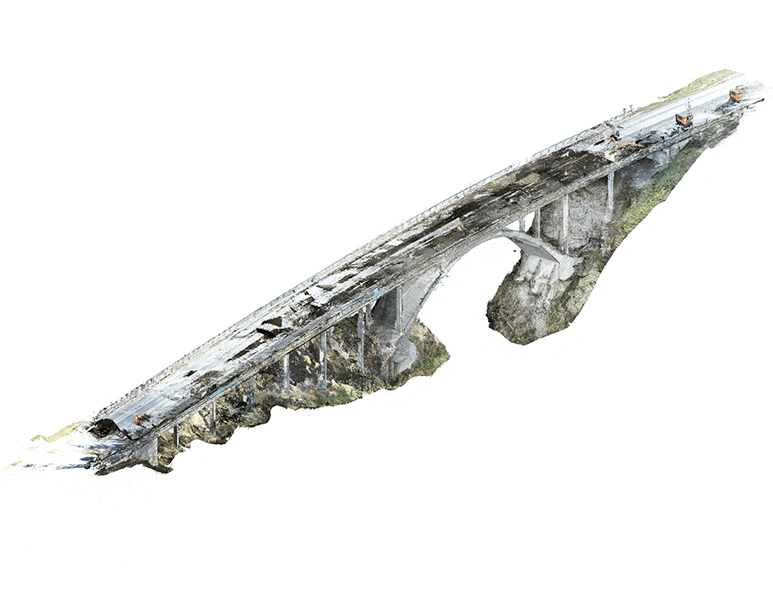

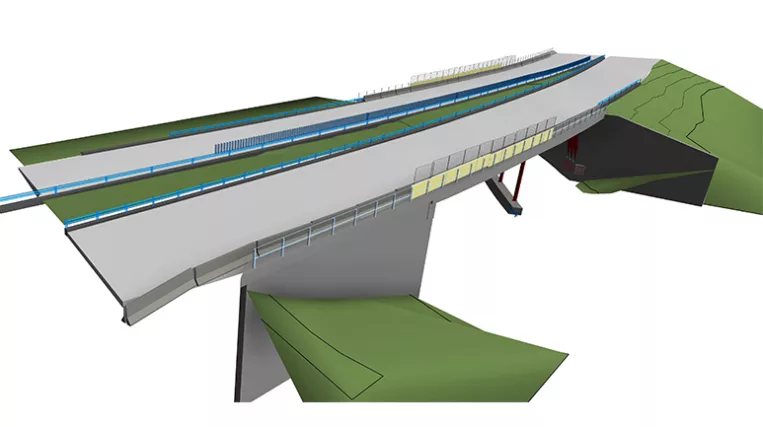

The client specializes in capturing infrastructure objects to create digital models, extracting real textures from photos, and applying them to the model. This process serves as vital documentation for identifying damages like cracks, corrosion, etc. Based on these models, building inspection reports are generated, and further plans for reconstruction and maintenance are developed.

