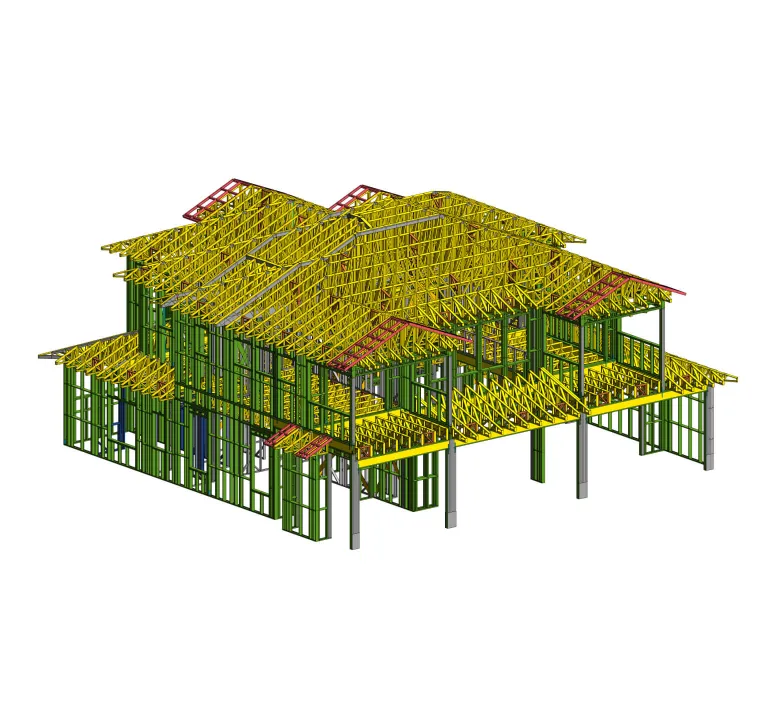

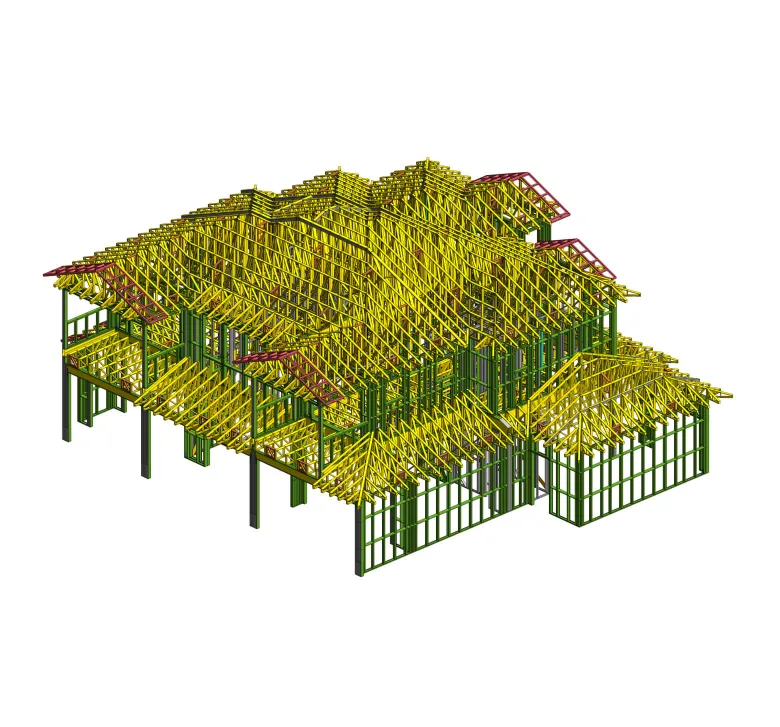

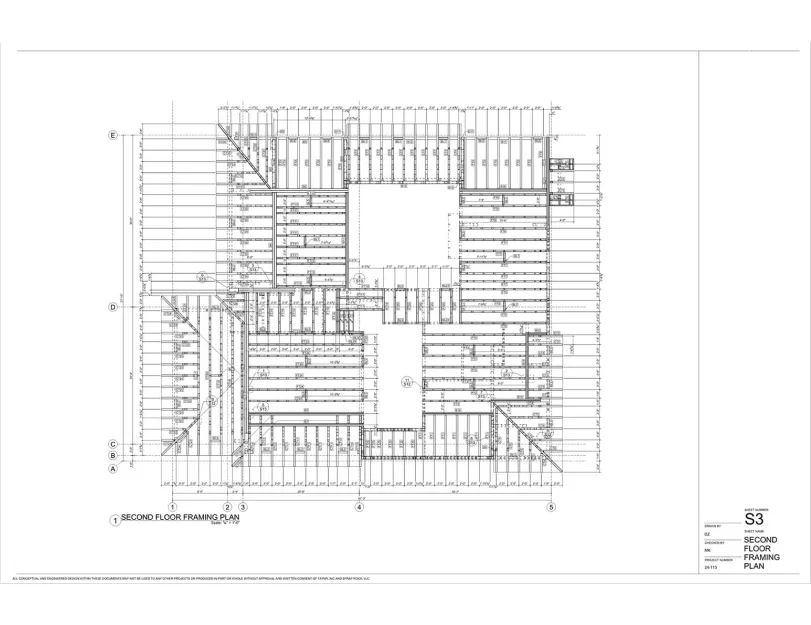

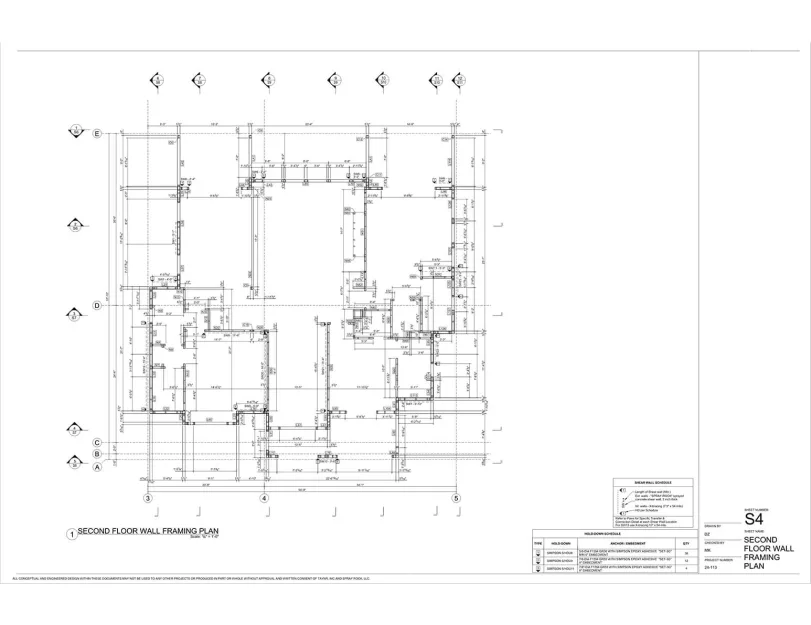

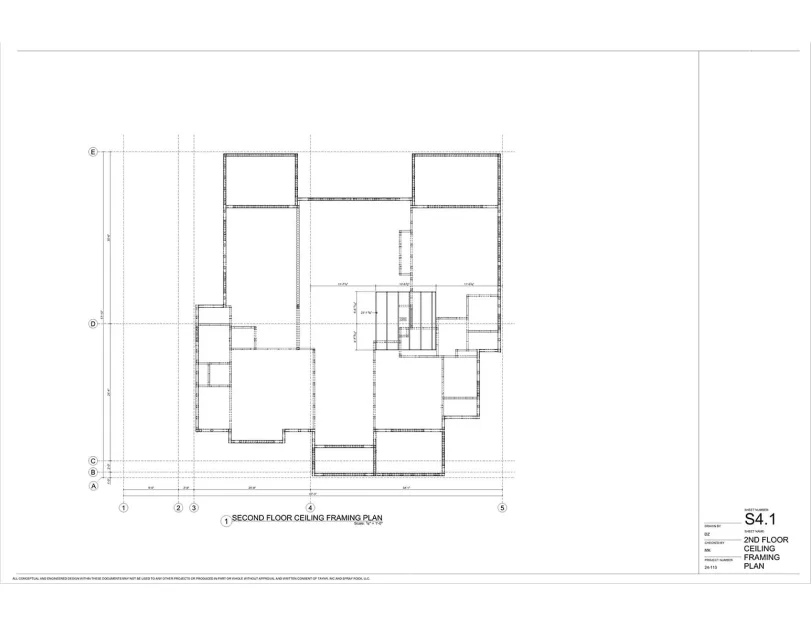

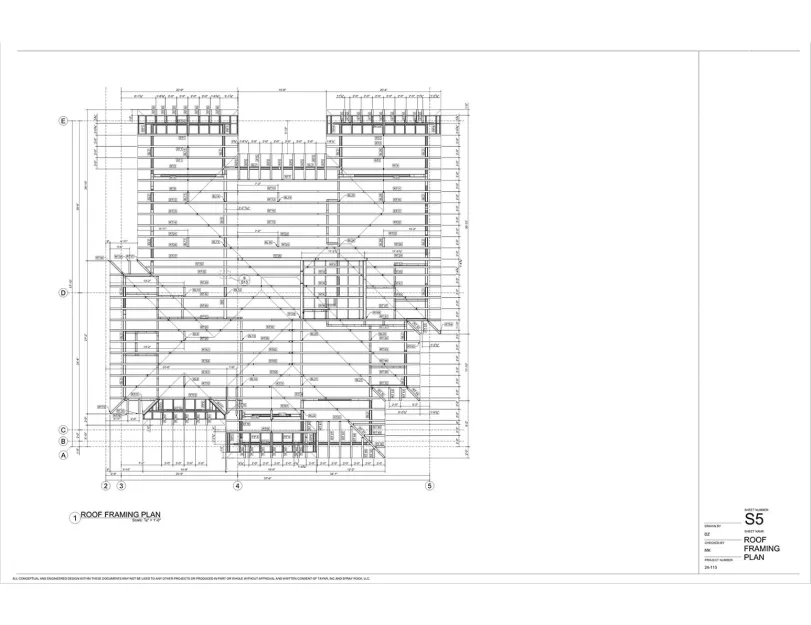

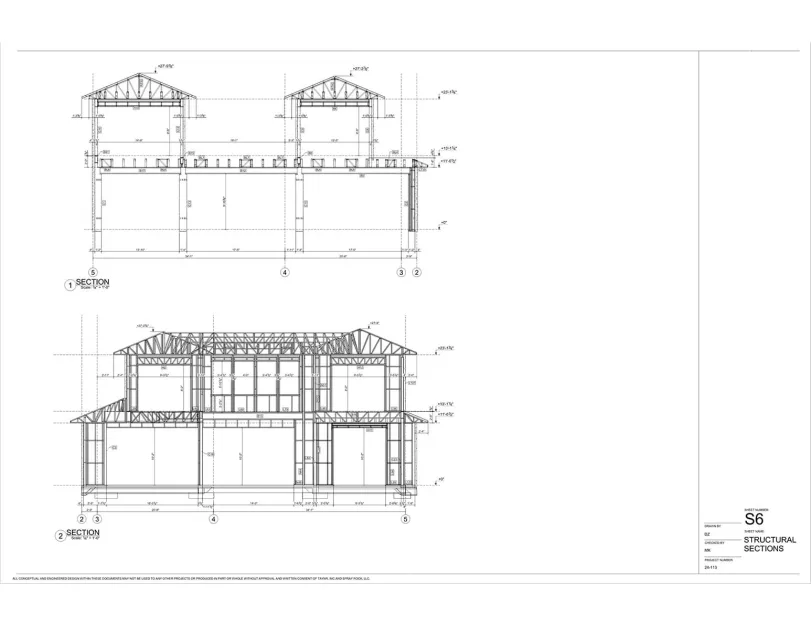

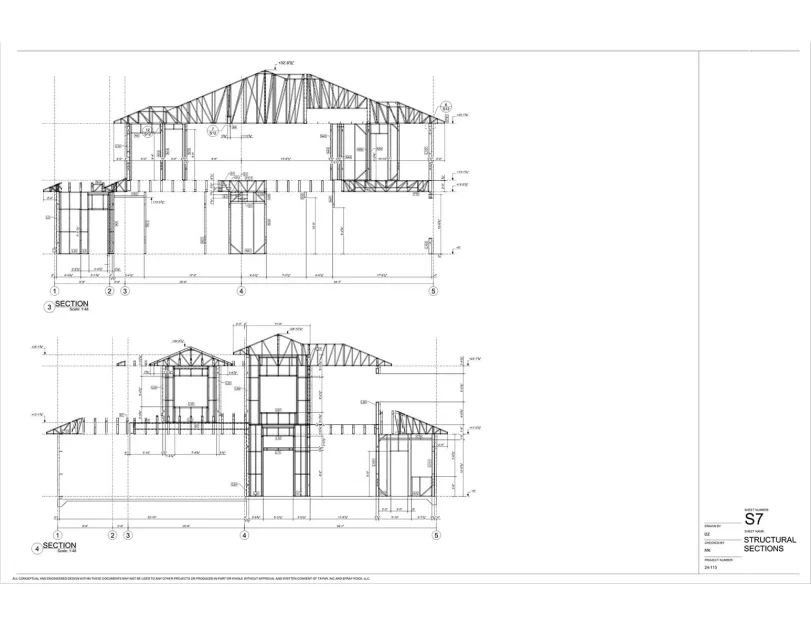

