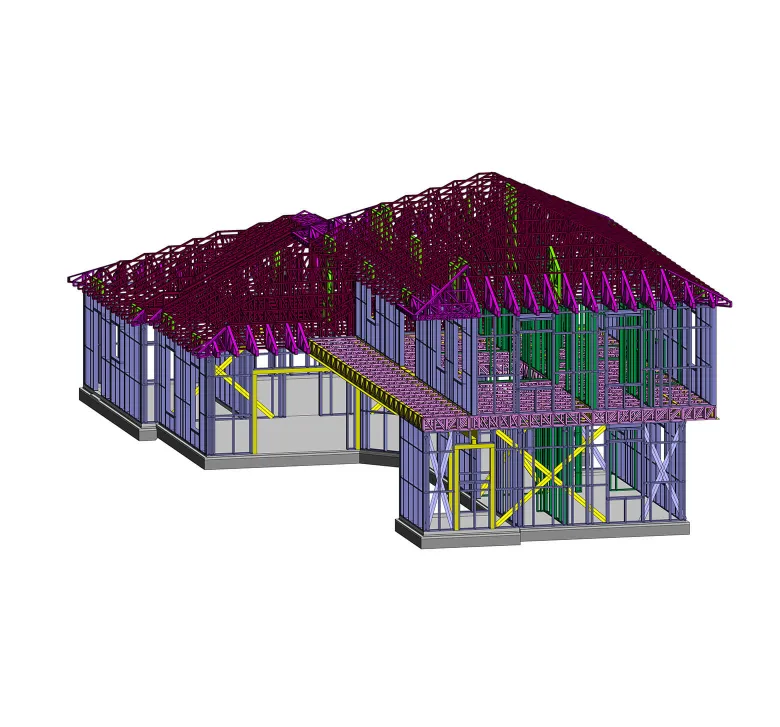

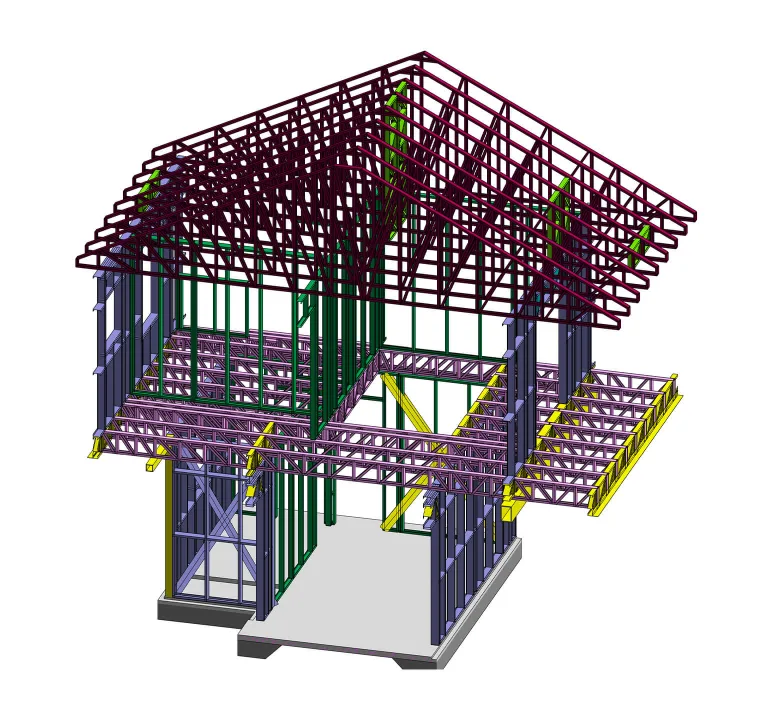

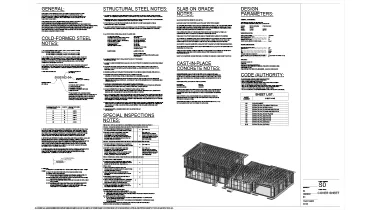

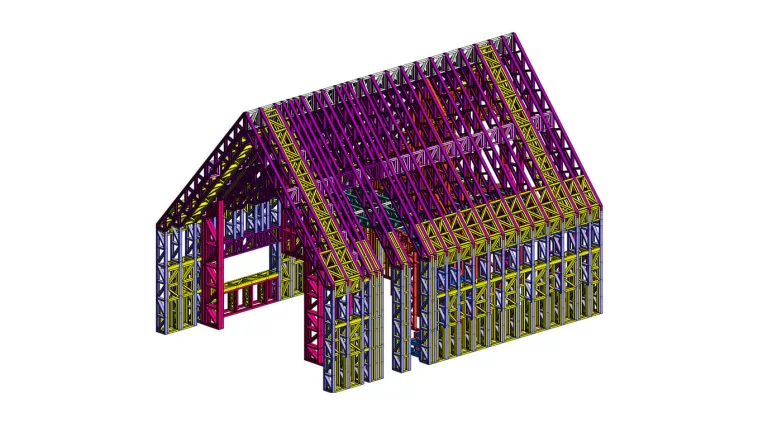

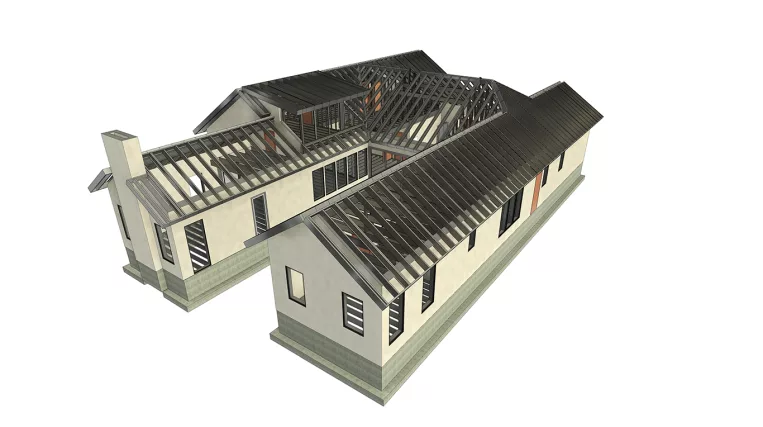

A seemingly typical two-story residential house, this project came with a big twist because of its unconventional construction approach.

