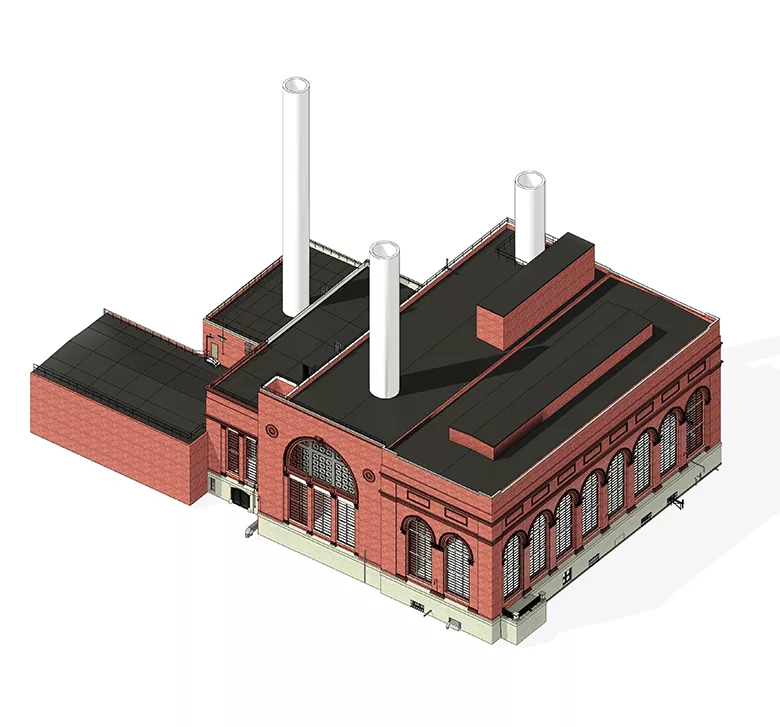

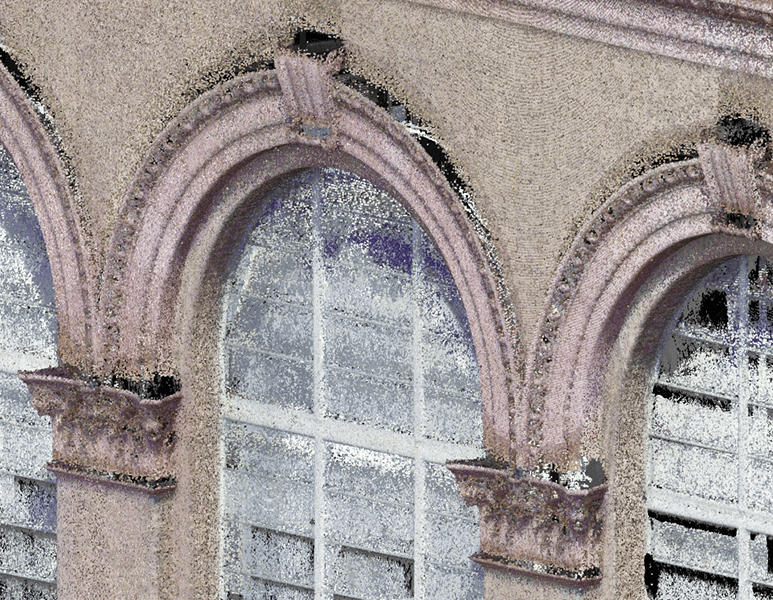

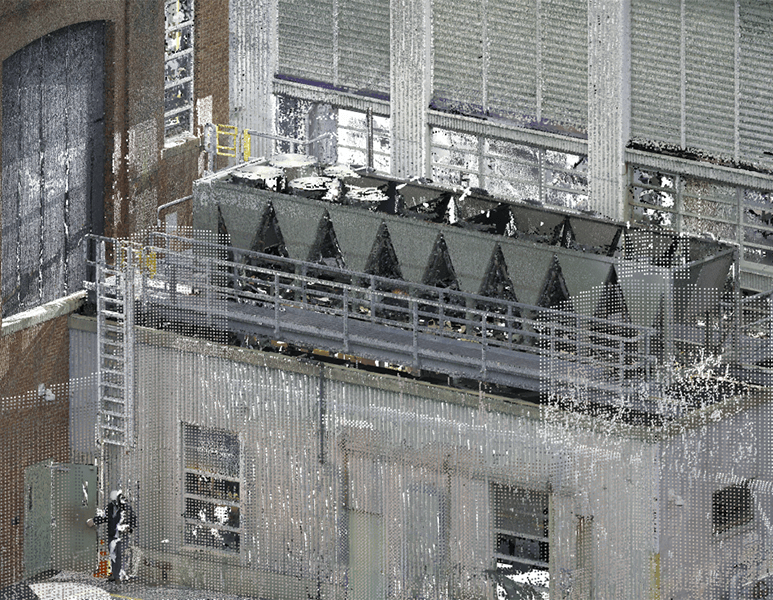

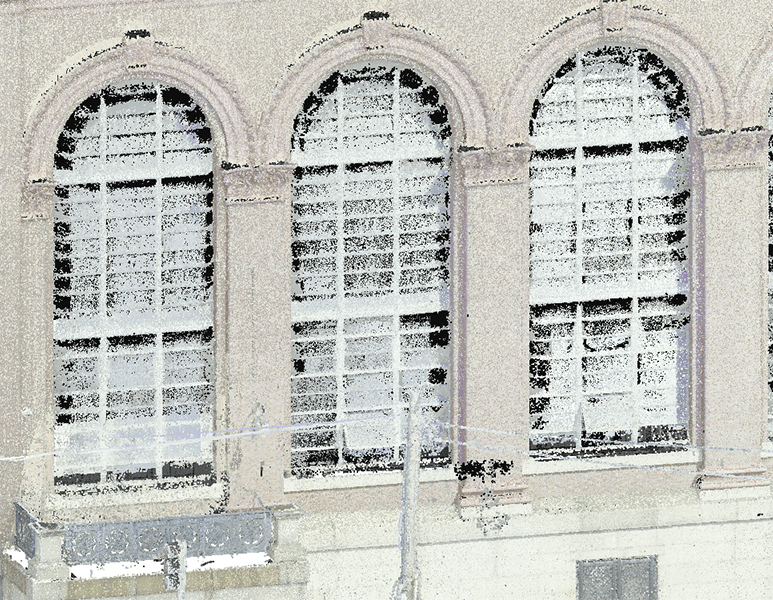

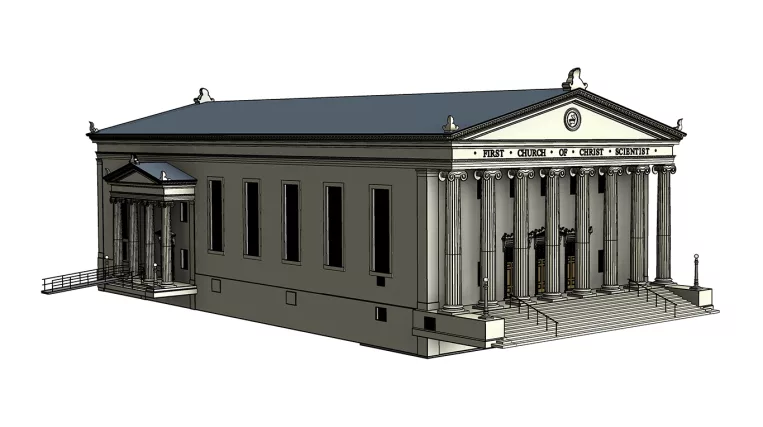

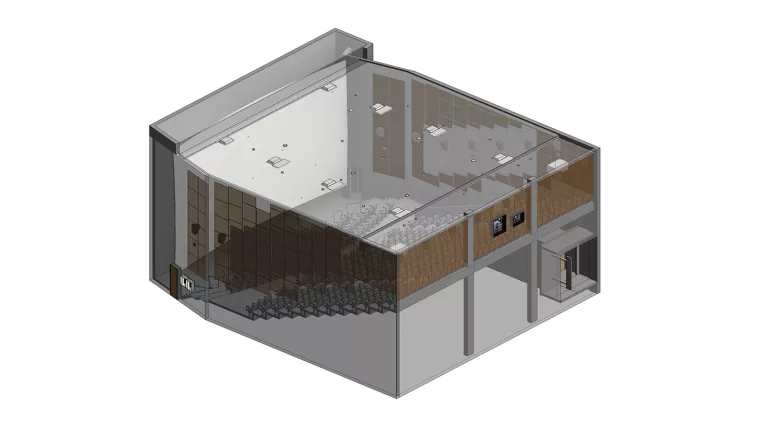

The historical building, which currently is used as a plant room for the distribution of different communications (such as electricity, water, etc.), required window replacement reconstruction. For these aims, a full laser scan of the exteriors of the building was provided, along with a fragmentary survey of the building’s interiors. A couple of stations of laser scanners were placed inside the building to acquire information about wall thicknesses only.

