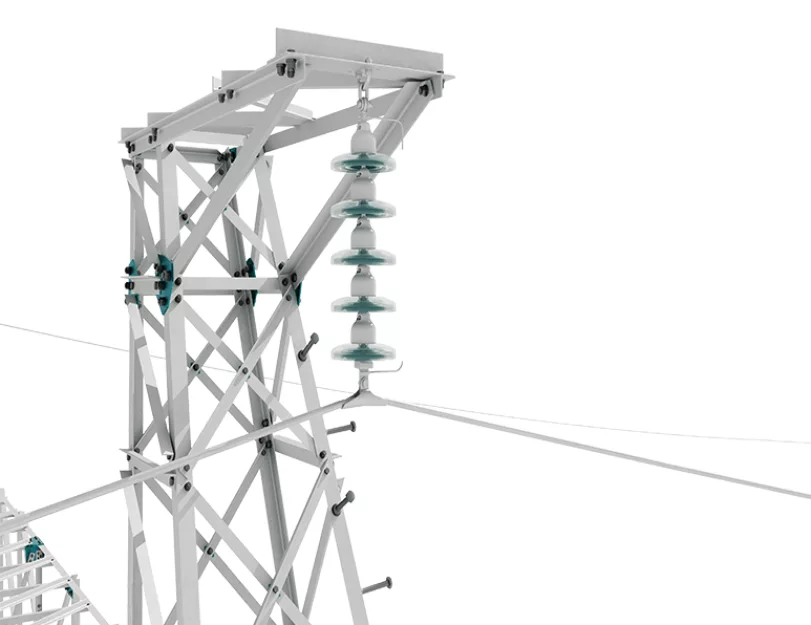

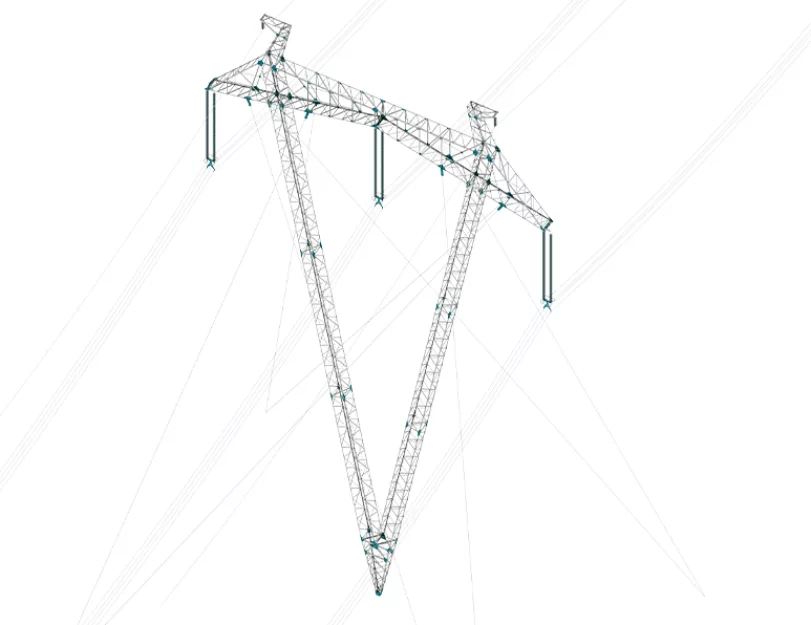

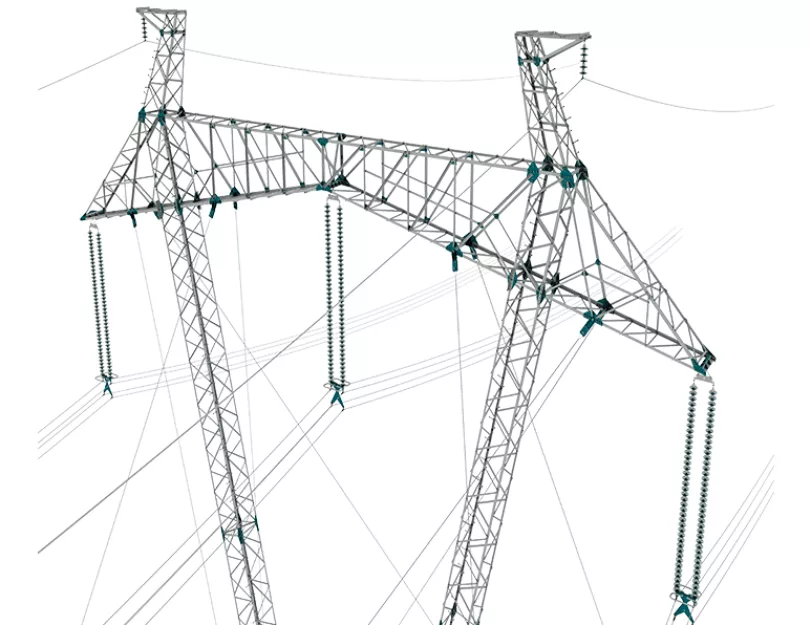

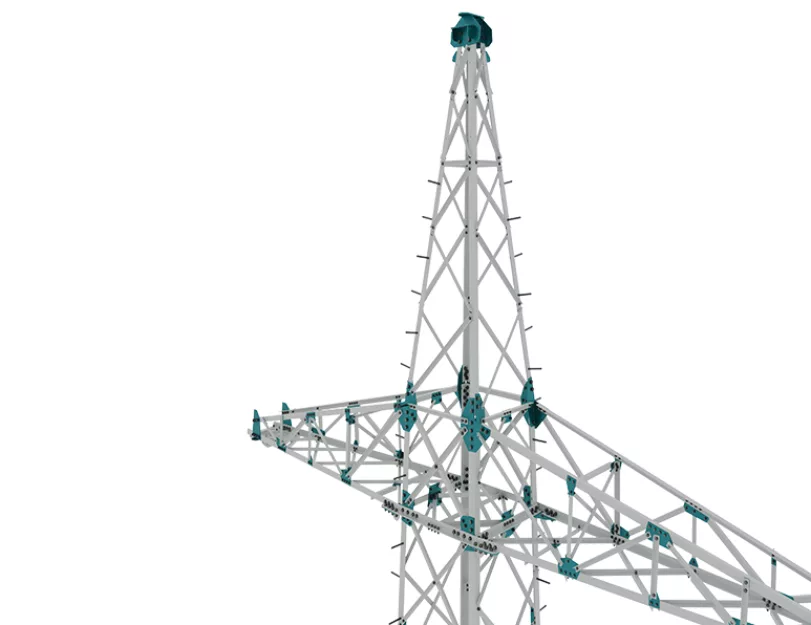

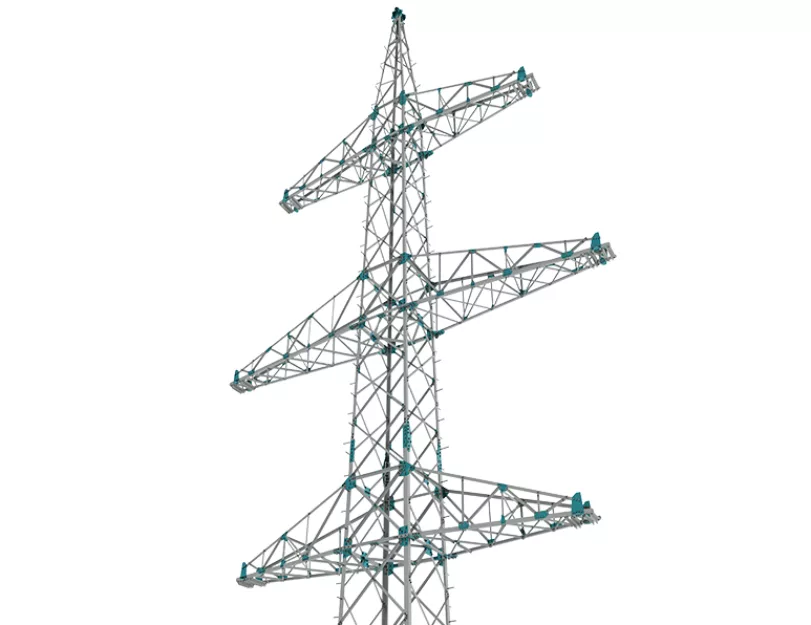

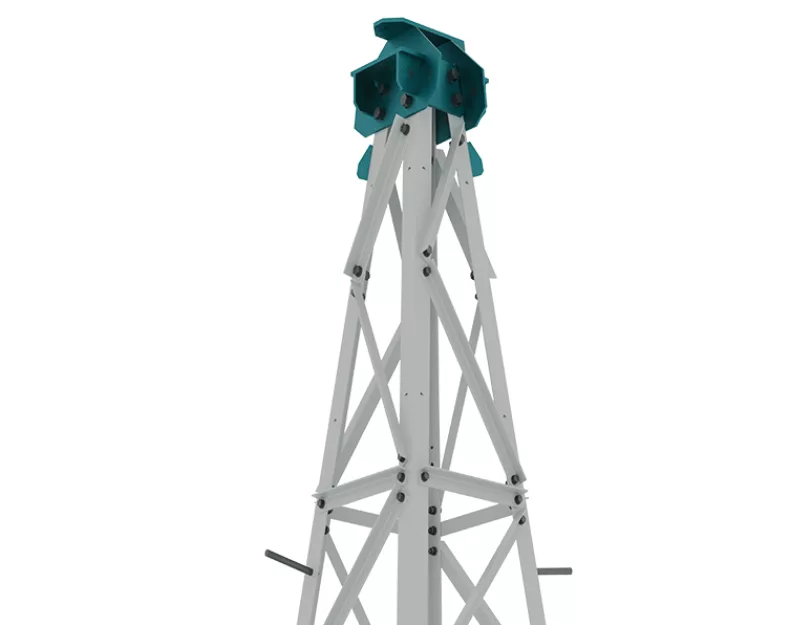

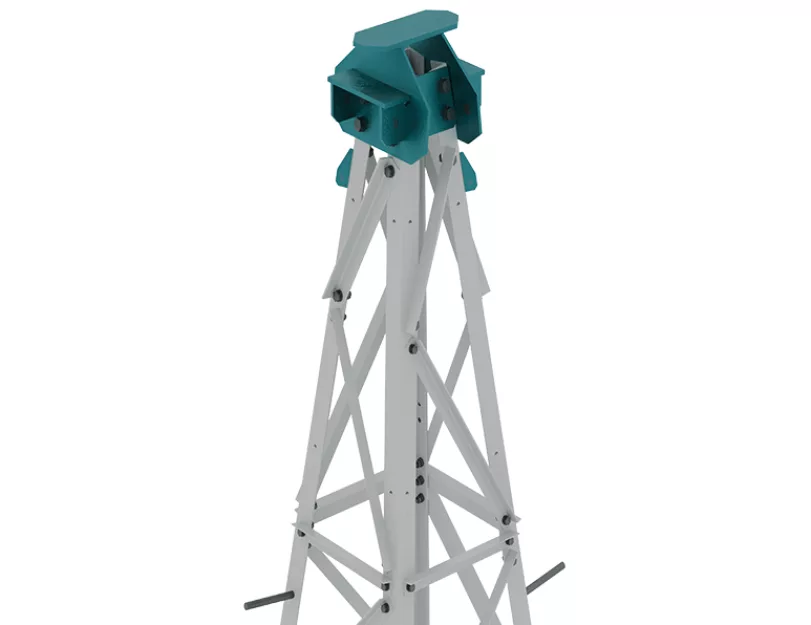

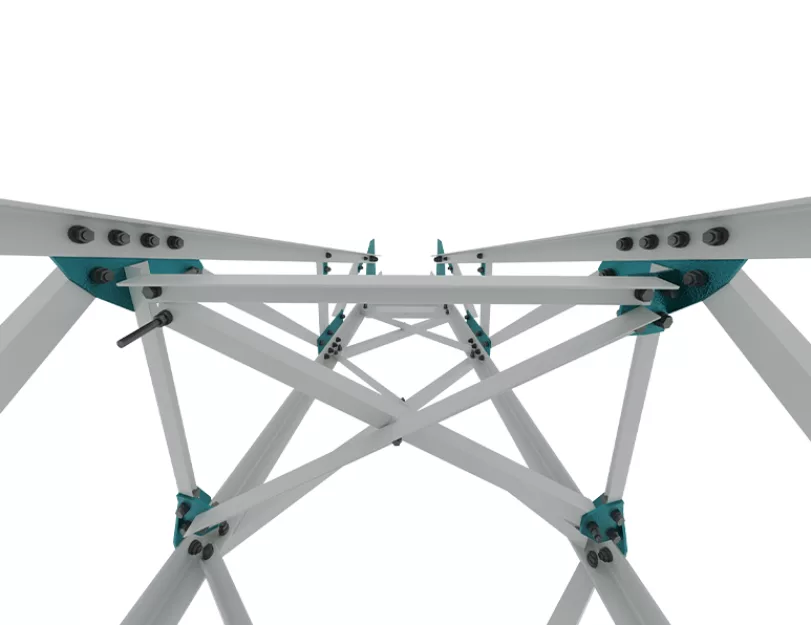

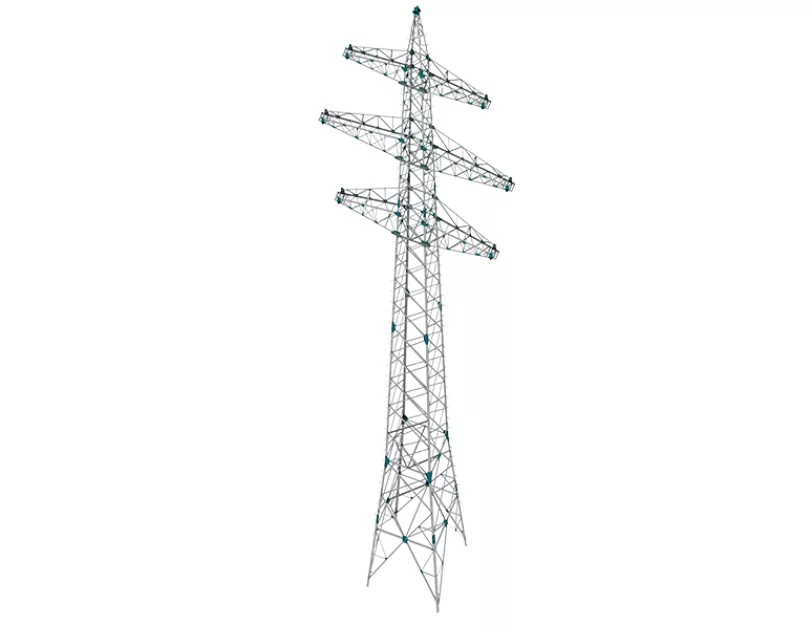

Electric power transmission towers are of great importance as structures. These large lattice Atlases support high-voltage transmission lines that carry the power over long distances from production sites to the users.

It is to these made-of-steel hard workers that we owe the light in our refrigerator when, under the veil of night, we sneak for a snack. Their failure may lead to power cuts and therefore disrupt the day-to-day life of people as well as whole industries dependent on electricity.

The construction of these towers is quite a task and requires rigorous compliance with the tower erection methodology.

