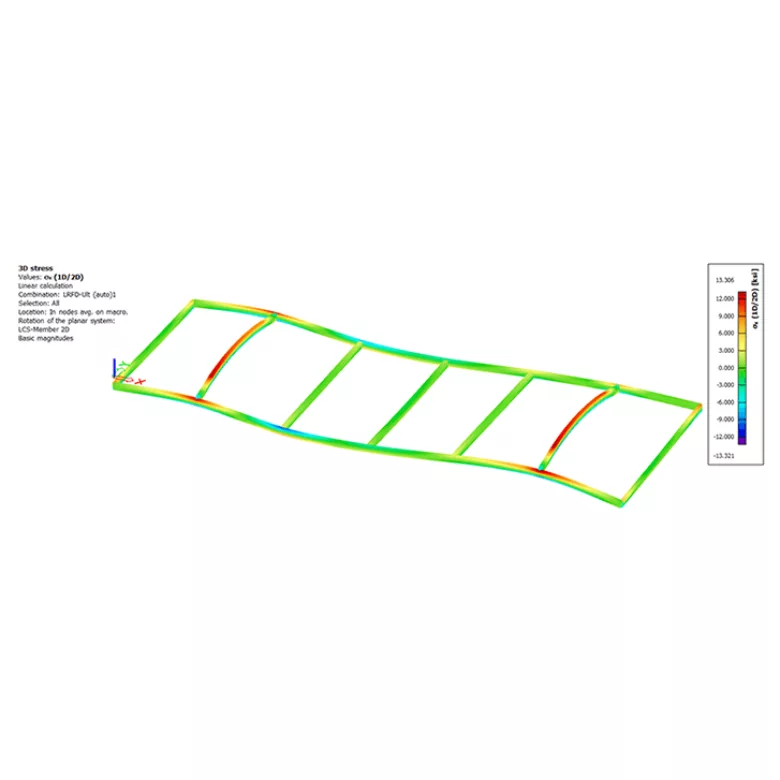

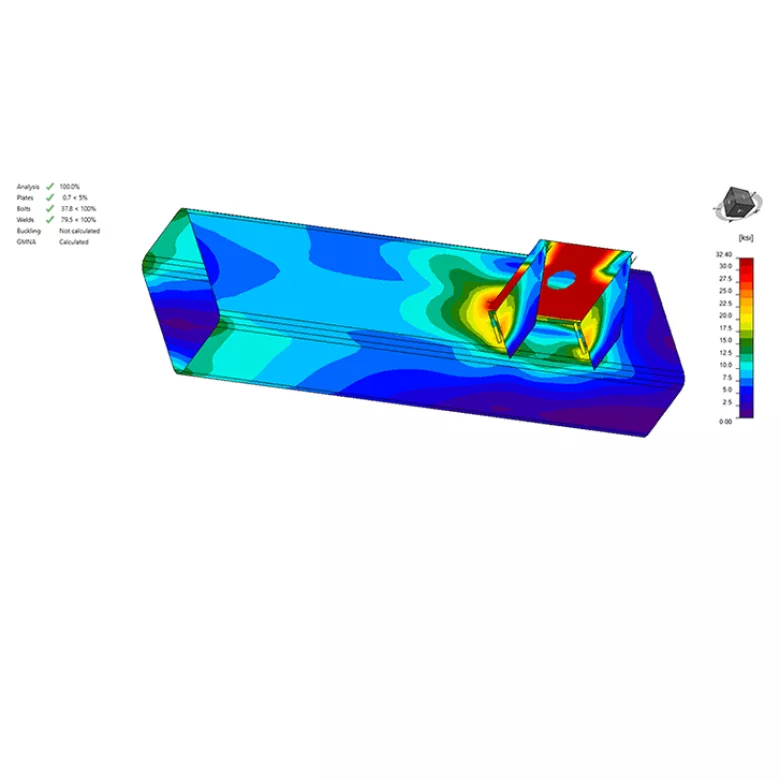

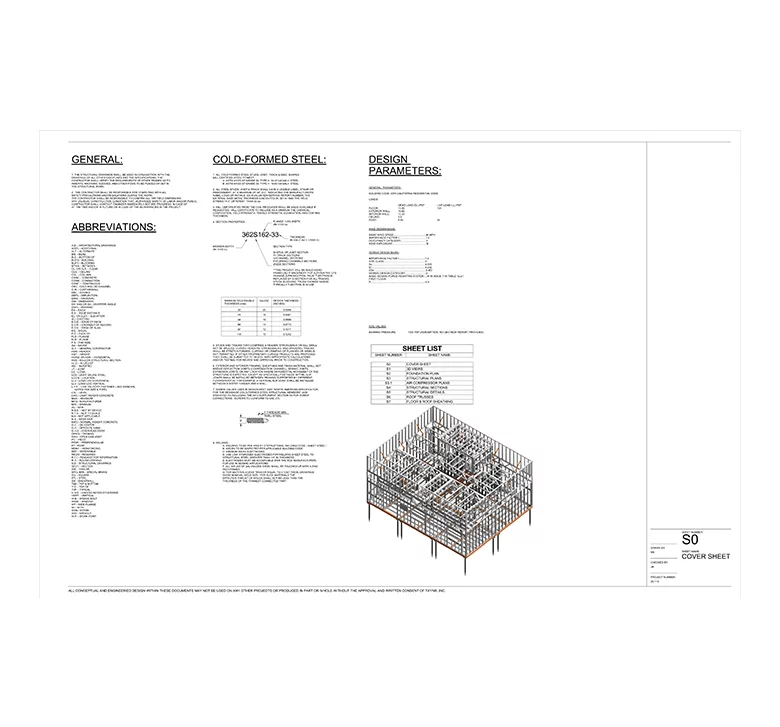

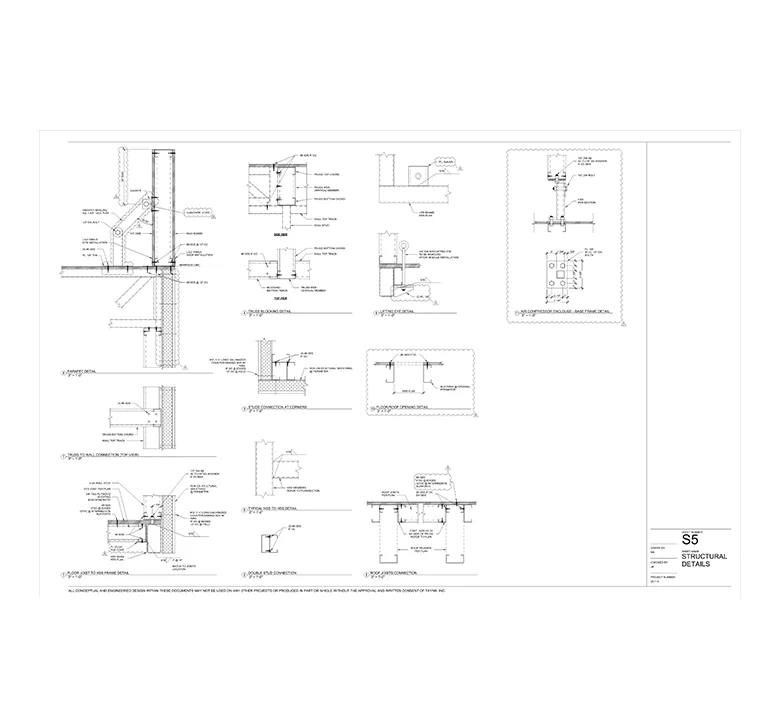

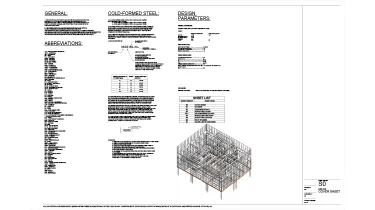

ORIGIN has been commissioned to develop structural construction drawings and perform structural analysis of the LGS framing and foundation of the building.

