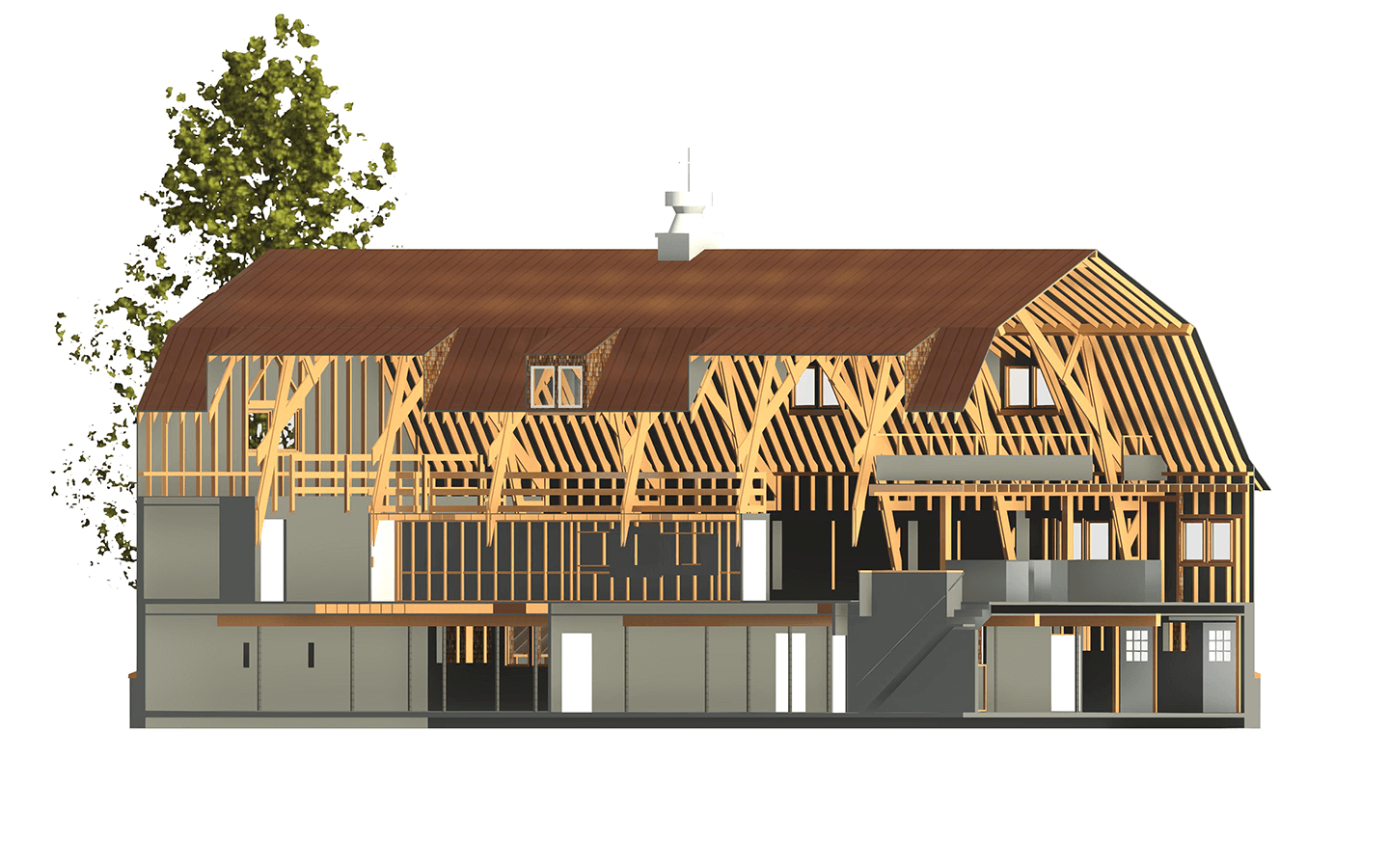

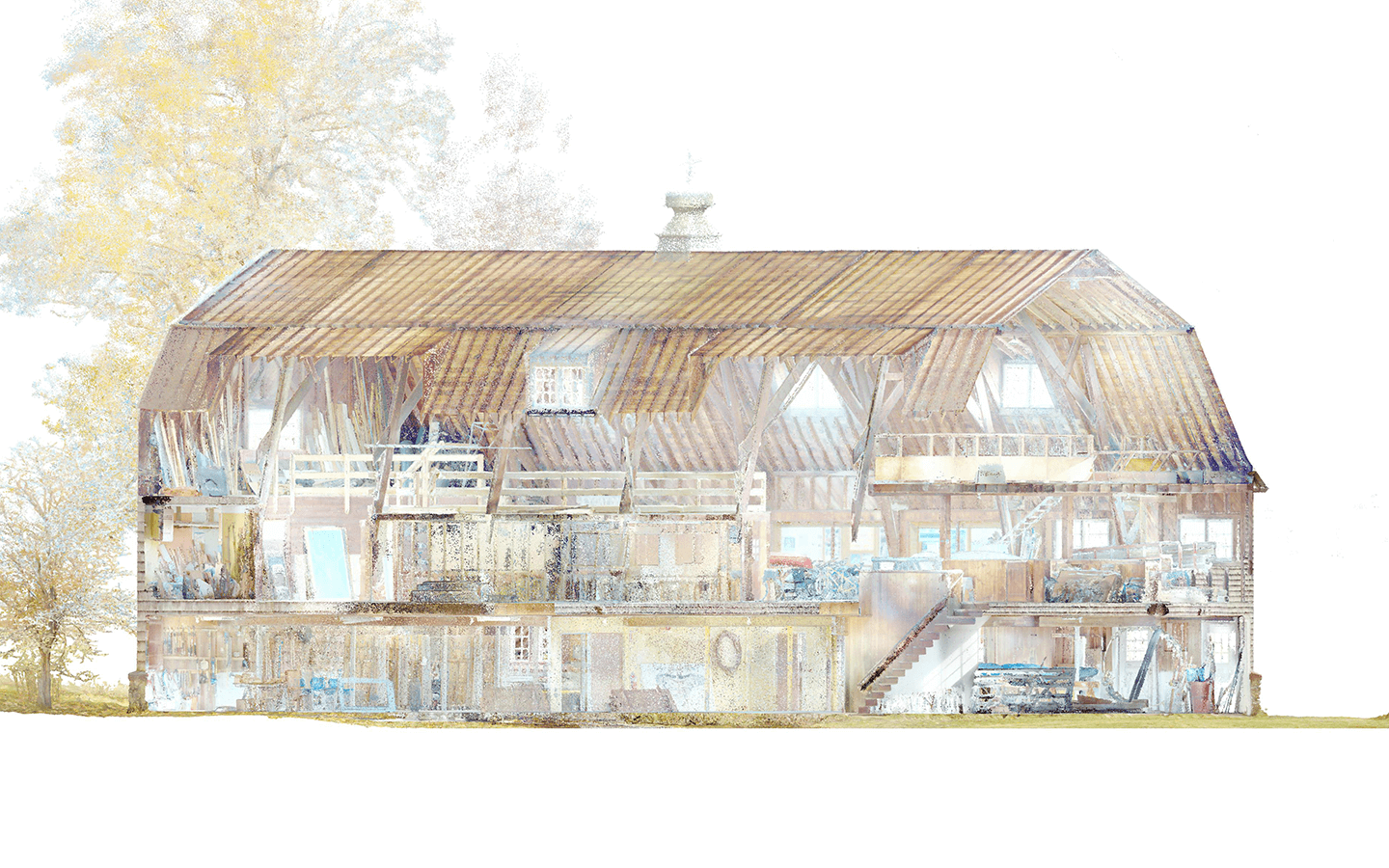

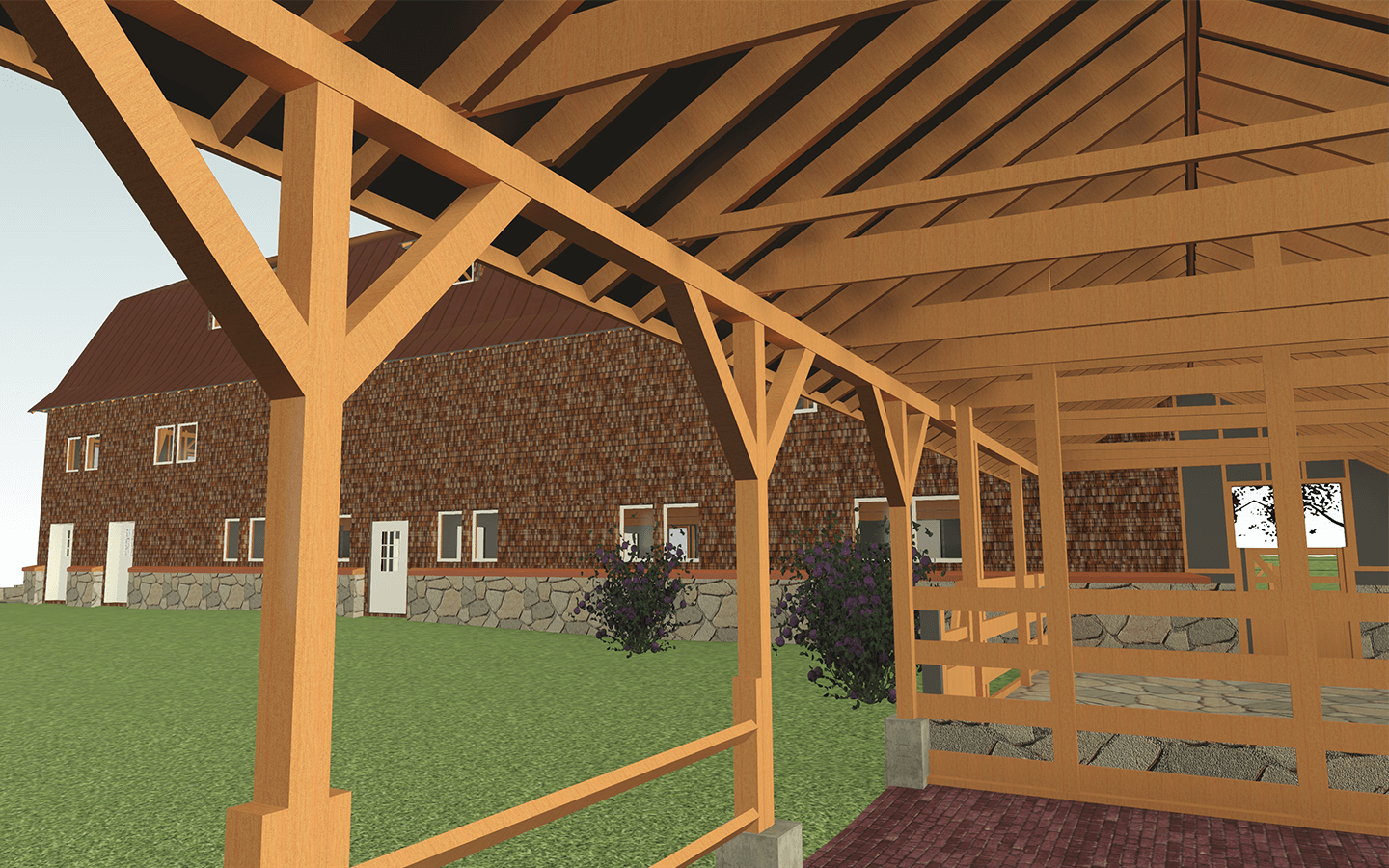

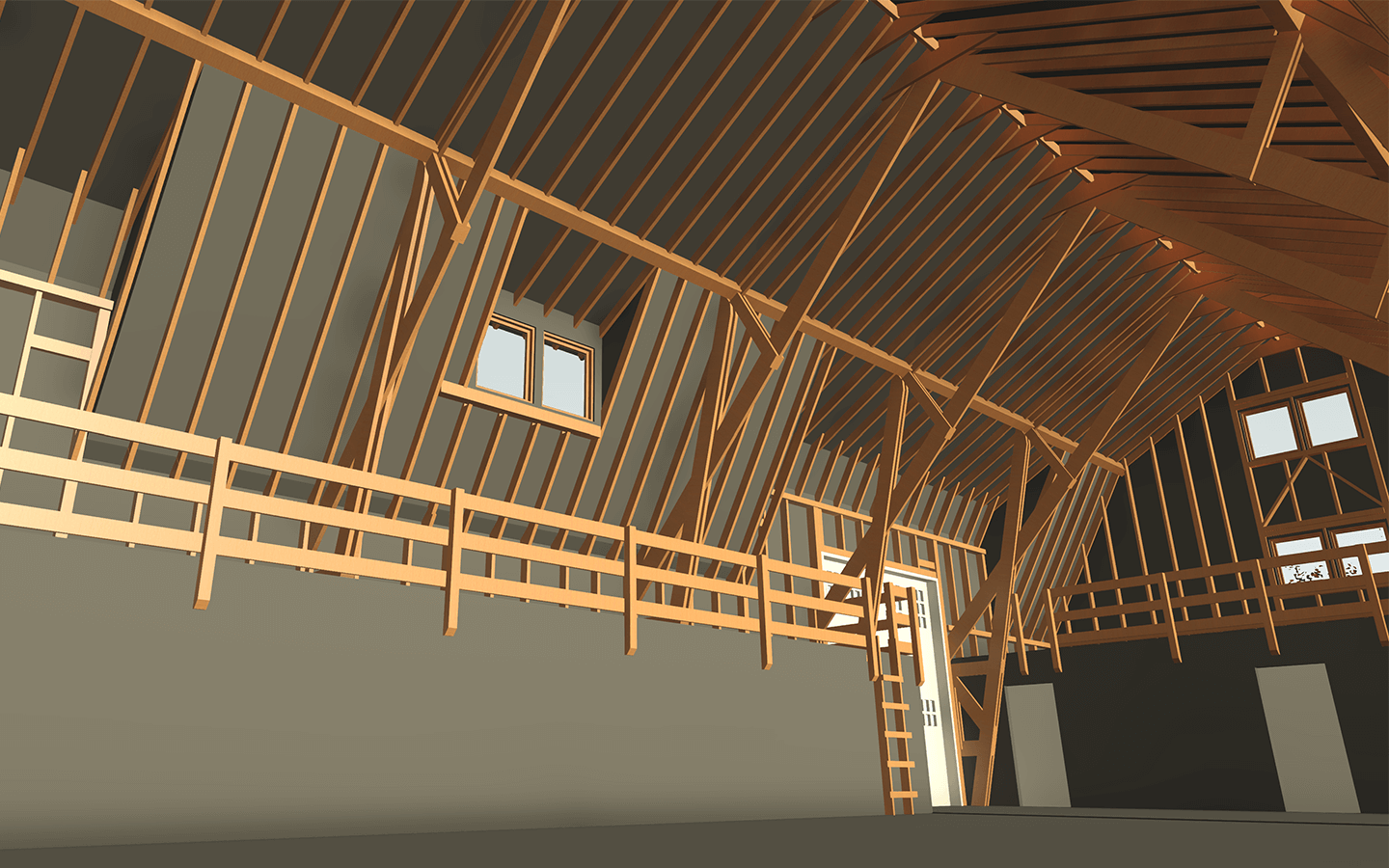

The client’s request was to show in the model all the elements of exposed wooden structures of an old barn. It was allowed to simplify and unify the elements since the building is old and the elements are exposed to the influence of natural forces like humidity, temperature fluctuations, etc.

Unprotected wooden framing tends to undergo different types of deformations, and the team aimed to find a way to simplify the model in a manner that:

- All the elements still be within the set tolerance;

- We could save time by not repeating all the individual conditions of each wooden element.