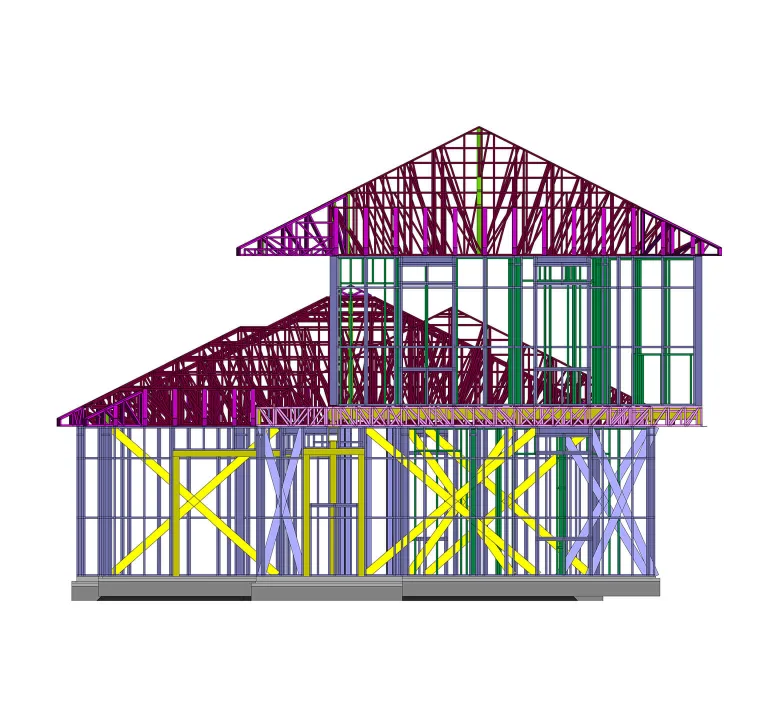

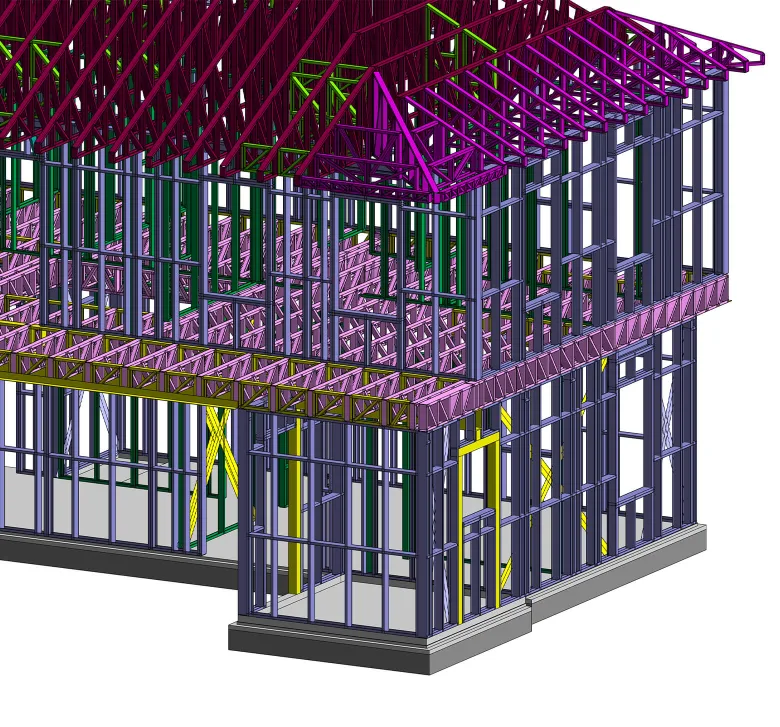

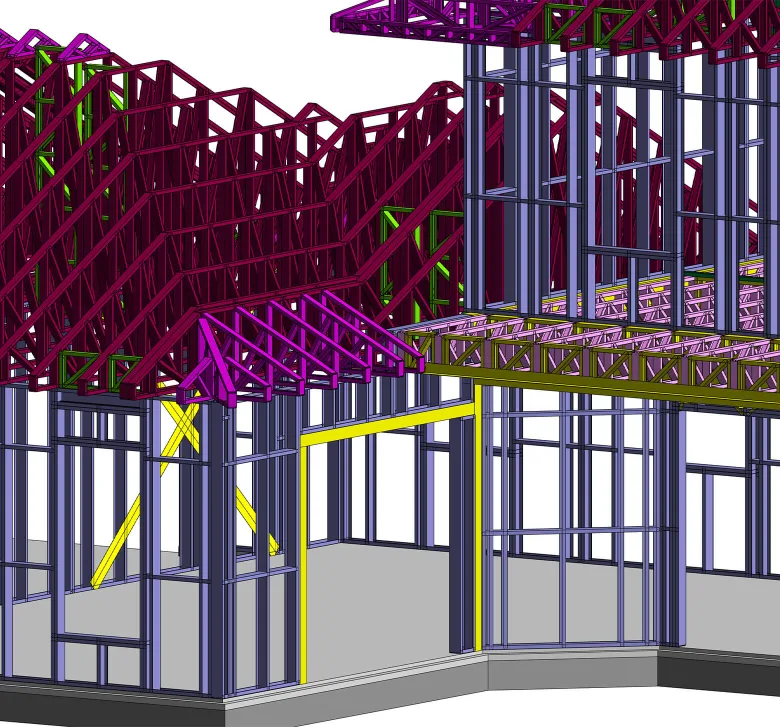

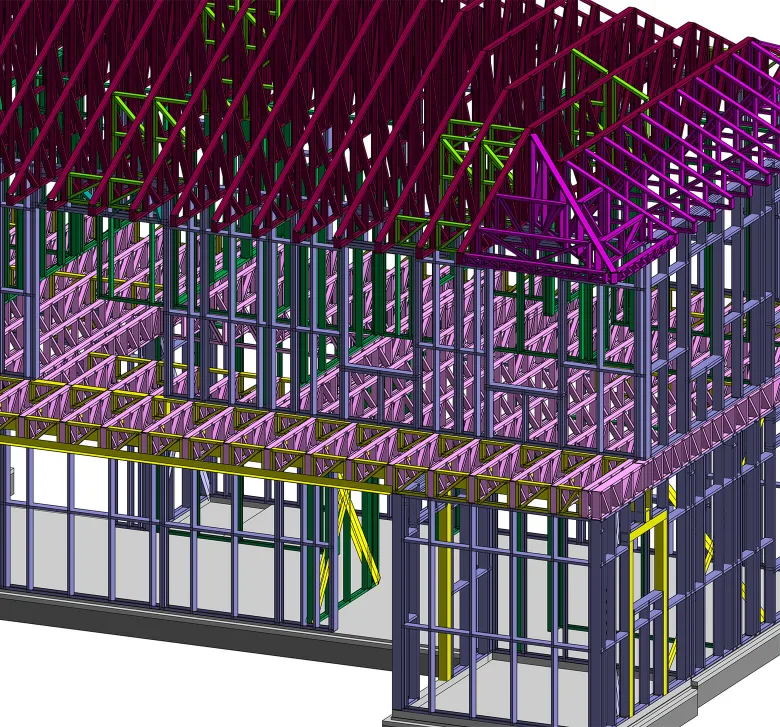

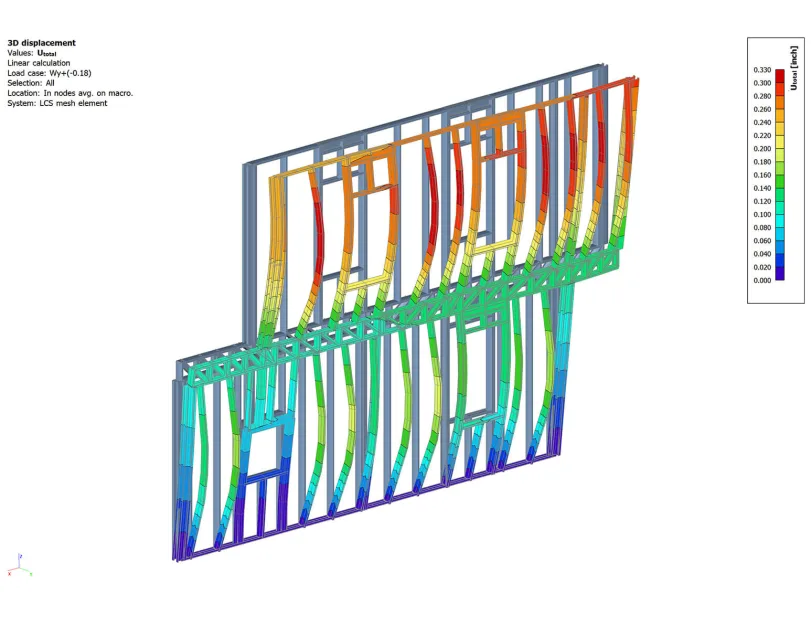

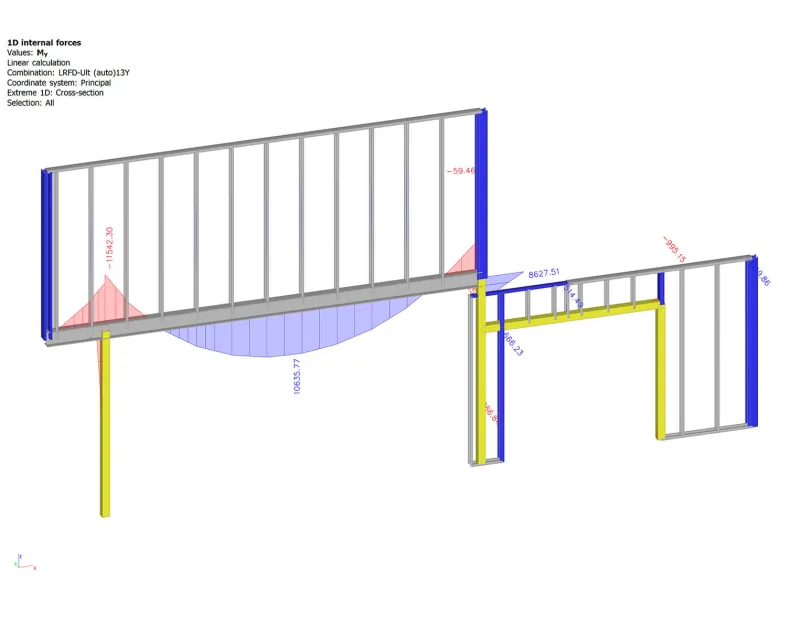

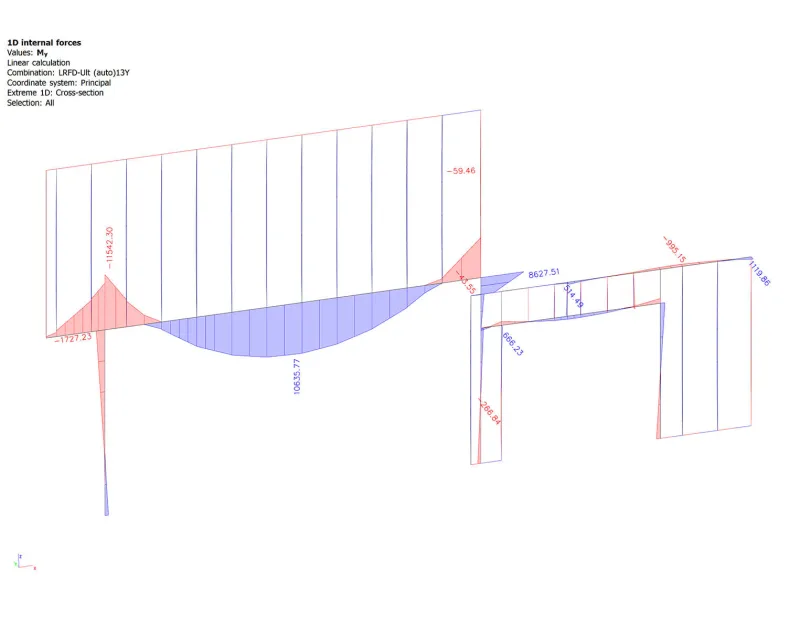

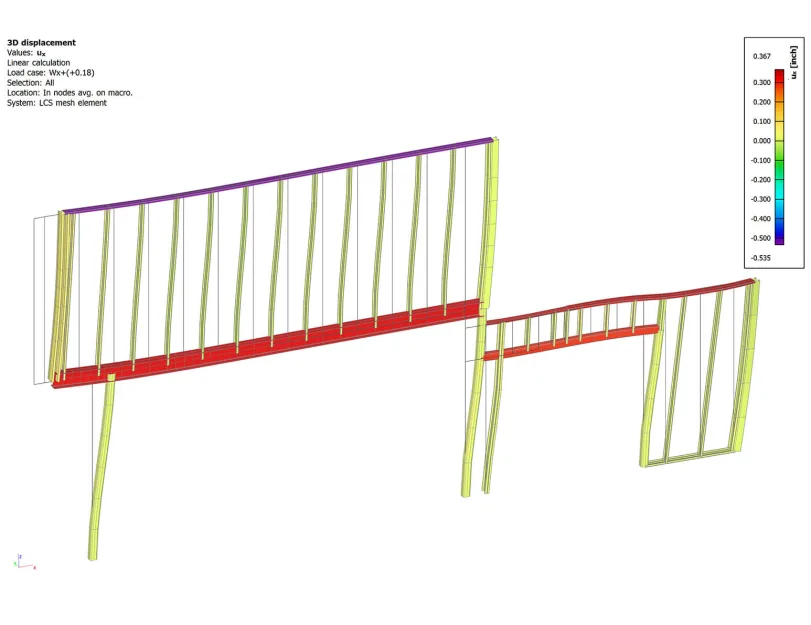

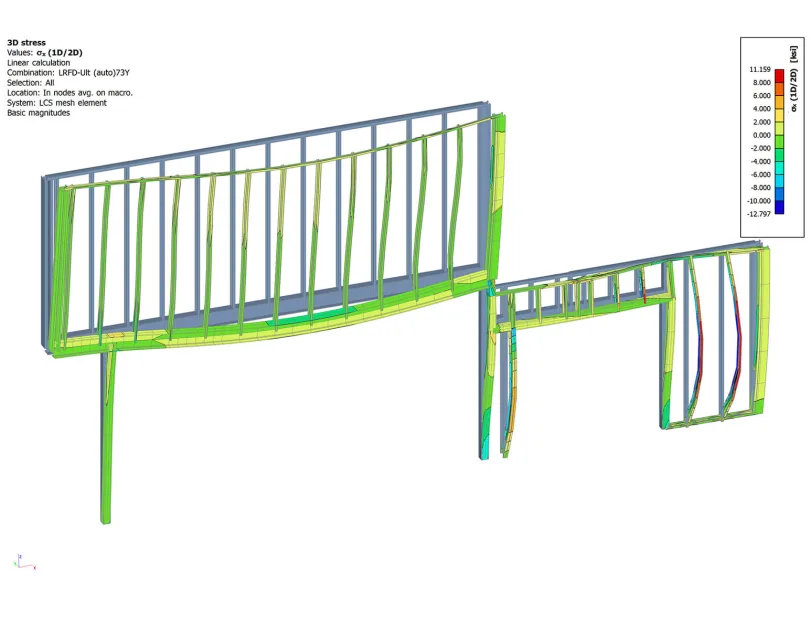