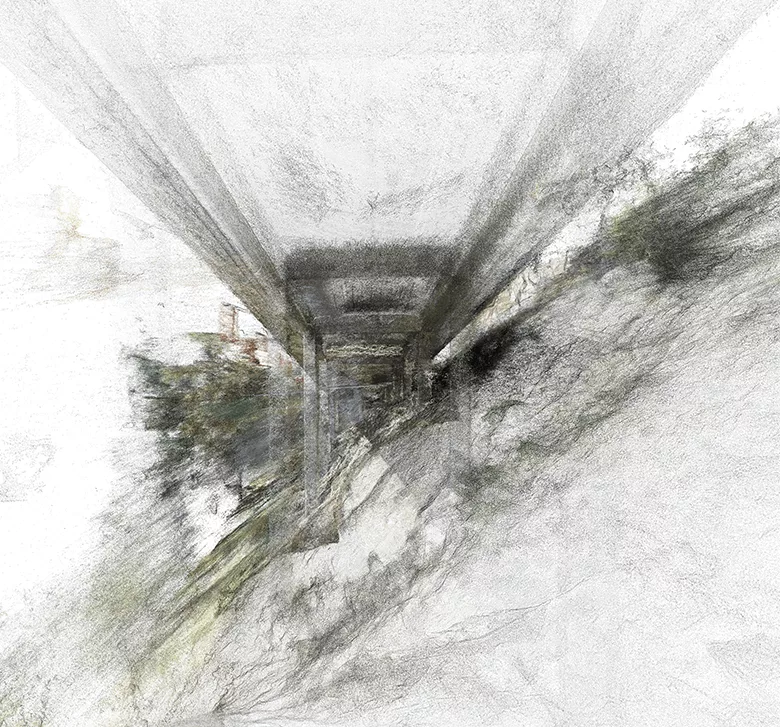

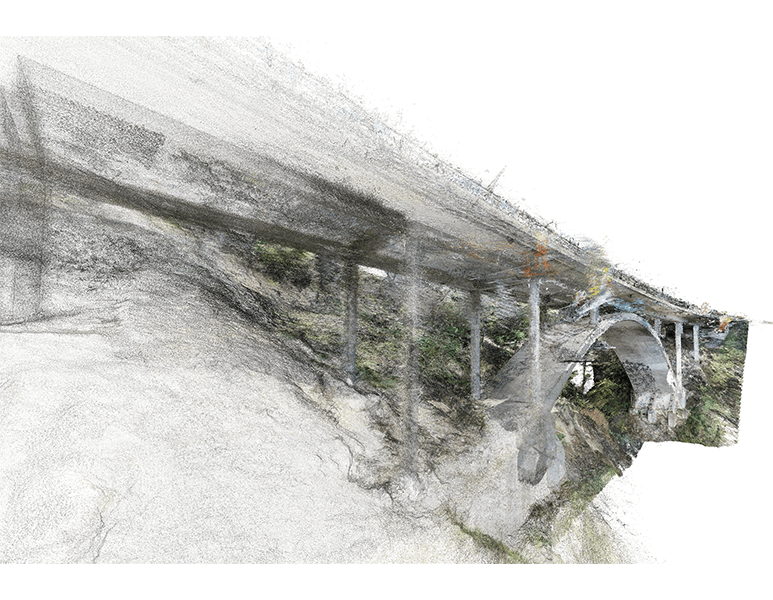

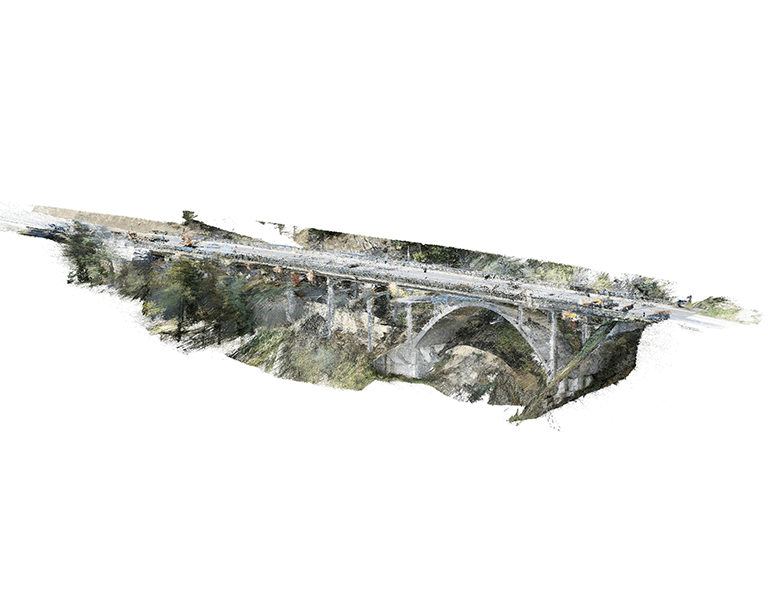

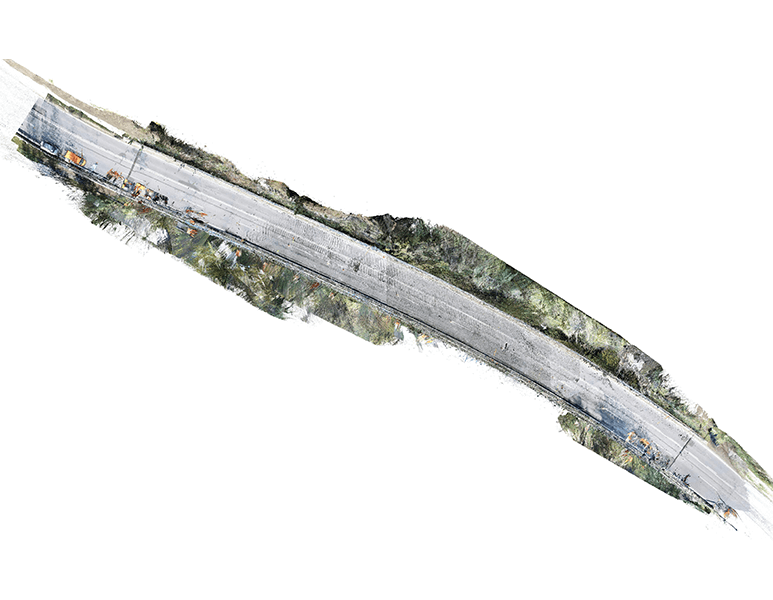

The client employs photogrammetry technology based on drone-taken photos, particularly chosen for its ability to access low-accessibility areas compared to standard scanners or digital cameras.