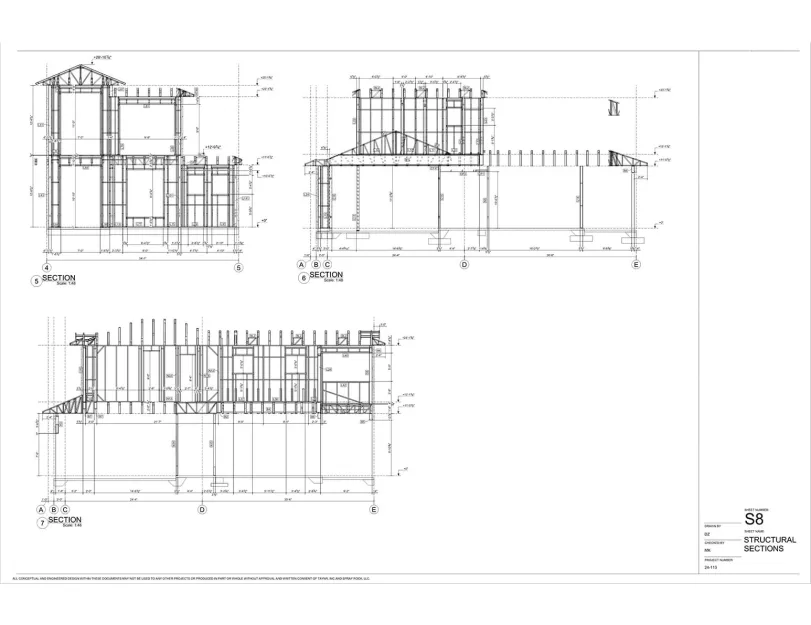

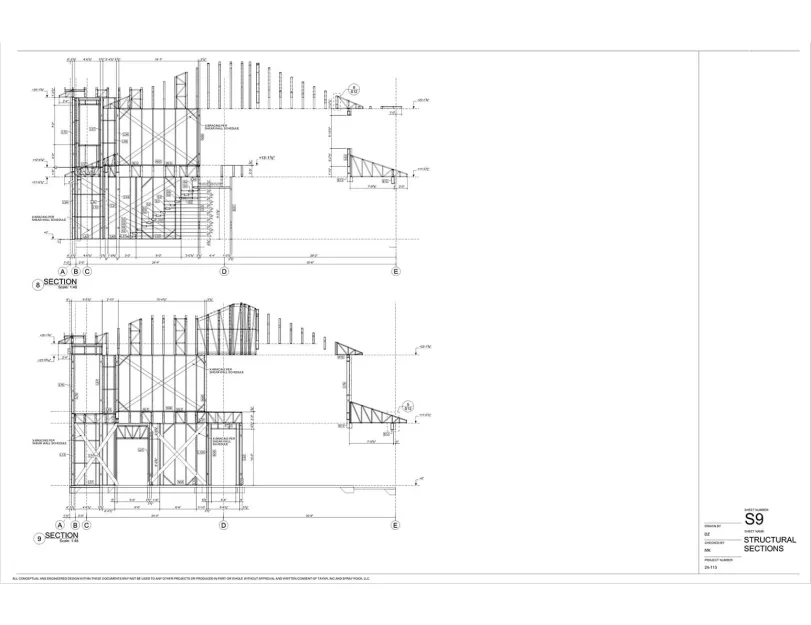

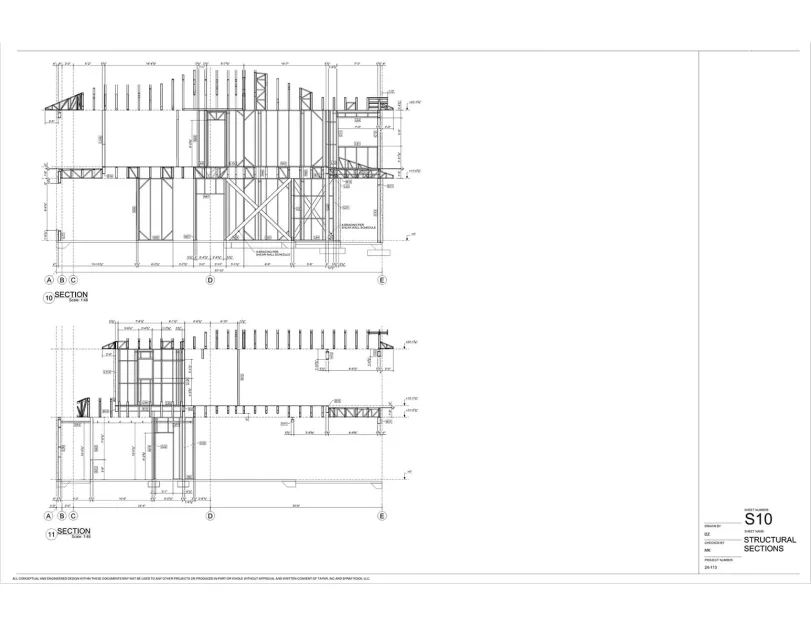

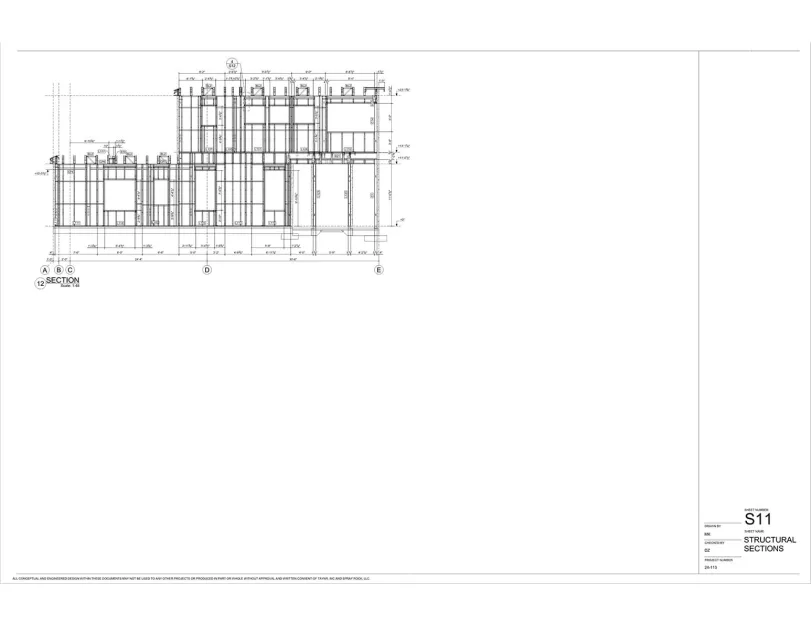

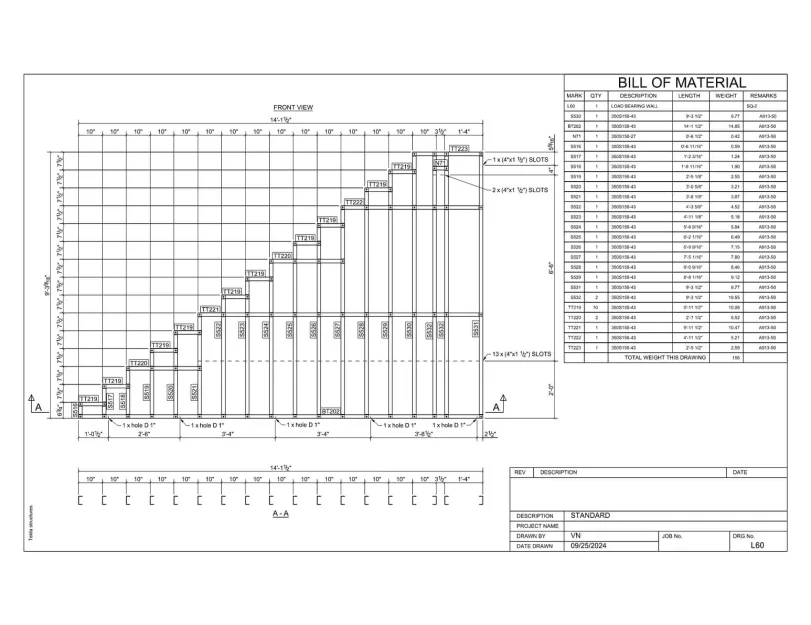

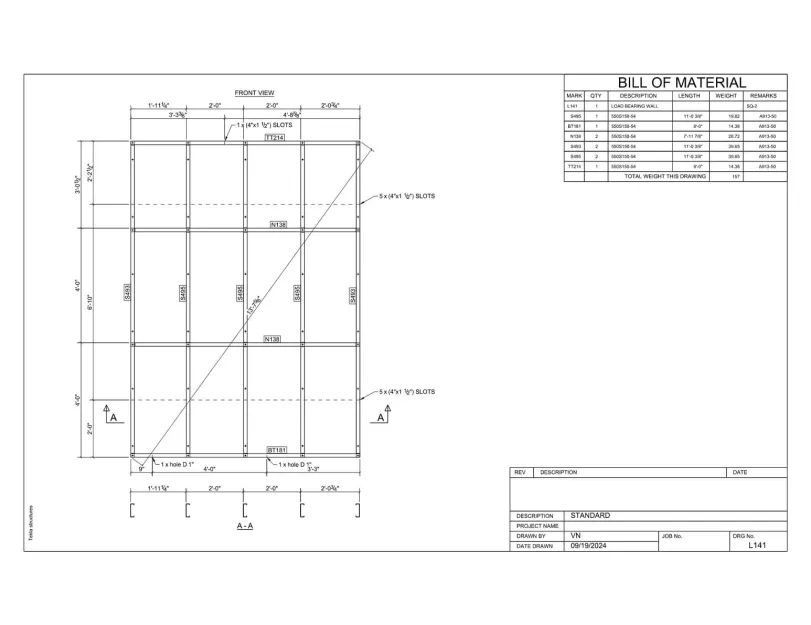

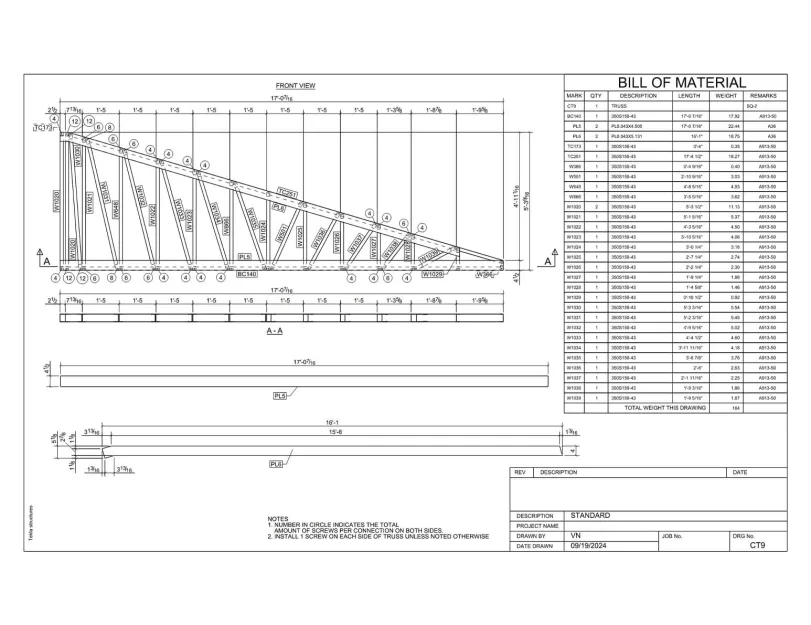

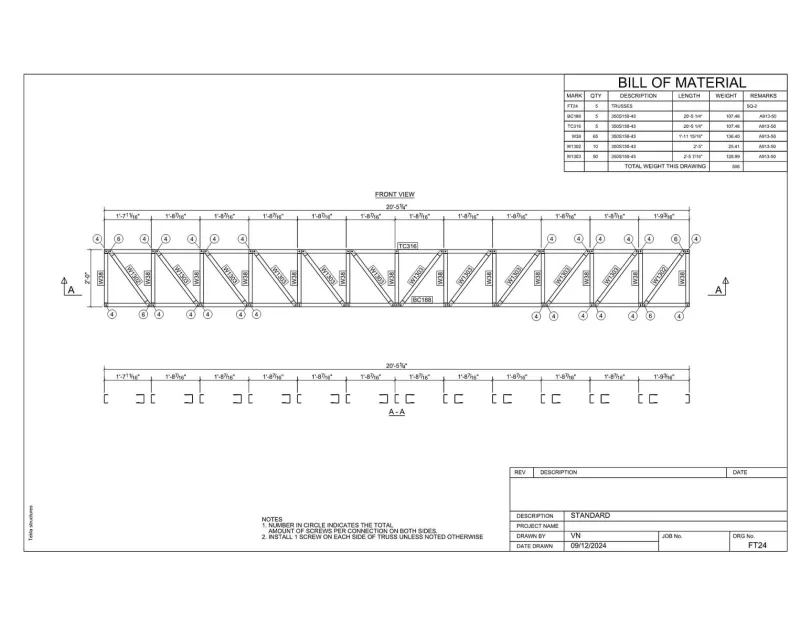

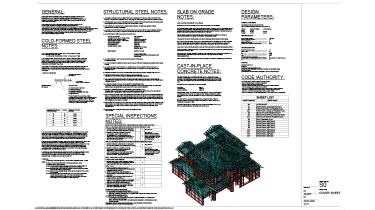

