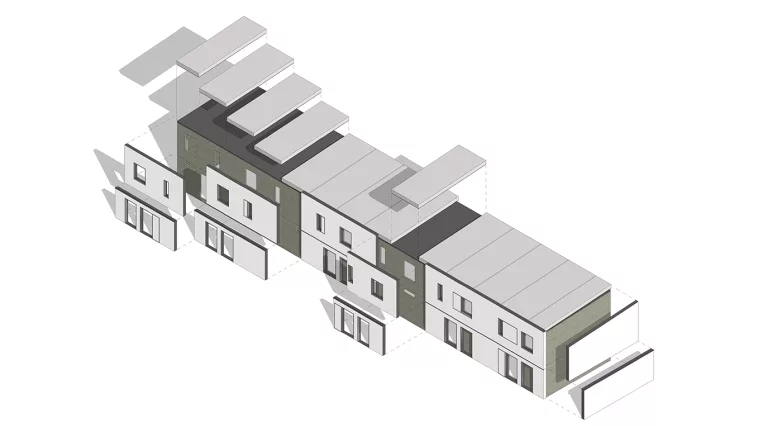

The project involved the design and production of GFRC cladding panels for the ground floor of the Viterbi Family Vision Research Center — a modern building at the UC San Diego campus serving as a state-of-the-art research facility dedicated to the treatment and study of ophthalmological diseases.

While the building emphasized the balance between the transparency of the center’s operations and the functionality of laboratory spaces, its complex architecture posed a range of challenges — requiring advanced expertise and meticulous dedication to tackle efficiently.

Input: Architectural/Structural drawings set and a reference model.

Output:

- Shop drawings set;

- Manufacturing drawings;

- Mold drawings;

- Embed layout drawings.