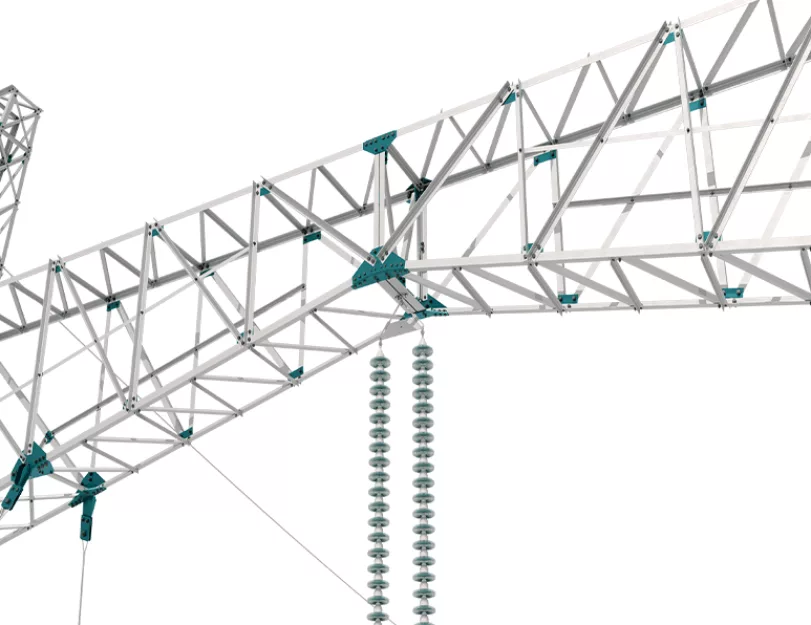

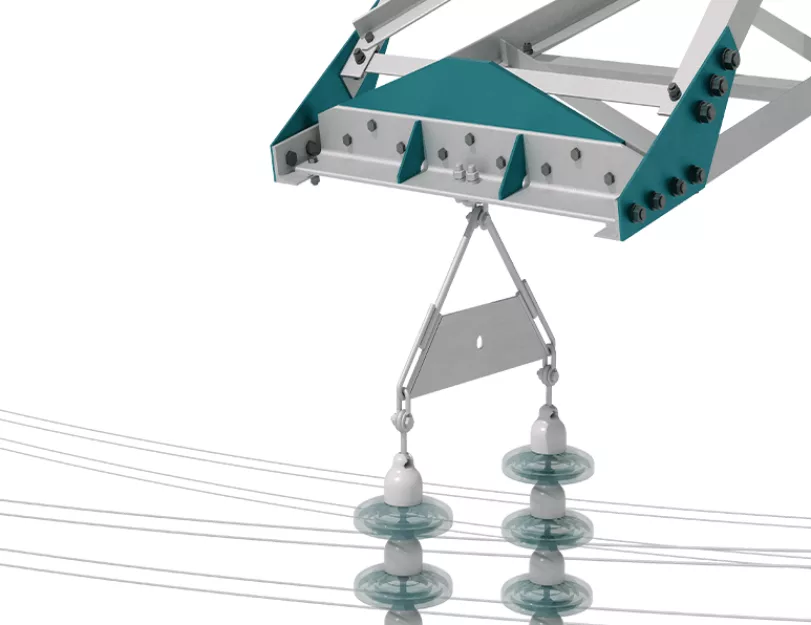

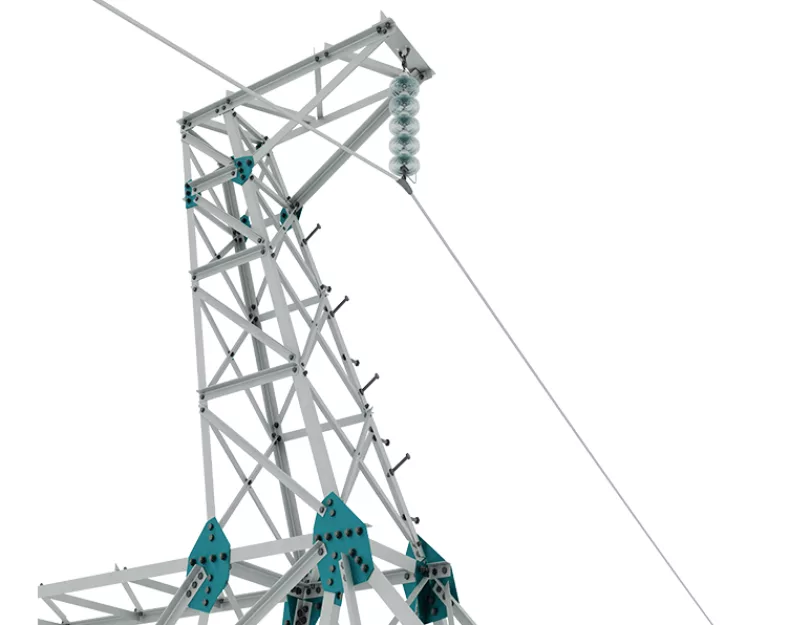

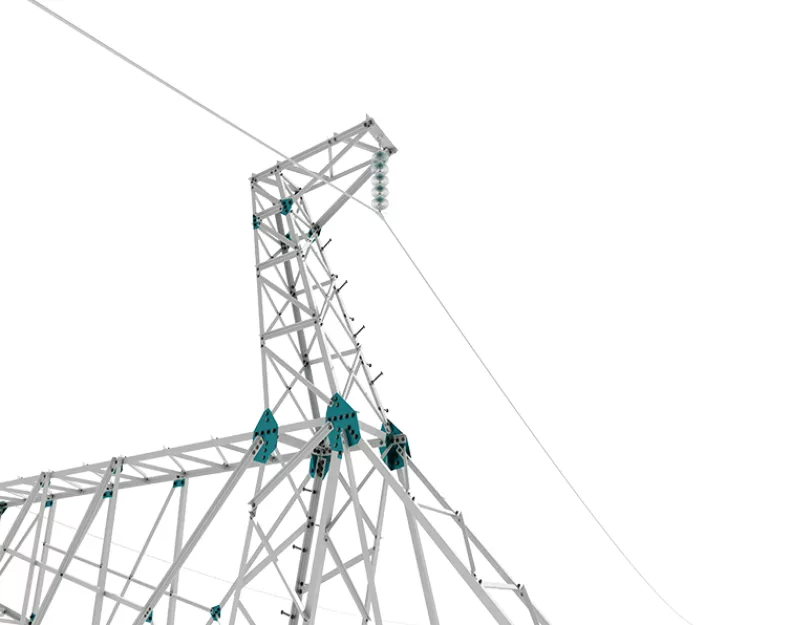

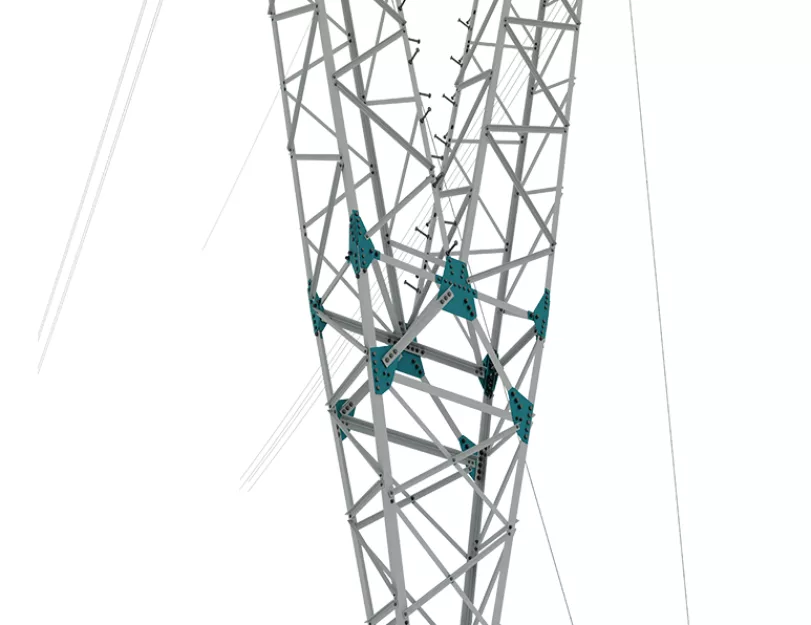