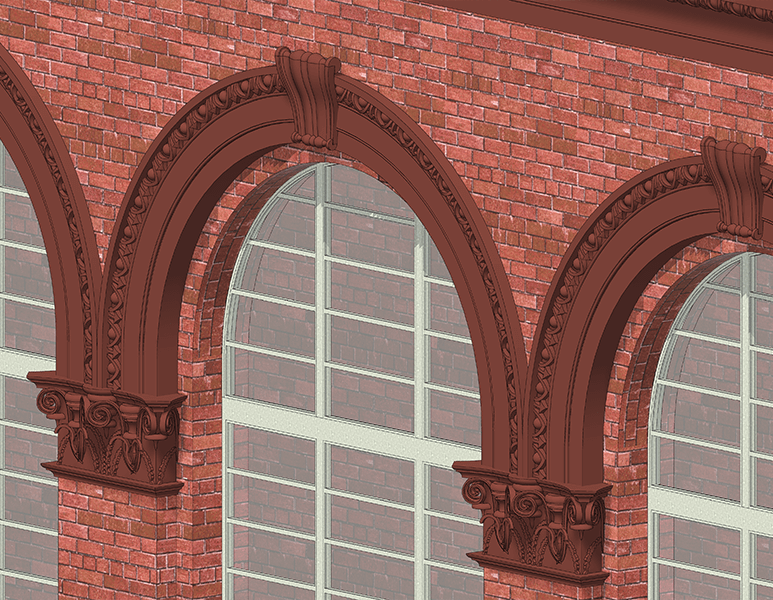

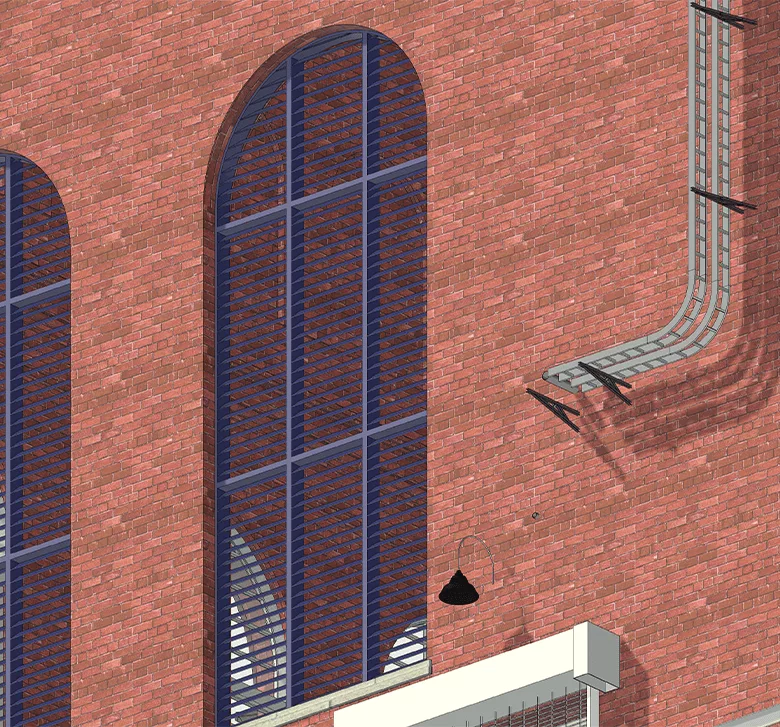

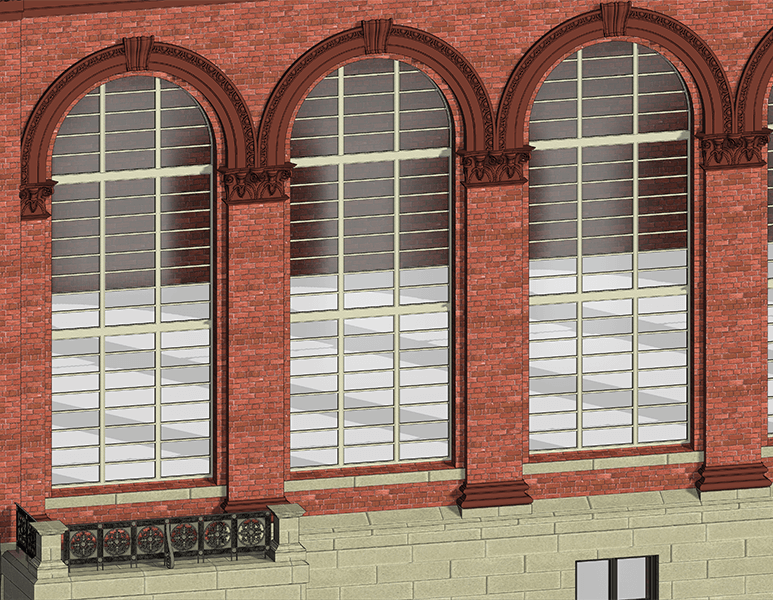

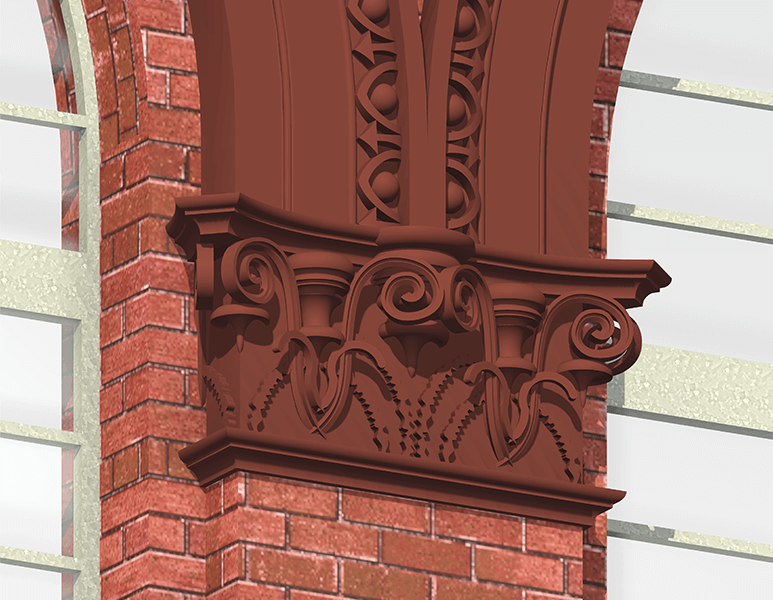

The request for a high level of detail in the exterior decoration elements made this project interesting in terms of architectural modeling.