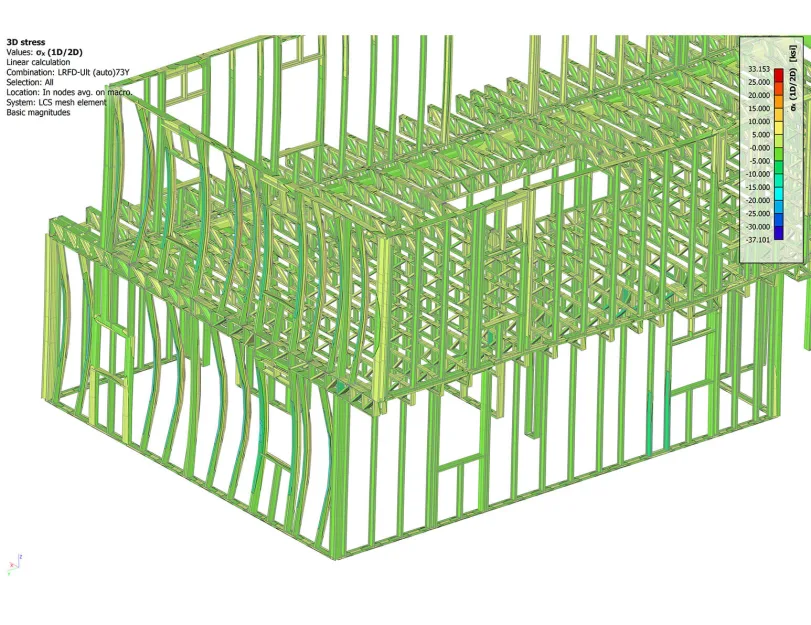

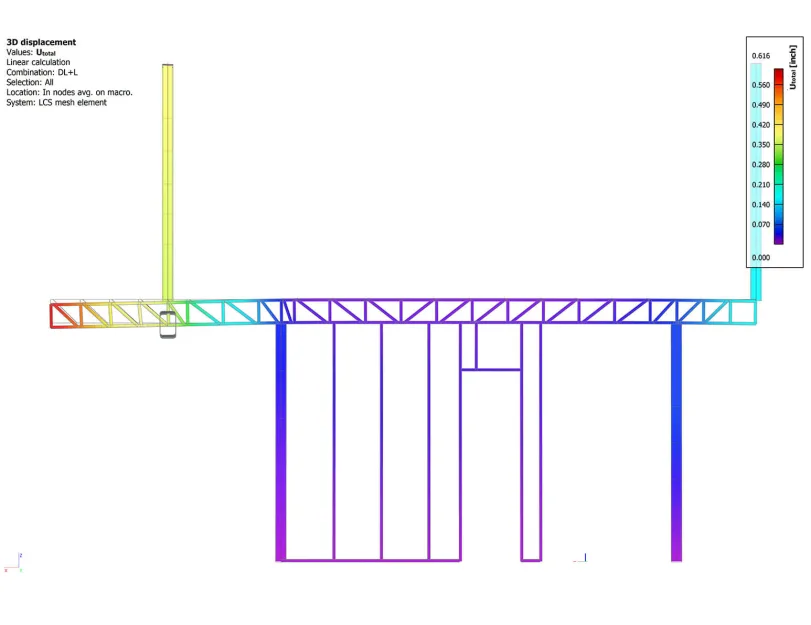

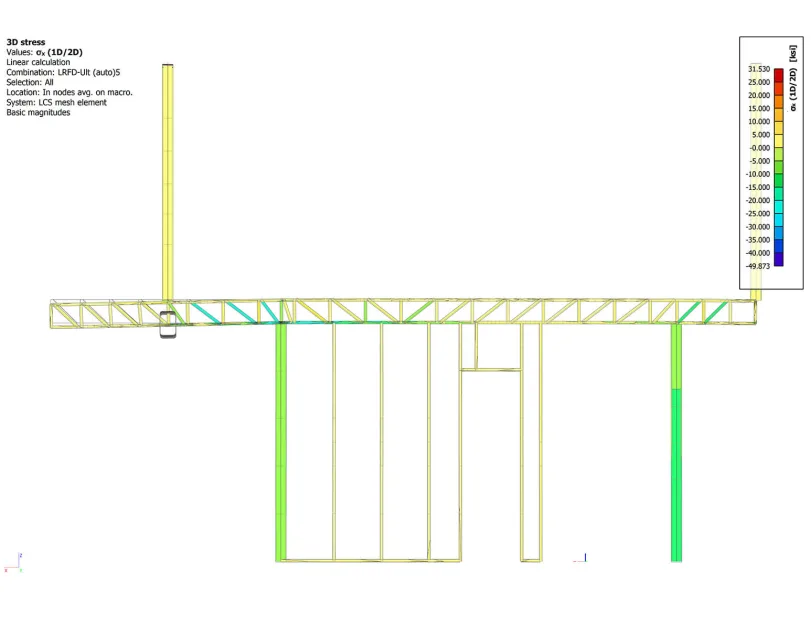

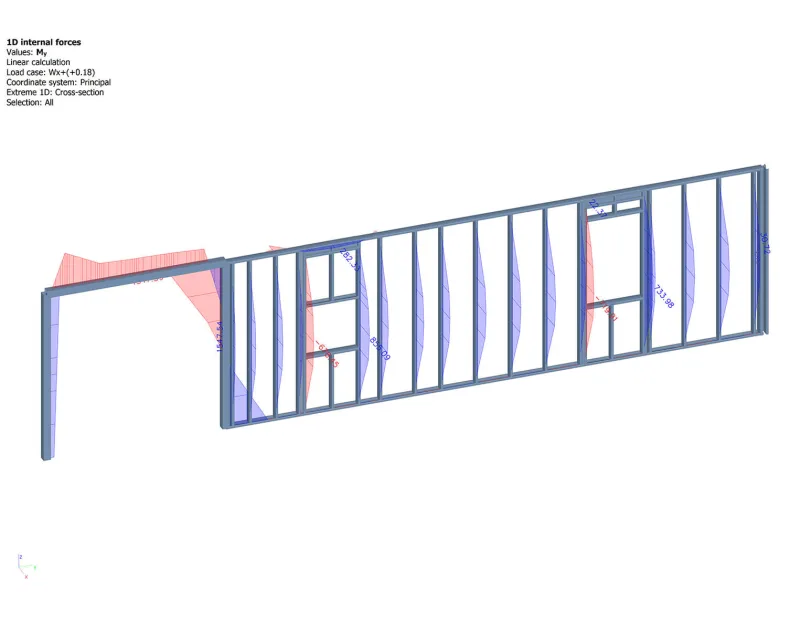

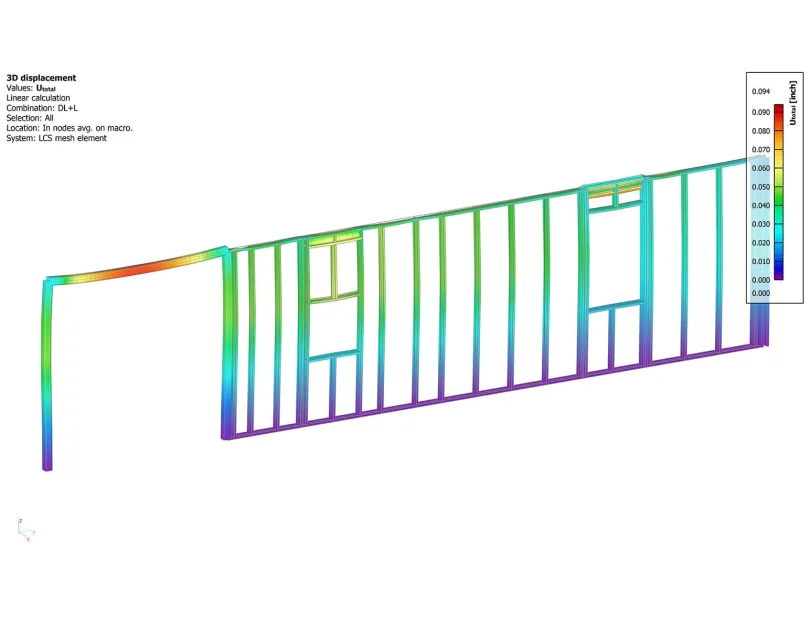

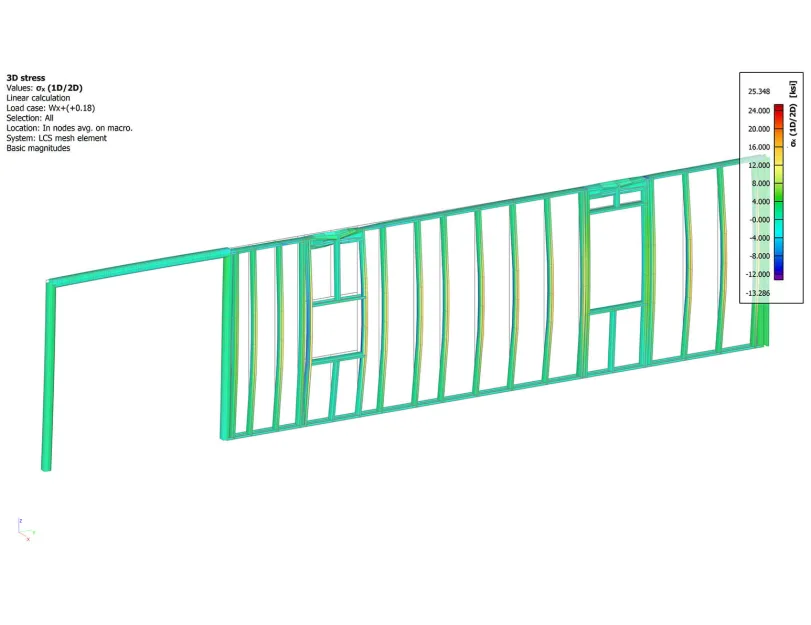

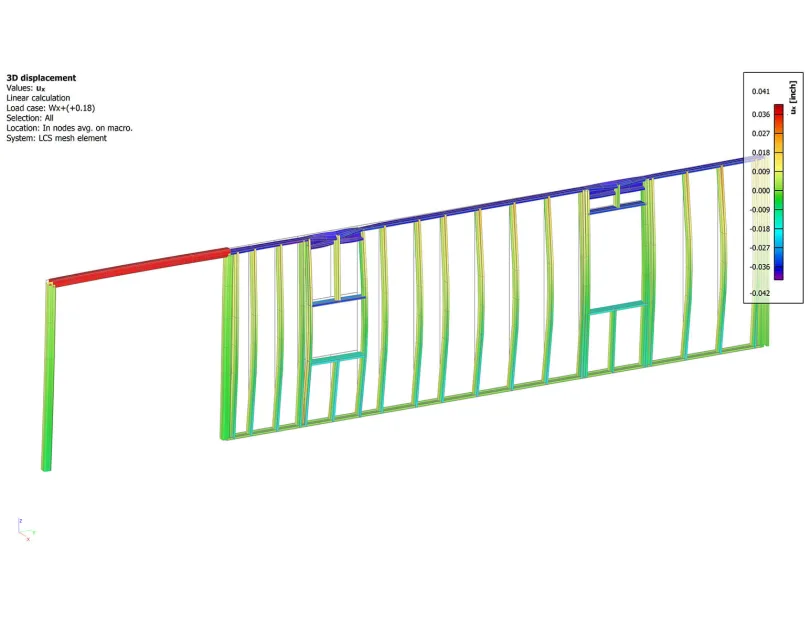

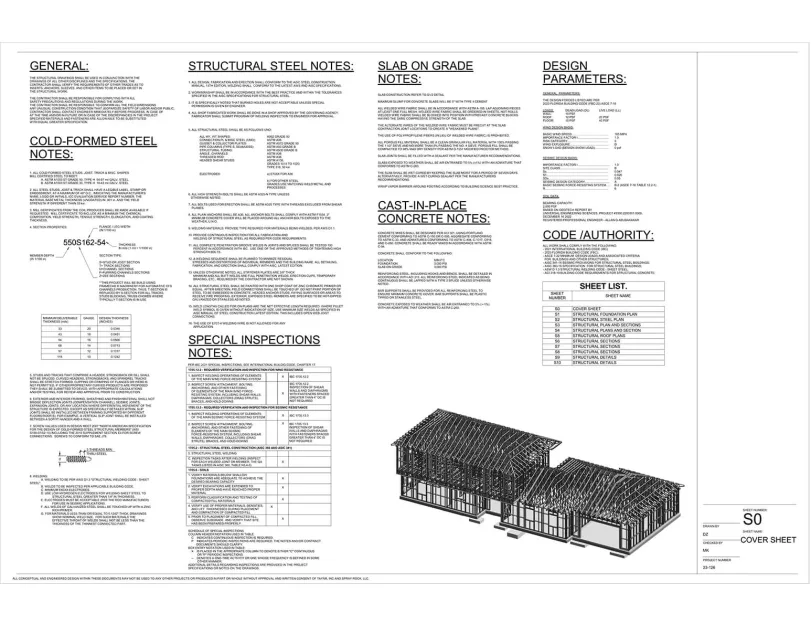

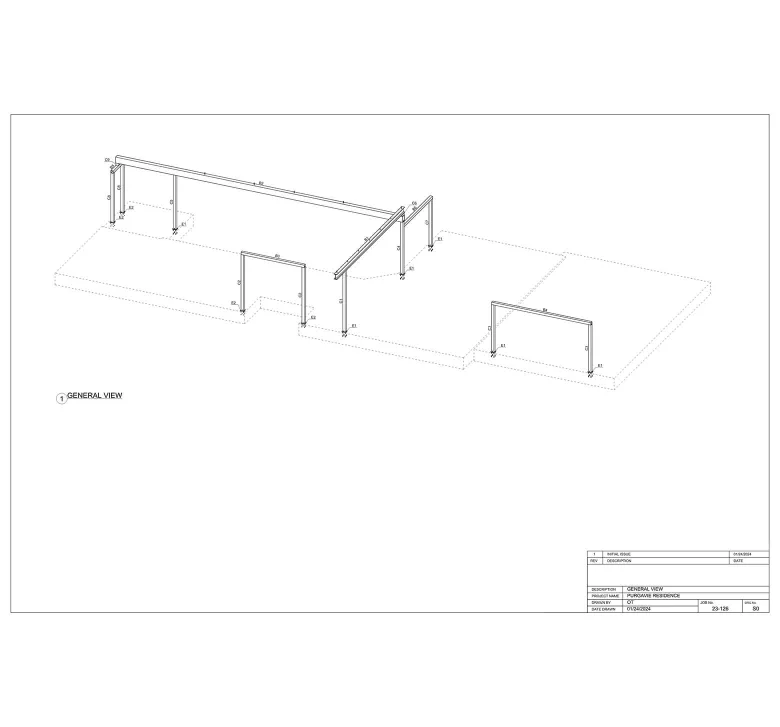