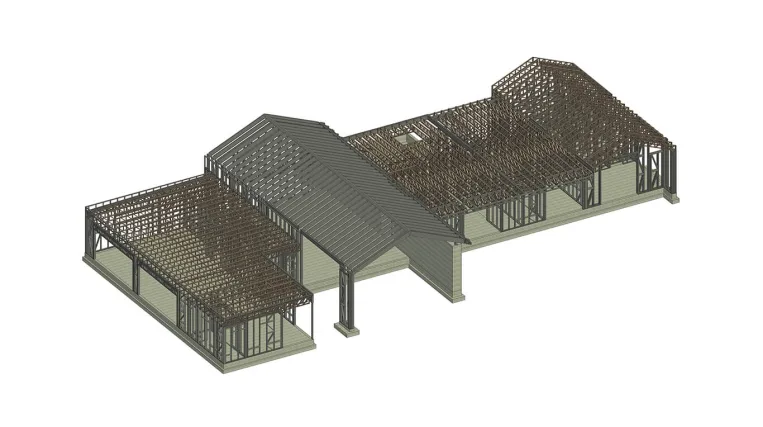

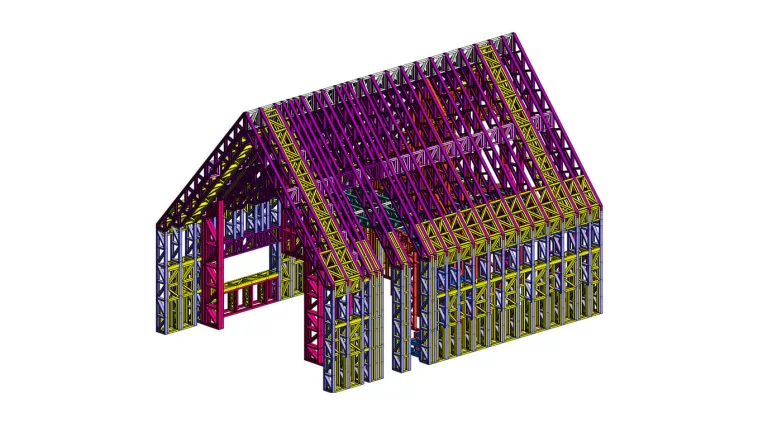

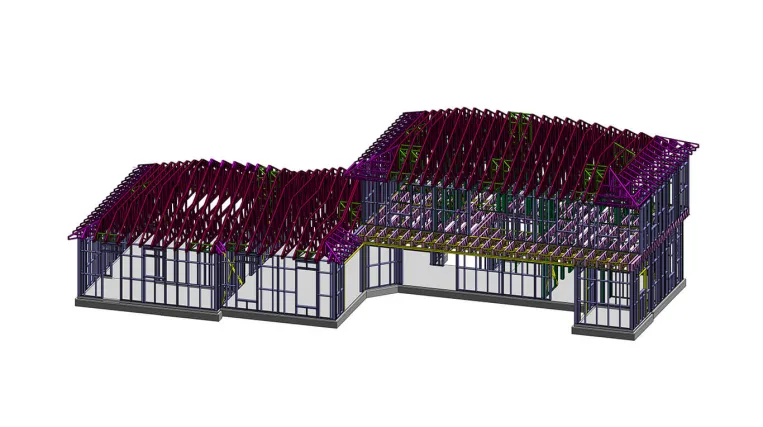

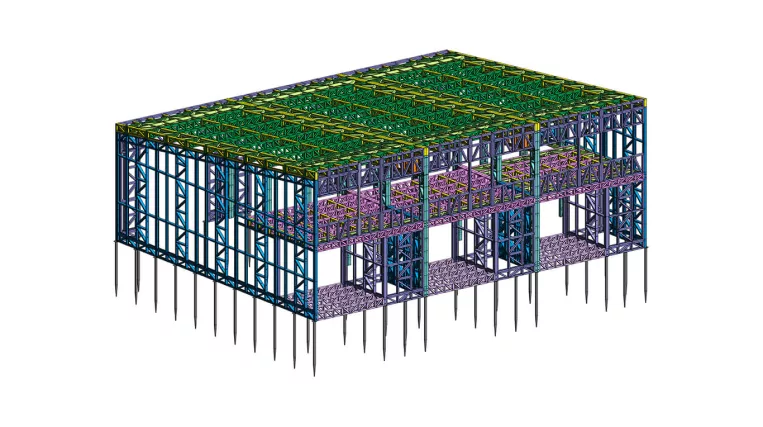

The project involved Revit modeling, Shop drawings, and CNC file generation for a spacious two-story building measuring 69′ × 58′ with a complex floor plan.