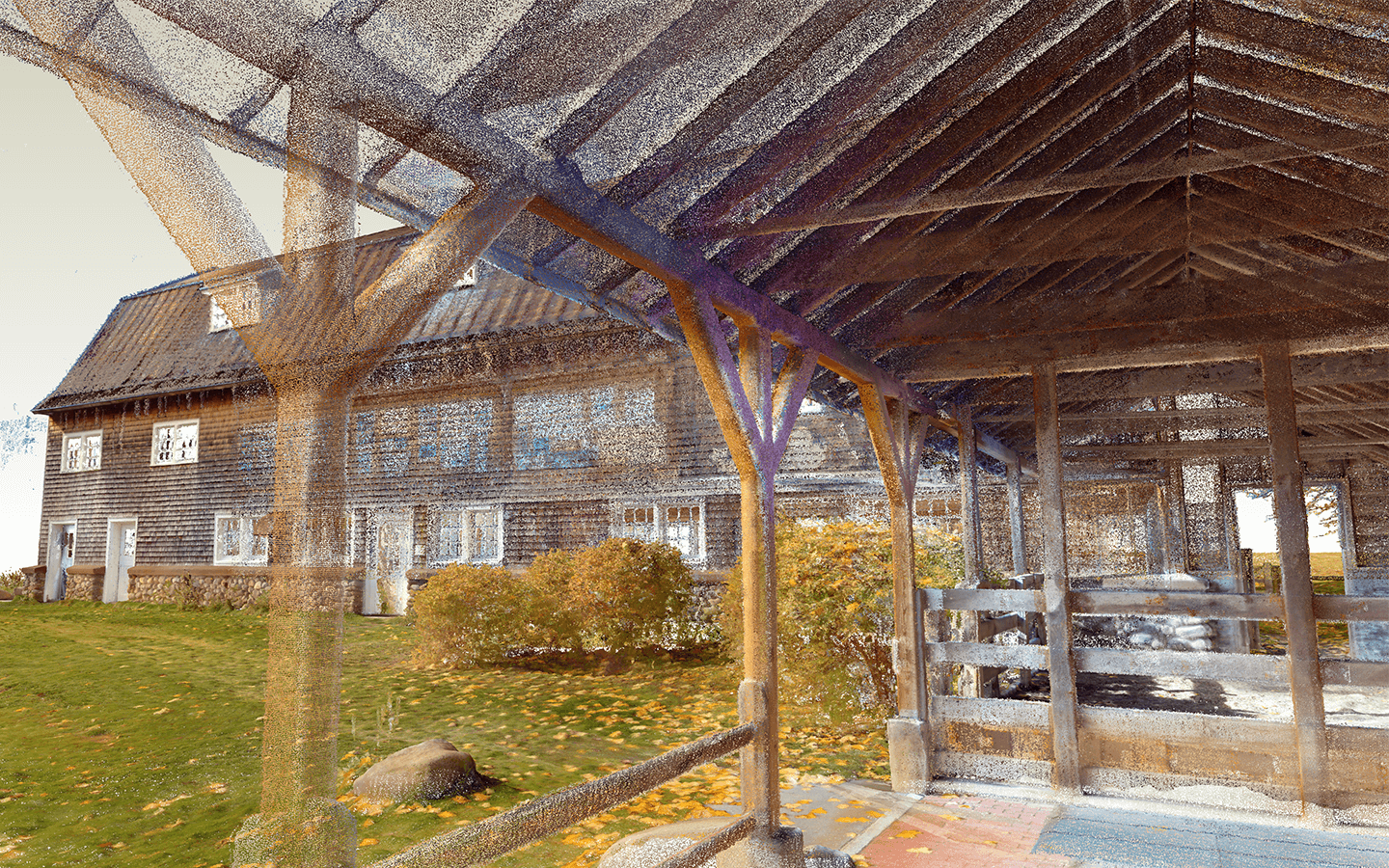

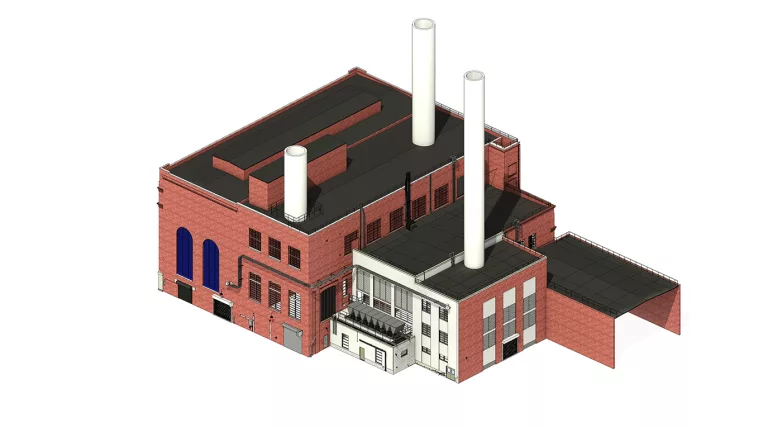

Scope of work: Modeling an old wooden barn with numerous exposed structural elements and modeling the surrounding areas of the barn.