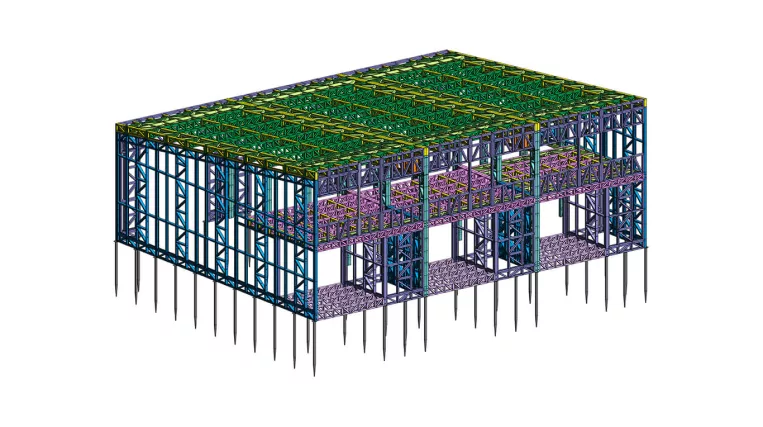

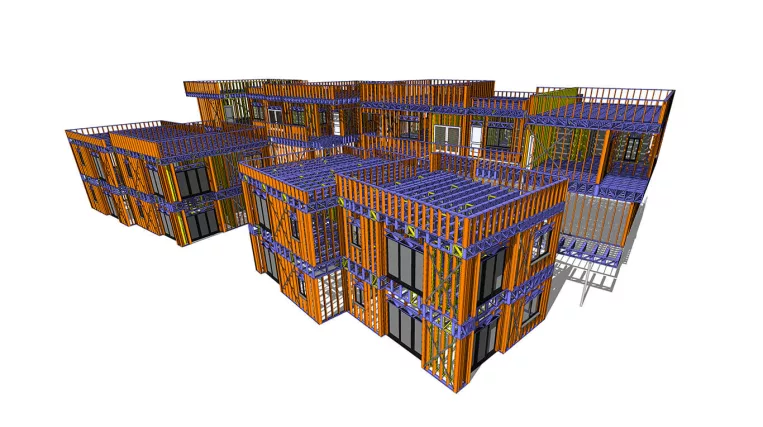

The project’s uniqueness lay in the fact that the construction company used a patented technology of spraying gunite mixture onto the rebar attached to prefabricated LGS panels. Therefore, from the foundation to the roof eave, this project was completely different from any other US standard LGS building.