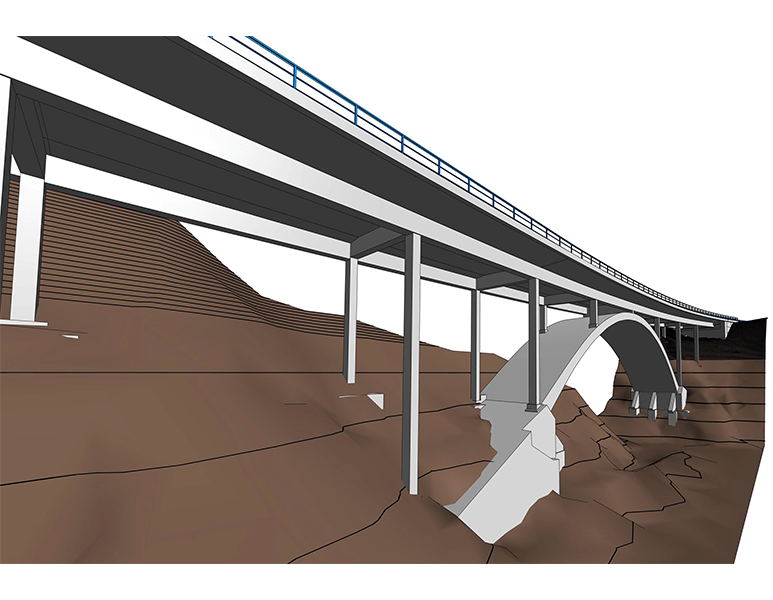

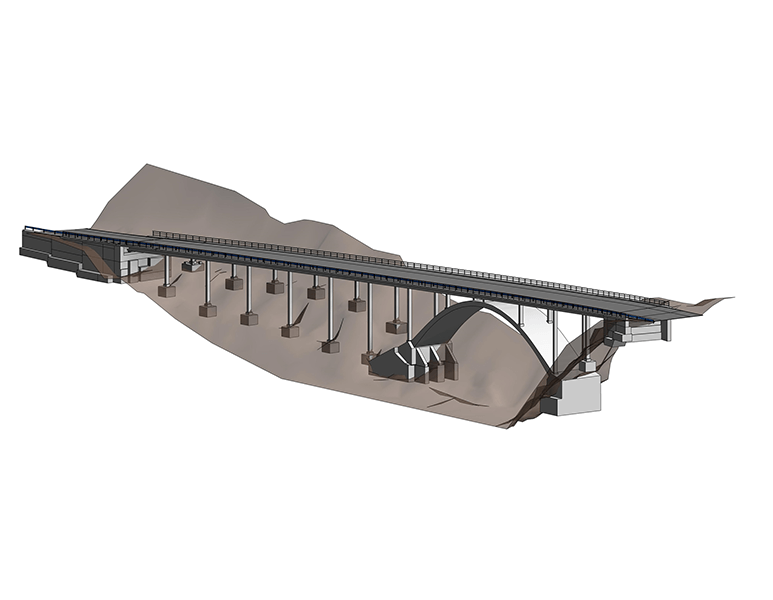

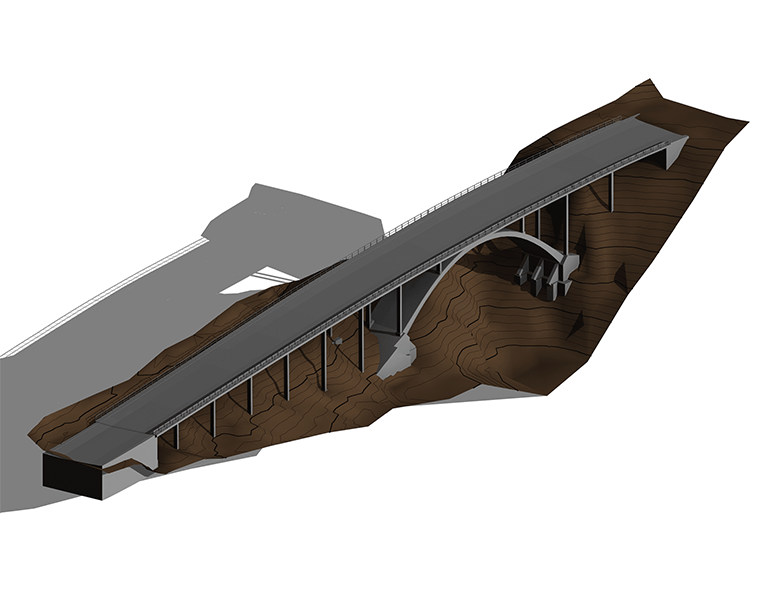

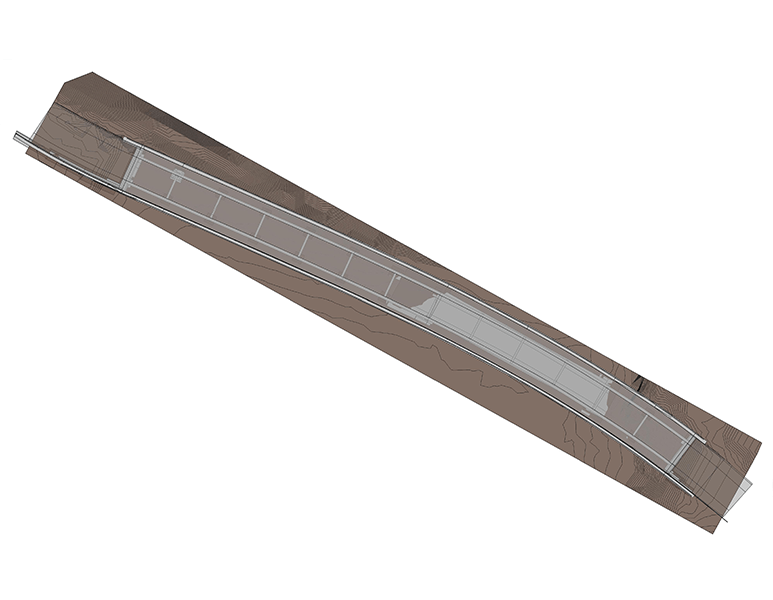

Scope of work: Precise modeling of the concrete arch bridge and the adjacent ground surface.

Input: Full Point Cloud of the bridge and adjacent area obtained through photogrammetry (drone capture).

Output: 3D Model of the bridge at LOD300.