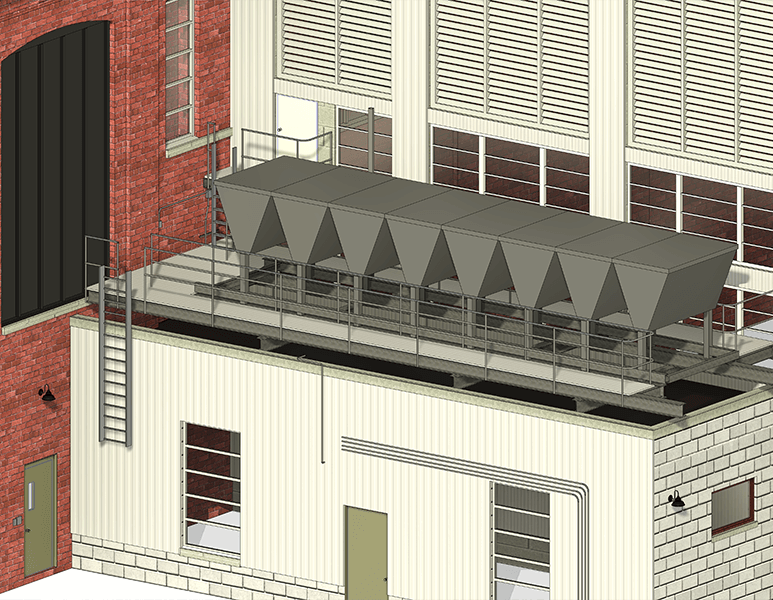

Scope of work: Detailed modeling of the building’s facades (50% historical, 50% industrial) for window replacement.

Input: Complete point cloud of the building’s exteriors (interiors provided for reference only).

Output: 3D Model at LOD 350.