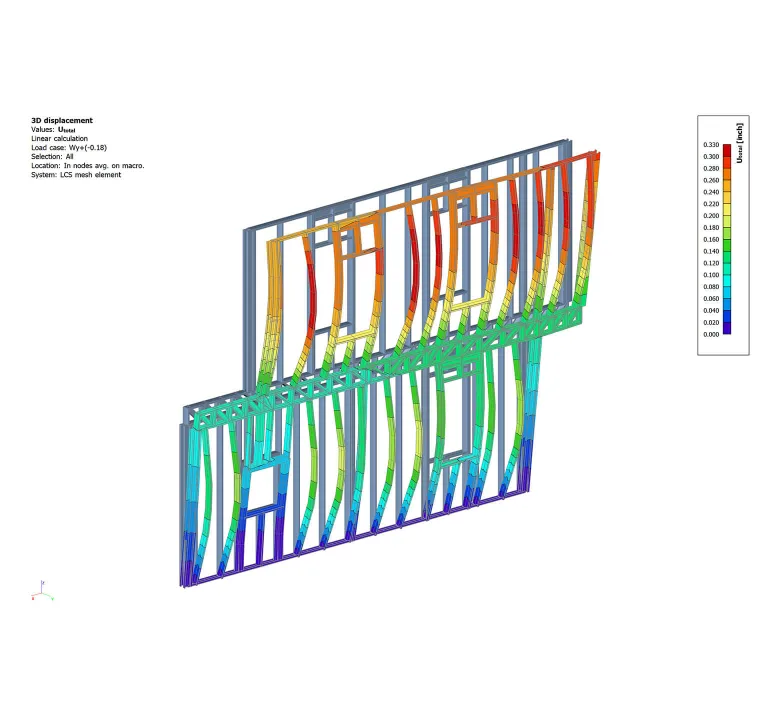

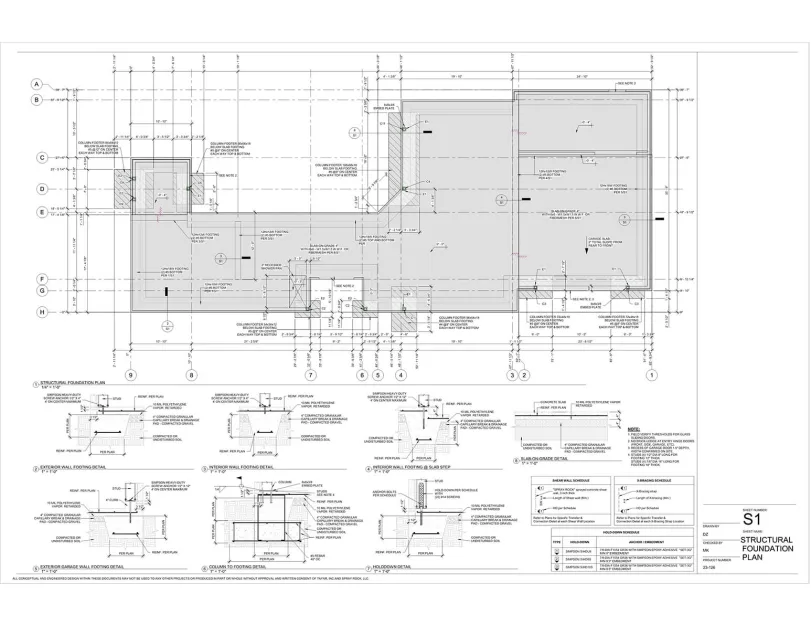

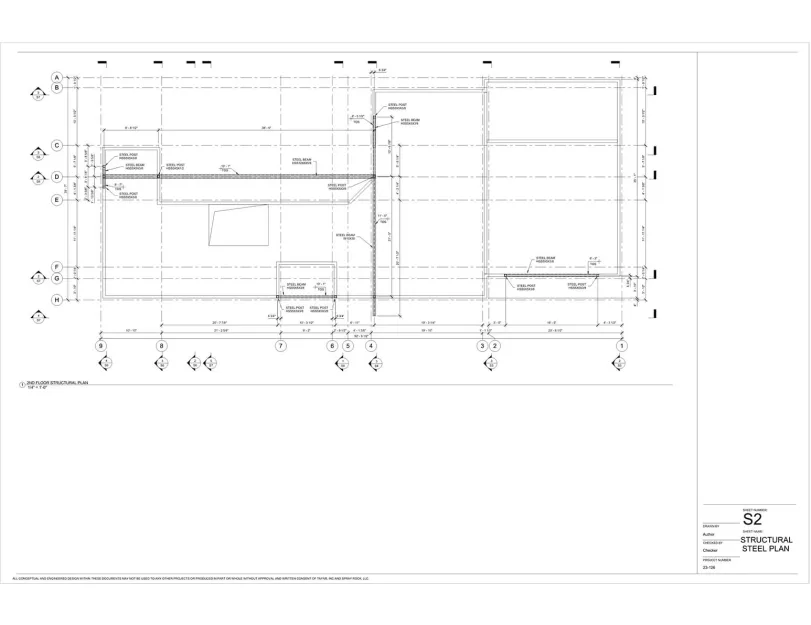

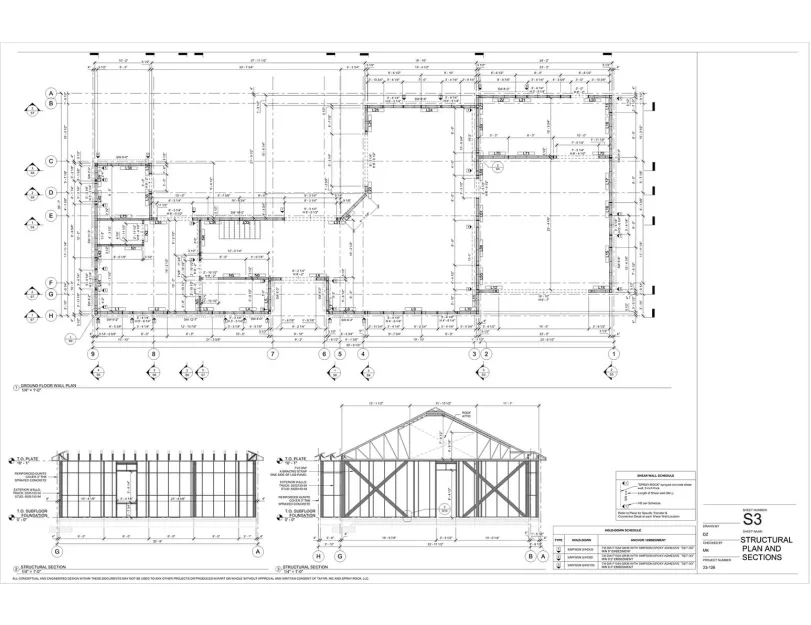

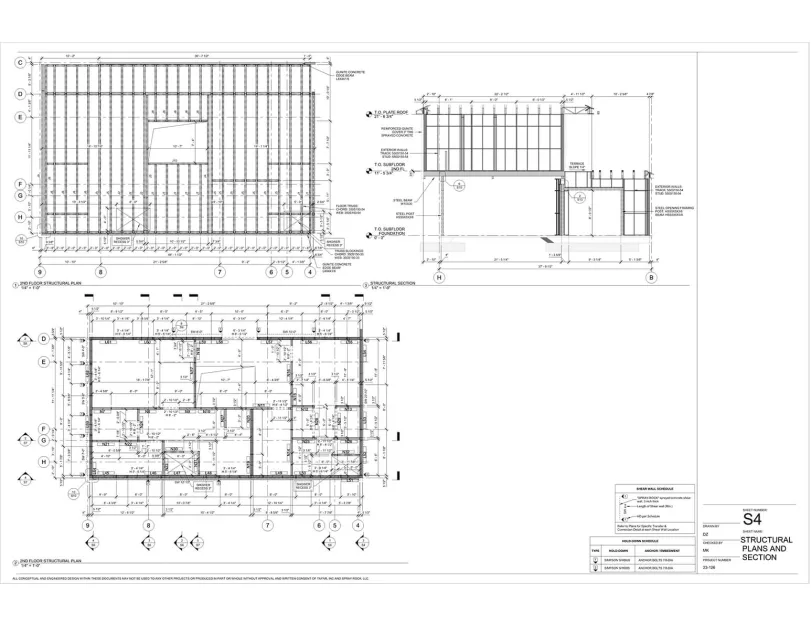

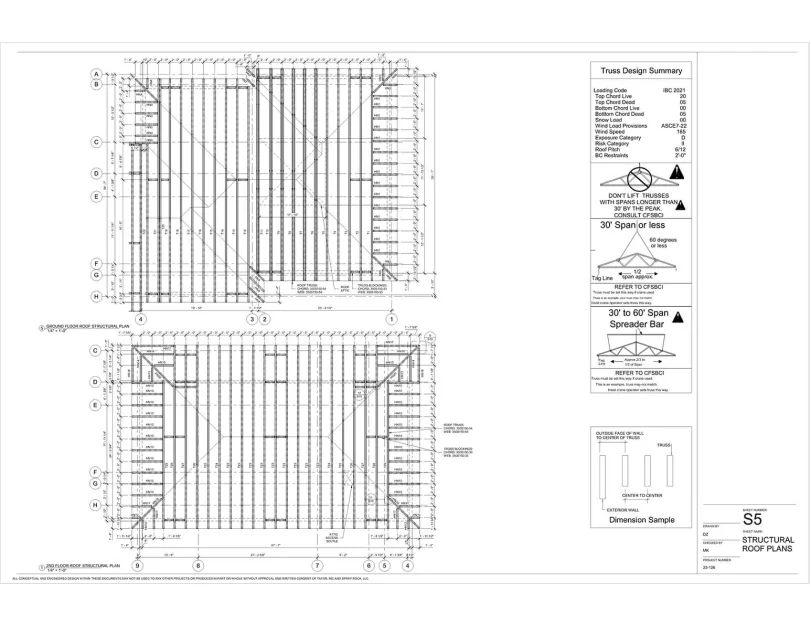

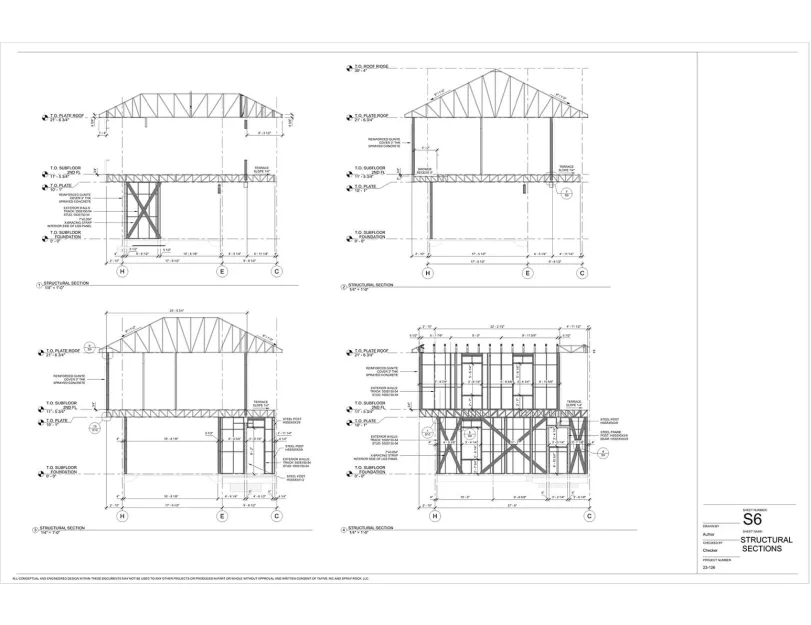

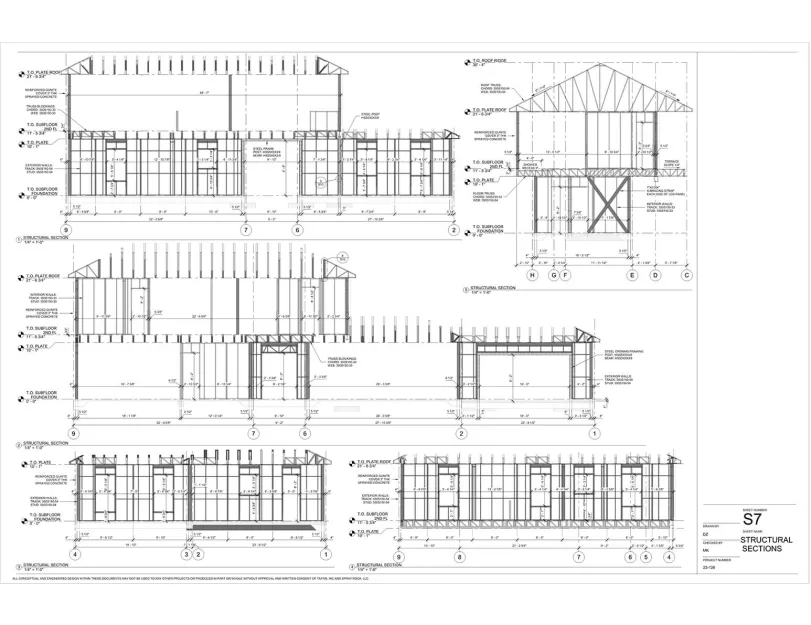

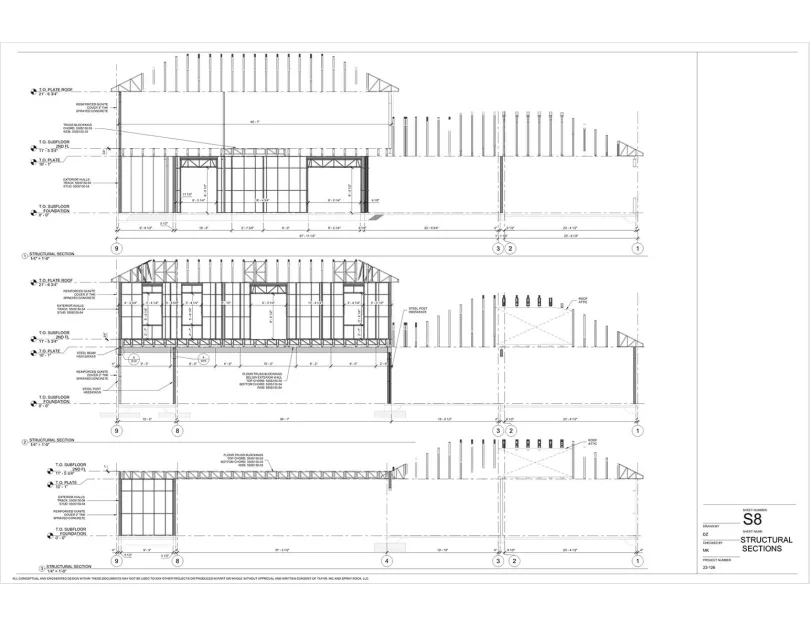

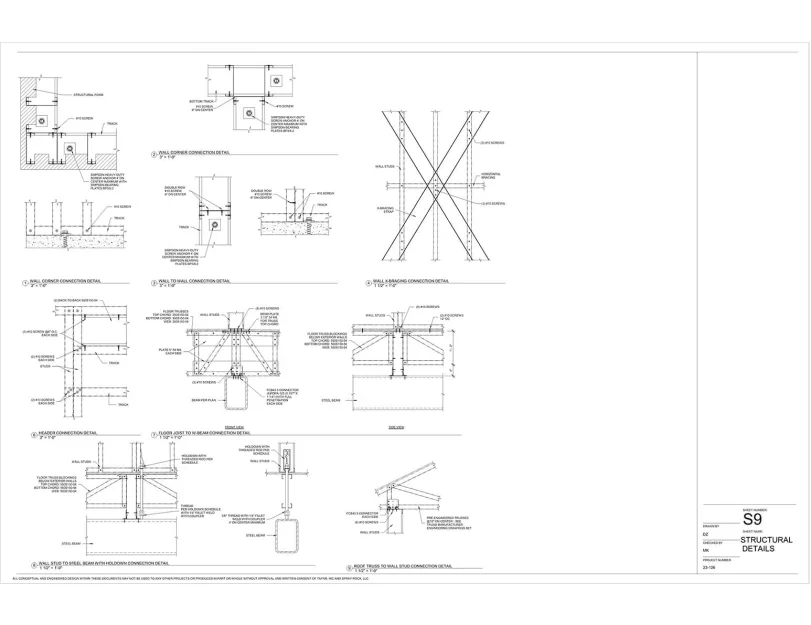

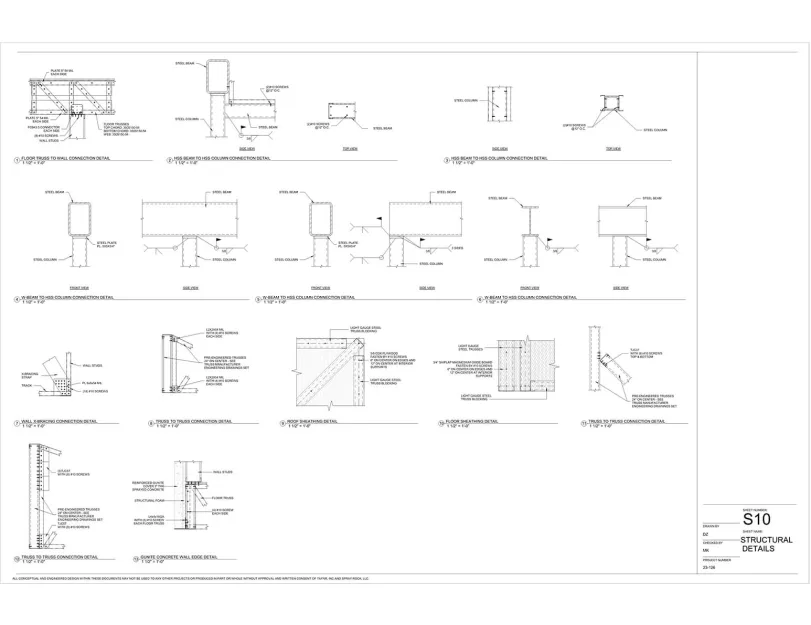

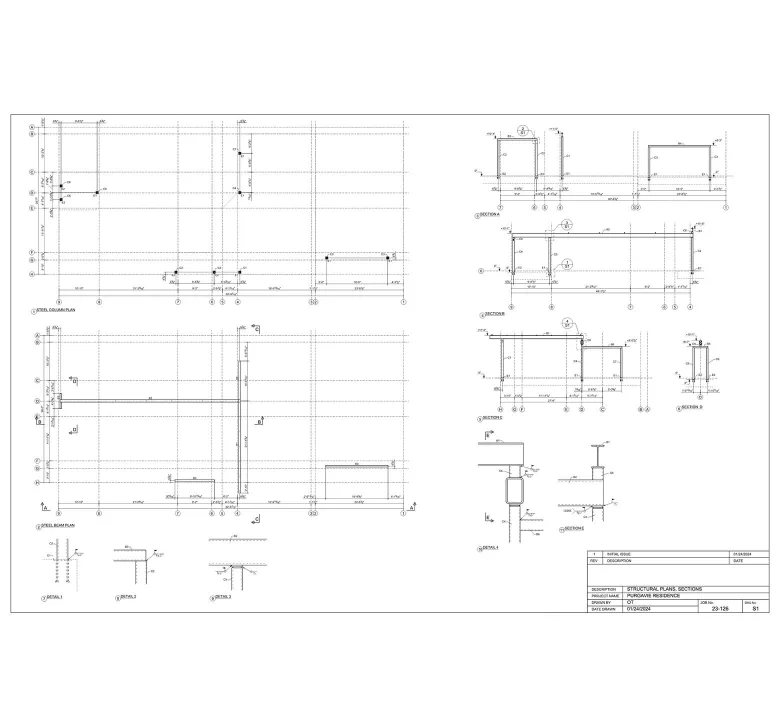

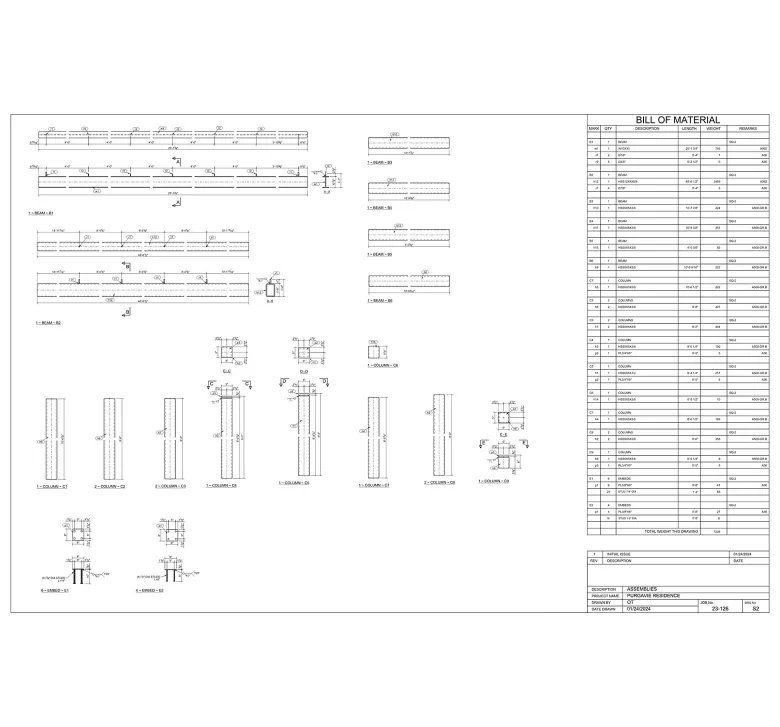

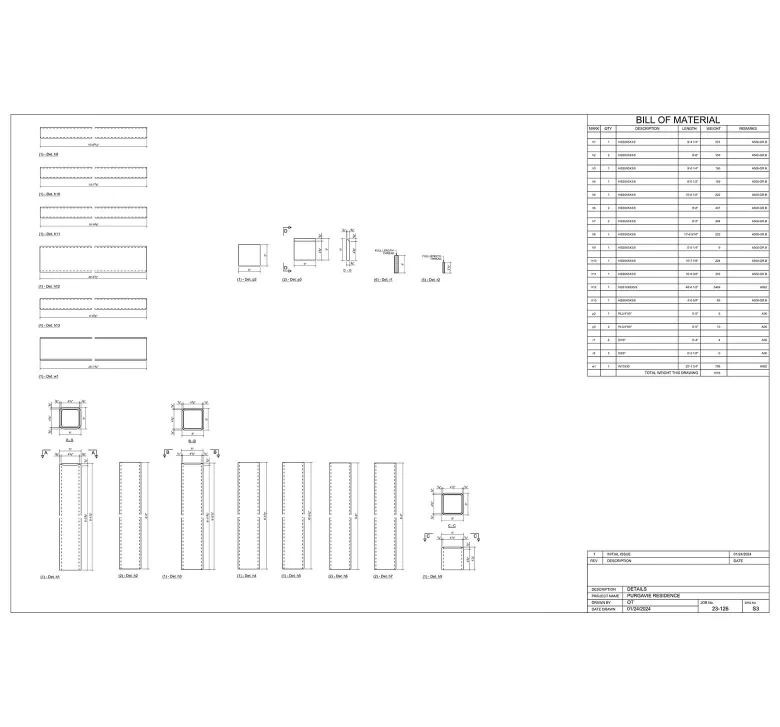