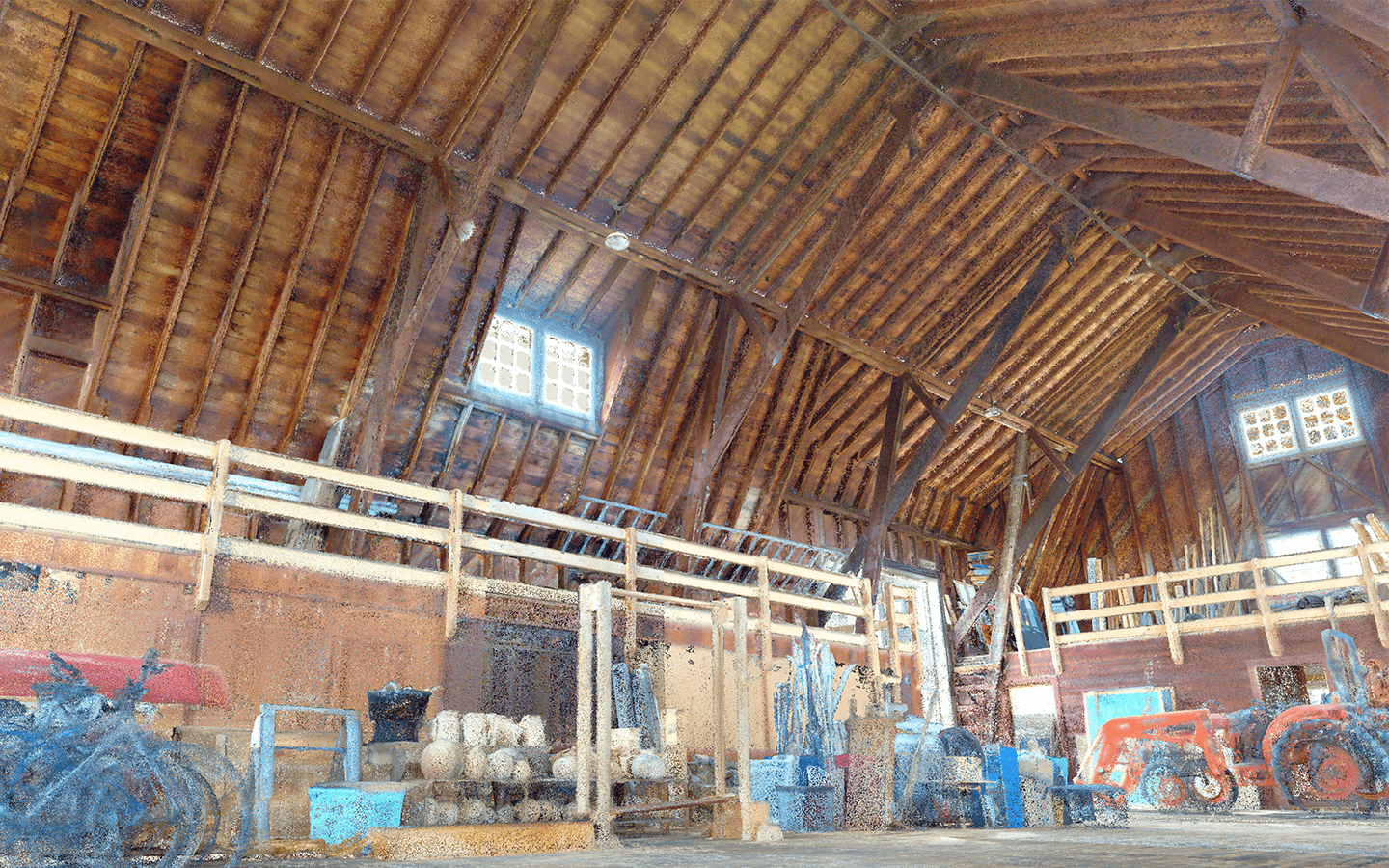

Input: Complete point cloud of the barn’s interiors and exteriors.

Output: 3D Model at LOD 300.