Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum. — Change

Overview

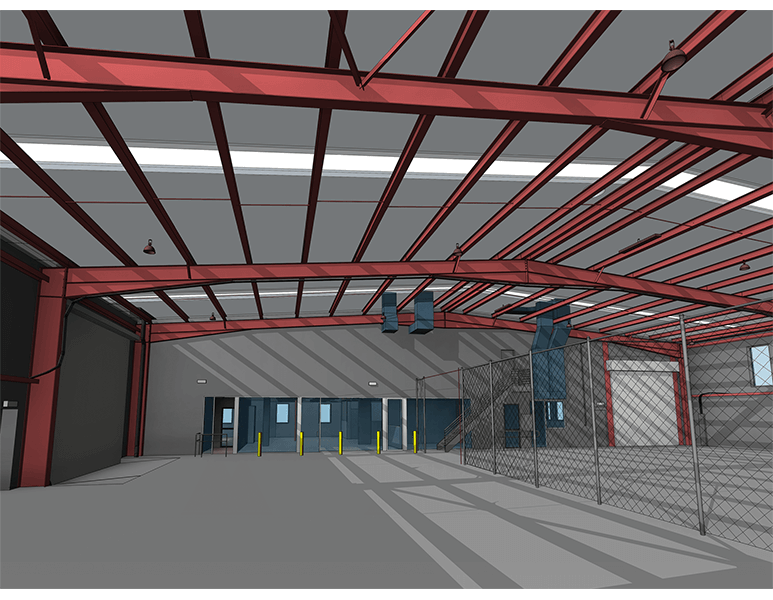

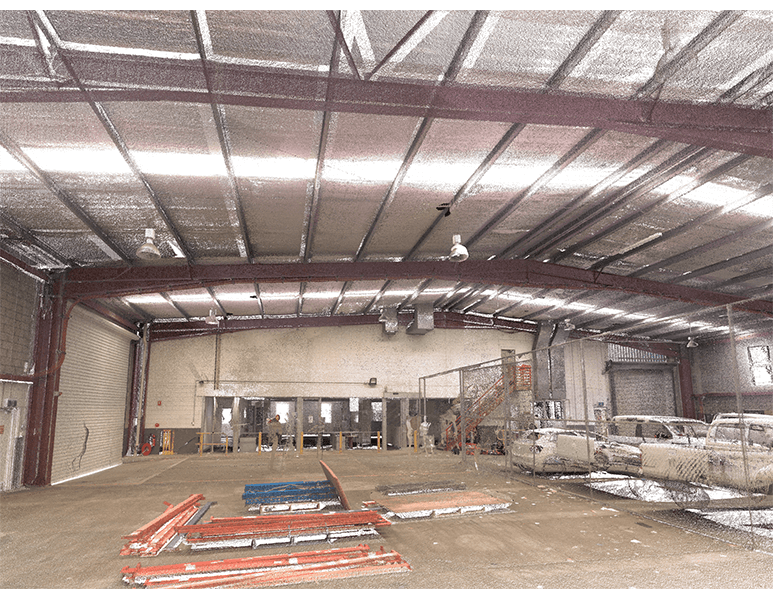

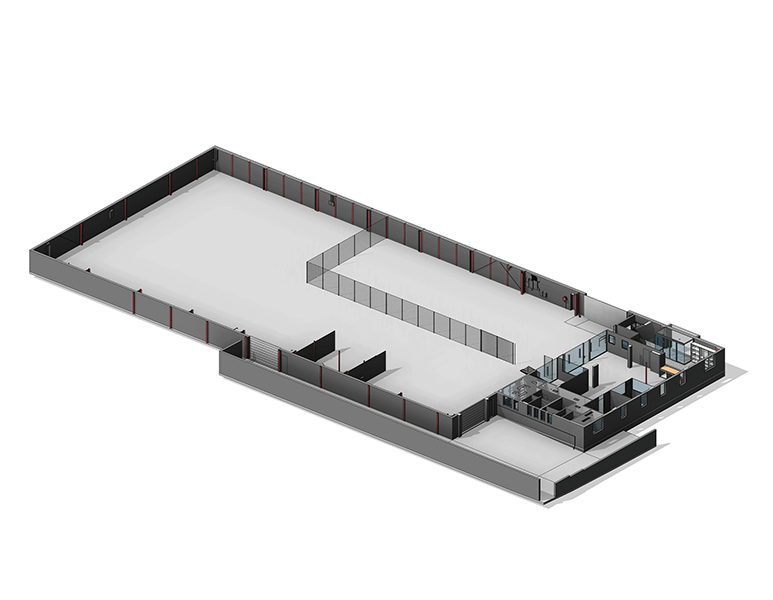