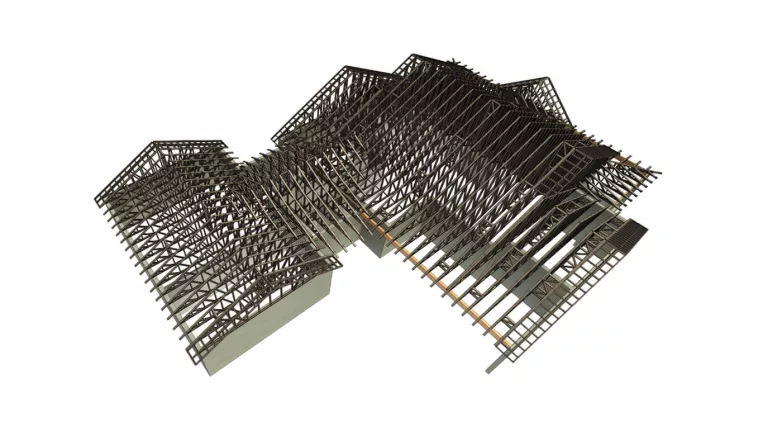

To cover every step from concept to fabrication, the ORIGIN team was requested to create a range of deliverables: structural construction drawings, the structural analysis for the LGS framing and foundation system, and CNC files for the Framecad machine. Not to mention, strict compliance with multiple codes and standards was non-negotiable, too.

Input: Architectural drawings set

Project deliverables:

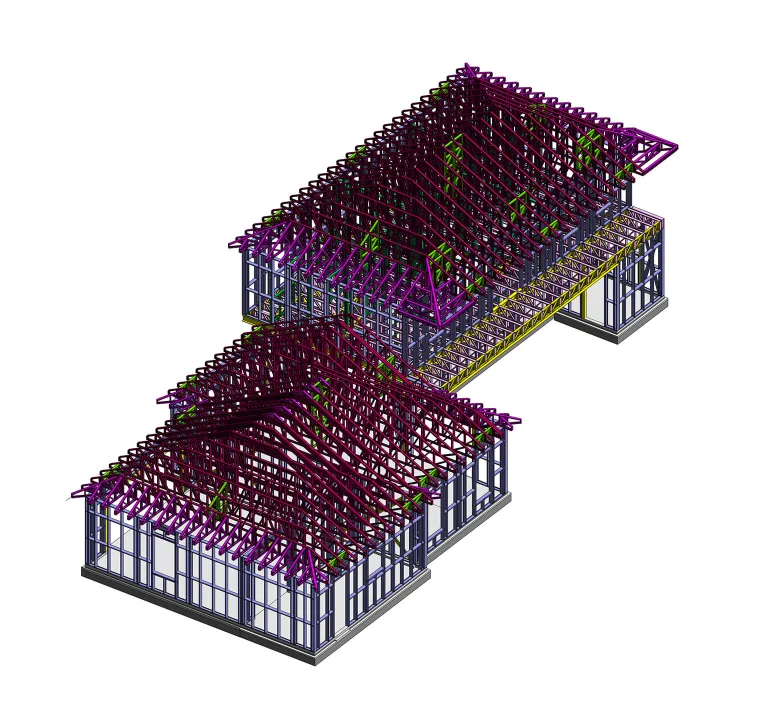

- Structural drawings set;

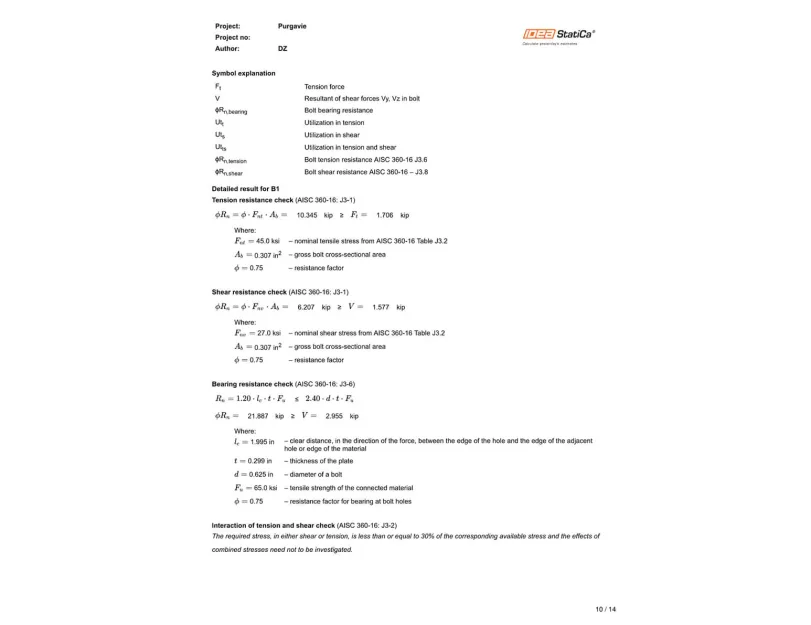

- Structural analysis report;