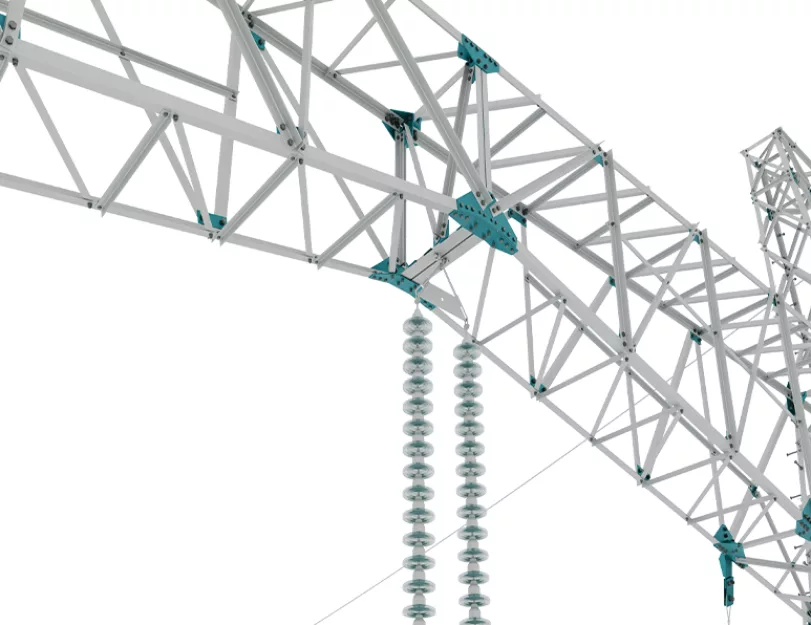

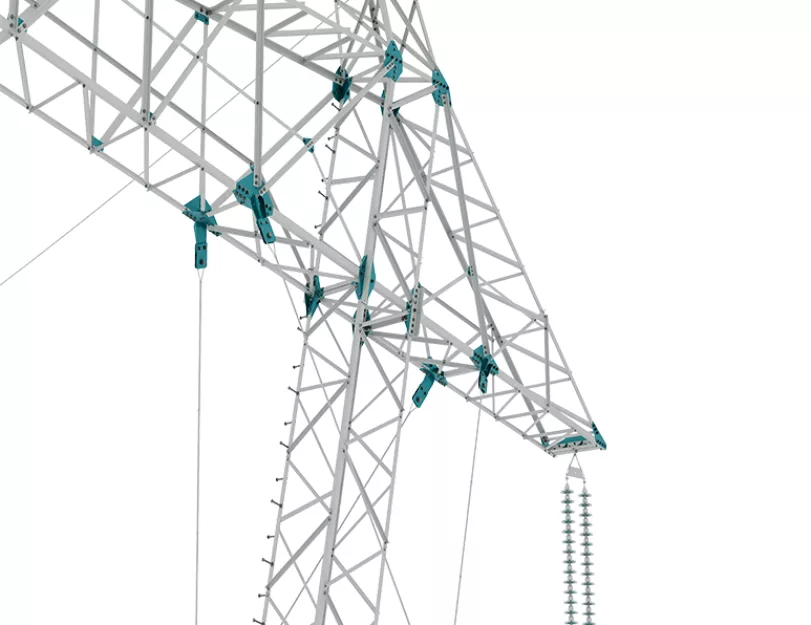

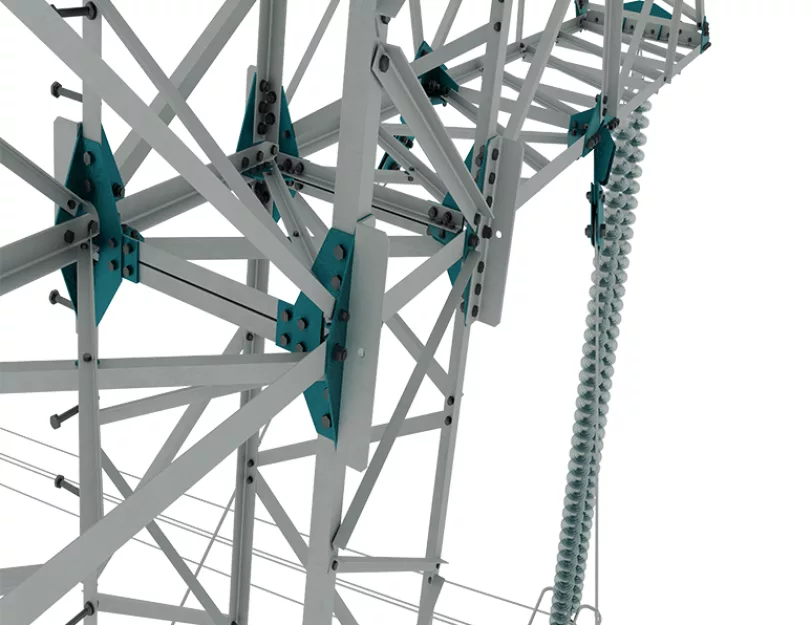

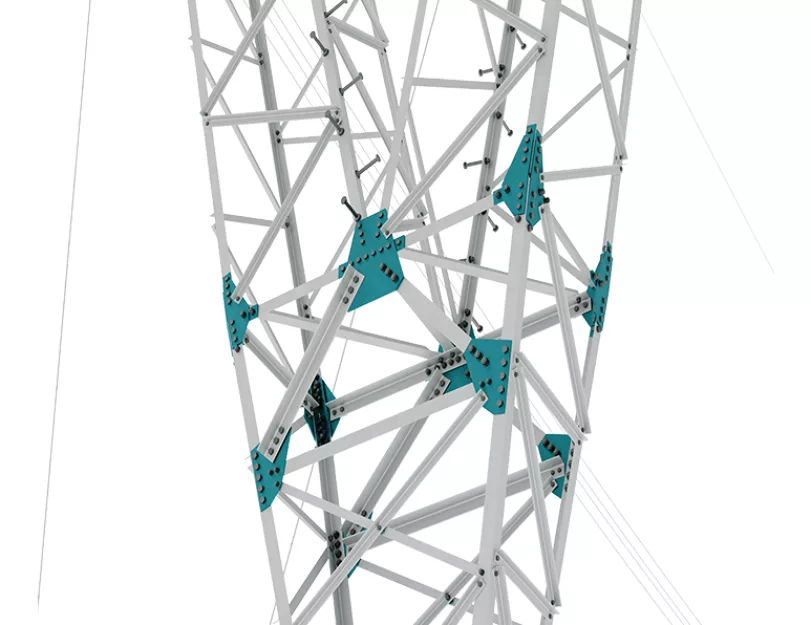

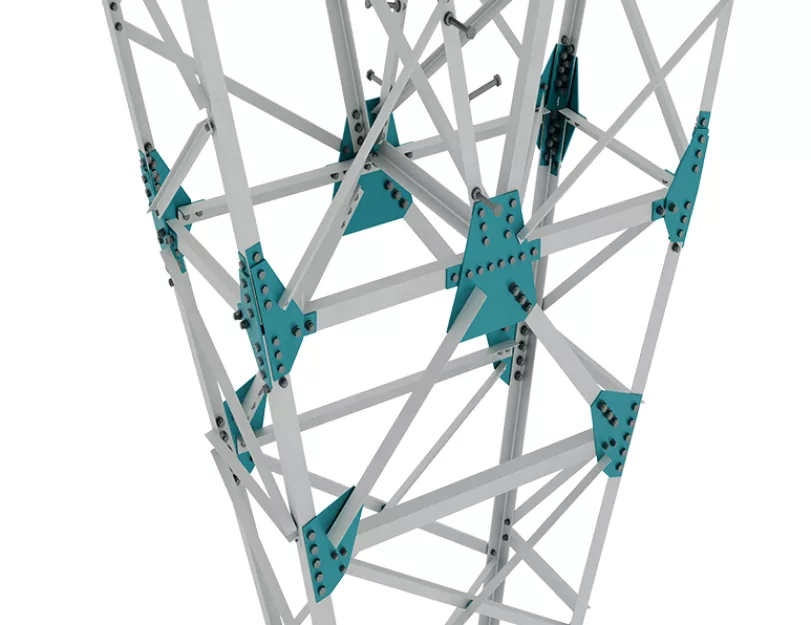

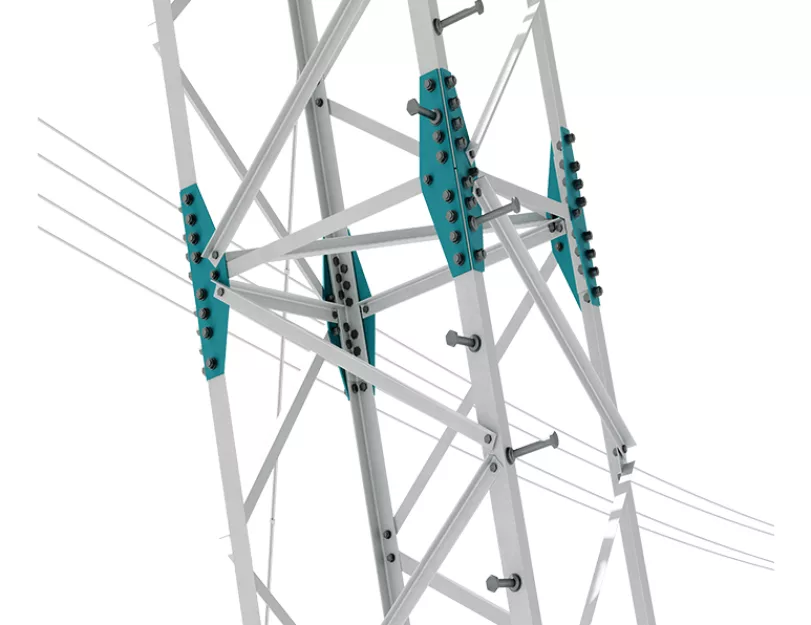