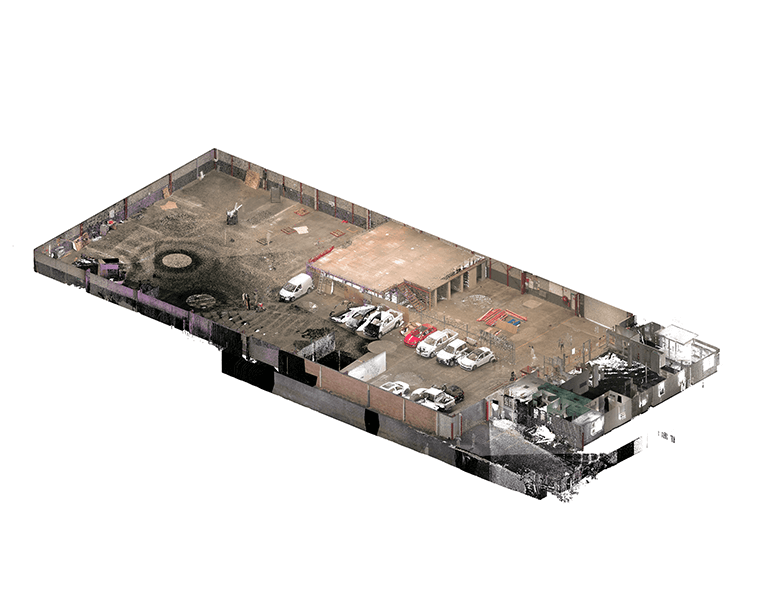

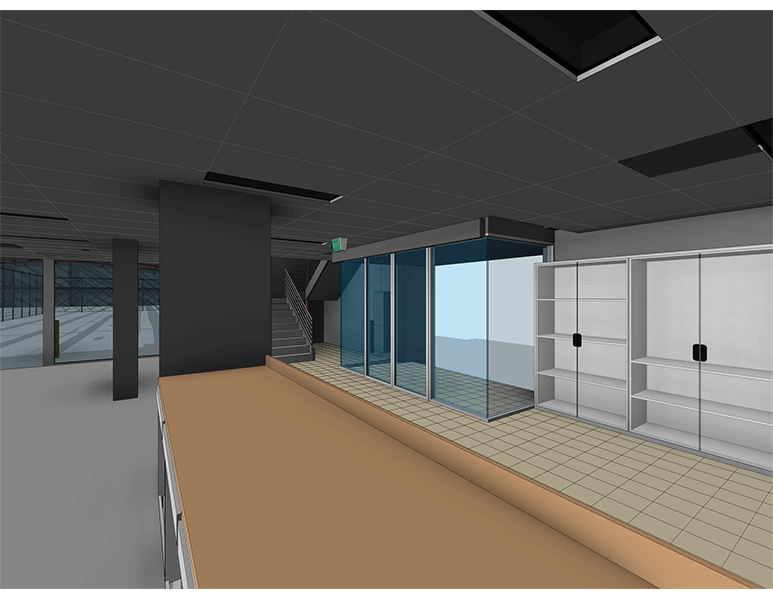

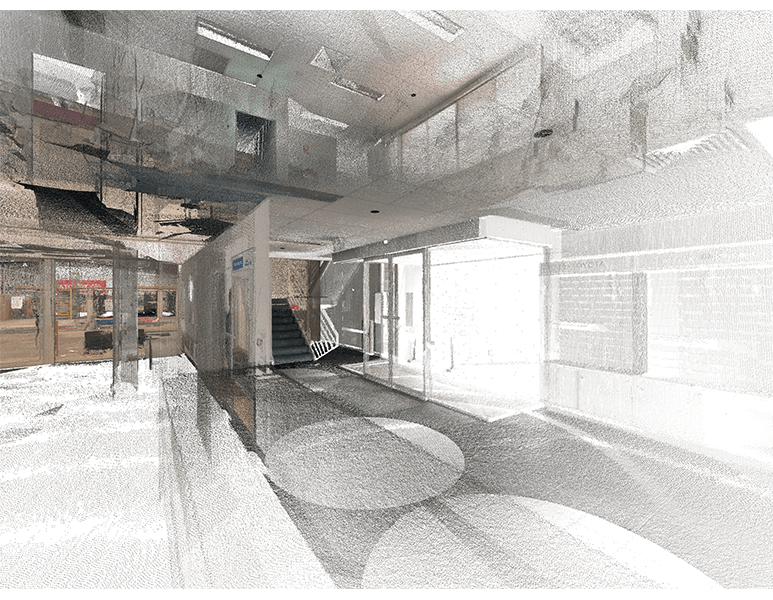

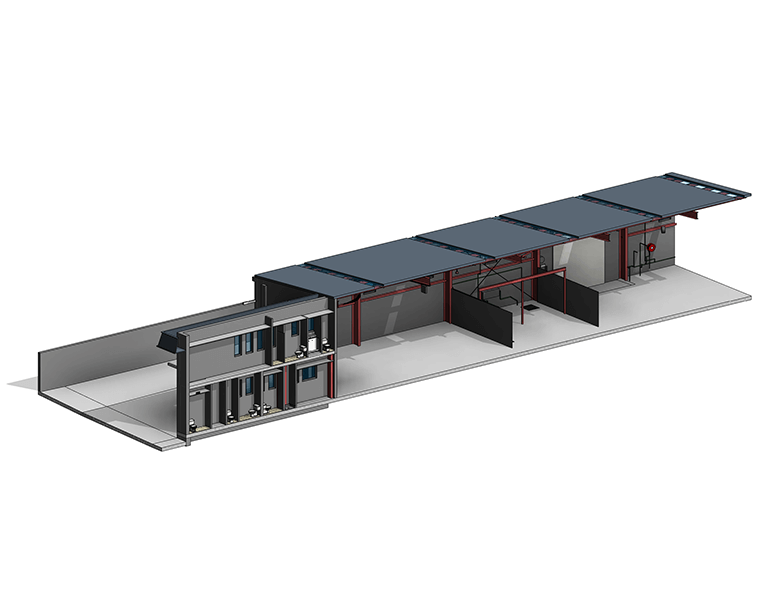

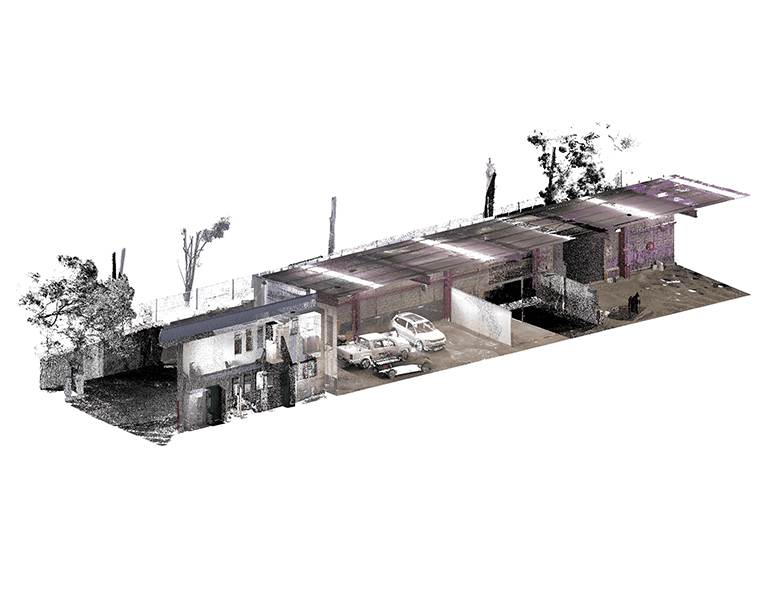