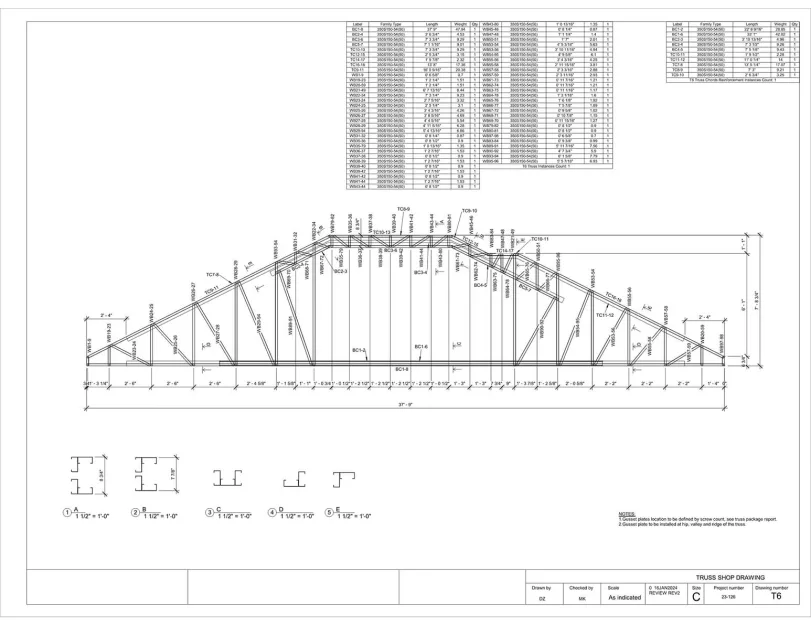

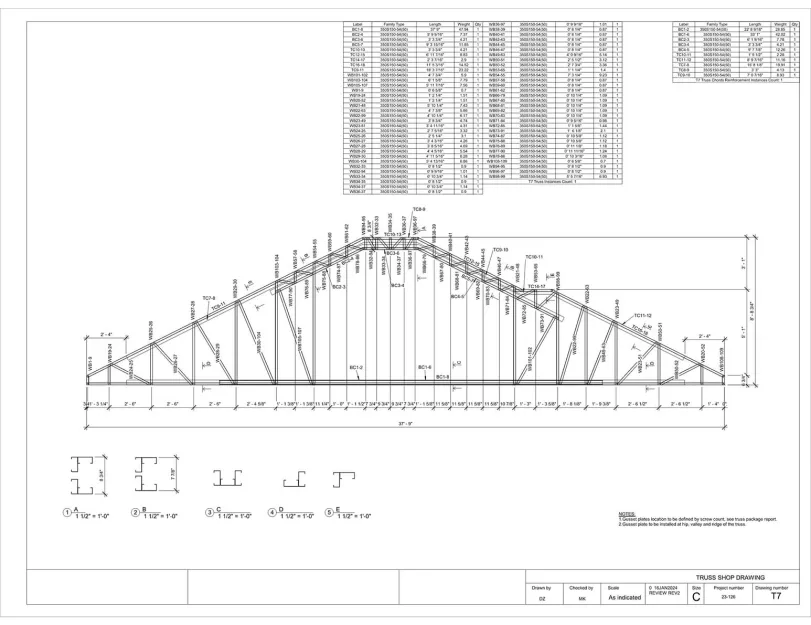

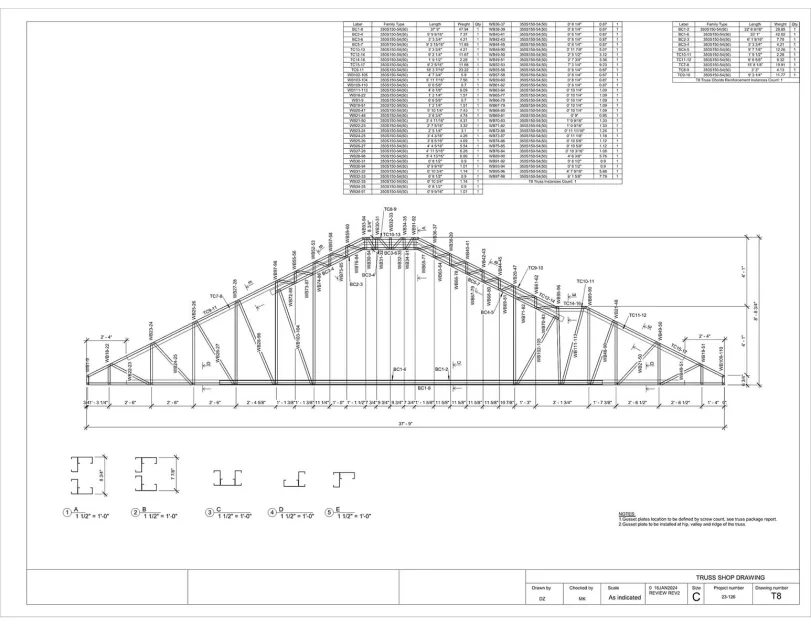

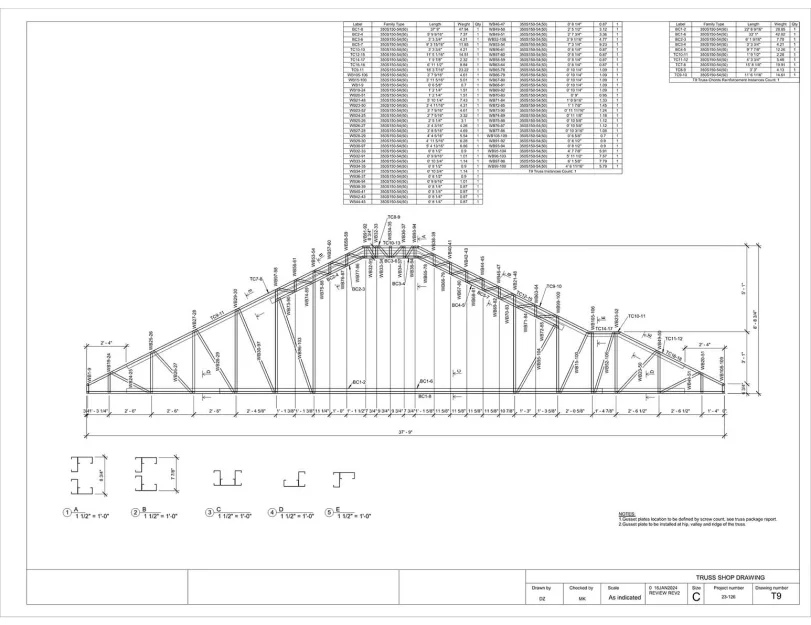

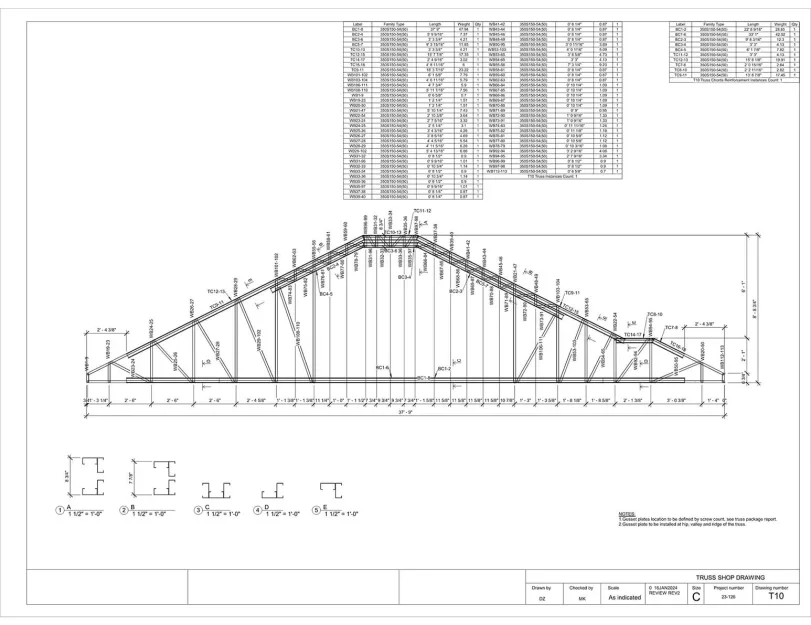

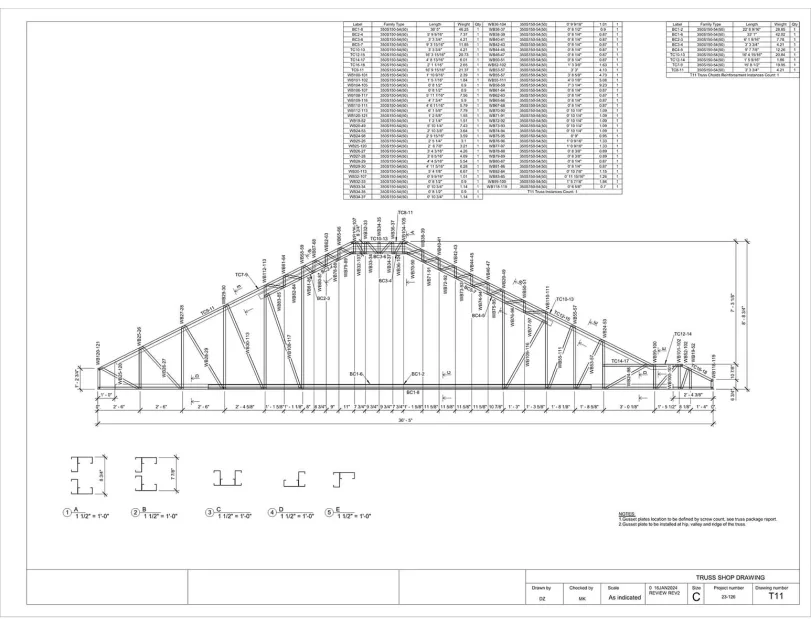

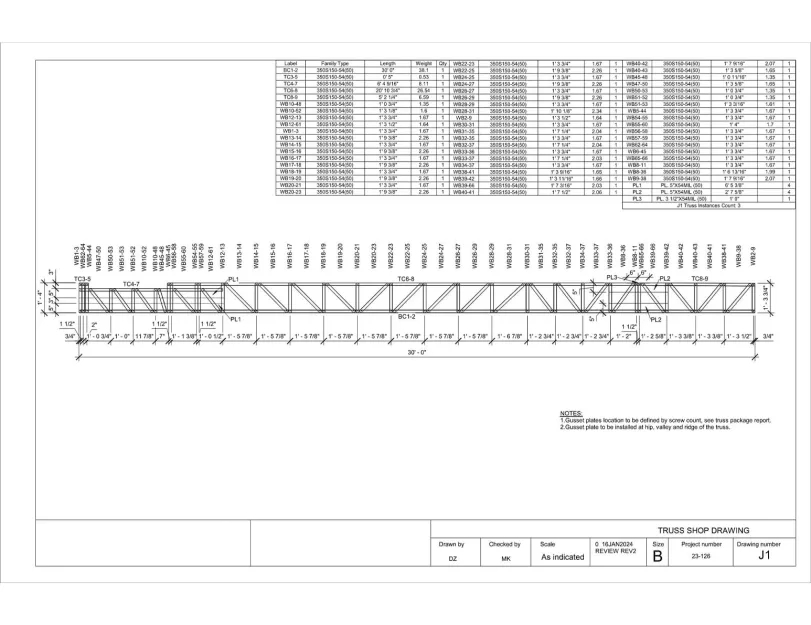

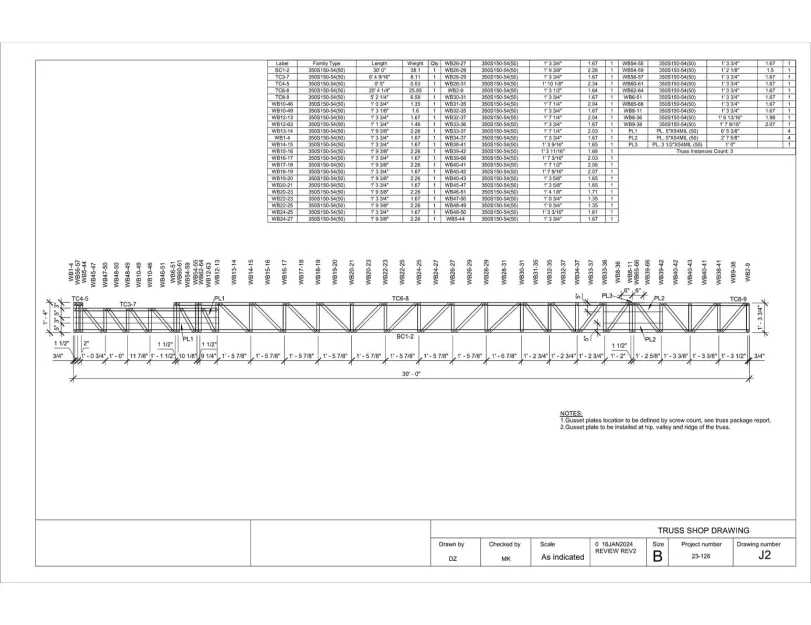