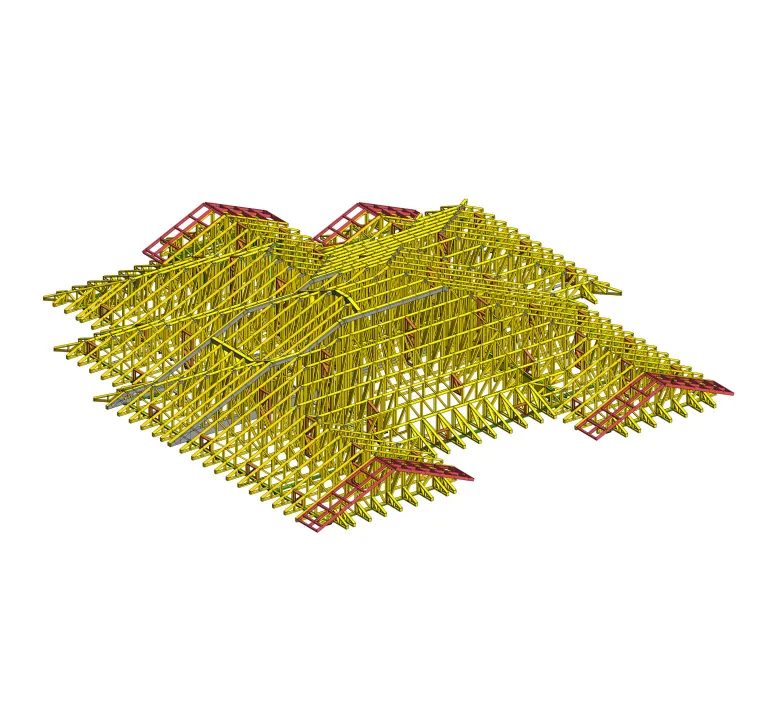

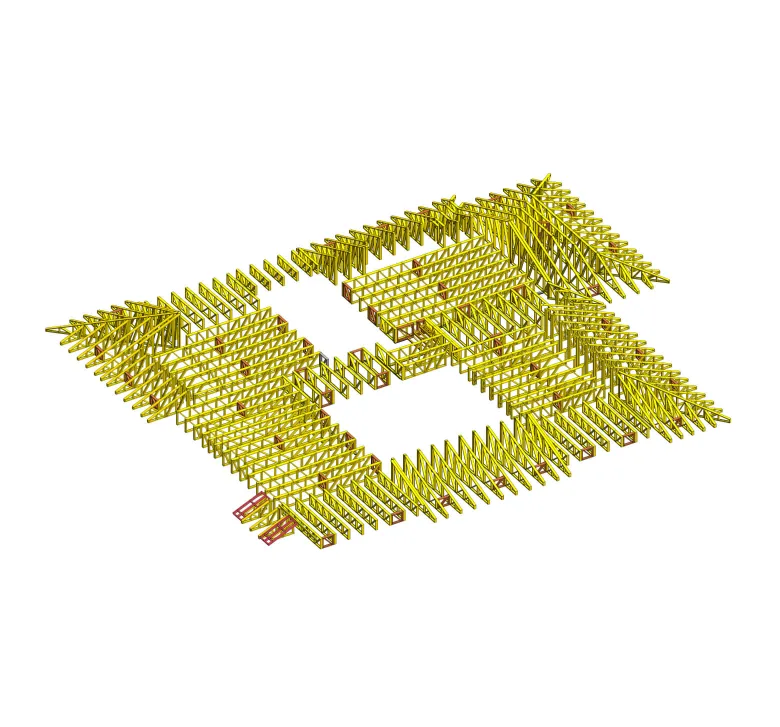

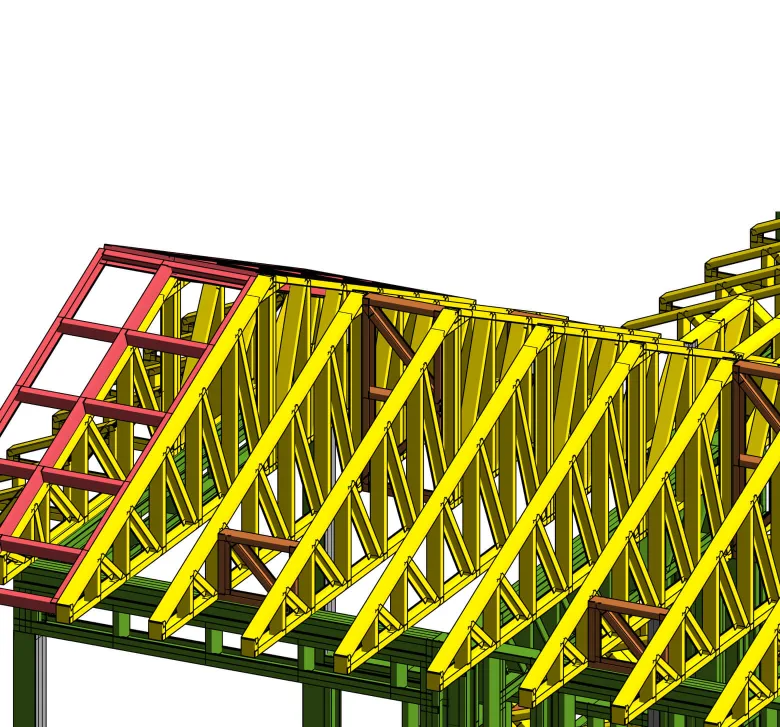

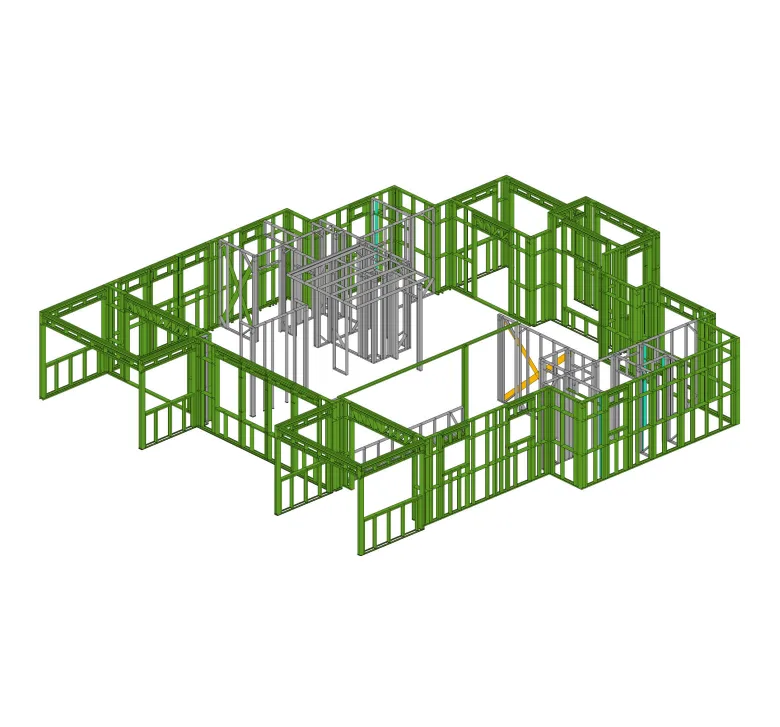

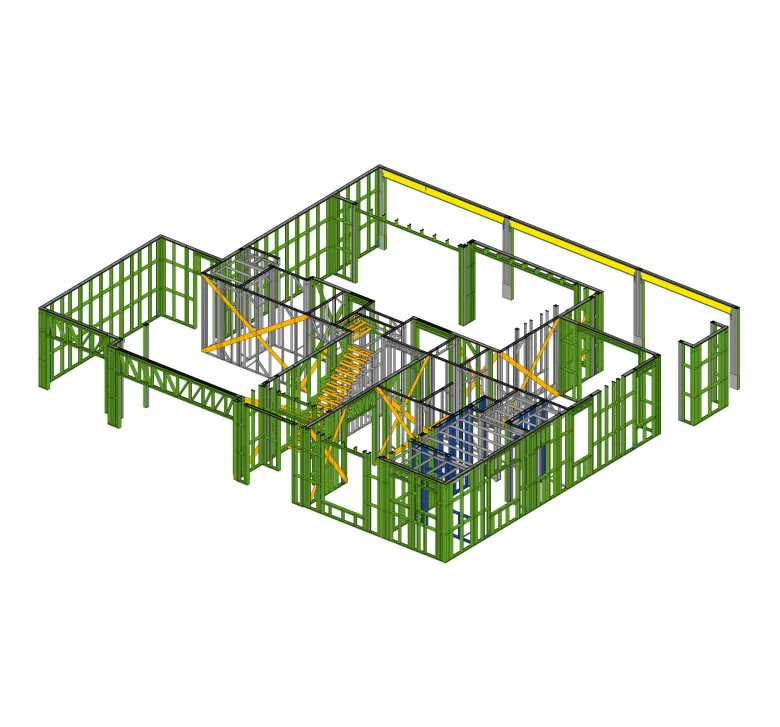

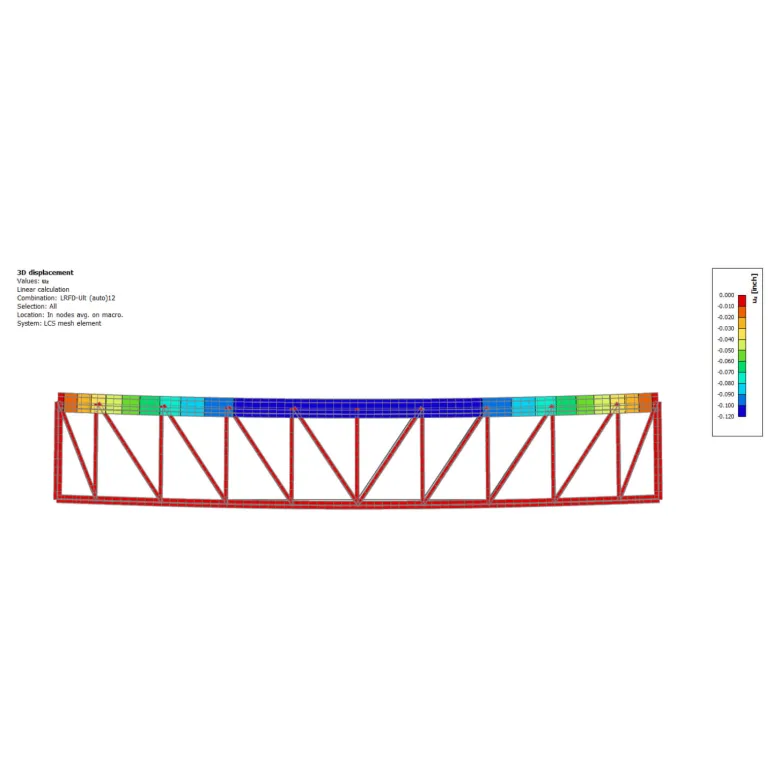

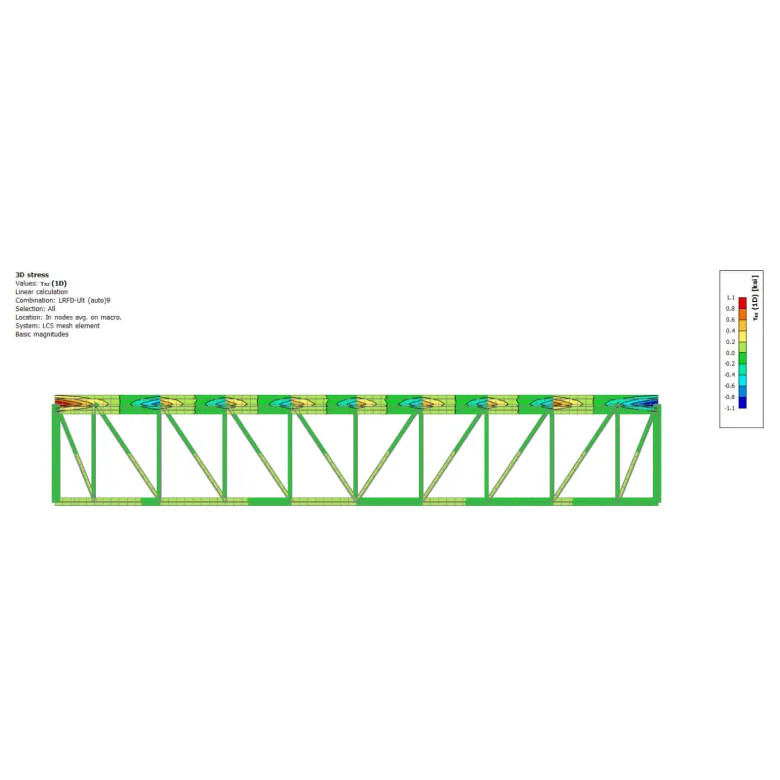

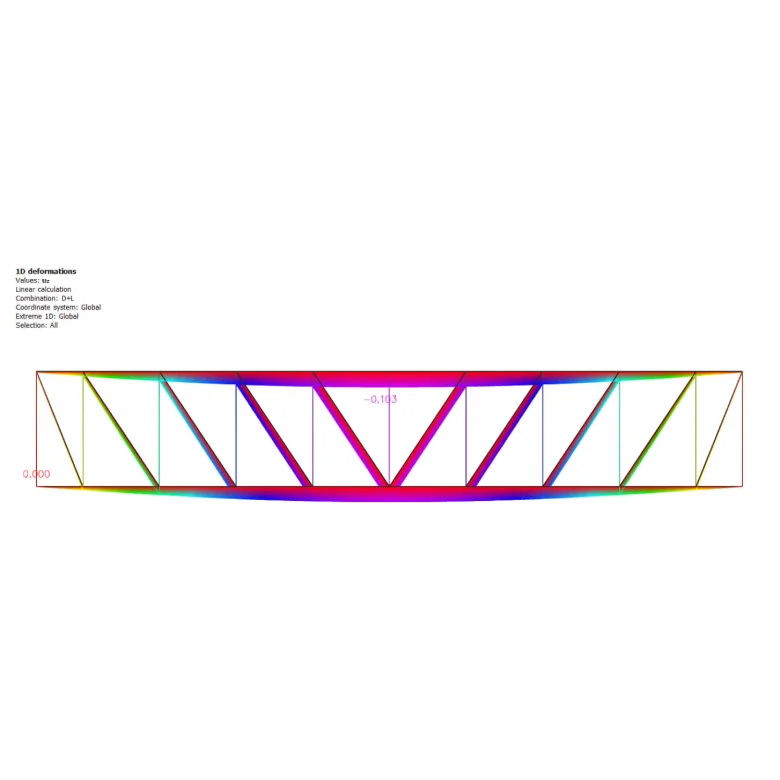

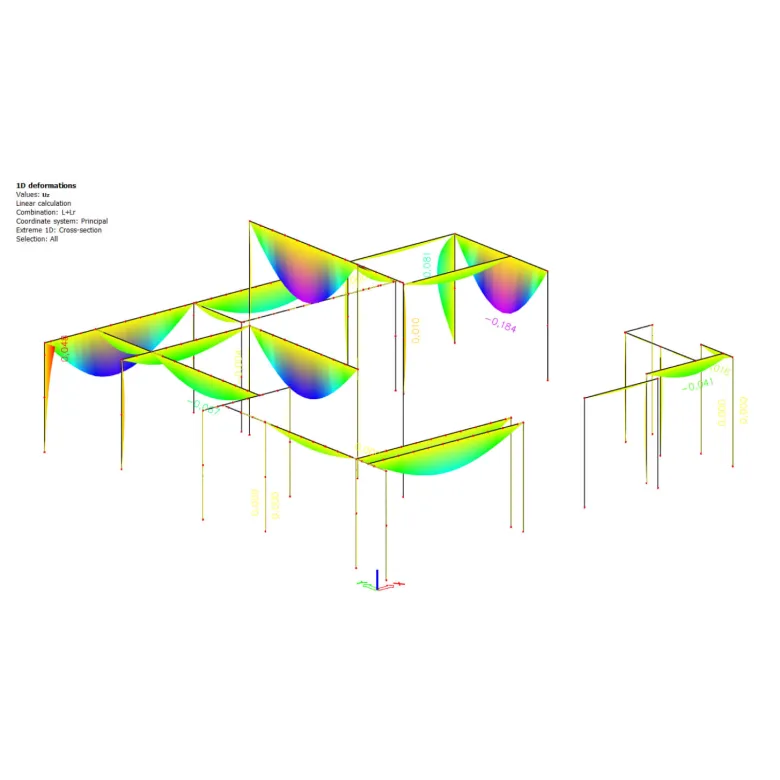