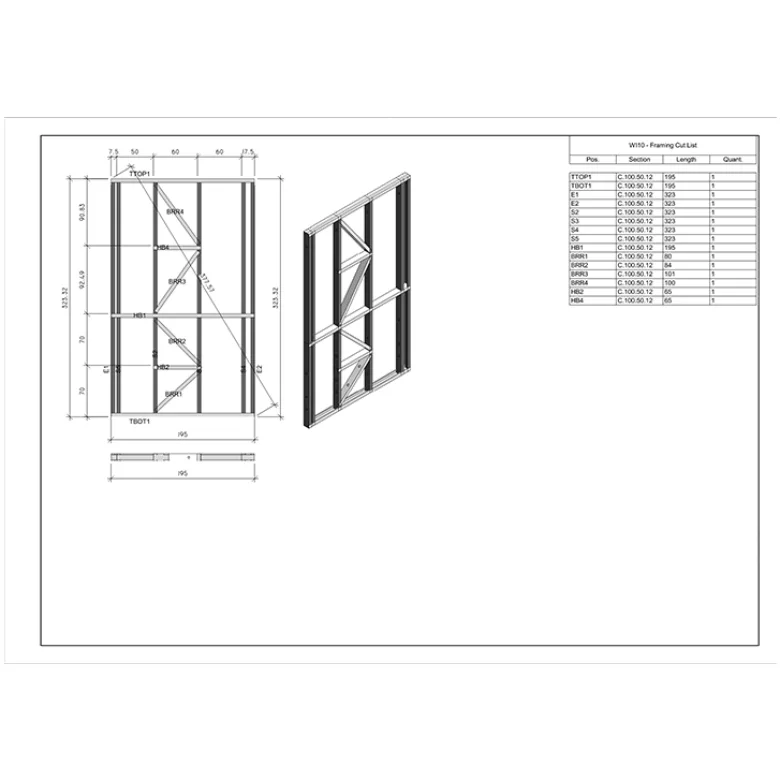

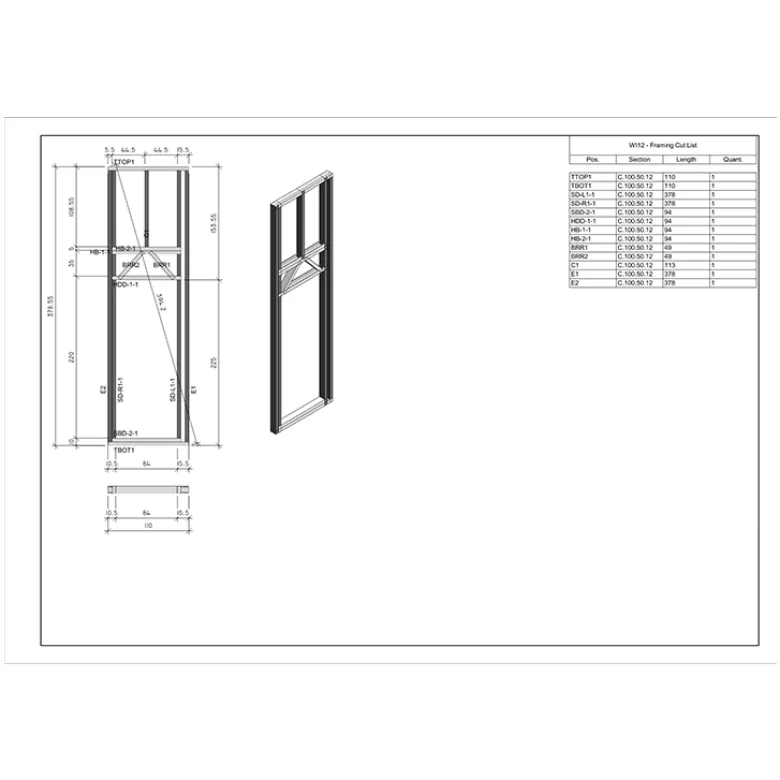

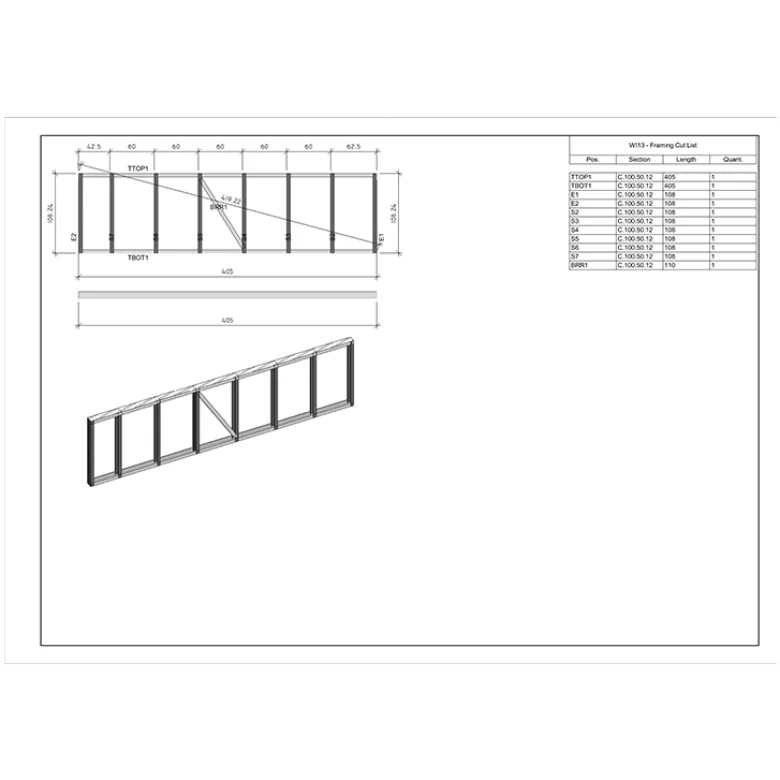

Since the project’s builder owns a Framecad rollformer, CNC files for LGS panel production were also required.