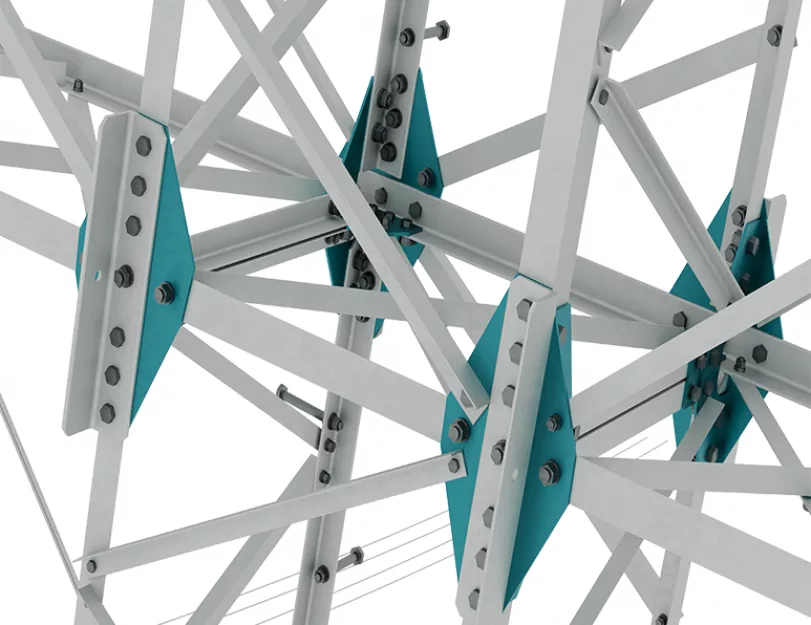

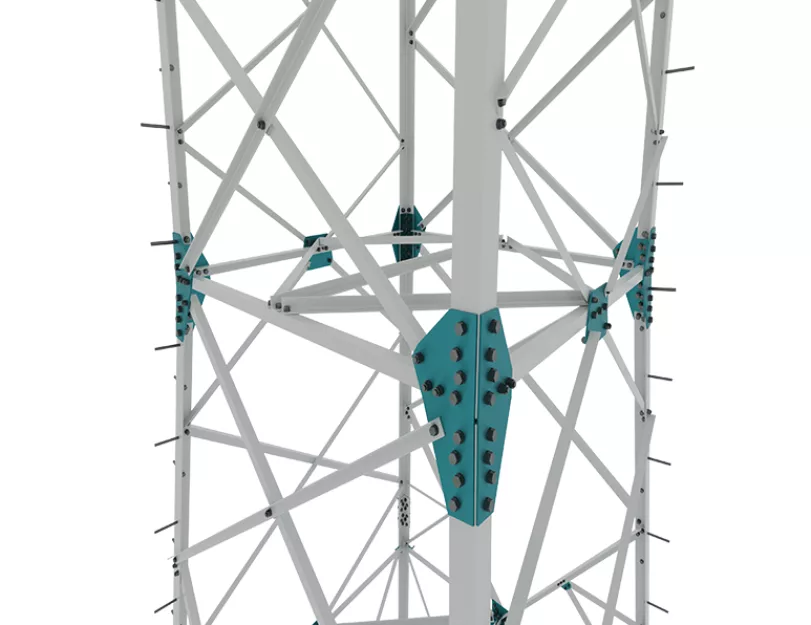

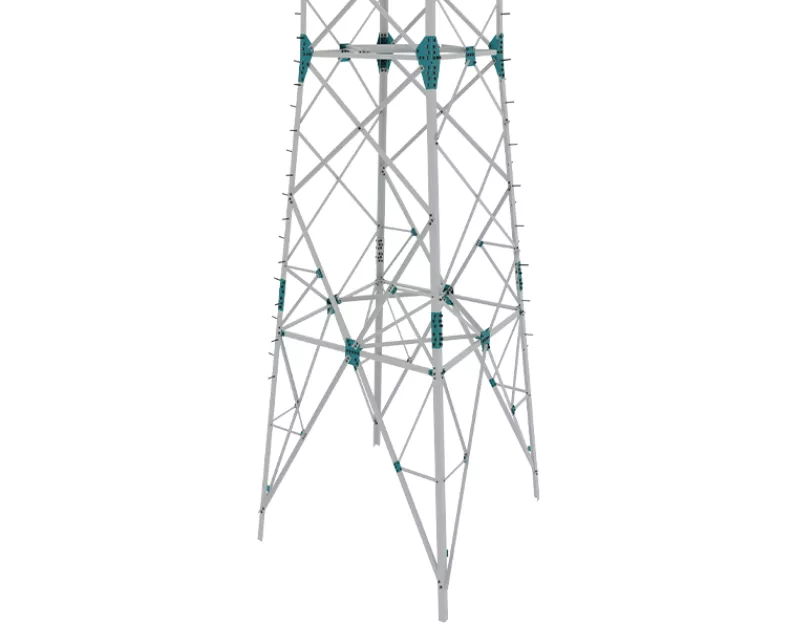

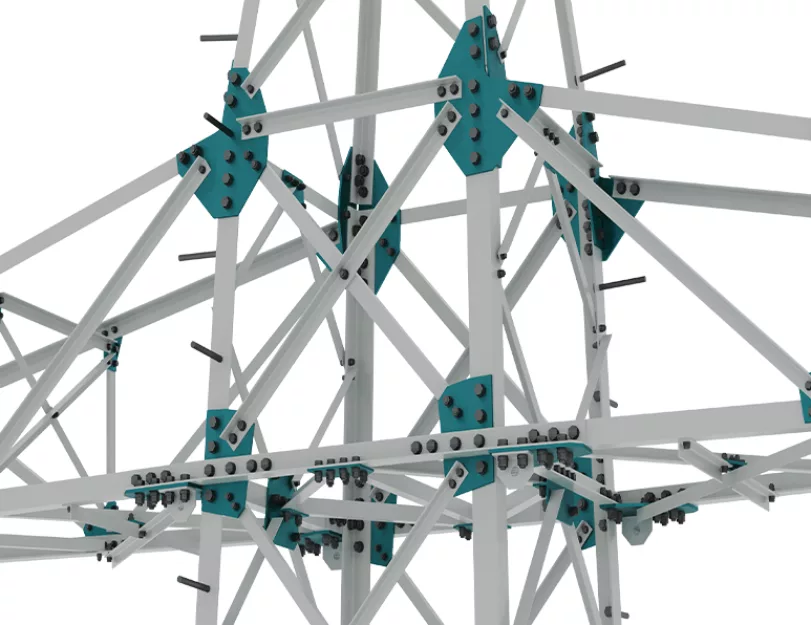

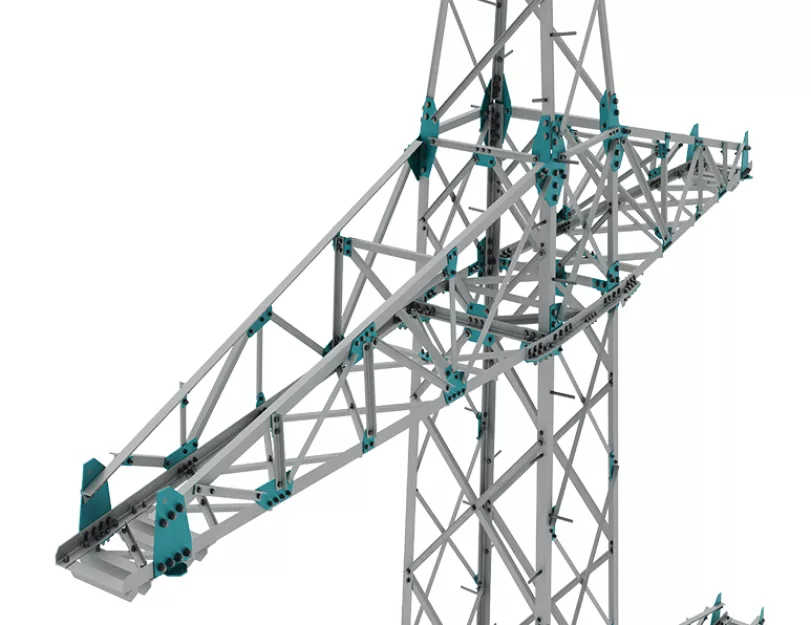