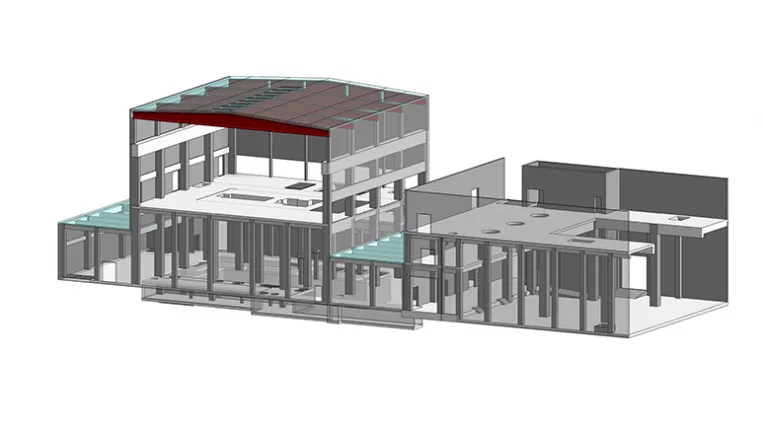

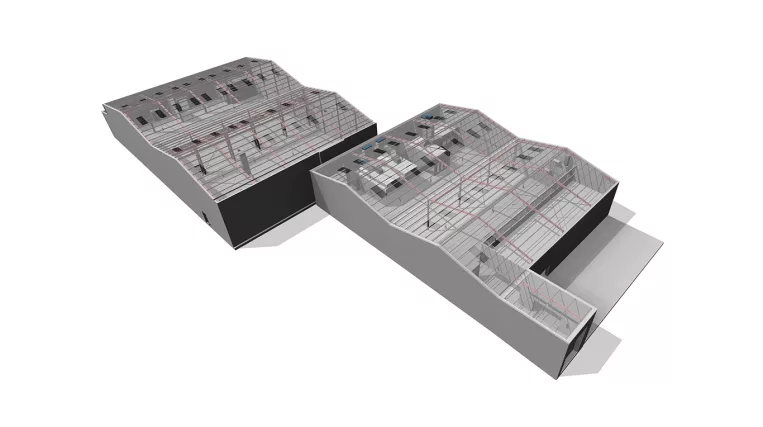

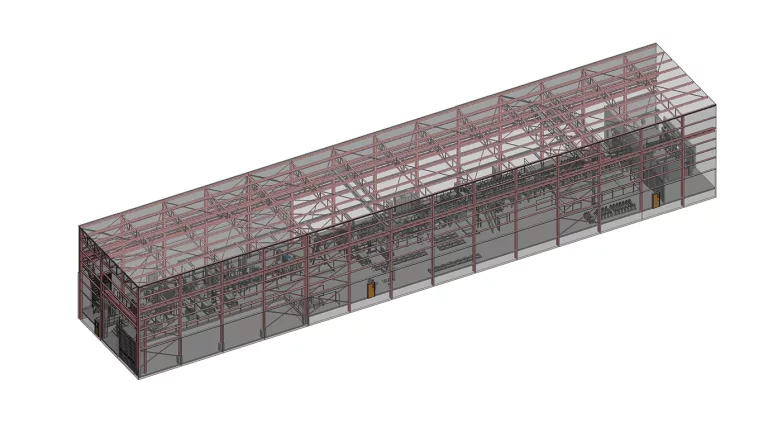

| Services: | BIM, STRUCTURE |

| Subservices: | Scan to BIM |

| Industry: | Industrial |

| Object type: | Warehouse |

| Area: | 2600 m² / 27990 ft² |

| Tools used: | Autodesk Revit, Autodesk ReCap |

| Share: |

Point cloud vs Model

Tools used

Autodesk Revit

Autodesk ReCap

Similar projects