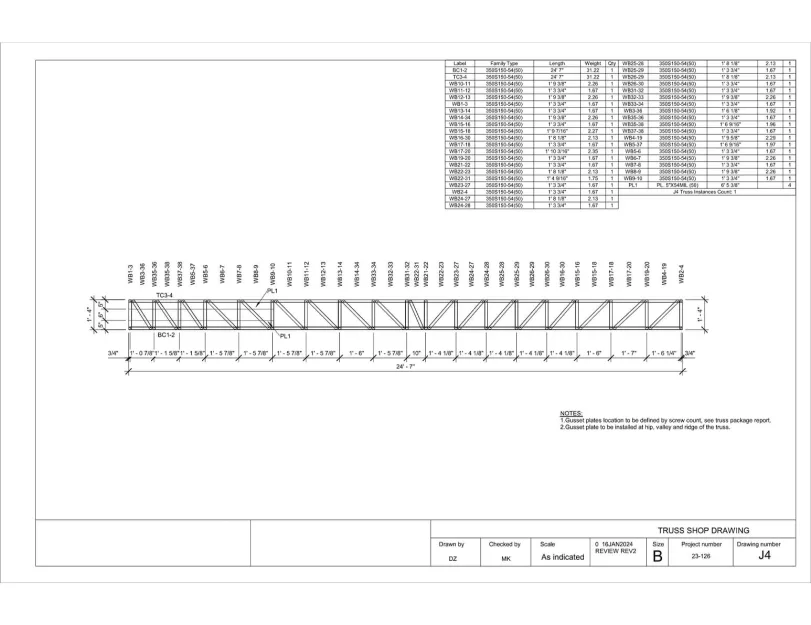

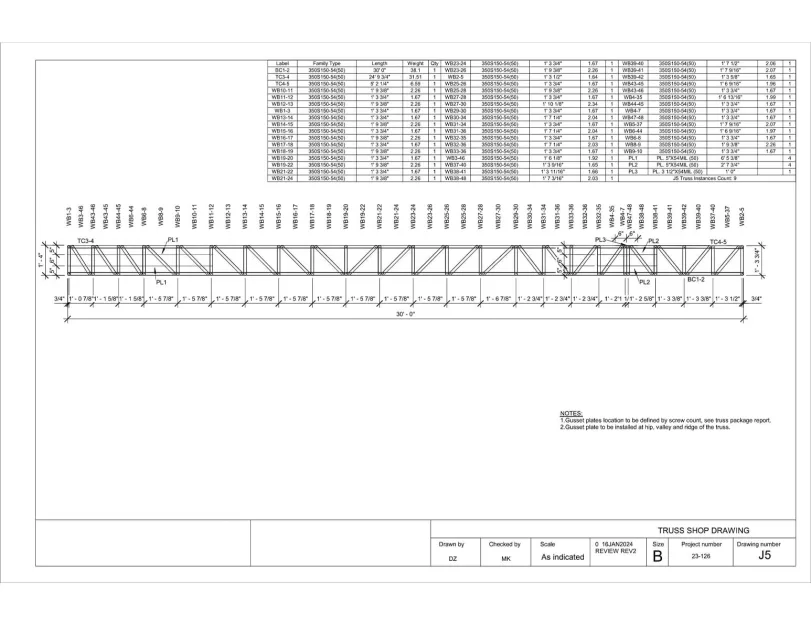

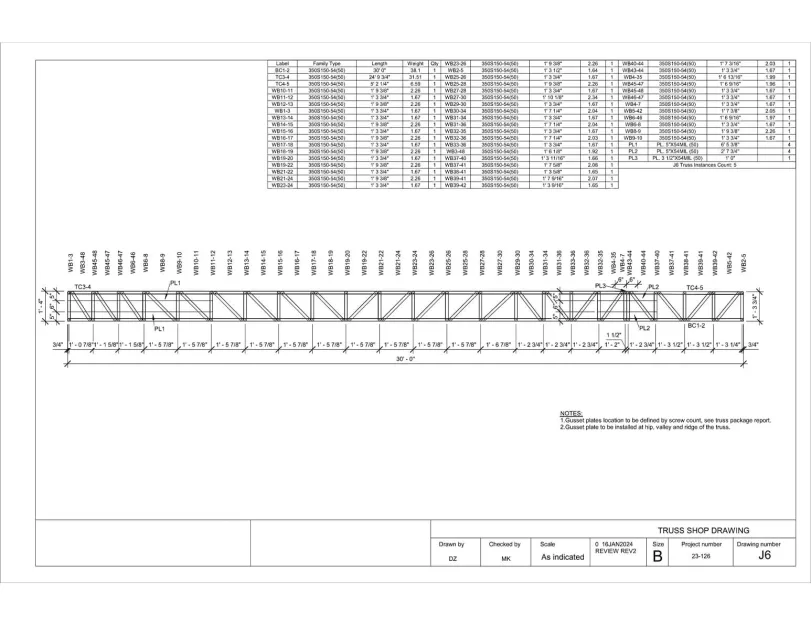

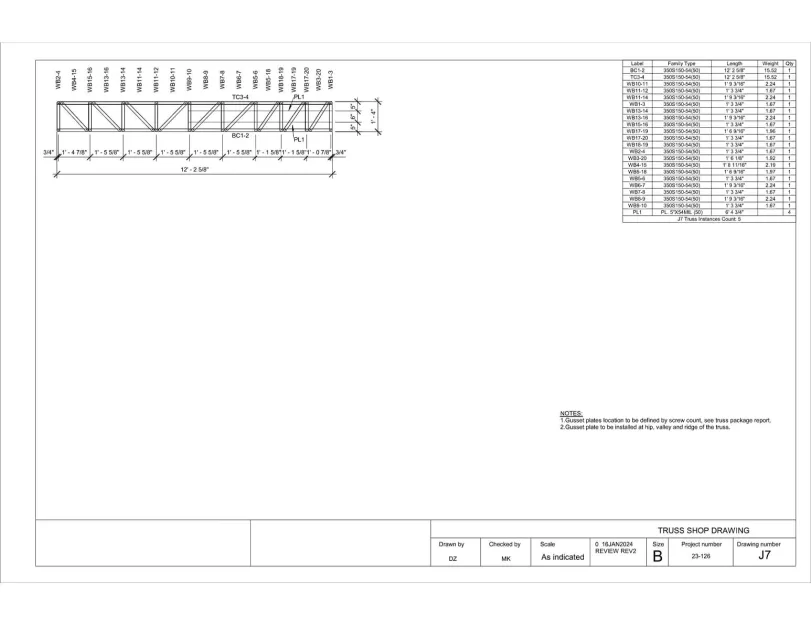

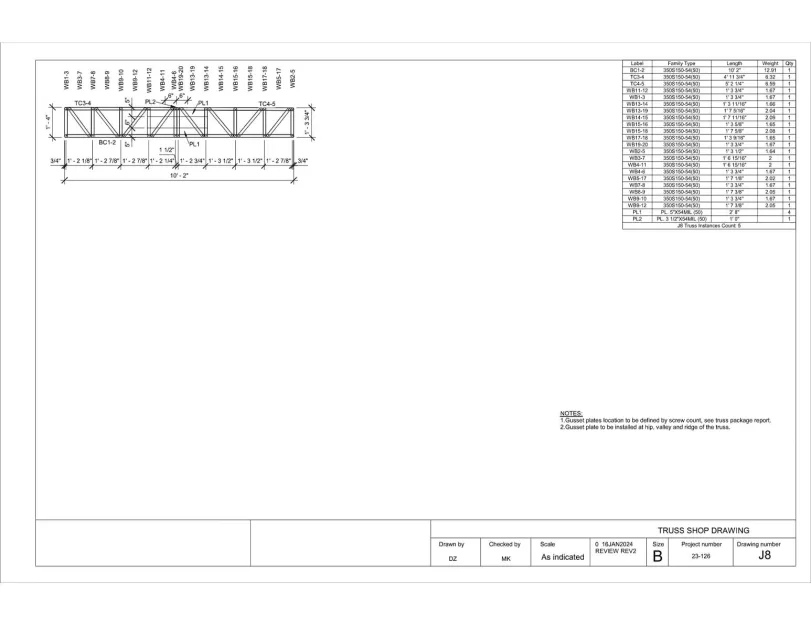

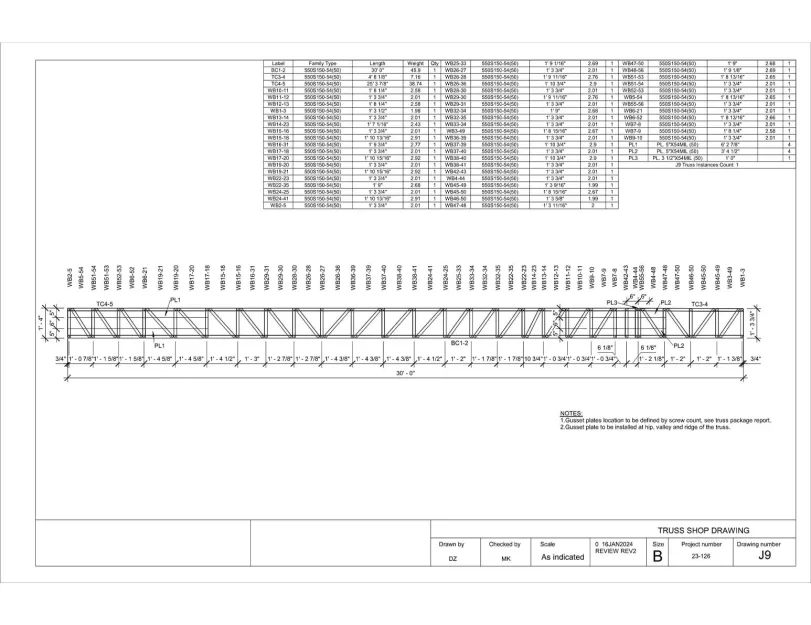

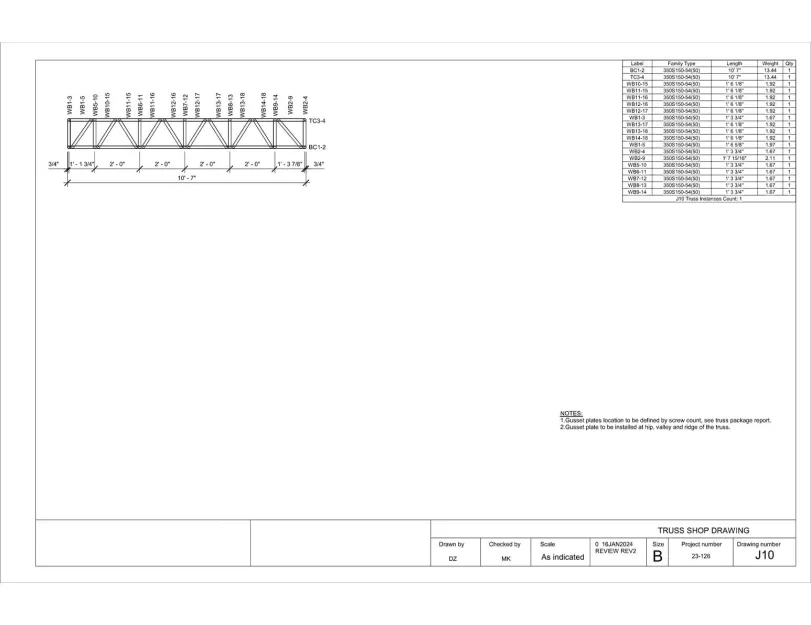

- LGS shop drawings;

- Framecad CNC files for LGS panels production.