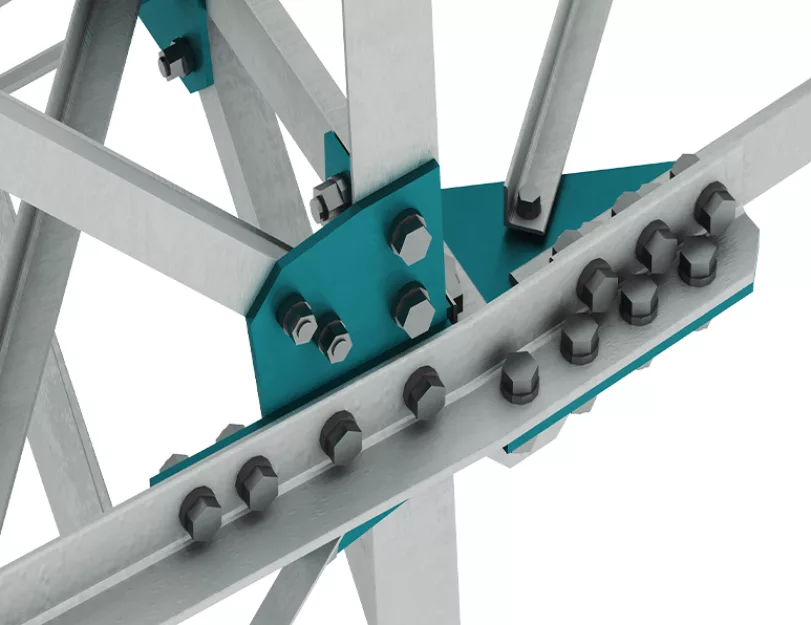

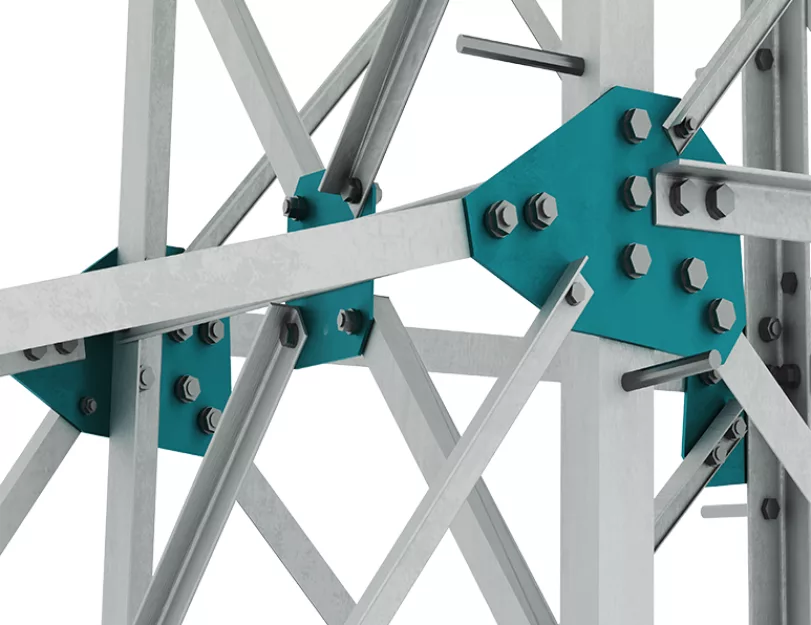

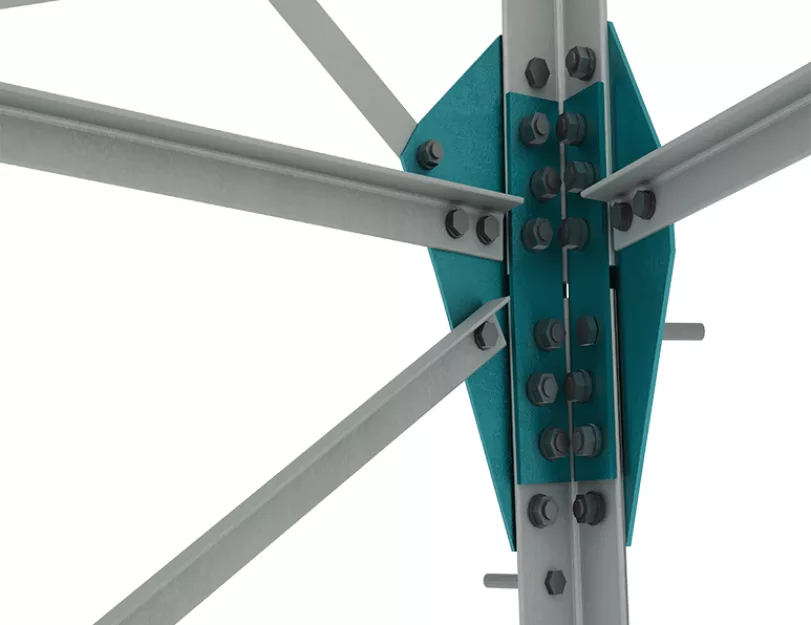

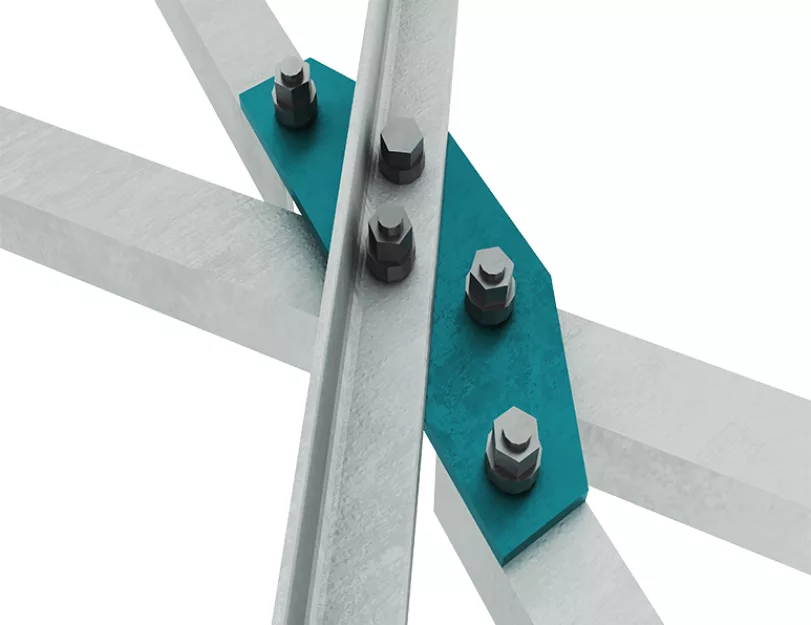

Steel construction requires an exhaustive and