Input: Architectural drawing set.

Project Deliverables:

- Structural drawing set;

- Structural analysis report;

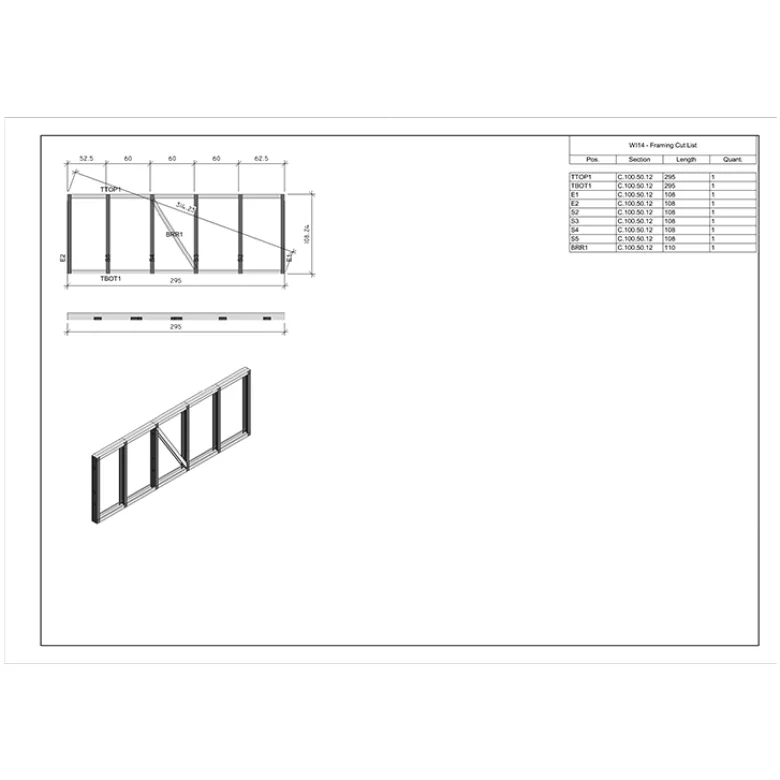

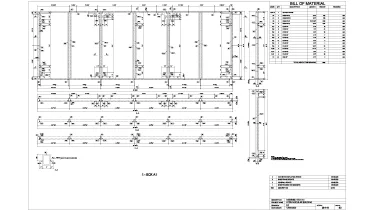

- LGS shop drawings;

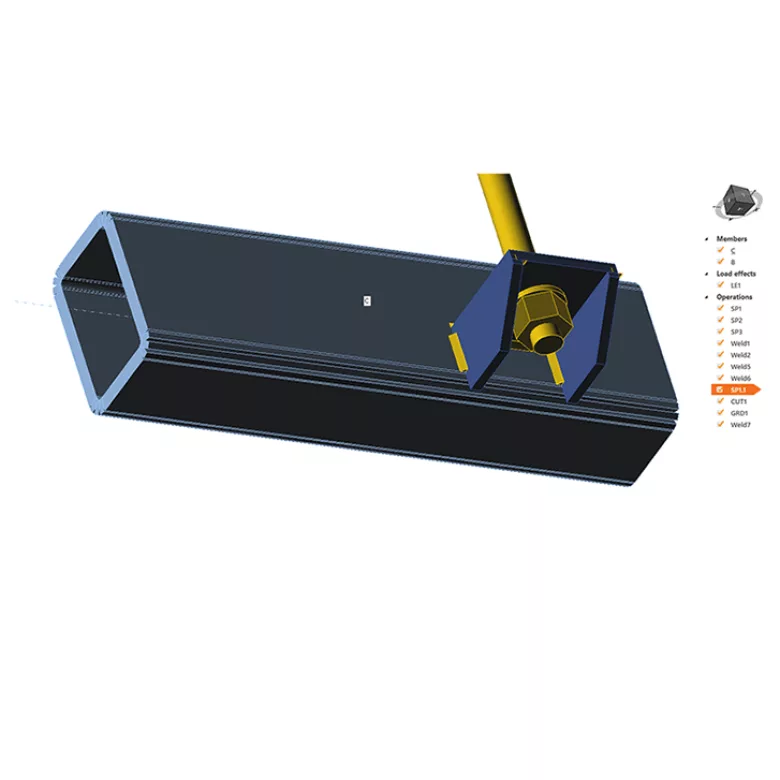

- Hot-rolled shop drawings;

- Framecad CNC files for LGS panel production.