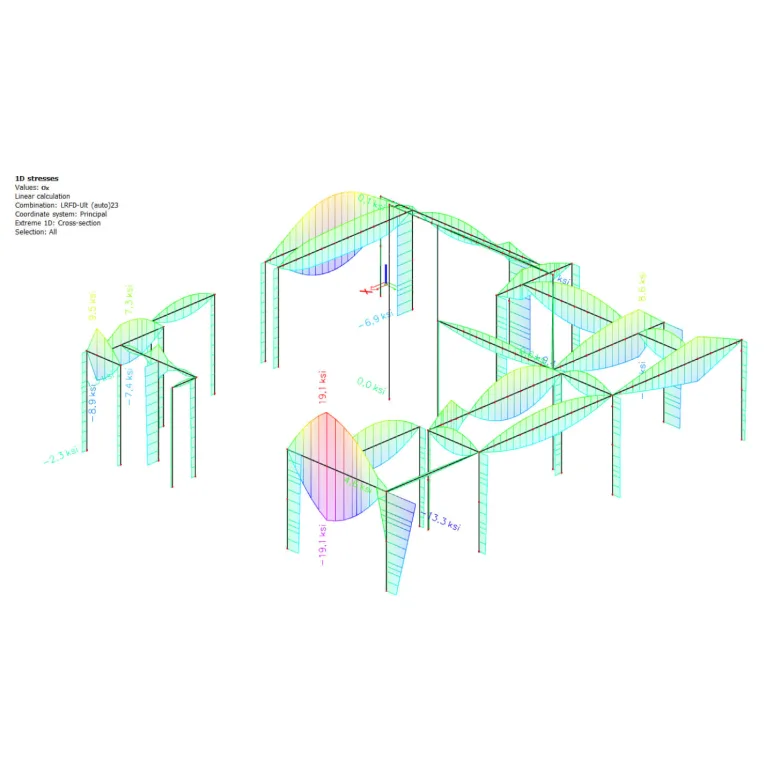

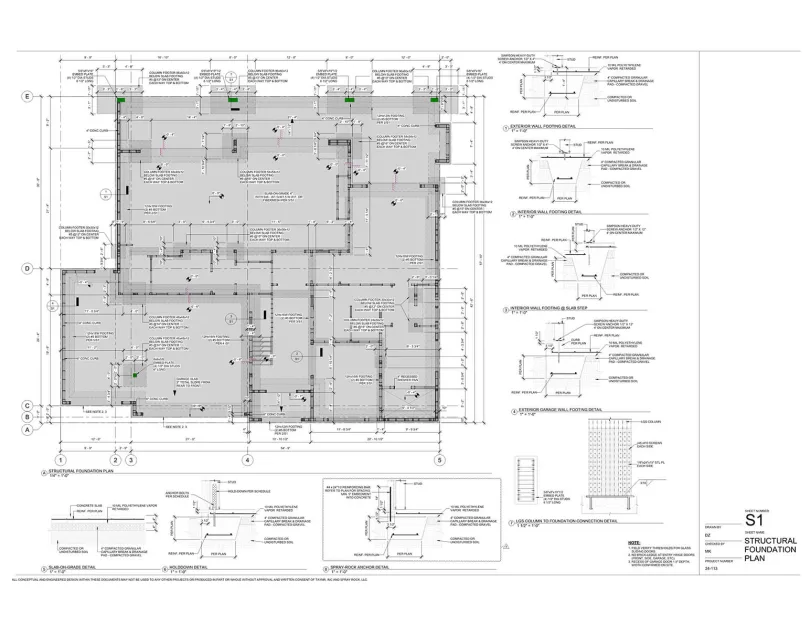

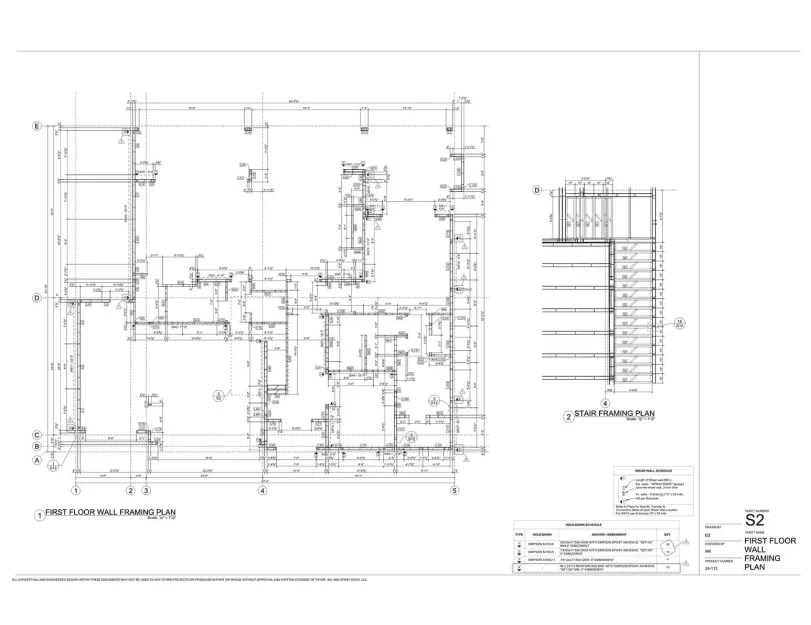

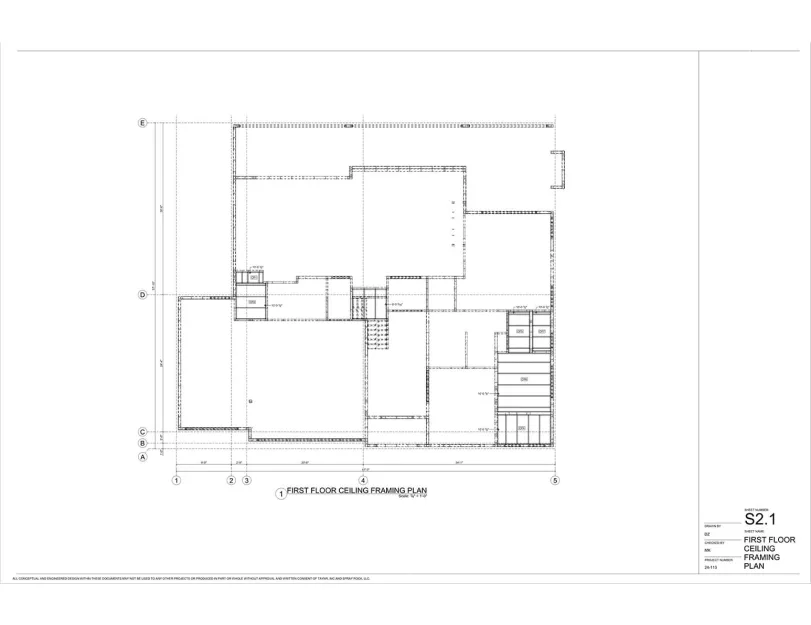

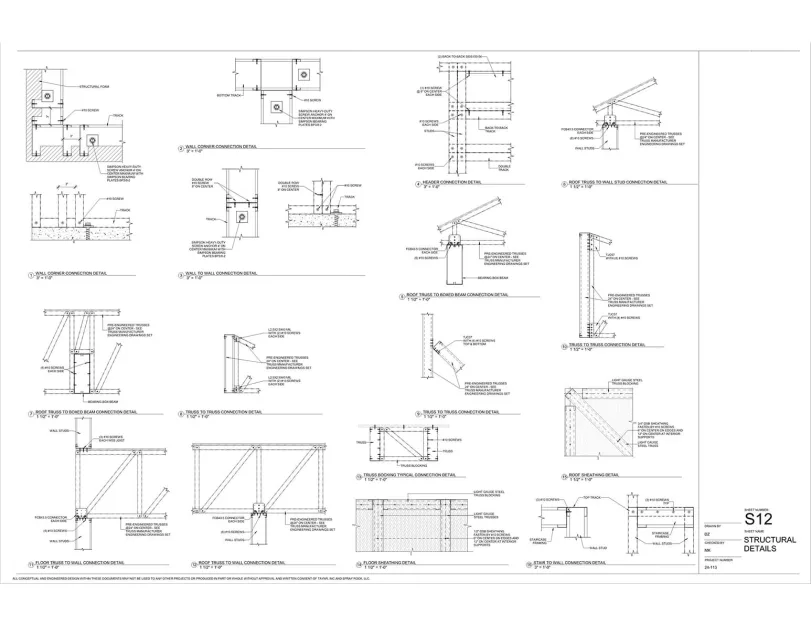

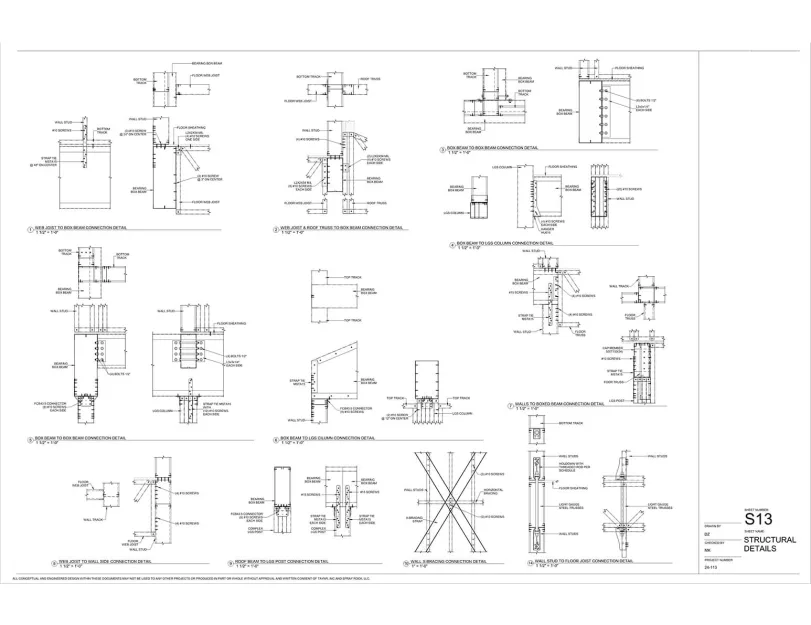

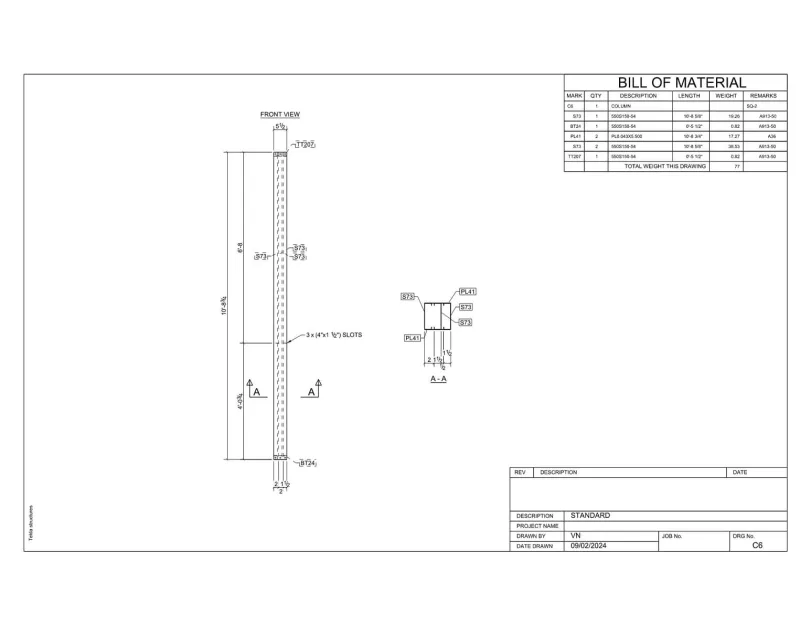

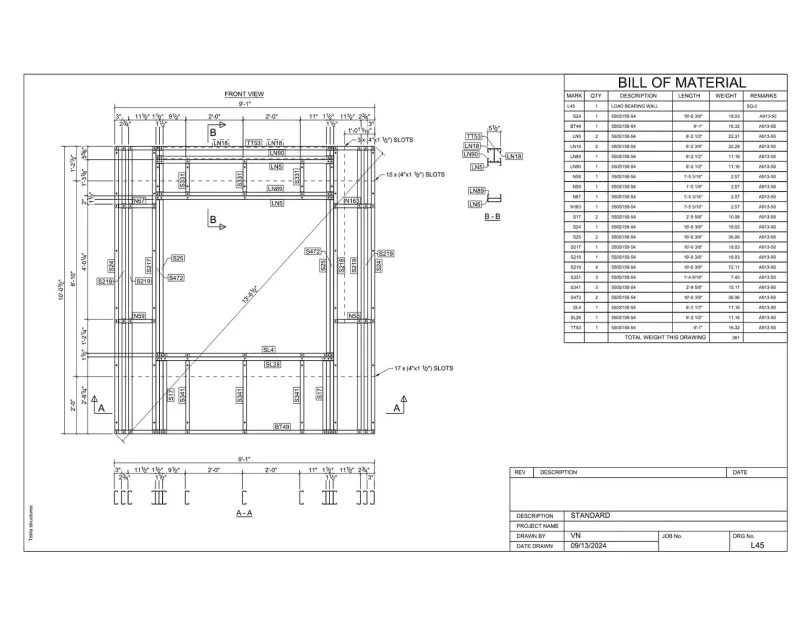

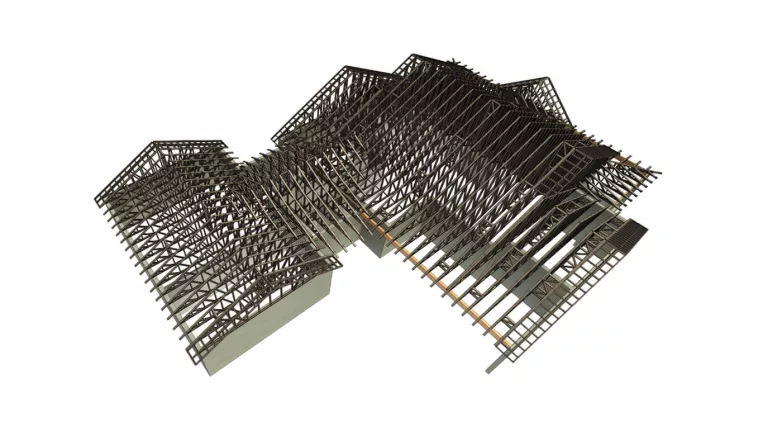