precise detailing project to transform design sketches and specifications into drawings, lists, and CNC (Computer Numeric Controlled) files for fabrication and construction.

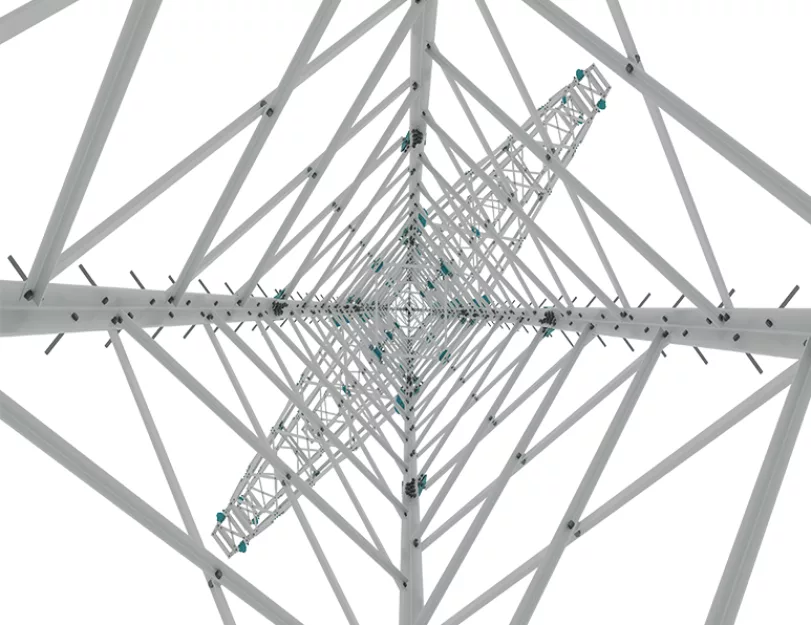

For that, we develop a detailed 3D BIM model that comprises every single structural steel part of the project. From this model, we are able to produce Workshop and Assembly Drawings, Erection Drawings, Bolt Lists, and CNC files.