All building’s walls, floors, and roof trusses are designed in light-gauge steel. The uniqueness of the building lies in the second-floor walls, some of which are offset inward and supported by the floor system, along with a combination of vertical X-bracing straps and a sprayed concrete shear wall. The foundation utilized a slab-on-grade foundation, with additional footings provided where LGS columns require support.

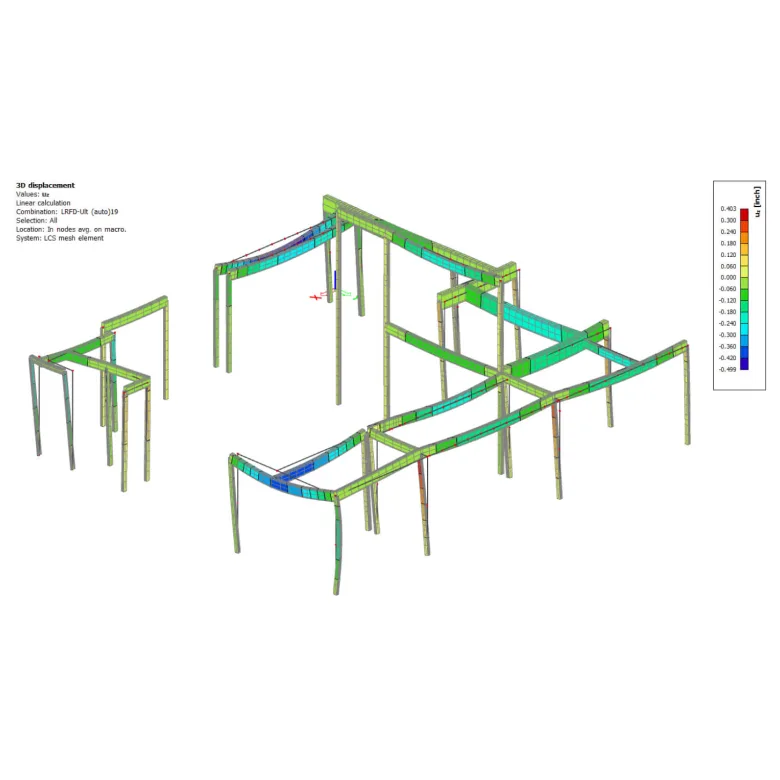

As a project result, the ORIGIN team produced a spatial model, providing a comprehensive 3D analytical representation of the structure. In addition, the design follows the requirements of the 2021 Edition of the International Building Code, as listed in the code/authority references below.

Input: Architectural drawings set

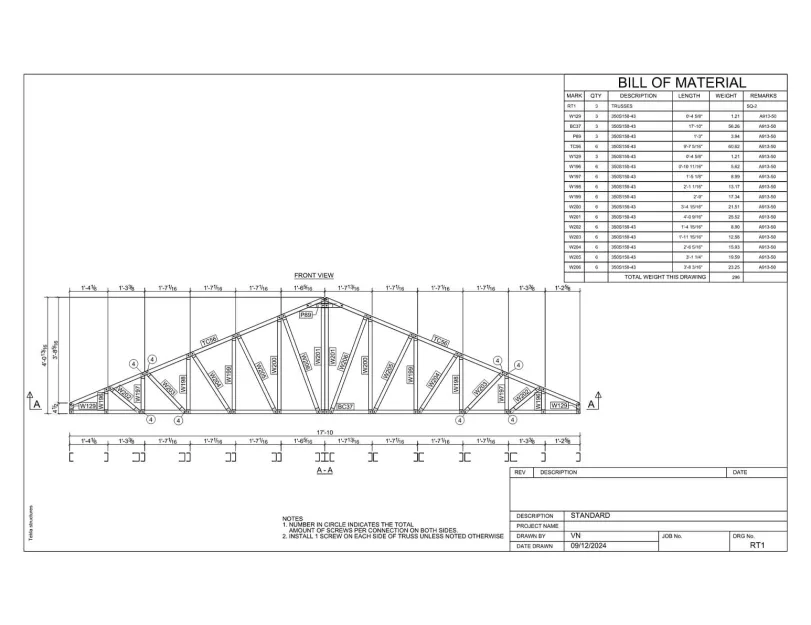

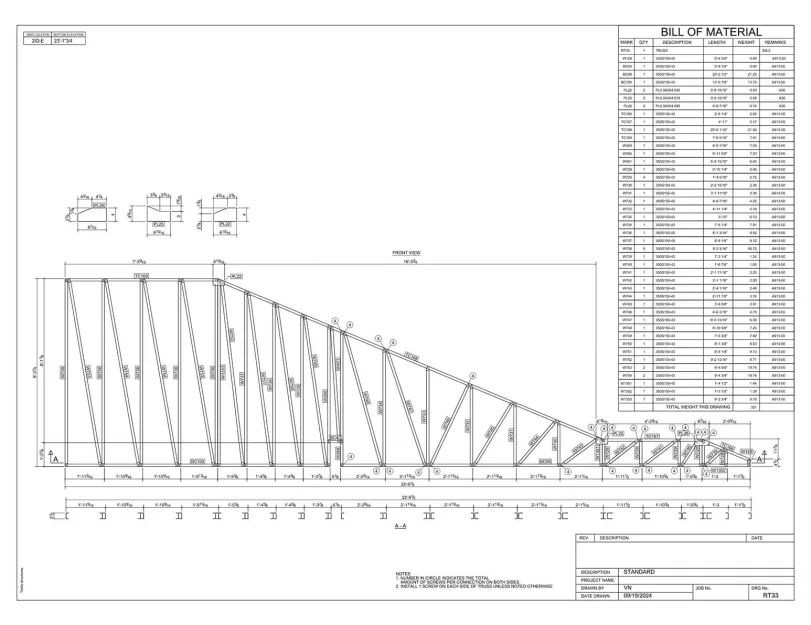

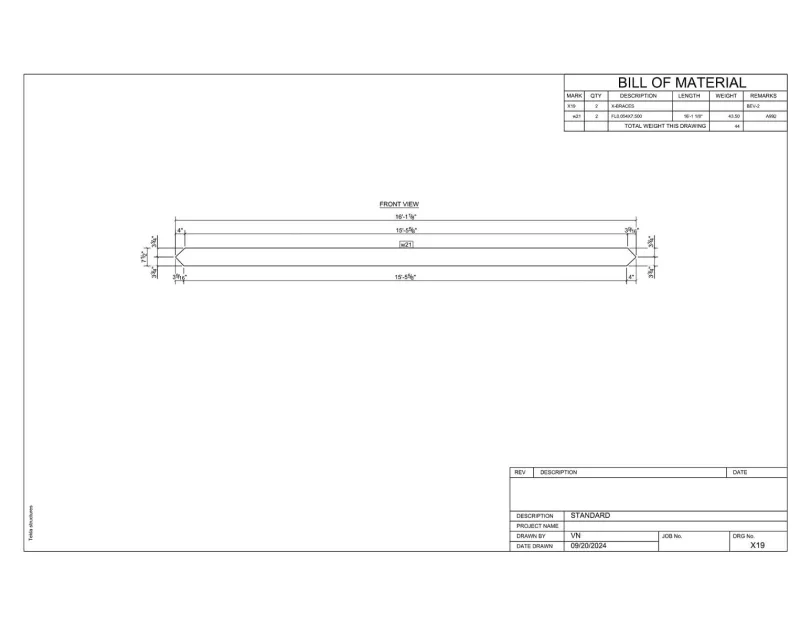

Project deliverables:

- Revit model;

- Structural analysis report;

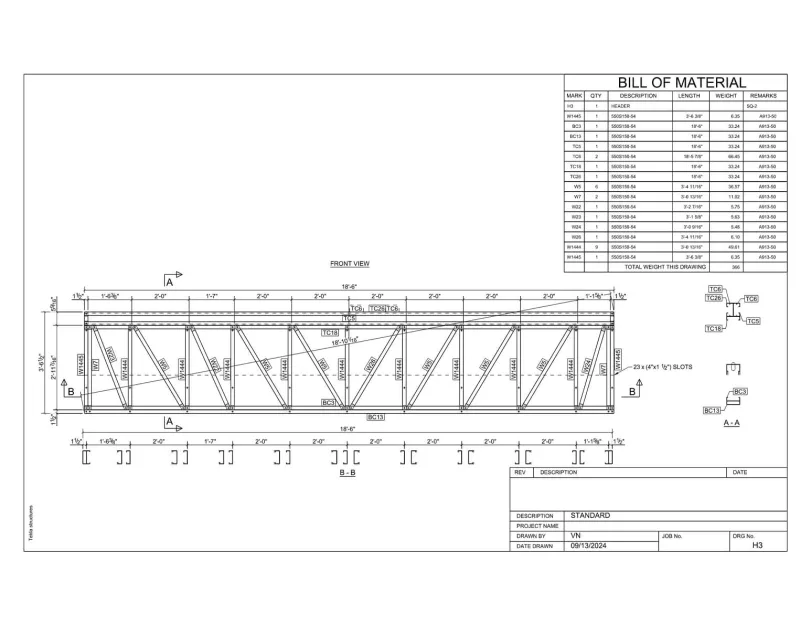

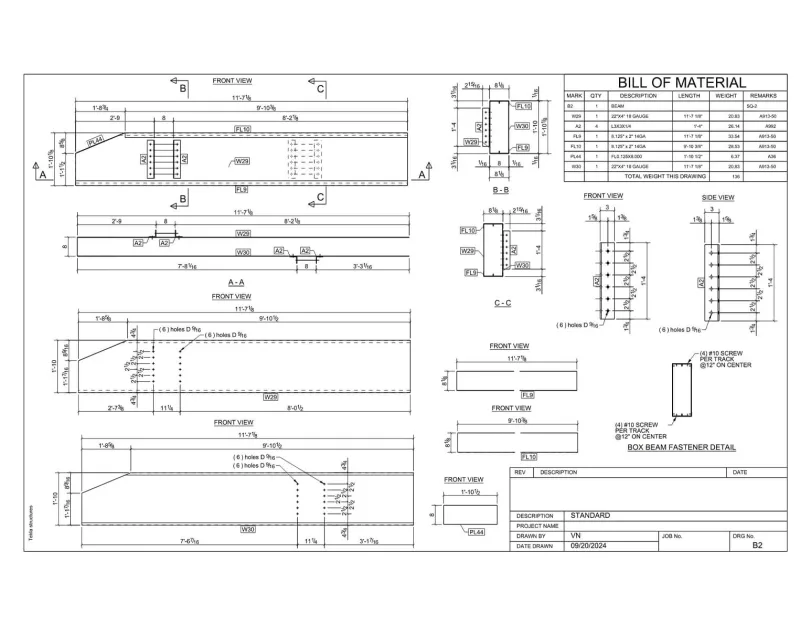

- Structural drawings set;

- Shop drawings;

- CNC files.